Introduction: Why BOPP Recyclability Matters Now

Biaxially Oriented Polypropylene (BOPP) film has become one of the “workhorse” materials in flexible packaging. It is light, clear, stiff, cost-effective and widely used for snacks, bakery, labels, lamination and many other applications. At the same time, brands, retailers and converters are under growing pressure to reduce plastic waste and move toward recyclable packaging.

This is why more and more packaging buyers, engineers and procurement teams are asking a simple but critical question: “Is BOPP recyclable?”

The short answer is:

- Yes, pure BOPP film is technically recyclable as a polypropylene (PP) material.

- In practice, whether a specific BOPP package is “recyclable” depends on pack structure, local recycling infrastructure, and how the pack is designed.

In this guide, CloudFilm – a professional BOPP film manufacturer and supplier in China – explains BOPP recyclability in a way that is clear for both technical and non-technical readers. We will cover:

- What BOPP film is and where it is used

- When BOPP packaging can enter PP recycling streams

- How different BOPP film types (clear, matt, pearlized, metallized, lamination grade, etc.) affect recyclability

- Design tips for mono-material PP structures

- FAQs that buyers and engineers often ask about BOPP recycling

Throughout the article, we will also point you to relevant CloudFilm resources, such as our BOPP film series, recyclable packaging guides and technical blogs, so you can move from theory to real projects more quickly.

What Is BOPP Film And Where Is It Used?

Basic Definition

BOPP (Biaxially Oriented Polypropylene) film is made by extruding polypropylene resin into a sheet and then stretching it in both the machine direction (MD) and transverse direction (TD). This biaxial orientation improves:

- Tensile strength and stiffness

- Clarity and gloss (for clear grades)

- Moisture barrier

- Dimensional stability on high-speed lines

Because BOPP is 100% polypropylene, it is intrinsically compatible with PP recycling streams, provided the overall pack structure is also PP-based.

For a general overview of BOPP performance and markets, many buyers first read resources like CloudFilm’s articles on BOPP film uses in the packaging industry and different types of BOPP film.

Main Applications

Typical BOPP applications in flexible packaging include:

- Food packaging – chips, biscuits, confectionery, noodles, instant coffee, ice cream, etc.

- Non-food packaging – personal care, detergents, tissues, dry pet food.

- Labels and overwraps – pressure-sensitive labels, wrap-around labels, cigarette overwrap.

- Lamination and printing – as a printable outer layer or inner sealant in BOPP/CPP, BOPP/BOPP and other polyolefin structures.

- Paper–plastic lamination – book covers, magazines, premium cartons using films such as BOPP adhesive-free lamination film.

Because BOPP is so widely used, improving its recyclability can create a big positive impact in overall plastic waste reduction.

Why BOPP Has Good Recyclability Potential

From a materials viewpoint, polypropylene is:

- A thermoplastic that can be melted and reprocessed multiple times

- Resistant to strong degradation under typical mechanical recycling conditions

- One of the core polyolefins targeted in many mono-material packaging roadmaps

Industry guidelines such as CEFLEX’s “Designing for a Circular Economy” for polyolefin films highlight mono-PP and mixed polyolefin structures as key candidates for large-scale recycling.

This means that, if you design your packaging correctly – for example, mono-PP laminates based on BOPP plus other PP layers – BOPP can fit well into modern recycling strategies.

So, Is BOPP Recyclable? Short Answer And Key Factors

Pure BOPP Film Is Technically Recyclable

In pure material terms, BOPP is recyclable. It belongs to PP (often marked as recycling code “5 – PP”), and many recycling technologies already handle PP containers and films. Industry sources confirm that PP films, including BOPP, can be reprocessed into pellets and used again in films, injection-molded parts or other plastic products.

However, technical recyclability does not automatically mean your finished package will be accepted by local recyclers.

What Really Decides If A BOPP Pack Is “Recyclable”?

