Introduction

In the world of packaging, one term that frequently comes up—especially in food, pharmaceutical, and consumer goods industries—is “lidding film.” But what exactly is lidding film, and why is it so important?

In this guide, we’ll break down everything you need to know about lidding film, from its basic structure and materials to its wide-ranging applications and how to choose the right one for your needs.

CloudFilm has been manufacturing and exporting flexible packaging films since 2002, supplying brand owners and converters with lidding films based on PET, PP, PE and aluminum structures for dairy, ready meals, coffee capsules and medical packs.

If you are responsible for buying tray or cup lidding, this guide will help you understand common lidding structures, compare options such as peelable vs weld-seal films, and prepare the key technical information needed to get an accurate quotation from CloudFilm.

{ Lidding Film Is Applied In Multiple Fields Of The Packaging Industry }

What is Lidding Film?

Lidding film is a thin layer of material used to seal containers such as cups, trays, and tubs. It provides a protective barrier, preserves freshness, and often includes features like peelability or printability for branding. Typically made from plastic or aluminum foil, lidding films are engineered to meet specific requirements such as heat resistance, puncture resistance, and barrier properties against moisture, oxygen, and contaminants.

In modern thermoformed cup and tray packaging, the lidding film works as the “top web”, matching with bottom materials like APET, PP or PS and running on high-speed sealing lines. Typical structures include PET/PE, PET/CPP, BOPP/CPP and PET/AL/PE, depending on the required barrier and sealing performance.

For peelable lids on yogurt, jelly, coffee capsules or ready meals, many CloudFilm customers choose easy peel film as a dedicated lidding film, combined with suitable tray materials and heat-seal parameters.

Structure and Composition of Lidding Film

Lidding films are generally multi-layered structures, each layer serving a distinct purpose:

- Sealant Layer: The innermost layer that comes into contact with the container rim. It ensures a tight seal and can be designed for peelable or weld-seal applications.

- Barrier Layer: Provides protection against gases (like oxygen), moisture, and UV light. Common materials include EVOH, aluminum foil, or metallized films.

- Carrier Layer: The outermost layer that offers mechanical strength, printability, and durability. Materials like PET, PP, or paper are often used here.

| Material | Heat Resistance | Barrier Properties | Recyclability | Best Use Case |

|---|---|---|---|---|

| PET | High | Moderate | Widely recyclable | Microwave trays |

| PP | Medium | Low | Recyclable | Dairy products |

| Aluminum | Very high | Excellent | Not recyclable | Coffee, pharmaceuticals |

| PLA (Bio) | Low | Low to moderate | Compostable | Eco-friendly packaging |

{ Material Comparison Table }

This combination of layers ensures that the lidding film not only seals the product but also extends its shelf life and maintains quality.

For high-barrier lidding films, the barrier layer is often an ALOx PET film, an aluminized PET film or a PVDC coated film, laminated with PE or CPP sealant films. CloudFilm helps you balance barrier performance, visibility and cost when choosing between transparent barrier (ALOx), metallized (VMPET) and coated high-barrier structures.

In many projects, CloudFilm also designs lidding structures that match brand sustainability targets, for example by replacing aluminum foil with high-barrier PET or PE-based solutions to support recyclability.

Types of Lidding Films

Lidding films can be categorized based on their functionality, material composition, and sealing properties:

Peelable Lidding Films

These films allow consumers to easily peel back the seal without tools. They are widely used in dairy products like yogurt and cottage cheese.

CloudFilm supplies peelable lidding solutions based on easy peel film that can be tailored for PS, PP, PET and aluminum trays, helping you fine-tune peel strength for different markets and age groups.

Weld-Seal Lidding Films

These create a permanent, tamper-evident seal. They are common in medical packaging and products requiring high security.

For retort pouches and high-temperature trays, CloudFilm often combines PET or high-barrier PET with retort CPP film as the weld-seal layer, ensuring seal integrity during sterilization and transport.

High-Barrier Lidding Films

Ideal for oxygen- and moisture-sensitive products such as coffee, ready-to-eat meals, and pharmaceuticals.

Typical high-barrier lidding structures include PET/AL/CPP, PET/VMPET/PE and PET/ALOx-PET/PE, using CloudFilm’s ALOx PET film, aluminized PET film or PVDC coated film as the barrier layer.

