Introduction

In flexible packaging projects, one of the most common questions from brand owners and converters is:

“Should I choose BOPP, BOPET or BOPA film for this product?”

These three biaxially oriented films look similar as clear plastic, but their properties and best-fit applications are very different. In this guide, we compare BOPP, BOPET and BOPA films from a practical, packaging-focused angle – not just from textbook definitions.

At CloudFilm, we manufacture and supply all three film families in China – BOPP film, polyester BOPET film and nylon-based BOPA film – and combine them into custom laminates for food, industrial and specialty packaging. This article gives you a high-level map: what each film is, where it works best, and how to choose the right one for your next pouch, lidding or lamination project.

Quick snapshot:

- BOPP film – Best for moisture barrier, clarity and cost-effective front webs in snacks, confectionery and labels. See our full BOPP film series.

- BOPET film – Strong, stiff and heat-resistant, ideal as a printing and barrier layer in retort, lidding and industrial laminates. Explore our BOPET film range.

- BOPA film – The “barrier and toughness champion” for demanding vacuum, retort and bone-in packs. Learn more from our BOPA film portfolio.

Why Film Choice Matters

Selecting the right packaging film is not just a sourcing decision – it directly affects shelf life, product safety, line efficiency and sustainability performance. Different films bring different levels of:

- Barrier against oxygen, moisture and aroma;

- Mechanical strength and toughness for sharp, heavy or frozen products;

- Heat resistance for hot-fill, pasteurization or retort;

- Cost and recyclability, especially in mono-material PP or PE structures.

By understanding the strengths and trade-offs of BOPP, BOPET and BOPA films, you can design laminates that protect the product, run smoothly on your machine and align with retailer and regulatory requirements.

When you need application-specific support, the CloudFilm technical team can recommend suitable structures and thicknesses based on your packing format and filling process.

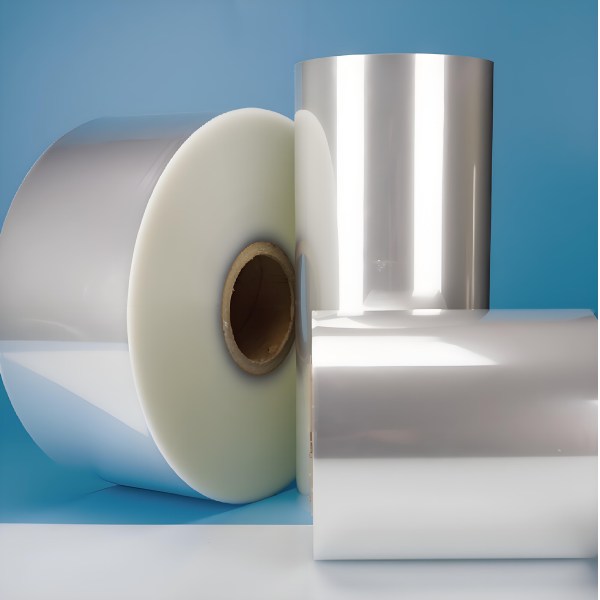

BOPP Film: Versatile and Affordable

What is BOPP?

Biaxially Oriented Polypropylene (BOPP) film is manufactured by stretching polypropylene film in both machine and transverse directions, which enhances its strength and clarity.

Key Properties

- Moisture Barrier: Excellent resistance to water vapor.

- Tensile Strength: Strong and durable, making it resistant to tearing and punctures.

- Clarity and Gloss: Offers a clear view of the product, ideal for marketing purposes.

Common Uses

BOPP is widely used in snack packaging, label production, and as a lamination material. Its versatility also extends to stationery, textiles, and consumer goods.

Pros and Cons

While BOPP is cost-effective and offers excellent clarity and durability, it is not the best choice for high-temperature applications and has moderate barrier properties against gases. However, with the development of technological innovation after coating treatment or adding specific additives, the shortcomings in this area are not obvious.

When your project prioritizes cost, clarity and moisture barrier – for example, snack, candy and dry food packaging – BOPP film is usually the first candidate CloudFilm recommends. For high-barrier needs, it can be combined with metallized BOPP, BOPET or BOPA in a laminate.

BOPET Film: Durable and Heat-Resistant

What is BOPET?

Biaxially Oriented Polyethylene Terephthalate (BOPET) film is known for its strength and thermal stability. Derived from PET, it is stretched similarly to BOPP.

Key Properties

- Heat Resistance: It can withstand higher temperatures, making it suitable for heat applications.

- Gas Barrier Properties: Good resistance to gases like oxygen and carbon dioxide.

- Chemical Resistance: Less prone to damage from oils and acids.

Common Uses

BOPET’s durability makes it a popular choice in food packaging, particularly for products requiring a longer shelf life. It’s also used in industrial applications and as a protective film in electronics.

Pros and Cons

BOPET’s superior heat and chemical resistance are more expensive than BOPP.

For a deeper dive into applications, you can refer to our articles “Top Uses of BOPET Film in Everyday Products” and “The Complete Guide to Understanding BOPET Film Types & Applications”

BOPA Film: The Barrier Champion

What is BOPA?

Biaxially Oriented Polyamide (BOPA),also called nylon film, is valued for its outstanding puncture resistance and gas barrier. When combined with PE, CPP or aluminum foil in laminates, BOPA is the “backbone” layer in many vacuum, retort and high-abuse packs.

