Unleashing Efficiency with CloudFilm’s Heat Sealable PET Film

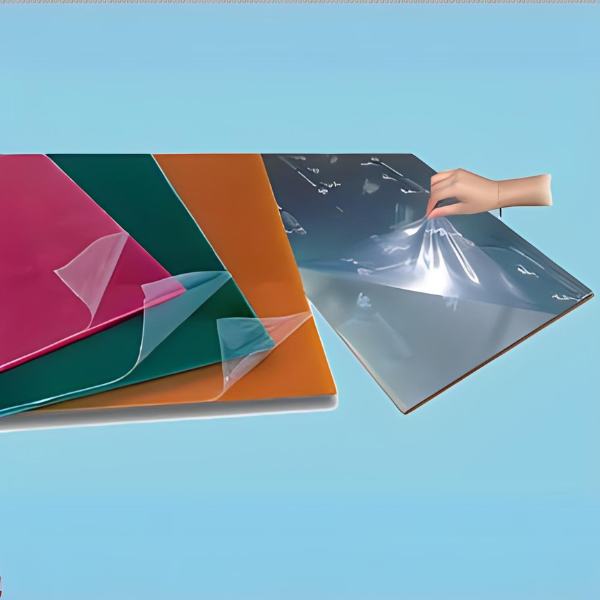

Unlock the potential of your packaging process with CloudFilm’s cutting-edge heat sealable PET film, a pinnacle of technological innovation designed to meet the dynamic needs of modern packaging.

Our product stands out as a beacon of quality in the realm of biaxially oriented films, offering unparalleled heat seal performance across a broad temperature spectrum.

This versatility ensures compatibility with a diverse range of packaging machinery, making it a prime choice for manufacturers aiming for operational efficiency without compromising seal integrity.

Tailored Solutions for Diverse Packaging Needs

Our heat sealable PET film is engineered for perfection, providing a robust seal that withstands the rigors of packaging and distribution. Whether you’re packaging food, pharmaceuticals, or high-demand consumer goods, our film’s resistance to high temperatures and non-toxic properties ensure your products are securely and safely enclosed.

Available in thicknesses ranging from 12 to 40 microns, we offer customization options to align with your specific packaging requirements, demonstrating our commitment to delivering solutions that fit your unique needs.

Partner with CloudFilm for Packaging Excellence

Choose CloudFilm as your partner in packaging innovation. With our expertise in producing high-quality heat sealable PET films and our dedication to customer satisfaction, we’re here to elevate your packaging process.

Our comprehensive approach, from product development to after-sales support, ensures you have the resources and support needed to thrive in today’s competitive market.

Contact us to discover how our heat sealable PET film can transform your packaging strategy, enhancing product safety, aesthetic appeal, and market readiness.