For brand owners and converters, three big factors determine whether a BOPP-based pack is considered recyclable in practice:

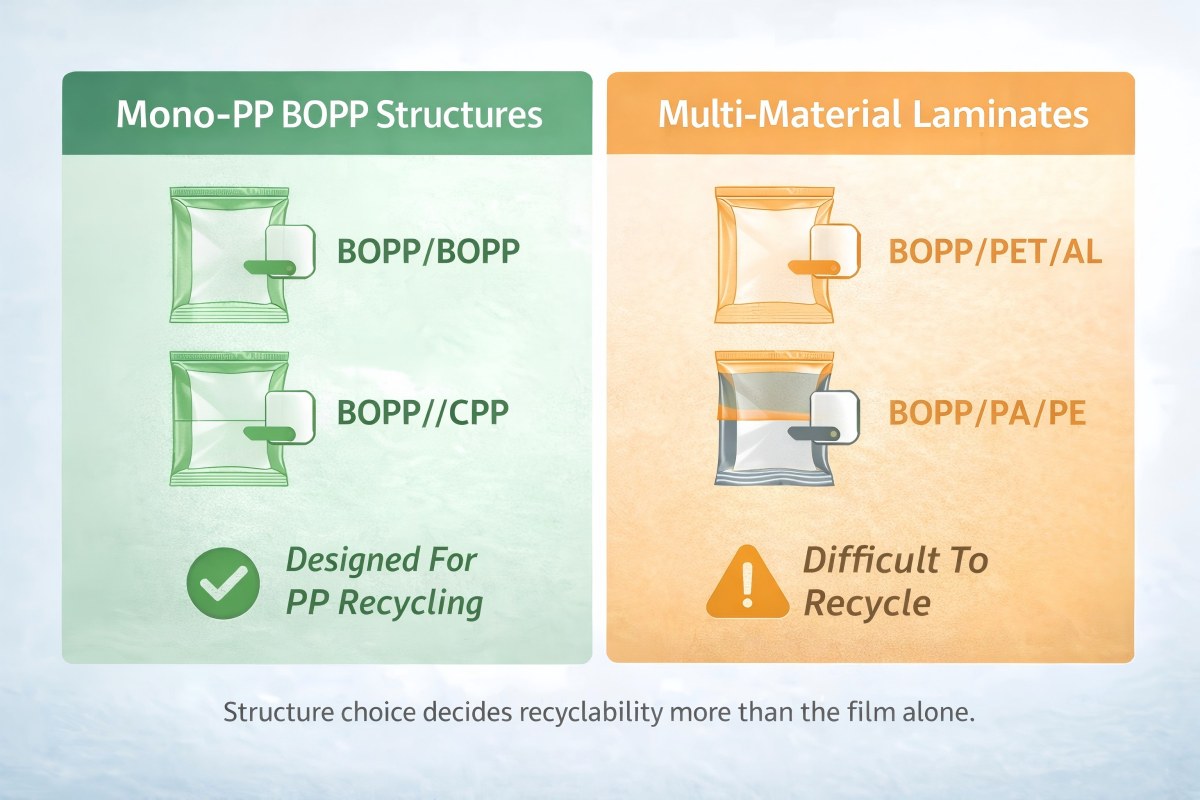

- Material Structure

- Mono-PP structures (e.g. BOPP/BOPP, BOPP//cast PP, BOPP + PP sealant) have much better chances of being accepted in PP recycling streams.

- Multi-material laminates combining BOPP with PET, PA, PVC or thick aluminum may be classified as “non-recyclable” in many markets today.

- Local Recycling Infrastructure

- Some regions already have collection and sorting streams for PP flexible packaging; others are still focused mainly on PET bottles or PE films.

- In practice, many BOPP packs are still downcycled or sent to energy recovery where dedicated recycling programs are not available.

- Design For Sortability And De-inking

- Over-printed, heavily metallized, multi-layer or dark-colored films can be harder to sort and recycle.

- Large paper labels, non-recyclable adhesives or incompatible coatings can also hurt recyclability.

