Introduction – Getting Straight to the Point and Establishing Authority

1.1. Opening with a Relatable Scenario to Address a Pain Point

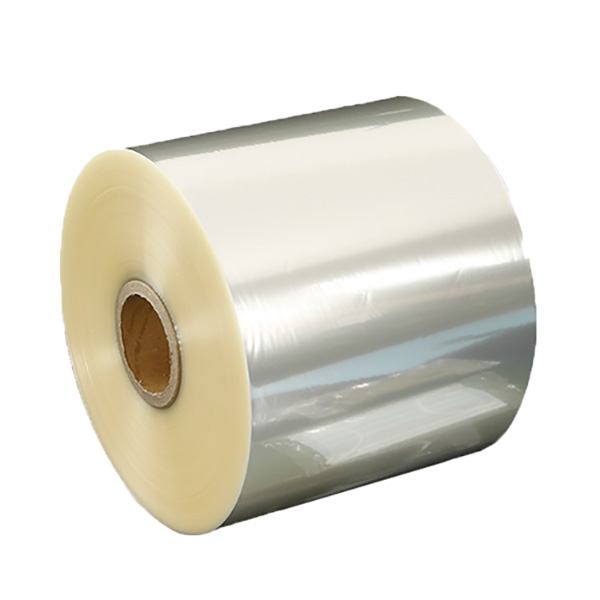

When you walk down the snack aisle at the supermarket, what catches your eye? Perhaps it’s a bag of colorful, gummy candies, or a clear window on a box of chocolates that reveals the treats inside. The packaging that keeps these products fresh, appealing, and protected is a marvel of modern material science. Have you ever wondered what this material is and what makes it so effective?

This material is likely Biaxially Oriented Polypropylene (BOPP) film, a cornerstone of the global packaging industry. Its unique combination of properties makes it the go-to choice for countless applications, from food to consumer goods. Understanding its properties is the first step for anyone involved in packaging design, procurement, or manufacturing.

{ BOPP Film Production Line }

1.2. Definition and Overview

BOPP stands for Biaxially Oriented Polypropylene. In simpler terms, it’s a plastic film made from polypropylene resin that has been stretched in both the machine direction (lengthwise) and the transverse direction (crosswise) during its manufacturing process. This “biaxial orientation” is the secret sauce.

It aligns the polymer molecules in a uniform, grid-like pattern, dramatically enhancing the film’s mechanical strength, optical clarity, and barrier properties compared to non-oriented polypropylene (CPP) or cast polypropylene.

At CloudFilm, we specialize in engineering and supplying high-performance BOPP films tailored to meet the diverse needs of our clients. This guide will walk you through everything you need to know about BOPP properties.

1.3. Why Understanding BOPP Properties is Crucial

For product managers, packaging engineers, and procurement specialists, selecting the right packaging film is a critical decision that impacts product quality, shelf life, consumer appeal, and overall cost. A deep understanding of BOPP properties allows you to:

- Optimize Product Protection: Choose a film that provides the right barrier against moisture, oxygen, and contaminants.

- Enhance Brand Image: Leverage the excellent printability and gloss of BOPP to create stunning, eye-catching packaging.

- Improve Production Efficiency: Select a film with the right stiffness and sealing properties for high-speed packaging lines.

- Reduce Costs: Achieve the desired performance with a thinner, lighter, and more cost-effective material.

In-Depth Analysis of Core BOPP Properties

This section breaks down the key characteristics that define BOPP film and explain their practical significance.

2.1. Optical Properties: The Power of Clarity and Gloss

- High Transparency & Gloss: BOPP film is renowned for its crystal-clear transparency and high gloss. This allows consumers to see the product inside, building trust and enhancing visual appeal. Think of a clear salad bag or the window on a cracker box.

- Low Haze: Haze is the measure of cloudiness. BOPP has extremely low haze, ensuring that printed graphics appear sharp and vibrant, and the product inside is clearly visible without distortion.

- Practical Significance: These properties are crucial for retail products where “sellability” is directly linked to visual presentation. A glossy, clear package signals quality and freshness.

2.2. Mechanical Properties: Strength and Durability

- High Tensile Strength & Stiffness: The biaxial orientation process gives BOPP exceptional strength and rigidity. It is resistant to stretching and tearing, which means the package can withstand the stresses of filling, sealing, transportation, and handling without puncturing or breaking.

- Excellent Dimensional Stability: BOPP film is highly stable and does not shrink or deform easily under changes in temperature or humidity. This is vital for maintaining the integrity of the package and the accuracy of printed designs.

- Practical Significance: This strength allows for the use of thinner gauges (down-gauging), reducing material consumption and cost without sacrificing performance. It ensures the package arrives on the store shelf in perfect condition.

2.3. Barrier Properties: The Guardian of Freshness

- Excellent Moisture Barrier: BOPP provides an outstanding barrier against water vapor. This is perhaps its most famous property, making it ideal for moisture-sensitive products like snacks, biscuits, and powders, which must stay crisp and dry.

- Good Oxygen Barrier (Standard BOPP): While standard BOPP offers a moderate barrier to oxygen, it is often enhanced with coatings (like PVDC or acrylic) or through metallization to create a high-barrier film. This is essential for products that are sensitive to oxidation, such as nuts, fried foods, and coffee.

- Practical Significance: The right barrier properties directly extend the shelf life of a product, reduce food waste, and maintain flavor, aroma, and texture from production to consumption.

