Introduction – Addressing Pain Points and Building Connection

Are you struggling to choose a packaging material that is both visually appealing and highly functional? Have you come across the term “BOPP PE” on a purchase order but aren’t quite sure what it means? Worry no more. This article will fully demystify “BOPP PE” for you.

Whether you’re a procurement manager, a product developer, or a newcomer to the packaging industry, after reading this guide, you’ll have a clear and comprehensive understanding of this widely used composite packaging material.

In flexible packaging specifications, “BOPP/PE”, “BOPP + PE” or “OPP/PE” usually refer to the same two-layer laminated film: a printable BOPP outer web plus a heat-sealable PE inner web that protects and seals the product.

CloudFilm manufactures both BOPP film and PE films in-house, so in this guide we will explain how to match the right BOPP and PE grades to your snack, coffee, pet food or detergent projects and avoid common selection mistakes.

If you later want to go deeper into single-layer film basics, you can also check our detailed guides on BOPP density and PE packaging film and its uses, which complement this BOPP/PE structure guide.

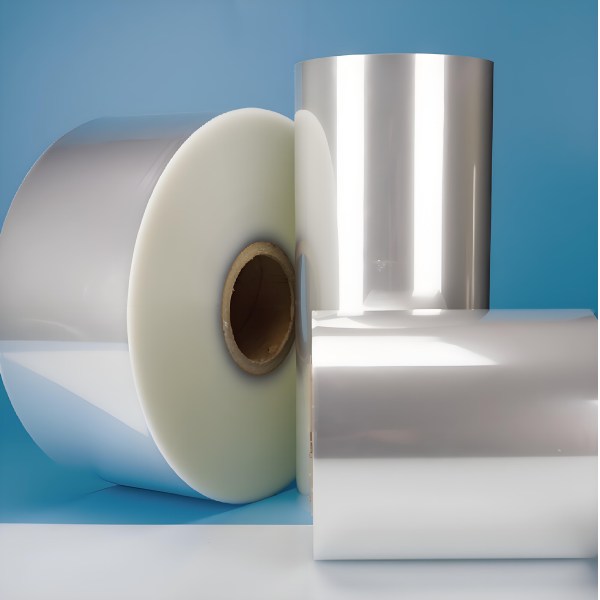

{ BOPP Film Production Line }

{ PE Blown Film Production Line}

Core Analysis – What Exactly Is BOPP PE?

BOPP PE is not a single material but a high-performance packaging structure created by laminating two different plastic films, each serving a distinct function.

- Outer layer: BOPP (Biaxially Oriented Polypropylene)

– Provides excellent printability, gloss/matte visual effects, transparency, stiffness, and smooth surface for high-speed packaging machines. - Inner layer: PE (Polyethylene)

– Serves as the heat-sealable layer, offering strong sealing performance, moisture resistance, and flexibility, making it suitable for direct contact with food or products.

In simple terms, BOPP PE is like a “two-layer armor” that combines appearance and protection. The outer layer attracts consumers and conveys your brand message, while the inner layer quietly protects the product and ensures seals do not fail.

In most projects, the BOPP side is a transparent or matte BOPP printing film that carries your artwork, while the PE side is a blown LLDPE film or MDO PE film tuned for the right seal strength, coefficient of friction and stiffness on your vertical or horizontal form-fill-seal lines.

Depending on your barrier and cost targets, CloudFilm can also combine BOPP with special PE structures or high-barrier webs such as metallized BOPP film, PVDC coated filmcor co-extruded PE/EVOH films, so that you can upgrade from a simple BOPP/PE to a higher-barrier system without completely changing your converting process.

When you see “BOPP/PE 20/60” or “BOPP/PE 18/70” in a specification, you can read it layer by layer as follows:

- Outer layer (e.g. 18–25 μm BOPP): appearance, printability, stiffness and machinability.

- Inner layer (e.g. 40–90 μm PE): sealing strength, puncture resistance, moisture barrier and product contact.

Understanding which layer does what is the foundation for communicating clearly with film manufacturers like CloudFilm and for comparing quotations from different suppliers.