How This Guide Helps Procurement And Technical Teams

Because of these complexities, packaging teams are increasingly searching for “BOPP recyclable packaging supplier” or “BOPP film manufacturer for mono-material PP” when they start new projects. This guide gives you:

- A realistic view of what is and is not considered recyclable today

- Concrete examples of more recycling-friendly BOPP structures

- A way to discuss requirements with your BOPP film supplier, such as CloudFilm, from the very first RFQ stage

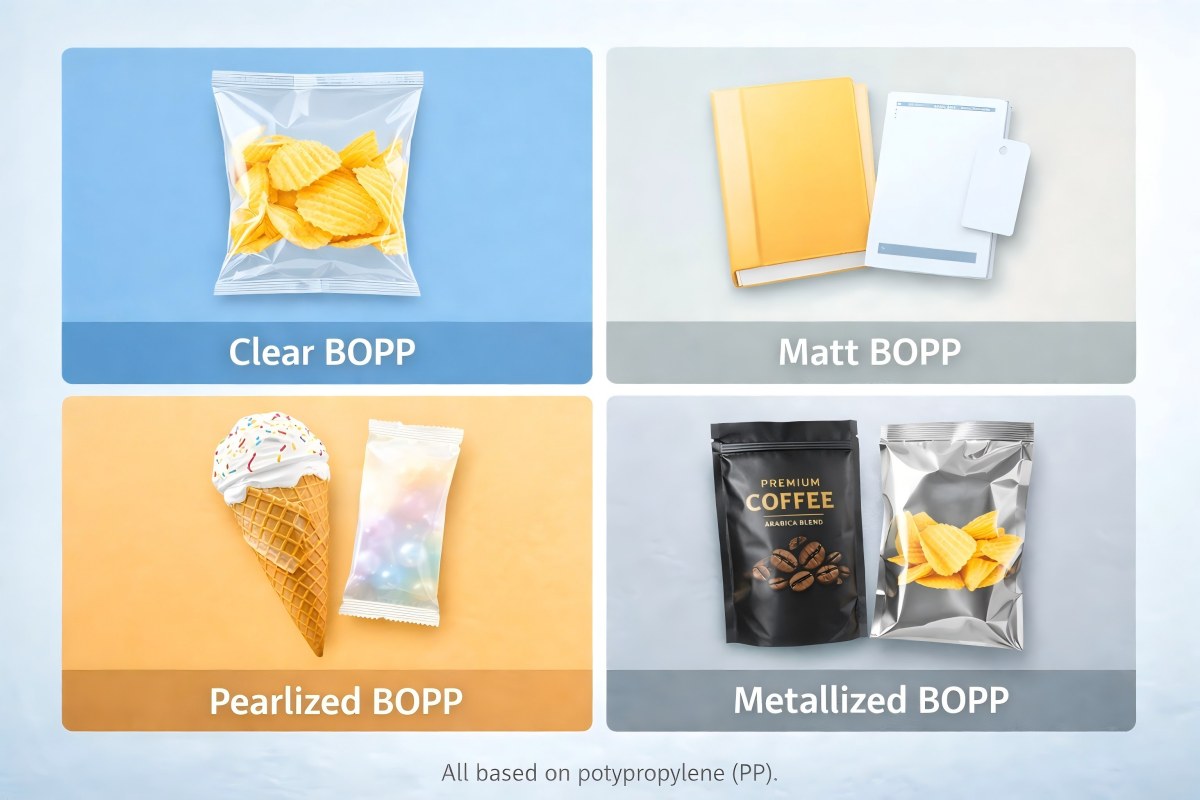

Recyclability Of Different BOPP Film Types

Different BOPP film grades behave slightly differently from a recyclability perspective. Below is a practical summary for buyers and engineers.

