Introduction

In the world of plastic films, terms like “PET film” and “polyester film” are often used interchangeably, leading to confusion among buyers, engineers, and product developers. Are they the same material? If not, what distinguishes one from the other?

This article, brought to you by CloudFilm, aims to clarify these concepts, provide a detailed comparison, and help you make informed material choices for your specific applications.

CloudFilm specializes in manufacturing and exporting flexible packaging films, including BOPET polyester film rolls

, BOPP, BOPA, PE and speciality films, so this guide is written from the viewpoint of a supplier who helps converters and brand owners choose the right PET and polyester structures every day.

Whether you are evaluating clear PET film for flexible packaging, white PET film for labels, or high-barrier coated polyester films, CloudFilm’s technical team can recommend suitable grades and provide free samples so you can test materials on your own lines before placing bulk orders.

What is PET Film?

PET (Polyethylene Terephthalate) film is a type of polyester film made from the polymerization of ethylene glycol and terephthalic acid. It is the most widely used and commercially significant form of polyester film. Known for its excellent mechanical strength, thermal stability, and chemical resistance, PET film is a staple in industries ranging from packaging to electronics.

Key characteristics:

- High tensile strength

- Excellent dimensional stability

- Good electrical insulation properties

- Transparency and gloss

- Recyclability

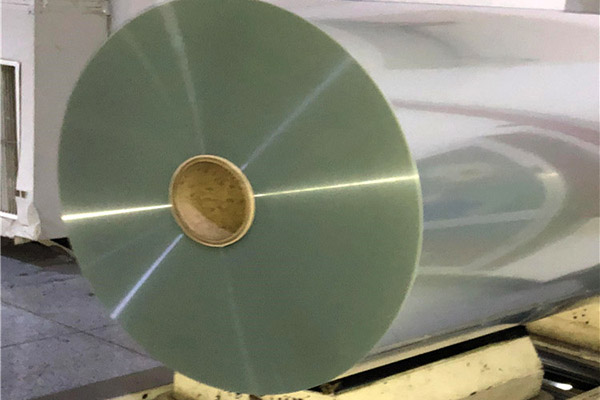

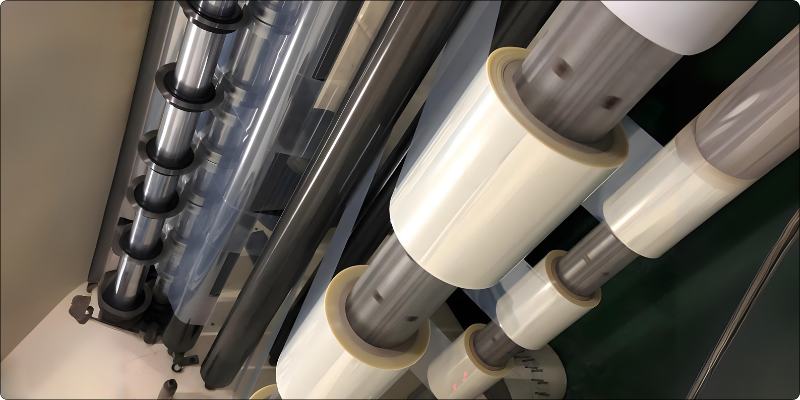

{ PET Film Production Line }

Most PET film used in packaging and industrial applications is supplied as biaxially oriented BOPET polyester film rolls

with controlled thickness, width and surface treatment, making it easy to print, laminate and slit to your required size.

CloudFilm can deliver a full portfolio of PET polyester films, including gloss PET film, matte PET film, white PET film, aluminized PET film and soft touch polyester film, so you can cover printing, lamination, labelling, insulation and premium decorative needs with one supplier.

For flexible packaging structures, PET film is often laminated with PE or CPP to create strong seals and good shelf appearance; you can refer to CloudFilm’s PET/PE laminated film for typical food, coffee and frozen food applications.

What is Polyester Film?

Polyester film is a broader category that includes PET as well as other polyesters such as PBT (Polybutylene Terephthalate) and PEN (Polyethylene Naphthalate). While PET dominates the market, other polyesters offer specialized properties that make them suitable for niche applications.

For example:

- PBT offers superior chemical resistance and is often used in engineering plastics.

- PEN provides higher thermal resistance and mechanical strength than PET, making it ideal for high-performance applications.

In short: All PET films are polyester films, but not all polyester films are PET.