Typical BOPP/PE Structures And Thickness Combinations

Once you understand that BOPP/PE is a two-layer laminate, the next practical question is: “What thickness combinations should I use for my product?” Below are some common examples that CloudFilm frequently supplies to customers worldwide (for reference only; final structures will be tailored to your needs).

- Lightweight snack pillow bags (chips, puffed snacks, biscuits):

Typical structure: 20 μm high-gloss BOPP (e.g. BOPP gloss film) // 40–60 μm PE.

This balances good shelf appearance, crinkle effect and sufficient sealing strength for small pack weights. - Premium matte snack or nuts packaging:

Typical structure: 18–20 μm BOPP matte film// 60–70 μm PE.

The matte BOPP layer delivers a refined, low-glare look while the thicker PE layer improves puncture resistance and seal integrity. - Instant noodles, rice and detergent pillow bags:

Typical structure: 25 μm BOPP pearlized film or printed BOPP // 70–90 μm PE.

This combination provides a whiter background, higher stiffness and better load-bearing capacity for heavier fills. - Small 3-side-seal sachets for powders or dry mixes:

Typical structure: 15–18 μm BOPP // 40–50 μm PE, used on VFFS machines to produce 3 side seal pouches. - Pre-made stand up pouches using BOPP/PE:

For some markets, converters still use BOPP/PE laminates (or BOPP//metallized BOPP//PE) for stand up pouches and flat bottom pouches, especially when they want high gloss graphics and do not need retort or ultra-high oxygen barrier.

If you are unsure which thickness combination to choose, simply tell CloudFilm your product type, filling weight, target shelf life and pack format (pillow bag, stand up pouch, 3-side-seal, etc.). Our team can recommend 1–2 suitable structures and explain the trade-offs in cost, stiffness and barrier.

Key Advantages – Why Choose BOPP PE Laminated Film?

BOPP PE is widely used in food, daily chemical, and other industries due to the following core advantages:

| Advantage | Contribution from BOPP | Contribution from PE | Value Delivered |

|---|---|---|---|

| Excellent Printability | ✅ Smooth surface, ideal for multi-color printing | ❌ | Enhances brand image and attracts consumers |

| High Clarity | ✅ Great optical properties | ❌ | Product contents are clearly visible, building trust |

| Sealable & Moisture-Proof | ❌ | ✅ Strong heat seal, blocks moisture | Extends shelf life and prevents spoilage |

| Flexible & Durable | ❌ | ✅ Impact and puncture resistant | Protects products during transport and handling |

| Cost-Effective | ✅ Material cost is manageable | ✅ Mature manufacturing process | Balances performance with affordable packaging costs |

In summary, BOPP/PE hits a “sweet spot” for clear, non-retort flexible packaging where moisture protection, print quality and cost-effectiveness are more important than extreme oxygen barrier or high-temperature resistance.

For many dry foods, snacks and daily chemicals, BOPP/PE offers all the essential performance you need without the extra cost of very high-barrier or retort-capable structures.

If your product does require higher gas barrier or pasteurization/retort, CloudFilm may recommend alternative laminates such as PET/PE film or PA/PE film while keeping similar pouch formats and packing equipment. This makes it easier to upgrade performance without redesigning your entire line.

When comparing BOPP/PE offers from different suppliers, it is crucial to check not only price per kilogram but also film density, grammage and thickness. These factors strongly influence stiffness, feel and runnability. Our BOPP density guide explains how to calculate thickness from grammage so you can compare quotations more scientifically.

BOPP/PE vs Other Common Packaging Structures (EN)

In real projects, BOPP/PE is often compared with other popular laminates. Understanding the differences helps you choose the right structure from day one.

