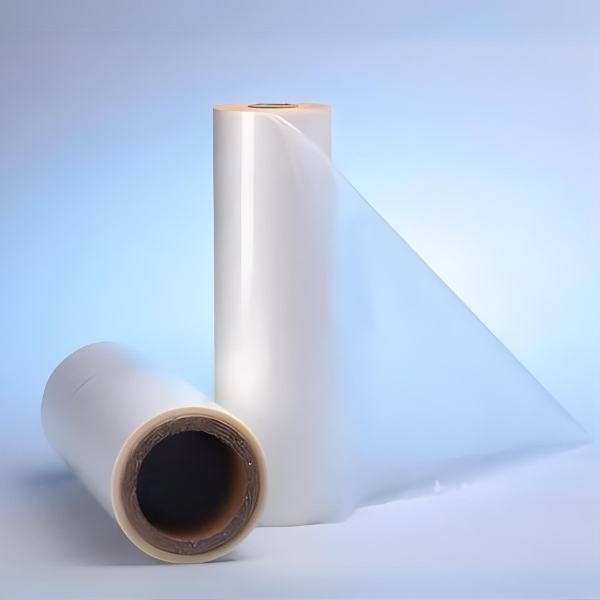

Elevating Barrier Solutions with Co-extrusion EVOH Film

Revolutionizing Packaging with High-Barrier EVOH Films

Modern packaging is paramount in its quest for sustainable materials that offer superior barrier properties without compromising sustainability. Our Co-extrusion EVOH film, also known as Ethylene Vinyl Alcohol Copolymer film, emerges as a revolutionary solution engineered to meet the complex demands of today’s packaging industry.

As a leading EVOH film manufacturer, we specialize in producing films that offer an exceptional barrier to gases, odors, and flavors, preserving the integrity and extending the shelf life of packaged goods.

Advanced EVOH Films for Ultimate Protection

Our EVOH barrier films are a testament to our commitment to innovation and quality. Designed for many applications, from food packaging to medical supplies, these films offer unparalleled protection against oxygen, moisture, and contaminants.

By leveraging the unique properties of ethylene vinyl alcohol copolymer, our EVOH barrier films ensure that your products stay fresher and longer. This makes us the preferred EVOH film suppliers for businesses looking for reliable and effective packaging solutions.

Your Partner in Sustainable Packaging Excellence

Choosing our EVOH films means more than accessing high-quality barrier solutions; it’s about partnering with a company that prioritizes your needs and the planet’s well-being. Our co-extruded films provide superior barrier performance and, with their recyclability, support sustainability efforts.

As EVOH film manufacturers committed to excellence, we offer customized solutions to meet your specific packaging requirements. This ensures your products stand out in the competitive market while minimizing environmental impact.

Join us in embracing the future of packaging with our co-extrusion EVOH films – where innovation, protection, and sustainability converge.