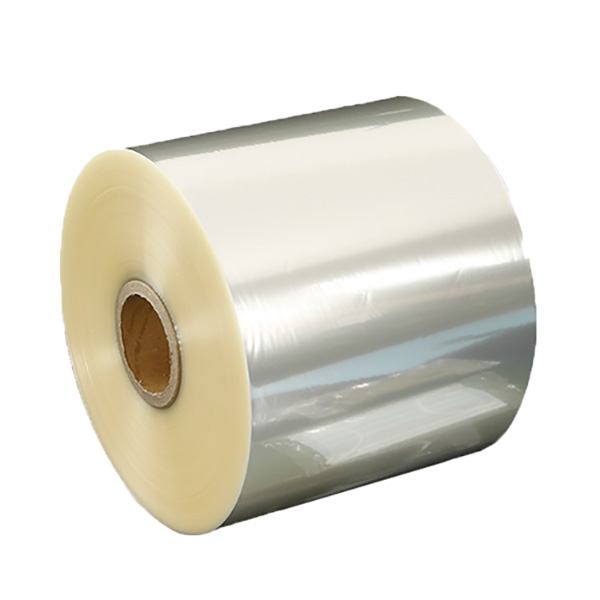

Unlock the Clarity Your Products Deserve: Discover Our Premier BOPP Anti-Fog Film Solutions

Embrace Unparalleled Visibility with State-of-the-Art Packaging Solutions

In today’s competitive market, ensuring your product stands out on the shelf is more important than ever. Our anti-fog BOPP film represents the pinnacle of packaging innovation and is designed to maintain optimal visibility and freshness for your perishable goods.

Manufactured in the heart of Qingdao with cutting-edge German technology, our films promise to protect and showcase the quality of your products in the most transparent way possible.

Your Gateway to Excellence: Our Commitment to Quality and Diversity

Our diverse range of biaxially oriented films, including BOPP, BOPET, BOPA, and BOPE, is tailored to meet various packaging needs across multiple markets.

With a focus on high-quality production and competitive pricing, our BOPP anti-fog films are engineered to prevent condensation, ensuring your products remain front and center in any retail environment.

Our dedication to excellence is evident in our rigorous quality assurance processes and long-standing partnerships with industry leaders.

A Partnership for Success: Why Choose Us for Your Packaging Needs

Choosing our anti fog BOPP film means investing in a partnership with a company that values quality, innovation, and customer satisfaction above all.

With a strategic location in Qingdao, we offer efficient supply chain management and access to major markets in Southeast Asia, South Korea, the United States, and China. Our skilled workforce, with a monthly production capacity of 2000 tons, ensures the timely delivery of high-standard products.

Moreover, our comprehensive pre-sales, in-sales, and after-sales services, backed by a 24/7 customer support team, underline our commitment to your success.

Let’s Shape the Future Together

Our mission is to empower your products with packaging solutions that speak volumes of their quality, ensuring they capture the attention they deserve.

We invite you to leverage our expertise in BOPP anti-fog films and join us toward unparalleled product visibility and market success. Together, we can create a brighter future for your brand.

Contact us today to explore how our BOPP anti-fog film solutions can transform your packaging needs into an opportunity for growth.