- BOPP/PE vs BOPP/CPP:

BOPP/CPP (using clear or retort CPP film) is generally stiffer and has higher heat resistance than BOPP/PE, making it suitable for some high-speed horizontal form-fill-seal lines and certain hot-fill or high-temperature applications. BOPP/PE, on the other hand, offers better low-temperature sealability and flexibility, which is ideal for many snack pillow bags and daily chemical packs. - BOPP/PE vs PET/PE:

PET/PE has better temperature resistance, stiffness and oxygen barrier than BOPP/PE, so it is commonly used for coffee, high-end snacks and many export packs. However, PET is denser and usually more expensive than BOPP. For products that do not need very high barrier or high-temperature resistance, BOPP/PE often delivers a more cost-effective solution. - BOPP/PE vs PA/PE (nylon/PE):

PA/PE laminates like PA/PE film are designed for deep-draw vacuum packs and bone-in meat or cheese applications where puncture resistance is critical. For regular dry food and daily chemicals, BOPP/PE is usually sufficient and more economical. - BOPP/PE vs mono-PE structures (BOPE/MDO PE):

With the growth of recyclability requirements, more brands are shifting some SKUs from BOPP/PE to mono-PE laminates using BOPE film and MDO PE film. These structures improve compatibility with PE recycling streams, but they may require equipment adjustments and careful structure design. Our article MDO PE vs BOPE explains when to use each film in mono-PE systems.

CloudFilm can supply both traditional BOPP/PE and newer mono-PE solutions. When you share your project brief, we can present BOPP/PE, PET/PE and mono-PE options side by side so you can align technical performance with sustainability and cost goals.

Application Scenarios – Where Is BOPP PE Used?

BOPP PE laminated film is nearly everywhere, especially in the following sectors:

- Food Packaging:

- Snacks: Potato chips, biscuits, candies, puffed snacks.

- Dry Goods: Coffee beans, tea leaves, noodles, spices.

- Frozen Foods: Dumplings, tangyuan, frozen vegetables (requires special low-temperature PE).

- Daily Chemical Products:

- Laundry detergent, detergent pods, wet wipes, facial mask sheets.

- Other Industries:

- Dust-proof and moisture-proof packaging for garments, textiles, small hardware, and electronic components.

Tip: Different products have different packaging requirements. For example, high-fat foods need stronger oxygen barriers, while heavy-duty products require higher tensile strength. CloudFilm can customize the optimal BOPP PE structure based on your specific product needs.

For VFFS pillow bags and small sachets, BOPP/PE is often the first choice. CloudFilm regularly supplies BOPP/PE roll stock that is converted into pillow pouches and 3 side seal pouches for snacks, instant beverages, dry powders and seasoning mixes.

For pre-made bags, many buyers use BOPP/PE laminates for non-retort stand up pouches and flat bottom pouches, especially when they want a premium shelf appearance and crisp printing but do not need extreme barrier.

Outside food and daily chemicals, BOPP/PE is also widely used as dust-proof outer wraps for garments, textiles and household items, where appearance, clarity and basic protection matter more than high barrier.

Sourcing Guide – How to Choose a Reliable BOPP PE Supplier?

Choosing the right supplier is just as important as selecting the right material. When sourcing BOPP PE laminated film, consider the following:

- Clarify Your Product Requirements:

- What kind of product are you packaging? Snacks, coffee, pet food, daily chemical products, or something else?

- What is the target shelf life and storage environment (room temperature, refrigerated, or frozen)?

- Define Packaging Format and Structure:

- Bag type: Pillow bag, stand-up pouch, three-side seal bag, etc.

- Do you need special functions such as easy tear, zip-lock, hanging holes, or degassing valves?

- Confirm Film Specifications:

- Specify thickness of BOPP and PE layers (e.g., 20 μm BOPP + 60 μm PE).

- Determine roll width, diameter, core size, and inner diameter.

- Evaluate Supplier’s Capabilities:

- Does the supplier have stable sources of both BOPP and PE base films?

- Are they able to help you design the structure and optimize it based on your equipment and product?

- Request Samples and Technical Support:

- Before making a bulk purchase, always run trials to ensure sealing, appearance, and machinability meet expectations.

- A strong supplier will proactively help analyze any issues that arise and suggest improvements.

When you contact CloudFilm or any other supplier, try to share as much information as possible in the first email: product type, filling weight, target markets, pack format, expected shelf life, preferred structure and whether you need roll stock or pre-made pouches.

This allows the technical team to quickly shortlist 1–2 suitable BOPP/PE structures instead of going through multiple rounds of guesswork.

CloudFilm’s engineering and sales teams often prepare a short comparison table for you (showing BOPP/PE thickness, potential PET/PE or PA/PE alternatives and even mono-PE options) so you can discuss the trade-offs internally with your marketing, operations and sustainability teams.

