When it comes to flexible packaging films, matt BOPP (Biaxially Oriented Polypropylene) stands out for its excellent printability, aesthetic appeal, and versatility. One of the most critical technical parameters you need to consider when selecting or evaluating this material is its density.

In this article, we’ll explore what matt BOPP film density is, why it matters, and how it influences the performance and suitability of the film in various applications.

For buyers, engineers and brand owners, understanding matt BOPP film density helps you compare different structures, calculate yield and control packaging cost while keeping a premium matte finish.

If you also work with glossy or special BOPP grades, you can compare this article with CloudFilm’s broader guide “Exploring the Different Types of BOPP Film”to build a complete BOPP film selection toolbox.

CloudFilm is not only a matt BOPP film manufacturer, but also a solution partner that helps you match density, thickness, and structure to your specific packaging line and end-use.

{ BOPP Matte Film Production Line }

What Is Matt BOPP Film Density?

Density, in the context of polymer films, refers to the mass per unit volume, typically expressed in grams per cubic centimeter (g/cm³). For matt BOPP film, density not only reflects the material’s composition but also affects its mechanical properties, transparency, and surface characteristics.

n simpler terms, density tells you how “heavy” the film is at a given thickness, which links directly to GSM (g/m²), yield (m²/kg) and how stiff or soft the pack feels in hand.

If you want a broader background on BOPP density beyond matt grades, you can also refer to CloudFilm’s article “The Ultimate Guide to BOPP Density”.

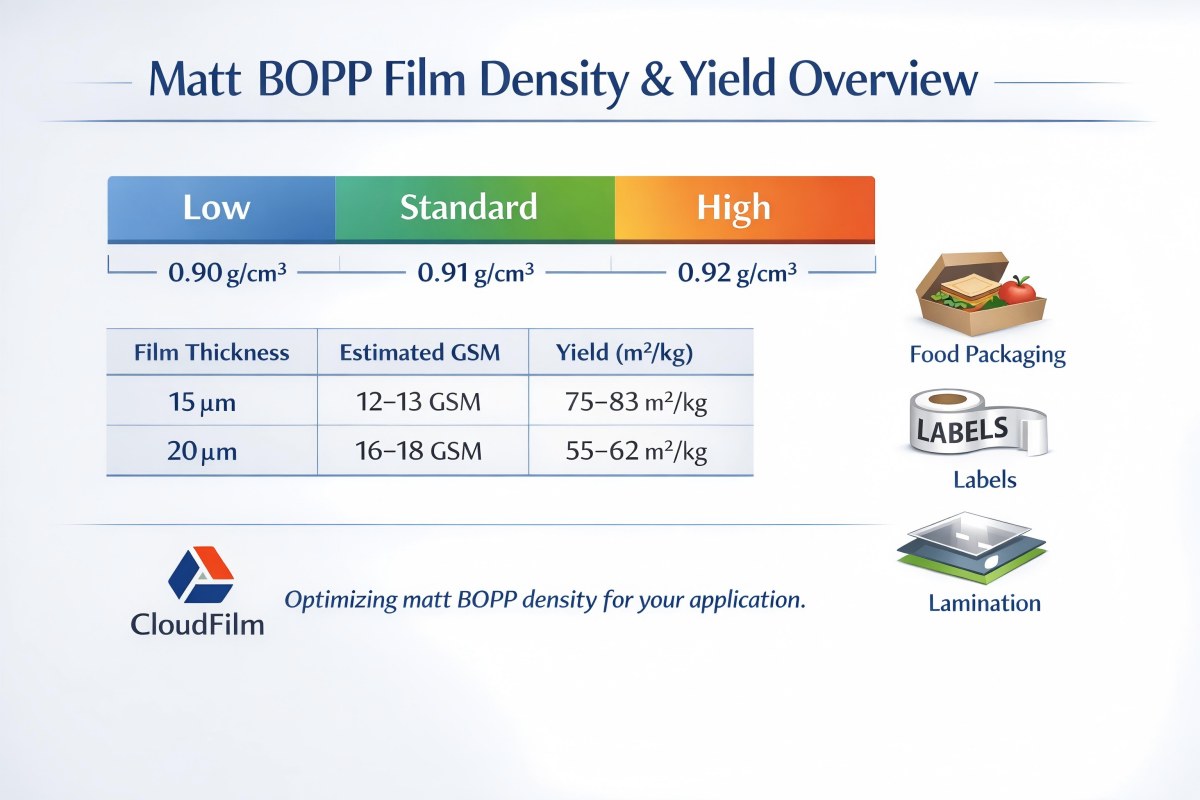

Typical Density Range for Matt BOPP Film

In the flexible packaging industry, the density of matt BOPP film typically falls between 0.90 and 0.92 g/cm³. This range can vary depending on the formulation—films with higher mineral filler content may have a density closer to the upper limit, while unfilled or lightly filled films tend to be on the lower end.