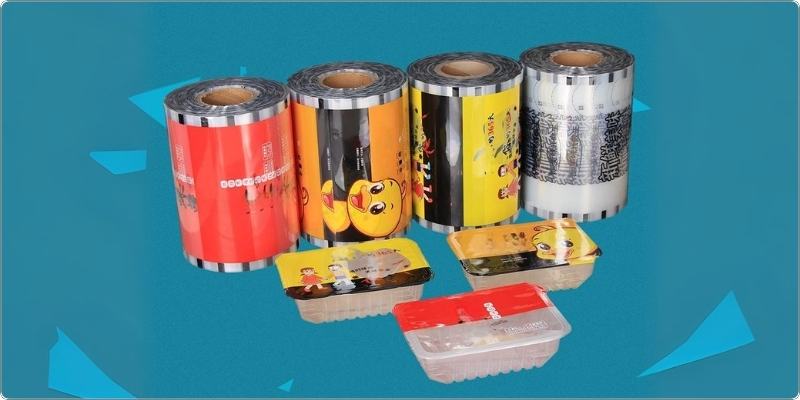

Printable Lidding Films

These allow high-quality graphics and branding, making them popular in consumer-facing products.

By combining high-clarity PET or BOPP with optimized corona treatment and primer, CloudFilm enables rich brand graphics, QR codes and regulatory information to be printed directly on the lidding web.

Microwaveable Lidding Films

Specially designed to withstand microwave heating, often used in frozen meals and ready-to-eat products.

Heat-resistant PET lidding, often using CloudFilm heat sealable PET film, is widely used for microwave trays and “heat and eat” meals.

Easy-Tear Lidding Films

Some packages require controlled tearing instead of peel-off lids, such as condiment sachets and stick packs. CloudFilm offers easy tear film and PET easy tear film that can be laminated with lidding structures to create precise easy-tear openings for food, pharmaceutical and personal care products.

{ Coffee Capsule Easy-Peel Film }

Applications of Lidding Film

Lidding films are used across a wide range of industries:

Food Industry

- Dairy Products: Yogurt, cream cheese, butter

- Ready Meals: Trays for pasta, rice, vegetables

- Snacks: Nuts, dried fruits, confectionery

- Beverages: Coffee capsules, juice cups

CloudFilm frequently designs PET/PE, PET/CPP and BOPP/CPP lidding structures for these applications, and our CPP anti fog film is especially suitable for salad bowls, fresh-cut vegetables and chilled fruits that must stay clear in refrigerated cabinets.

Pharmaceutical Industry

- Blister Packs: For tablets and capsules

- Medical Device Trays: Sterile packaging for surgical tools

In this sector, high-barrier lidding structures often incorporate ALOx PET, aluminized PET or PVDC coated films combined with PE or CPP sealant layers to meet strict shelf-life and sterility requirements.

Personal Care & Cosmetics

- Creams and Lotions: Sealed jars and tubs

- Wipes: Resealable packaging for wet wipes

Easy-tear and easy-peel lidding films help consumers open sample sachets and travel-size packs cleanly, without spilling product or damaging graphics.

Industrial & Chemical

- Adhesives and Sealants: Secure packaging for chemical products

- Paints and Coatings: Tamper-evident seals for cans and tubs

In industrial applications, CloudFilm often prioritizes chemical resistance and puncture resistance, using reinforced PET or metallized PET lidding structures to protect sensitive contents.

Key Benefits of Lidding Film

- Product Protection: Shields against contamination, moisture, and oxygen.

- Extended Shelf Life: Barrier properties help maintain product freshness.

- Convenience: Features like peelability and resealability enhance user experience.

- Brand Visibility: Printable surfaces allow for high-quality branding and product information.

- Sustainability Options: Many lidding films are now recyclable or made from renewable resources.

With a properly designed lidding film, you reduce leakage risk, improve seal integrity during logistics, and keep aroma and flavor locked in until the moment of opening.

CloudFilm supports both traditional aluminum-based and more sustainable PET/PE or PP-based lidding structures, helping you improve shelf life while meeting retailer sustainability guidelines.

How to Choose the Right Lidding Film

Selecting the right lidding film depends on several factors:

1. Product Requirements

- Does the product need oxygen or moisture protection?

- Is it sensitive to light or UV exposure?

- Will it be microwaved or frozen?

2. Packaging Process

- What type of sealing equipment is being used?

- What are the speed and temperature requirements?

3. Consumer Experience

- Should the seal be peelable or permanent?

- Is resealability important?

4. Regulatory Compliance

- Food contact safety standards (e.g., FDA, EU regulations)

- Pharmaceutical packaging requirements (e.g., ISO standards)

5. Sustainability Goals

- Is recyclability a priority?

- Are bio-based or compostable materials preferred?

At CloudFilm, we help clients navigate these considerations to find the perfect lidding film solution.

In practice, it is very helpful to share with CloudFilm your tray material (APET, CPET, PP, PS, aluminum), filling temperature, target shelf life, storage conditions and line speed. With this information, our engineers can quickly shortlist suitable lidding structures and recommend films such as heat sealable PET film, easy peel film or CPP anti fog film for line trials.