FAQs About BOPP PE Laminated Film (EN)

Q1. What Does “BOPP/PE 20/60” Mean In A Specification?

This notation indicates a two-layer laminate where the outer BOPP film is 20 μm thick and the inner PE film is 60 μm thick. BOPP provides appearance and printability; PE provides sealing and product protection. If you also see values for roll width and grammage, CloudFilm can help you verify whether the structure matches your pack size and filling weight.

Q2. When Should I Choose BOPP/PE Instead Of PET/PE Or PA/PE?

Choose BOPP/PE when you need:

- Clear, attractive packaging for snacks, dry foods or daily chemicals.

- Good moisture barrier but not extremely high oxygen barrier.

- Room-temperature storage (no retort or pasteurization).

- A competitive cost-performance ratio.

If your product requires higher gas barrier, deep-draw forming or high-temperature processing, PET/PE or PA/PE may be more suitable. CloudFilm can compare these options with you based on your exact project.

Q3. Is BOPP/PE Laminated Film Recyclable?

Technically, BOPP and PE are both polyolefins, but BOPP/PE is still a multi-material laminate. In many current recycling systems, mono-material structures (all-PE or all-PP) are preferred for easier sorting and reprocessing. Therefore, BOPP/PE is often classified as “difficult to recycle” in strict recyclability schemes.

If recyclability is a high priority, CloudFilm can help you evaluate mono-PE solutions using BOPE film and MDO PE film, drawing on the best practices discussed in our MDO PE vs BOPE article. For applications where recyclability is not yet mandatory, BOPP/PE remains a very practical and cost-effective choice.

Q4. What Information Should I Prepare Before Asking For A BOPP/PE Quotation?

To receive a precise offer faster, prepare at least the following:

- Product type and fill weight per pack.

- Pack format (pillow bag, stand up pouch, 3-side-seal, etc.).

- Target shelf life and storage conditions (room-temperature, refrigerated, frozen).

- Preferred structure and thickness, if any (e.g. BOPP/PE 20/60).

- Printing requirements (number of colors, matte or gloss, windows).

- Expected monthly volume and first order quantity.

Sending this information to CloudFilm at the beginning allows our team to respond with a tailored BOPP/PE structure and a realistic price level instead of generic ballpark figures.

Q5. Can CloudFilm Supply Both BOPP/PE Roll Stock And Ready-Made Pouches?

Yes. CloudFilm can supply:

- Printed or unprinted BOPP/PE laminated roll stock for your own converting lines.

- Ready-made flexible pouches (such as pillow pouches, stand up pouches, flat bottom pouches and 3 side seal pouches) based on structures like BOPP/PE, PET/PE or mono-PE.

You can start with roll stock while upgrading your own converting capacity, or outsource part of the pouch-making to CloudFilm to shorten your lead time and reduce investment pressure.

Q6. How Does BOPP/PE Run On Typical Packaging Machines?

Most BOPP/PE structures are designed for vertical (VFFS) or horizontal (HFFS) form-fill-seal machines. By adjusting BOPP stiffness and PE COF/heat-seal range, CloudFilm can match the film to your line speed, sealing jaw temperature and forming conditions. If you share your current film spec and machine settings, our engineers can optimize a BOPP/PE structure that runs smoothly with minimal adjustments.

Conclusion and Call to Action – From Knowledge to Action

BOPP PE laminated film has become an indispensable material in the modern packaging industry, thanks to its outstanding overall performance and cost-effectiveness. Understanding it, selecting it, and using it well will give your product a significant competitive edge in the market.

{ CloudFilm Provides Customized Solutions for You }

If you are looking for the ideal BOPP PE packaging solution for your product, feel free to contact CloudFilm today. Our team of technical experts is ready to provide free consultations and sample testing to help you create the best packaging solution tailored to your needs.

If you are currently evaluating or upgrading any BOPP/PE packaging, you are welcome to send CloudFilm your product details, existing structure (if any) and target markets. Our team can prepare a free proposal with recommended BOPP/PE thickness, suggested outer and inner films, estimated roll weights and container loading plans, helping you move from idea to shipment with lower risk and better cost control.