At CloudFilm, we ensure that our matt BOPP films are precisely engineered to meet your required density specifications, balancing performance, aesthetics, and cost-efficiency.

For most lamination, book-cover and label projects, buyers specify matt BOPP film in this 0.90–0.92 g/cm³ window, which matches the density range offered on CloudFilm’s BOPP Matte Filmproduct line.

By combining density control with thickness options such as 15, 18, 20 or 25 µm, CloudFilm helps you fine-tune both the visual effect and the material consumption of each structure.

Why Does Density Matter?

1. Mechanical Strength and Durability

Higher density often correlates with improved tensile strength and puncture resistance. If your packaging requires durability during transportation or handling, you may want a film with a density on the higher side of the typical range.

2. Optical and Surface Properties

Density influences the opacity and surface texture of the film. A controlled density helps achieve the desired matt finish and ensures consistent print quality, which is essential for high-end packaging.

3. Cost and Material Efficiency

Lower density films may offer cost savings due to reduced material usage, but they must still meet performance requirements. Understanding the density allows you to optimize material usage without compromising quality.

4. Environmental Impact

Lighter films (lower density) can contribute to reduced plastic consumption and lower carbon footprint, aligning with sustainability goals. However, this must be balanced with functional performance.

| Property | Low Density (~0.90 g/cm³) |

Standard Density (~0.91 g/cm³) |

High Density (~0.92 g/cm³) |

| Stiffness | Lower | Moderate | Higher |

| Transparency | Higher | Moderate | Slightly Reduced |

| Heat Resistance | Moderate | Good | Excellent |

| Typical Applications | Light-duty bags | Food packaging | Labels & laminates |

{ The Effect of Different Densities on the Performance of BOPP Matte Film }

From a sourcing and operations perspective, these density differences also influence roll handling, web tension stability on high-speed lines, and how many meters you can load into a given maximum roll diameter.

CloudFilm’s technical team can compare several candidate densities with you and simulate their impact on stiffness, yield and machine performance before you commit to a large order.

How Is Density Measured?

Density is typically measured using standardized methods such as ASTM D792 or ISO 1183. These involve calculating the mass-to-volume ratio of a sample, often through liquid displacement or gas pycnometry. At CloudFilm, we use advanced testing equipment to ensure that every batch of matt BOPP film meets the specified density tolerances, guaranteeing consistency and reliability.

In day-to-day quality control, many converters also check density indirectly by measuring film thickness and roll weight, comparing the calculated GSM with specification sheets.

For more detailed formulas and reference tables covering BOPP, BOPET and other films, you can consult CloudFilm’s technical article “Flexible Film Density: Formulas, Tables & Yield”.

Matt BOPP Film Density, Thickness and Yield: Quick Calculation Guide

For many packaging buyers, one of the most practical uses of density data is to estimate GSM and yield so you can budget material cost per pack.

A simple rule of thumb for polymer films is:

- GSM (g/m²) ≈ Thickness (µm) × Density (g/cm³)

- Yield (m²/kg) ≈ 1000 ÷ GSM

For example, for a matt BOPP film with density 0.91 g/cm³ and thickness 20 µm:

- GSM ≈ 20 × 0.91 = 18.2 g/m²

- Yield ≈ 1000 ÷ 18.2 ≈ 54.9 m²/kg

This means that one kilogram of this matt BOPP film can cover roughly 55 square meters of printed web, helping you estimate how many pouches, labels or covers you can produce per roll.

When you share your target thickness and structure with CloudFilm, our engineers can run these calculations for you and provide optimized film specifications and roll formats to hit your cost-per-pack targets.

Applications of Matt BOPP Film by Density

{ BOPP Matte Film Is Suitable For Various High-End Food Packaging }

Different applications may call for different density specifications:

- Food Packaging: Films with a density around 0.91 g/cm³ are often preferred for their balance of strength and lightweight properties.

- Labeling and Overwrap: Slightly higher density films (up to 0.92 g/cm³) provide enhanced stiffness and dimensional stability.

- Laminations: When used as part of a multi-layer structure, the density of the matt BOPP layer affects the overall performance of the laminate, including barrier properties and sealability.

For premium coffee bags, snack pouches and dry-food packaging, CloudFilm often recommends matt BOPP outer webs with a standard density around 0.91 g/cm³, combined with PET, PE or aluminum layers depending on barrier needs.