2.4. Electrical & Chemical Properties: Safety and Consistency

- Excellent Dielectric Strength: BOPP is a superb electrical insulator, making it suitable for applications like capacitor films.

- Good Chemical Resistance: It is resistant to most acids, alkalis, oils, and greases. This ensures the film won’t degrade or react when in contact with the product or during the printing process.

- Practical Significance: These properties ensure the safety and integrity of the packaged product and the reliability of the film in non-packaging industrial applications.

Key Advantages of BOPP Film in Application

Why is BOPP so popular? Because its properties translate into tangible advantages.

3.1. Superior Printability for Branding

The smooth, non-porous surface of BOPP is an excellent substrate for high-quality printing, including rotogravure and flexography. It allows for sharp, high-resolution graphics and vibrant colors that make a brand stand out on the crowded retail shelf.

3.2. Lightweight and Cost-Effective

BOPP is one of the lightest packaging films available. Its high strength-to-weight ratio means you can use less material to achieve the same or better performance as heavier alternatives. This leads to significant cost savings in both material and logistics.

3.3. Excellent Sealing Performance

BOPP can be easily heat-sealed to create a strong, airtight closure. Heat-sealable grades are available with a wide sealing temperature range, making them compatible with various high-speed packaging machines (VFFS, HFFS). This ensures production line efficiency and package integrity.

3.4. Food Safety and Hygiene

BOPP is an inert, non-toxic, and odorless material. It complies with global food safety standards (like FDA and EU regulations), making it a safe choice for direct and indirect food contact applications.

Diverse Application Fields of BOPP

The versatility of BOPP is demonstrated by its wide range of applications.

4.1. Food Packaging (The Largest Market)

- Snack Foods: Bags for chips, pretzels, and popcorn (often metallized BOPP for a light barrier and premium look).

- Confectionery: Wrappers for chocolate bars, candy, and biscuits.

- Fresh Produce: Bags for salads, vegetables, and fruits.

- Dried Goods: Packaging for pasta, rice, nuts, and coffee.

- Bakery Goods: Bread bags and wraps.

4.2. Non-Food Packaging

- Consumer Goods: Packaging for textiles, tissues, toys, and personal care products.

- Flower Wrapping: The clear, glossy film is perfect for creating attractive bouquets.

- Cigarette Packaging: The outer overwrap film provides tamper evidence and a premium feel.

{ BOPP Film For Fresh Flower Packaging }

4.3. Industrial and Specialty Applications

- Tape Packaging: The base film for pressure-sensitive adhesive tapes (e.g., packing tape).

- Labeling: Filmic labels for bottles and containers (BOPP labels are waterproof and durable).

- Capacitor Films: Utilizing its excellent dielectric properties in the electronics industry.

- Lamination: Used as a protective layer in book covers, posters, and documents.

How to Choose the Right BOPP Film: A Practical Guide

Selecting the correct BOPP film is key to success. Here’s a simple framework.

5.1. Clarify Your Core Requirements

First, ask yourself: What is the primary function of my packaging?

- Is it for visual appeal? Prioritize high gloss and clarity.

- Is it for long shelf life? Prioritize high barrier (moisture and/or oxygen).

- Is it for high-speed production? Prioritize excellent heat-seal performance and stiffness.

5.2. Match Properties to Your Product

- For crispy snacks (e.g., crackers): You need a strong moisture barrier. A standard BOPP or metallized BOPP would be ideal.

- For oxygen-sensitive products (e.g., nuts): You need a high oxygen barrier. A coated BOPP (e.g., with PVDC) or metallized BOPP is necessary.

- For products requiring a “see-through” window: A high-clarity, low-haze BOPP is essential.

{ BOPP Film For Window Packaging }

5.3. Consider the Production Process

Ensure the film you choose is compatible with your packaging machinery. Check the recommended sealing temperature range and the film’s stiffness to ensure it runs smoothly without jams or tears.

5.4. Don’t Forget Aesthetics and Sustainability

- Aesthetics: Do you need a glossy, matte, or metallized finish? The choice impacts brand perception.

- Sustainability: Consider recyclability. Mono-material BOPP structures are increasingly favored for their ease of recycling in existing streams. Ask your supplier, like CloudFilm, for sustainable options.

Conclusion and Future Outlook

6.1. Reiterating the Core Value

In summary, BOPP film’s winning combination of superior optical properties, mechanical strength, excellent barrier performance, and cost-effectiveness has cemented its position as an indispensable material in the packaging world. It protects products, enhances brands, and drives efficiency across the supply chain.

6.2. A Look at Future Trends

The BOPP industry is not standing still. The future is focused on innovation:

- Functionalization: Development of films with even higher barriers, anti-fog properties, and easy-peel seals.

- Sustainability: A major push towards creating BOPP films that are more easily recyclable, contain recycled content, or are designed for compostability in specific conditions. Mono-material structures are key.

- Lightweighting: The continuous pursuit of making thinner, stronger films to reduce environmental impact and costs.

6.3. Call to Action

We hope this comprehensive guide has given you a deeper understanding of BOPP properties and their critical role in modern packaging. If you are looking for the perfect BOPP film solution for your product, or if you have questions about which grade best suits your needs, do not hesitate to reach out to the experts at CloudFilm.

{ CloudFilm Provides You With Complete Packaging Solutions }

We are dedicated to providing not just films, but complete packaging solutions. Contact us today for a consultation and let’s build the future of packaging together. You can also download our technical data sheet for a detailed specification overview.