Illuminating the Market with BOPP Holographic Film: A Vision of Innovation

Elevating Packaging to a New Dimension of Attraction

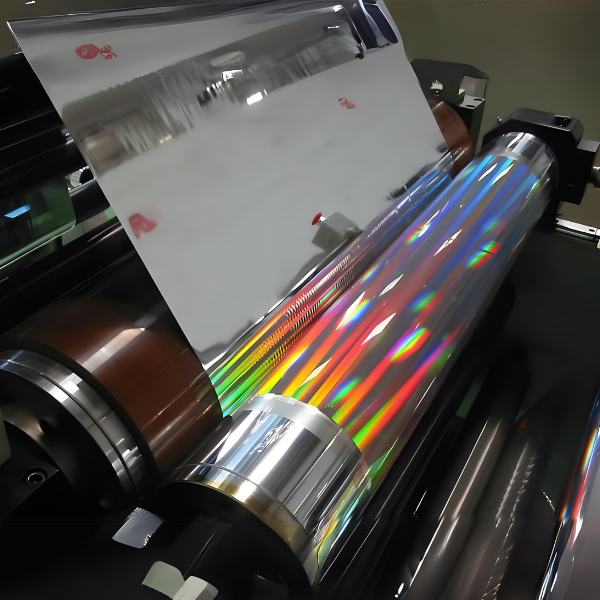

In the realm of standout packaging, BOPP holographic film emerges as a beacon of innovation, bringing products to life with its mesmerizing visual effects. As a pioneering holographic film manufacturer, CloudFilm takes pride in crafting films that captivate the eye and provide superior protection.

Our holographic solutions transform ordinary packaging into a dynamic canvas, showcasing your products in an unforgettable light. With BOPP holographic film, we invite your brand to enter a realm of infinite possibilities, where every angle and every light unveils a new spectacle of colors and patterns, engaging consumers with an irresistible allure.

Mastery Behind the Magic: CloudFilm’s Excellence in Holographic Innovation

CloudFilm stands at the forefront of holographic film production, combining the latest manufacturing technologies with an artistic vision to produce BOPP holographic films of unmatched quality and beauty.

Our commitment to excellence is evident in every roll of film we produce, ensuring that each product is a masterpiece of visual appeal and functional integrity.

As a leading holographic film manufacturer, we harness the power of holography to offer films that enhance product appeal and contribute to brand differentiation and market success. Our holographic thermal lamination films are designed to meet the highest standards of durability and aesthetics, making them the perfect choice for brands looking to make a lasting impression.

Beyond Brilliance: Tailored Solutions and Comprehensive Support

At CloudFilm, our relationship with clients transcends the supply of BOPP holographic film. We understand that each brand’s needs are unique, so we offer customized holographic solutions tailored to your specific requirements. Choose from a variety of holographic designs or create a custom BOPP holographic film to perfectly align with your brand identity.

Our team of experts works closely with clients to develop holographic thermal lamination films that meet and exceed expectations.

From concept to completion, we provide comprehensive support, ensuring a seamless experience and optimal results. With CloudFilm, you gain more than a holographic film manufacturer; you gain a partner dedicated to your brand’s success in the competitive landscape.