If you are exploring recyclable or mono-material packaging, CloudFilm can also propose PP-based or PE-based lidding concepts that work with MDO PE film and BOPE film , helping your packs enter PE recycling streams.

{ Yogurt Easy-Peel Film }

Innovations and Sustainability Trends in Lidding Films

The packaging industry is rapidly evolving, with sustainability at the forefront. Key innovations include:

1. Recyclable Lidding Films

Designed to be compatible with existing recycling streams, these films help reduce environmental impact.

2. Biodegradable and Compostable Options

Made from plant-based materials like PLA (polylactic acid), these films break down naturally under specific conditions.

3. Downgauging

Advances in material science allow for thinner films without compromising performance, reducing material usage and waste.

Integration of QR codes, NFC tags, and freshness indicators for enhanced consumer engagement and product safety.

5. Mono-Material Lidding For Recycling

Brand owners are increasingly exploring PE-based or PP-based lidding designs so that the whole pack—both lid and tray—can enter a single recycling stream. By combining BOPP, MDO PE film or BOPE film with compatible sealant layers, CloudFilm helps customers move from mixed-material laminates to more recyclable solutions.

CloudFilm is committed to staying at the cutting edge of these trends, offering innovative and sustainable packaging solutions.

CloudFilm Lidding Film Solutions and Technical Support

As a specialized manufacturer of flexible packaging films, CloudFilm not only supplies base films such as BOPP, BOPET, BOPA, CPP and PE, but also helps customers engineer complete lidding structures that match product performance, line conditions and sustainability goals.

Our team can support you from early concept—choosing between peelable, weld-seal, high-barrier or easy-tear lidding—through to pilot trials, specification confirmation and mass production. With global export experience to more than 30 countries, CloudFilm understands different regional regulations and shelf-life requirements.

Whether you need sample rolls for line testing, a full container of easy peel film for yogurt cups, CPP anti fog film for salads, or high-barrier PET structures for coffee capsules, our engineers and sales team will work together to propose practical, cost-effective lidding film solutions.

Frequently Asked Questions (FAQ)

Q: What is the difference between lidding film and regular plastic wrap?

A: Lidding film is specifically engineered for sealing containers, offering barrier properties, seal strength, and often peelability or printability. Regular plastic wrap lacks these specialized features.

Q: Can lidding films be customized?

A: Yes. CloudFilm offers customization in terms of material, thickness, print design, and sealing properties to meet specific client needs.

Q: Are there eco-friendly lidding films available?

A: Absolutely. We provide recyclable, biodegradable, and compostable lidding films to support sustainability goals.

Q: What industries benefit most from lidding films?

A: Food, pharmaceuticals, personal care, and industrial packaging are the primary industries that benefit from lidding films.

Q: Can the same lidding film work on different tray materials such as PET, PP and PS?

A: Sometimes yes, but sealant chemistry and sealing window are different for each substrate. CloudFilm will normally recommend specific sealant layers or easy peel film grades designed for APET, CPET, PP or PS trays to ensure stable sealing and controlled peel strength.

Q: Do you offer lidding films suitable for recyclable or mono-material packaging?

A: Yes. CloudFilm can design PE-based or PP-based lidding solutions using materials like MDO PE film

and BOPE film so that the lid and pouch or tray can enter a single recycling stream, supporting brand sustainability targets.

Q: What is easy-peel lidding film and how is peel strength adjusted?

A: Easy-peel lidding film is designed so the lid can be removed cleanly without tearing or leaving residue. CloudFilm adjusts peel strength by modifying the sealant layer, sealing temperature and dwell time, and can provide different peel force ranges to match local consumer preferences.

Q: What is the typical minimum order quantity (MOQ) for lidding film from CloudFilm?

A: For new projects, CloudFilm can usually supply trial rolls with flexible MOQ for testing. For mass production, MOQ often starts from around 1,000–2,000 kg per structure, depending on film type, thickness and width. Please contact us with your project details for a precise MOQ and pricing.

Conclusion

{ CloudFilm Provides You With Customizable Lidding Film Solutions }

Lidding film is a critical component of modern packaging, offering protection, convenience, and branding opportunities. Whether you’re in the food, pharmaceutical, or consumer goods industry, selecting the right lidding film can enhance product quality, extend shelf life, and improve consumer satisfaction.

When you view lidding as a strategic part of the pack—not just “a piece of film on top”—you can reduce waste, improve line efficiency, and create a more premium unboxing experience for your customers.

If you are planning a new cup, tray or pouch project and need support with lidding film selection, you can contact the CloudFilm team for free technical advice, sample rolls and a competitive quotation tailored to your market.