Revolutionizing Packaging with Simultaneous BOPA Film

Innovative Packaging Solutions with Simultaneous BOPA Film

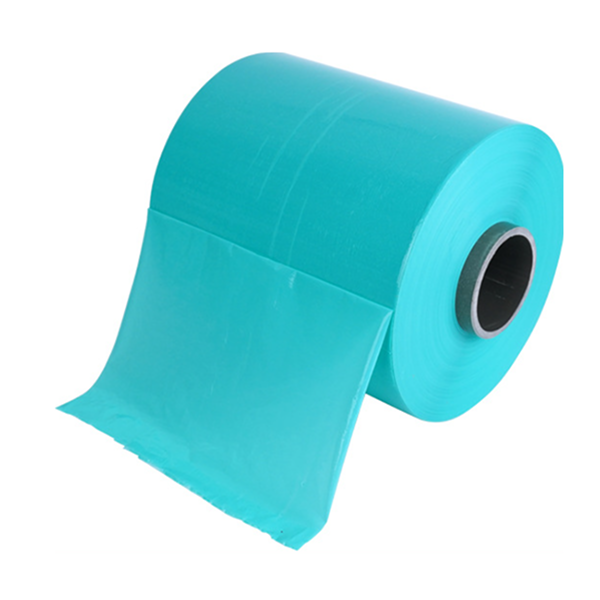

In the rapidly evolving world of packaging, the quest for materials that combine efficiency, quality, and versatility is relentless. Simultaneous BOPA film, a cutting-edge development in the Biaxially Oriented Polyamide (Nylon) family, sets new standards.

Crafted using advanced simultaneous biaxial stretching technology, this revolutionary packaging material, made from high-quality Nylon 6, is your ideal solution for diverse packaging needs.

Superior Performance for Diverse Applications

Simultaneous BOPA film distinguishes itself with unmatched transparency, uniform thickness, and superior barrier properties. It effectively blocks oxygen and moisture to safeguard and extend products’ shelf life.

Its mechanical stability and durability make it an unparalleled choice for the food and pharmaceutical industries, where maintaining freshness, nutrition, and efficacy is paramount.

Excellence in Printing and Brand Presentation

Simultaneous BOPA film excels in packaging aesthetics with its high transparency and smooth surface, ensuring vivid and clear print patterns and text. Its strong ink adhesion enhances the durability of the printed content, making it an ideal substrate for various printing techniques.

Whether traditional or modern printing methods, Simultaneous BOPA film ensures your products stand out on the shelves, enhancing brand appeal and market recognition.

CloudFilm: Your Trusted Supplier

As a leading supplier, CloudFilm is dedicated to providing high-quality Simultaneous BOPA films backed by a nationwide warehouse network that ensures quick and efficient delivery.

With us, you’re not just choosing a product; you’re opting for a partnership that guarantees innovative packaging solutions designed to meet and exceed your expectations.

Incorporate Simultaneous BOPA film into your packaging strategy to experience the benefits of a material that offers protection and efficiency and contributes to your products’ aesthetic appeal. Contact CloudFilm today to explore how our Simultaneous BOPA film can revolutionize your packaging needs.