CloudFilm is a dedicated BOPA film supplier, providing base BOPA film as well as PA/PE and PE PA PE structures for demanding food and industrial applications.

Key Properties

- Oxygen and Aroma Barrier: Excellent at preserving freshness and aroma.

- Puncture and Abrasion Resistance: Offers robust protection for the packaged product.

- Flexibility: Maintains integrity under stress and varying temperatures.

Common Uses

BOPA is the go-to film for perishable goods, vacuum packaging, and medical products, where maintaining a high barrier is crucial.

Pros and Cons

BOPA excels in barrier properties and durability but is more expensive. It’s also sensitive to humidity and temperature variations, requiring careful storage and handling.

For more technical details, you can refer to “BOPA Film Usage and Benefits” and “BOPA Film Density Explained: A Complete Guide”.

Comparison Table – BOPP vs BOPET vs BOPA

Use the summary table below as a quick filter. Then combine it with your real product, filling and logistics conditions to finalise the structure with your film supplier.

| Property | BOPP Film | BOPET Film | BOPA Film |

| Material | Polypropylene (PP) | Polyethylene Terephthalate (PET) | Polyamide (Nylon) |

| Moisture Barrier | High | Moderate | High |

| Heat Resistance | Low | High | Moderate |

| Gas Barrier | Moderate | High | Very High |

| Puncture/Abrasion Resistance | Moderate | High | Very High |

| Flexibility | Moderate | Low | High |

| Cost | Low | Moderate | High |

| Primary Uses | Packaging (snacks, labels), Lamination | Food Packaging, Industrial Applications,

Electrical Insulation |

Perishable Food Packaging, Medical Products,

Vacuum Packaging |

For project-level decisions, CloudFilm can combine this high-level table with your detailed requirements (product type, shelf-life target, filling temperature and packing format) to recommend a suitable laminate.

Which Film Is Best for Your Application?

Below is a quick rule-of-thumb guide. In most real projects, CloudFilm combines two or three films into a laminate to balance barrier, sealability and cost.

Snacks, biscuits and confectionery

- Front web: BOPP (gloss or matte) for clarity, print and moisture barrier.

- Inner web: Heat-sealable BOPP or PE / CPP for sealing strength.

Coffee, tea and premium dry foods

- Front web: BOPET for stiffness and print quality, optionally with ALOx PET or aluminized PET for higher barrier.

- Inner web: PE or CPP for sealing and machinability.

Vacuum and bone-in meat packaging

- Structure: PA/PE or PE PA PE laminates using BOPA as the central high-toughness layer.

Retort pouches and high-temperature sauces

- Structure: PET/AL/PA/PE or PET/AL/PE, where BOPET and BOPA provide heat resistance and puncture resistance, while aluminum and PE ensure barrier and sealing.

Labels, overwraps and tapes

- BOPP folia for wrap-around labels and overwrap.

- BOPP tape film for carton sealing and industrial tapes.

Share your target application, filling temperature and expected shelf life with the CloudFilm team, and we can suggest several workable film structures with clear pros and cons.

Choosing the Right Film

Factors to Consider

- Barrier Requirements: Consider the level of protection needed against moisture, oxygen, and other gases.

- Mechanical Properties: Assess the need for strength, flexibility, and durability.

- Cost Considerations: Balance the budget with the quality requirements.

Expert Opinions

Packaging experts recommend considering the entire product lifecycle, from manufacturing to disposal, to ensure an environmentally responsible choice that doesn’t compromise quality.

Conclusion

Understanding the differences between BOPP, BOPET, and BOPA films is crucial in making an informed decision for your packaging needs. Each film offers unique properties and serves different purposes, making the choice highly dependent on the product’s specific requirements and the manufacturer’s goals.

By selecting the right film, you can enhance your product’s shelf life, appeal, and sustainability, ultimately contributing to greater customer satisfaction and environmental responsibility.

FAQ – BOPP, BOPET and BOPA Films

Q1: Is BOPP or BOPET better for snack packaging?

A1: For typical dry snacks such as chips, biscuits or confectionery, BOPP is usually used as the main film because of its excellent moisture barrier, clarity and cost advantage. BOPET is added only when you need extra stiffness, heat resistance or higher gas barrier, for example in export or premium packs.

Q2: When do I really need BOPA film in a structure?

A2: You usually need BOPA when the product is sharp, heavy or requires very high oxygen barrier – for example, bone-in meat, vacuum packs, retort pouches and some high-value dry foods. In these cases, BOPA provides the toughness and barrier that BOPP or BOPET alone cannot offer.

Q3: Can BOPP, BOPET and BOPA be recycled?

A3: As single materials, PP-based BOPP and PET-based BOPET can enter existing recycling streams in many markets. BOPA is more challenging to recycle on its own, and multi-material laminates (such as PET/AL/PE or PA/PE) are more difficult to recycle mechanically. That is why CloudFilm also develops mono-material solutions, such as mono-PP and mono-PE structures, for customers with strict recyclability targets.

Q4: How can CloudFilm help if I am not sure which film to choose?

A4: You can simply send us your product description, filling process (temperature, time), target shelf life and any special requirements (such as puncture resistance, optical appearance or recyclability). Our technical and sales team will recommend several suitable structures with estimated cost levels and, if needed, prepare trial rolls for your line tests.