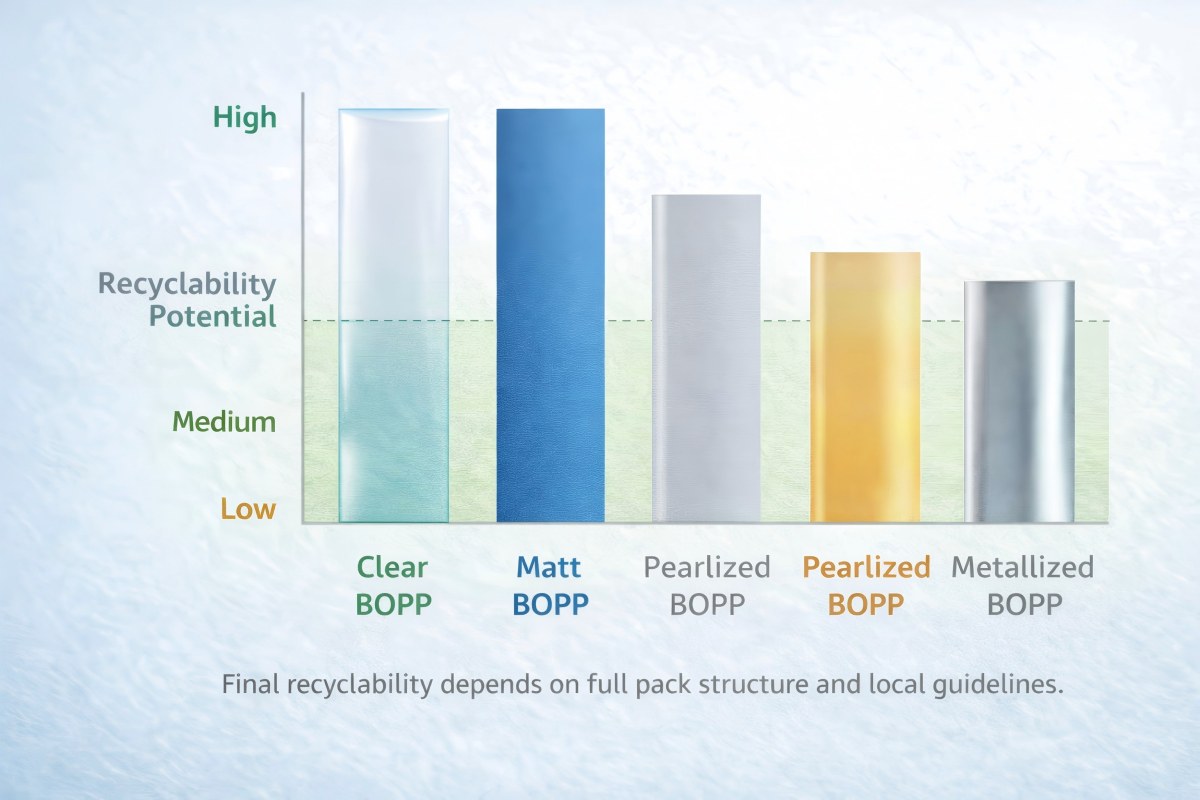

Clear And Printing BOPP

Standard clear BOPP used as an outer print web or inner layer is typically the easiest starting point for recyclable designs, especially in all-PP structures. It is suitable for:

- Simple BOPP/BOPP laminates

- BOPP//cast PP flow packs and pillow bags

- Transparent windows in mono-PP pouches

For a deeper look at performance and applications, you can review CloudFilm’s BOPP film series and related blogs.

Matt BOPP And Soft Touch BOPP

Matt BOPP and soft touch BOPP add visual and tactile value but must still fit mono-material rules. Products like BOPP matte film and soft touch BOPP film are still based on polypropylene, so in principle they can be part of PP recycling streams when used in PP-dominant laminates.

When you design recyclable premium packs (e.g. cosmetics, high-end snacks), discuss with your supplier:

- Coating types and thickness

- Ink coverage and color choices

- Whether you need scuff-resistant or anti-scratch features

Pearlized BOPP

BOPP pearlized filmis widely used for ice cream, candy, soap wraps and eye-catching labels. Its lower density and opacity come from micro-voids and fillers inside the PP matrix, but the core polymer is still polypropylene.

From a recycling viewpoint, pearlized BOPP can still fit PP recycling streams when combined with compatible PP sealants. However, high ink coverage or complex varnishes should be reviewed against local guidelines.

Metallized BOPP

Metallized BOPP film uses a very thin vacuum-deposited aluminum layer to provide high barrier and metallic appearance. Technically, the total structure is still dominated by PP; many recycling technologies can handle metallized films if the metal layer is thin and the final application allows some color variation in recyclate.

Regulatory and design guidelines differ by region. In Europe, for example, some mono-material PP metallized structures are being tested and certified for recyclability under specific conditions.

If you are developing high-barrier recyclable packs, it is wise to:

- Share your target country and requirement (e.g. CEFLEX, APR, store drop-off) with your BOPP supplier

- Consider metallized structures that have existing recyclability certifications or test data

CloudFilm’s articles on metallized BOPP films and metallized film manufacturing process provide additional technical insight and sourcing options.

