What Counts as a “Flexible Packaging Solution”?

A flexible packaging solution is not just a film roll. It’s a tailored combination of substrate selection, functional design (barrier, sealing, machinability), format engineering (pouch, lidstock, flow wrap), print & finish, and quality controls that align with your product’s shelf-life, brand goals, and cost targets.

Good solutions minimize waste, run efficiently on your lines, look great in-store/online, and are increasingly designed for recyclability.

Film Families & When to Use Them

Cast Polypropylene (CPP)

CPP is a go-to for clarity, toughness, and dependable sealing. Typical roles include lamination webs, lidding films, and overwraps needing balanced mechanicals and optics. If your application requires flatness and consistent gauge (good for high-speed converting), CPP is often the right starting point.

Cast Polyethylene (CPE)

CPE brings soft handfeel, flexibility at low temperatures, and forgiving sealing windows. It’s common in frozen, chilled, or bulky items where drop resistance and cold-crack performance matter. As part of mono-PE designs, CPE helps build recyclable structures while maintaining seal integrity.

Explore cast films and configurations: Cast Film | CPP & CPE Packaging – CloudFilm

BOPP / BOPET / BOPA

-

BOPP: very good optics, moisture barrier, and stiffness—great for snacks and general dry food.

-

BOPET: high temperature resistance, dimensional stability, ideal for retort lams or high-heat processes.

-

BOPA: toughness and puncture resistance; used where durability is critical (e.g., liquids, heavy or sharp-edged goods).

High-Barrier (EVOH, Metallized)

When shelf life depends on oxygen/light barrier, consider EVOH coextrusions or metallized films. EVOH provides tunable oxygen barrier; metallized films give both barrier + premium look—popular for coffee, snacks, and premium goods.

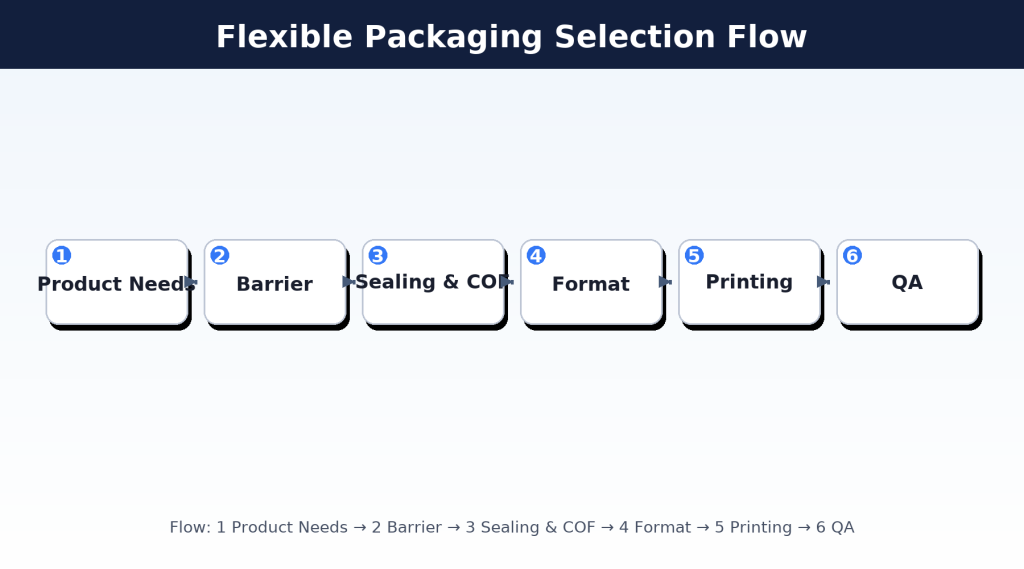

A Step-by-Step Selection Framework

-

Define product needs: dry vs. moist, oily vs. powder, sharp edges, aroma, light sensitivity.

-

Quantify barrier: target OTR/WVTR, light barrier, and aroma control.

-

Sealing & COF: choose sealing layer (CPP/CPE/PE) and manage slip/anti-block; set static/dynamic COF for line speed.

-

Format engineering: stand-up pouch (SUP), spouted, quad-seal, lidding, flow wrap, or sachet—each impacts stiffness, thickness, and web tensions.

-

Printing & finish: rotogravure/flexo/digital; matte vs. gloss; metallized accents; window areas for product visibility.

-

QA & compliance: migration, odor, food-contact, tensile/elongation, seal strength & hot-tack, dart/puncture, aging tests.

-

Scale & supply: lead time, MOQ, secondary converting (slitting, perforation), and replenishment planning.

