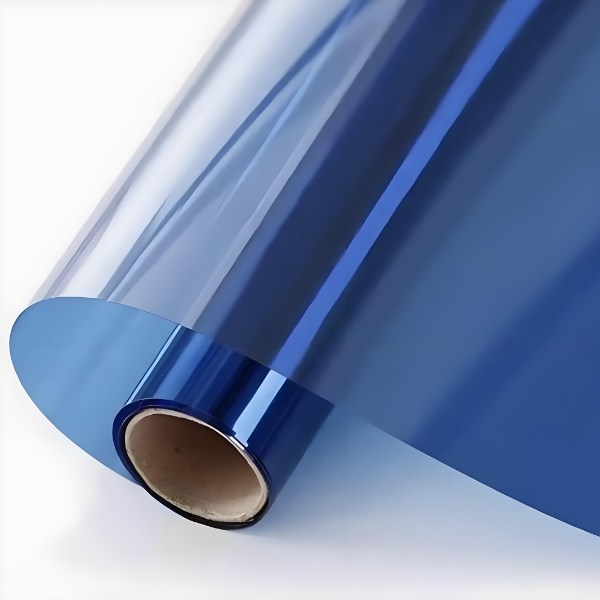

What is Crystal Flexible Packaging?

Crystal Flexible Packaging refers to high-clarity, lightweight, and versatile packaging solutions that combine excellent transparency with protective functionalities. It is widely used across industries where product visibility and durability are equally important.

1.1 Definition and Basic Concepts 📄

Crystal Flexible Packaging is a type of flexible packaging made from advanced polymer materials that offer superior optical clarity and barrier properties. It is designed to protect contents while allowing consumers to see the product inside.

1.2 Differences from Traditional Flexible Packaging 🔍

Unlike traditional flexible packaging, which may prioritize durability over aesthetics, Crystal Flexible Packaging emphasizes both visual appeal and performance. It is often thinner, more transparent, and better at preserving product freshness.

1.3 Key Features and Advantages Overview ⭐

Key features include high transparency, excellent moisture and oxygen barrier, lightweight design, and customizability. These advantages make it ideal for premium products where presentation matters.

Core Technical Features of Crystal Flexible Packaging

Crystal Flexible Packaging stands out due to its advanced technical properties, which ensure both product protection and visual appeal.

2.1 Transparency and Optical Performance 👁️

The packaging offers exceptional clarity, similar to glass, ensuring that products are displayed attractively on shelves. This enhances consumer trust and brand perception.

2.2 Barrier Properties Explained (Oxygen, Moisture, Light) 🛡️

One of the most critical features is its ability to block oxygen, moisture, and UV light, extending the shelf life of perishable goods like snacks and pharmaceuticals.

2.3 Material Strength and Durability 💪

Despite its thin profile, Crystal Flexible Packaging is highly resistant to punctures and tears, ensuring product integrity during transportation and handling.

2.4 Sealing Performance and Freshness Preservation 🌿

The packaging provides airtight seals, preventing contamination and maintaining freshness. This is particularly important for food and medical products.

Key Application Areas & Case Studies

Crystal Flexible Packaging is used across multiple industries due to its versatility and performance.

3.1 Food Industry Applications (Bakery, Snacks, Frozen Foods) 🍪

In the food industry, it is commonly used for packaging snacks, baked goods, and frozen foods, where visibility and freshness are crucial.

3.2 Pharmaceutical and Health Supplement Packaging 💊

Pharmaceutical companies use it for blister packs and sachets, ensuring product safety while allowing consumers to see the contents.

3.3 Cosmetics and Personal Care Products 💄

High-end cosmetics and personal care brands prefer Crystal Flexible Packaging for its premium look and protective qualities.

3.4 Industrial and Electronic Product Packaging 🔌

Even industrial and electronic products benefit from its anti-static and moisture-resistant properties.

3.5 Success Case Studies and Performance Analysis 📊

| Brand | Industry | Application | Result |

|---|---|---|---|

| SnackCo | Food | Potato Chips | 20% increase in sales due to better visibility |

| PharmaCare | Pharmaceuticals | Vitamin Sachets | Extended shelf life by 6 months |

| GlowBeauty | Cosmetics | Face Mask Packs | Improved brand perception |

Material Types & Selection Guide

Choosing the right material is essential for optimizing performance and cost.

4.1 Common Material Types (PET, PP, PE, etc.) 🧴

Common materials include PET (Polyethylene Terephthalate), PP (Polypropylene), and PE (Polyethylene), each offering different levels of clarity, strength, and barrier properties.

4.2 Composite Material Structure Analysis 📐

Multi-layer laminates combine different materials to enhance barrier properties while maintaining flexibility and transparency.

4.3 How to Select the Right Material Based on Product Needs ⚖️

Consider factors like shelf life, exposure to moisture, and printing requirements when selecting materials.

4.4 Cost vs. Performance Balance Considerations 💰

While high-performance materials may cost more, they can reduce waste and improve product longevity, offering long-term savings.

Production Process & Technology

The manufacturing of Crystal Flexible Packaging involves several advanced techniques.