BOPP For Paper–Plastic Lamination

BOPP films used for book covers, luxury boxes and paper lamination, such as BOPP adhesive-free lamination film, pose a different challenge: the paper and plastic are often hard to separate during recycling.

To improve recyclability in these applications, more printers and converters are:

- Switching to recyclable paper-only structures in some markets

- Or choosing laminating films and adhesives that allow easier separation in dedicated recycling schemes

BOPP vs PET, BOPA, CPP From A Recycling Angle

Sometimes buyers ask whether they should choose BOPP, BOPET or BOPA for a given application. Articles such as CloudFilm’s differences between BOPP, BOPET and BOPA films and BOPP vs CPP guide explain property and cost differences.

From a recyclability standpoint:

- BOPP and CPP are both PP-based and can be combined into mono-PP packs.

- PET and BOPA often deliver higher heat and gas barrier, but multi-material laminates with PP can be problematic to recycle unless advanced separation technologies are available.

How Is BOPP Film Recycled In Practice?

In real recycling plants, BOPP films (pre-consumer and, increasingly, post-consumer) usually go through the following steps:

- Collection – BOPP film waste comes from converters’ trim waste, misprints, obsolete stock, and, where systems exist, from post-consumer flexible packaging collections.

- Sorting – Optical sensors, NIR sorting equipment and manual inspection help separate PP films from other plastics, paper and metals.

- Shredding Or Granulating – Films are cut into flakes or small pieces to make washing and melting more efficient.

- Washing And De-inking – Contaminants such as dirt, adhesives and inks are removed via hot washing, friction washing or chemical processes, especially for heavily printed films.

- Drying And Extrusion – Clean flakes are dried and then melted in extruders; filters remove remaining impurities.

- Pelletizing – The molten material is cut into pellets, which can be used in new films, sheets or molded products.

Because BOPP has good mechanical strength and heat resistance compared with some other films, recycled PP from BOPP can retain reasonable performance when processed correctly.

Design Tips For More Recyclable BOPP Packaging

If you want your next packaging project to be “BOPP-based and recyclable”, consider the following practical design tips:

- Aim For Mono-PP Structures

- Combine BOPP with CPP or other PP sealants rather than PET or PA where possible.

- Consider BOPP/BOPP or BOPP//CPP laminates for many dry food applications.

- Limit Non-PP Layers And Additives

- Avoid thick PET, PA or PVC layers in otherwise PP-based packs.

- Use barrier coatings or thin metallization instead of heavy aluminum foil when recyclability is a priority.

- Control Printing And Labels

- Avoid 100% ink coverage; keep some clear or light areas to improve sortability.

- Use labels and adhesives that are compatible with PP recycling or can be removed during washing.

- Optimize Pack Structure Using Supplier Data

- Work with a BOPP film manufacturer who can provide OTR/WVTR, stiffness, SIT and seal strength data, so you avoid over-specifying materials.

- CloudFilm shares such data through product pages (e.g. BOPP matte film, metallized BOPP film) and density guides, allowing buyers to pick the right grade faster.

- Align With Local Guidelines Early

- Check whether your target market follows CEFLEX, APR or retailer-specific guidelines.

- Share these requirements with your BOPP supplier at RFQ stage so they can recommend compliant structures.

For a broader sustainability perspective, CloudFilm’s recyclable flexible packaging guide and mono-material flexible packaging trends are good companion readings.

How CloudFilm Supports Your Recyclable BOPP Projects

As a flexible packaging film manufacturer and exporter founded in 2002, CloudFilm focuses on BOPP, BOPET, BOPA, PE, CPP, metallized films and mono-material solutions for global customers.

For BOPP specifically, CloudFilm offers:

A complete BOPP film product category (gloss, matt, pearlized, metallized, thermal lamination, adhesive-free lamination, anti-fog, cigarette, etc.)

Technical blogs on topics like BOPP film uses, BOPP vs CPP and BOPP vs BOPET vs BOPA

Application-driven guidance on mono-PP and recyclable structures in our recyclable flexible packaging and mono-material films in packaging articles

When you work with CloudFilm as your BOPP film supplier:

- You can start from your product, pack format and sustainability target rather than from film codes alone.

- Our team helps match the right BOPP grade (clear, matt, pearlized, metallized) to your barrier, stiffness and sealing needs.