Flow diagram showing steps to choose flexible packaging films

Pack Formats & Converting Considerations

-

Stand-up pouches (SUP): need a balance of stiffness (for standability) and sealability. Mono-PP or mono-PE designs favor recyclability.

-

Lidding films: control peel strength, anti-fog, and seal compatibility to trays/bowls (PP, PET, PE).

-

Flow wrap (pillow packs): requires stable COF and consistent thickness for tight, wrinkle-free wraps.

-

Sachets & stick packs: focus on seal initiation temperature, hot-tack, and cutting/tear performance.

Sealing, COF & Machine Performance

Strong, consistent seals come from proper resin selection + additive packages. For high-speed VFFS/HFFS, dial in:

-

Seal initiation temperature (start sealing early without scorching ink or deforming)

-

Hot-tack (hold while hot)

-

COF (coefficient of friction) tuned to avoid slippage or jerky feed

-

Slip/anti-block balance so webs separate cleanly yet don’t become too slick for feed rollers

Print & Appearance: Clarity, Matte, Metallized

-

High clarity showcases product and branding; CPP/CPE and BOPP excel here.

-

Matte finishes create premium contrast; consider matte-coat or matte-surface layers.

-

Metallized delivers strong barrier + mirror-like shine for premium lines and light/oxygen protection.

Sustainability: Design for Recyclability

Regulations and retailers increasingly demand mono-material designs, typically PP-only or PE-only. That means replacing mixed substrates with CPP/CPE/PE seal layers compatible with the chosen recycle stream, and using EVOH or coatings judiciously.

To go deeper on mono-material packaging strategies, see our guide:

Recyclable Flexible Packaging: A Sustainable Guide

Typical Use Cases by Category

Snacks & Confectionery – prioritize moisture barrier, aroma retention, easy-open features; metallized or EVOH structures common.

Fresh Produce – anti-fog lidding, breathable or micro-perforated webs to manage condensation and respiration.

Frozen Foods – low-temperature toughness (CPE/PE), seal through contamination, tear initiation control.

Personal Care – chemical resistance, puncture/tear reliability; pouch fittings (spouts, sliders).

Household – detergents, wipes, disinfectants; stress-crack resistance and seal hermeticity.

Pharma & Medical – sterilization compatibility (e.g., retortable CPP), traceability, regulatory compliance.

Alt: Flexible packaging applications for snacks, produce, frozen foods, personal care, household and pharma, 9:5

Quality, Testing & Compliance

A robust program typically includes:

-

Mechanical: MD/TD tensile, elongation, tear, dart, puncture

-

Sealing: SIT, hot-tack, peel strength (ASTM), burst/leak

-

Barrier: OTR/WVTR vs. spec; light barrier for photosensitive fills

-

Food-contact: migration/overall compliance per destination markets

-

Aging & transit: accelerated aging, compression, drop; print adhesion, scuff & rub

-

Documentation: lot traceability, COA, and change-control

Cost, MOQ & Lead Time in Global Supply

Total cost is a mix of resin, additives/coatings, printing cylinders/plates, waste factors, and logistics. Typical export programs plan around:

-

MOQ aligned to resin runs and slitting plans

-

Lead time covering extrusion, treatment, printing/lamination, curing, slitting, and freight

-

Replenishment using forecast buckets and safety stock for promotions/seasonality

Why Work with CloudFilm — and How to Start

CloudFilm provides broader flexible packaging solutions with custom width, gauge, slip/COF, corona/primer, matte, peelable options that fit your converting line. Start with one of our most-requested categories:

Ready to brief us? Share: application, product, dimensions, target shelf-life, seal/lidding surface (PP/PET/PE), print method, expected run rate, and annual volume.

FAQs

Q1. Cast vs. blown—how do I choose?

Cast (CPP/CPE) offers excellent gauge control and flatness for high-speed converting; blown films are great for stiffness and balanced properties across directions. Your pack format, printing, and barrier targets will point to one or the other.

Q2. Can mono-material packs deliver high barrier?

Yes. Combine PP- or PE-based structures with EVOH or metallized layers where appropriate, then validate recyclability in your target market.

Q3. What data shortens quotation & sampling?

Product type, fill conditions, target barrier (OTR/WVTR), sealing surface, run speed, pack format, artwork/print method, and desired MOQ/lead time.

Q4. How do I avoid fogging in chilled lidding?

Specify anti-fog in the sealing web, match SIT to tray, test peel strength at actual chill/condensation conditions.

Q5. Typical lead time & MOQ?

Depends on configuration and printing; unprinted base films are faster than printed laminates. Share your timeline and we’ll align capacity accordingly.

Call to Action: Tell us about your project to get a tailored film stack-up and samples.