5.1 Printing Technologies and Decoration Options 🎨

High-definition printing allows for vibrant graphics and branding, while matte or gloss finishes enhance visual appeal.

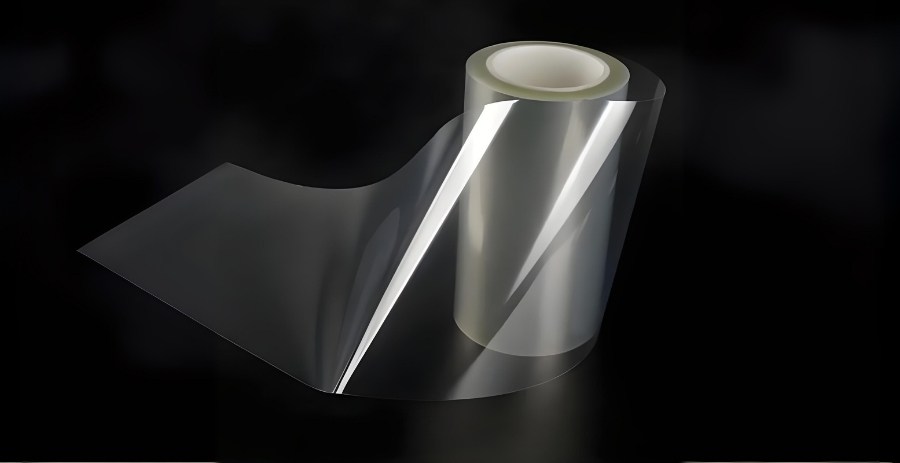

5.2 Lamination and Composite Processes 🔗

Lamination bonds multiple layers together, improving barrier properties without compromising flexibility.

5.3 Bag Making and Forming Technologies ✂️

Advanced forming techniques ensure precise shaping and sealing, accommodating various product sizes.

5.4 Key Quality Control Points ✅

Strict quality control measures ensure consistency in thickness, clarity, and seal integrity.

Environmental Sustainability

Sustainability is a growing concern in packaging, and Crystal Flexible Packaging offers eco-friendly solutions.

6.1 Recyclable Crystal Flexible Packaging Options ♻️

Many Crystal Flexible Packaging materials are recyclable, reducing environmental impact.

6.2 Advances in Biodegradable Materials 🍃

Biodegradable and compostable options are being developed to further enhance sustainability.

6.3 Design Strategies to Reduce Packaging Waste 📉

Lightweight designs and minimal material usage help reduce waste while maintaining performance.

6.4 Environmental Certifications and Standards 🏆

Certifications like FDA, EU food contact standards, and ISO 14001 ensure compliance with environmental regulations.

Market Trends & Innovations

The demand for Crystal Flexible Packaging is growing, driven by consumer preferences and technological advancements.

7.1 Global Market Overview and Growth Forecast 🌐

The global market is expected to grow at a CAGR of 5.2% from 2023 to 2030, with Asia-Pacific leading the demand.

7.2 Frontiers of Technological Innovation 💡

Innovations like smart packaging with QR codes and anti-counterfeiting features are gaining traction.

7.3 Changes in Consumer Preferences 🛍️

Consumers increasingly prefer sustainable and visually appealing packaging, influencing brand decisions.

7.4 Future Development Opportunities and Challenges 🔮

Opportunities lie in biodegradable materials and smart packaging, while challenges include cost management and regulatory compliance.

How to Choose the Right Crystal Flexible Packaging Supplier

Selecting the right supplier is crucial for quality and reliability.

8.1 Supplier Evaluation Criteria 📋

Look for suppliers with certifications, advanced technology, and a strong track record.

8.2 Quality Certifications and Compliance Requirements 📜

Ensure suppliers meet industry standards like ISO, FDA, and EU regulations.

8.3 Sample Testing and Validation Processes 🧫

Request samples to test clarity, durability, and seal performance before bulk orders.

8.4 Cost Structure and Negotiation Techniques 💼

Understand pricing models and negotiate based on volume and long-term partnerships.

FAQs (Frequently Asked Questions)

Q: What are the main advantages of Crystal Flexible Packaging? ✅

High transparency, excellent barrier properties, lightweight, and customizability.

Q: Is Crystal Flexible Packaging recyclable? ♻️

Yes, many variants are recyclable, and biodegradable options are emerging.

Q: How does it compare to glass packaging? 📦

It is lighter, shatter-resistant, and more cost-effective while offering similar clarity.

Q: Can it be used for liquid products? 💧

Yes, with proper sealing and material selection, it is suitable for liquids.

Q: What industries benefit the most from it? 🏭

Food, pharmaceuticals, cosmetics, and electronics industries benefit significantly.

Conclusion: The Future of Crystal Flexible Packaging

Crystal Flexible Packaging is revolutionizing the packaging industry with its blend of aesthetics, functionality, and sustainability. As consumer demands evolve, innovations in materials and smart packaging will drive further growth. Companies like CloudFilm are at the forefront, providing cutting-edge solutions that meet both performance and environmental goals.

🌟 Ready to upgrade your packaging? Contact CloudFilm today for premium Crystal Flexible Packaging solutions! 🌟