- For export-oriented brands, we balance performance, cost and recyclability so your pack works in both domestic and overseas markets.

FAQ – Common Questions About BOPP Recyclability

Below are typical questions that packaging buyers, engineers and sustainability managers ask when they evaluate BOPP packaging.

Q1. Is BOPP film recyclable or biodegradable?

BOPP is recyclable as a polypropylene (PP) material when designed into mono-PP structures and collected in PP recycling streams. It is not biodegradable; instead of biodegrading, it should be handled via proper collection and mechanical recycling.

Q2. What recycling code does BOPP use?

BOPP belongs to the PP family, which is usually labeled as recycling code “5 – PP”. On some packs, you might see general “PP” or “Other plastic film” labels depending on local systems.

Q3. Is metallized BOPP recyclable?

Technically, metallized BOPP still consists mostly of PP with a very thin aluminum layer, so it can often be processed in PP recycling systems. However, you must check regional guidelines and, where possible, use metallized structures that are tested or certified as recyclable. Working with a knowledgeable BOPP film supplier is critical here.

Q4. Can BOPP be recycled together with PE films?

In many schemes, PP and PE film streams are separated. Mixing them can lower recyclate quality if not controlled. Some “mixed polyolefin” recycling concepts accept both, but if your target is a PP-specific stream, keep structures PP-dominant and labeled accordingly.

Q5. Are BOPP labels and tapes recyclable?

BOPP labels and adhesive tapes are recyclable in principle, but in practice:

- The adhesive system, ink and backing material matter a lot.

- Too much label area or incompatible adhesives can reduce recyclability.

When designing labels, choose BOPP facestocks and adhesives that have been tested in PP recycling streams.

Q6. How does BOPP recycling compare with PET or PE film?

- PET has strong, well-established bottle recycling but flexible film recycling is still evolving.

- PE has long experience in film recycling (bags, shrink films).

- BOPP (PP) is catching up quickly as more mono-PP solutions enter the market and dedicated PP film recycling lines appear. In all cases, mono-material design improves outcomes.

Q7. Does BOPP recyclability impact food safety?

Recyclability and food safety are related but different topics. Virgin BOPP and well-controlled metallized BOPP grades are widely used for food packaging and can comply with major regulations. For recycled PP in direct food contact, specific regulations and certifications apply; design your structures and specify whether you need virgin or recycled content with your film supplier.

Q8. How can I start a recyclable BOPP project with CloudFilm?

You can begin by sharing:

- Your product type and shelf-life target

- Pack format (pillow bag, stand-up pouch, label, etc.)

- Current structure (if any) and sustainability goals

CloudFilm’s team will recommend suitable BOPP film grades and mono-PP structures. You can also reference our flexible packaging solutions guide and custom flexible packaging solutions for brands to understand how we work with global customers.

Q9. Are there cost penalties for recyclable BOPP structures?

Often, recyclable BOPP structures are cost-neutral or even cost-saving compared with complex multi-material laminates, especially when material reduction and logistics savings are considered. Some high-barrier mono-PP solutions may have higher material costs but can deliver long-term value by meeting retailer or regulatory requirements.

Q10. What should I ask a BOPP film manufacturer about recyclability?

When you talk with a BOPP film manufacturer or supplier, key questions include:

- Can this film be used in a mono-PP structure?

- Do you have experience supporting recyclable or mono-material projects in my target market?

- Can you share typical test data (OTR, WVTR, SIT, seal strength) and any recyclability assessments?

- What alternative structures do you suggest if my current pack is not recyclable?

Conclusion: BOPP Recyclability As A Strategic Advantage

BOPP film is not just a versatile packaging material – when designed correctly, it can also be a strong asset in your sustainability and brand strategy. Pure BOPP is technically recyclable as PP; by moving toward mono-PP structures, controlling print and labels, and aligning with local guidelines, you can turn many existing packs into more recycling-friendly solutions.

For brands and converters, partnering with an experienced BOPP film manufacturer and supplier like CloudFilm helps you:

- Reduce trial-and-error in structure design

- Shorten the path from concept to compliant, recyclable packs

- Communicate clear sustainability messages to retailers and consumers

If you are planning your next recyclable BOPP project, you are welcome to contact CloudFilm, share your product and packaging goals, and request tailored film recommendations and samples.