In label and overwrap applications, slightly higher density matt BOPP grades improve flatness and die-cutting performance, especially when used together with BOPP Printing Film or specialty films like Soft Touch BOPP Film.

For projects that require a stiffer, higher-temperature-resistant matte surface, designers can compare matt BOPP with Matte PET Film to decide which base film best fits the brand position and process window.

How to Choose the Right Matt BOPP Film Grade for Your Project

When selecting a matt BOPP film, density is one of several parameters you should consider alongside thickness, surface treatment, slip, sealability and print requirements.

A practical selection checklist includes:

- End use and pack format (snack bags, coffee valves, labels, book covers, etc.)

- Required stiffness and hand-feel of the finished pack

- Printing method and ink system

- Lamination partners (PET, PE, AL, CPP, etc.)

- Regulatory and food-contact requirements

- Sustainability targets and material reduction goals

CloudFilm’s BOPP Matte Film product page provides typical mechanical and optical data so you can benchmark options quickly.

For projects where you need to compare matt BOPP with gloss BOPP, pearlized BOPP or other BOPP specialty grades, CloudFilm’s broader BOPP film portfolio enables you to standardize suppliers while still tailoring each structure.

Why Work with CloudFilm for Matt BOPP Film

In summary, matt BOPP film density is more than just a number—it’s a key indicator of the film’s performance, cost-efficiency, and suitability for specific applications. Whether you’re an engineer, procurement specialist, or packaging designer, understanding this parameter will help you make better material choices.

{ CloudFilm Can Provide You With High-Quality BOPP Matte Film }

If you’re looking for high-quality matt BOPP film with a density tailored to your needs, CloudFilm is here to help. Contact us today to discuss your requirements or request samples, and let’s create smarter, more sustainable packaging solutions together.

With over 22 years of flexible packaging film experience and a full BOPP/BOPET/BOPA/PE portfolio, CloudFilm can support you from lab sampling to commercial-scale shipments.

You can start by sharing your target density, thickness and structure via the inquiry form on the BOPP Matte Film

page or the general Contact CloudFilm page—our team will respond with a tailored proposal and free technical suggestions.

For projects that also involve matte lamination on paperboard, don’t miss CloudFilm’s Matte Lamination Guide, which explains how matt BOPP, soft touch BOPP and matte PET can work together in a unified finishing system.

Matt BOPP Film Density – FAQs

Q1: What is the typical density range of matt BOPP film?

A: Most matt BOPP films used in flexible packaging fall between 0.90 and 0.92 g/cm³. Within CloudFilm’s production, 0.91 g/cm³ is a common “standard density” target that balances stiffness, printability and material usage.

Q2: How does matt BOPP film density affect yield and cost?

A: At the same thickness, a lower-density film has lower GSM and therefore higher yield (more square meters per kilogram). This can reduce material cost per pack. However, very low density may reduce stiffness or toughness, so CloudFilm helps you select a density that optimizes both cost and performance.

Q3: How can I check whether the matt BOPP film I receive meets the specified density?

A: You can request a density certificate from the supplier and also perform spot checks. A practical method is to measure roll weight and average thickness, calculate GSM, and back-calculate the implied density using the formulas in CloudFilm’s Flexible Film Density Guide. If needed, third-party labs can perform ASTM D792 or ISO 1183 tests.

Q4: Which density should I choose for labels vs. laminates?

A: For labels and overwraps that need higher stiffness and dimensional stability, slightly higher density (around 0.92 g/cm³) is often preferred. For laminates used on snack and dry-food pouches, a standard density around 0.91 g/cm³ usually offers a good balance between toughness and material efficiency. CloudFilm can provide different matt BOPP grades according to your application.

Q5: Does matt BOPP film density influence recyclability?

A: Within the normal 0.90–0.92 g/cm³ range, density has limited impact on recyclability compared with factors such as ink, adhesives and laminate partners. However, lower-density films can reduce total plastic usage, which supports overall sustainability efforts. CloudFilm can also recommend mono-material BOPP or polyolefin structures if recyclability is a core design target.

Q6: How does matt BOPP density compare with gloss BOPP or pearlized BOPP?

A: Gloss BOPP grades often have similar base densities but different surface treatments and crystallinity, affecting gloss and stiffness. Pearlized BOPP usually has a lower “effective density” because of voids created by cavitation, which greatly increases yield but also changes opacity and feel. For a detailed comparison, you can refer to CloudFilm’s BOPP resources and discuss your structure with our technical team.