{ PEN Film Production Line }

In many technical discussions, the term “polyester film” may refer generally to PET, but for high-temperature or high-voltage environments, specialty polyesters such as PEN are selected because they can withstand higher continuous operating temperatures and offer better dielectric performance than standard PET.

For packaging buyers, “polyester film” usually means BOPET film used as a printing, barrier or lidding layer; you can learn more from CloudFilm’s article BOPET Film for Packaging and the in-depth guide The Complete Guide to Understanding BOPET Film Types & Applications.

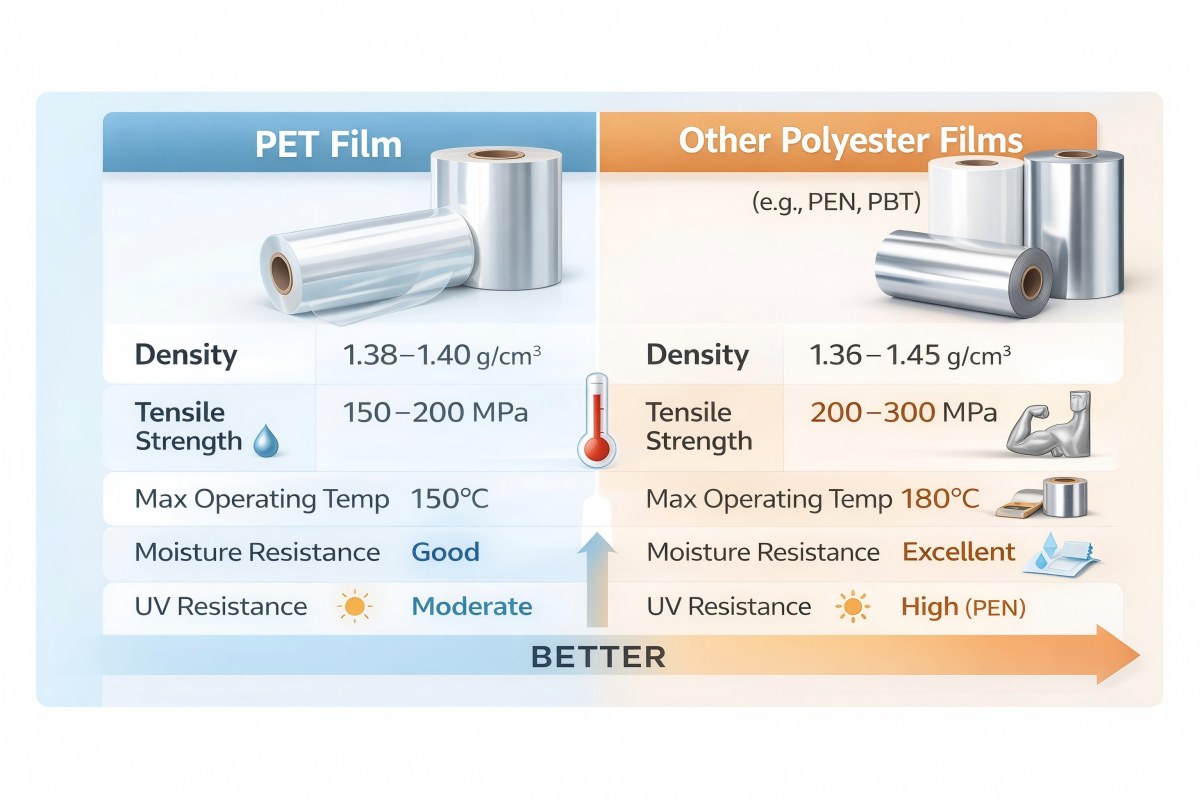

Key Differences Between PET Film and Polyester Film

1. Chemical Composition

- PET Film: Made from polyethylene terephthalate.

- Polyester Film: A family of polymers, including PET, PBT, PEN, etc.

2. Physical and Mechanical Properties

| Property | PET Film | Other Polyester Films (e.g., PEN) |

|---|---|---|

| Density (g/cm³) | 1.38–1.40 | 1.36–1.45 |

| Tensile Strength (MPa) | 150–200 | 200–300 (PEN) |

| Max Operating Temp (°C) | 150 | 180 (PEN) |

| Moisture Resistance | Good | Excellent (PBT) |

| UV Resistance | Moderate | High (PEN) |

3. Thermal and Electrical Behavior

PET film performs well under normal temperature ranges but may deform under extreme heat. PEN, on the other hand, retains its properties at higher temperatures, making it suitable for automotive and aerospace applications.

Electrically, PET is an excellent insulator, but PEN offers superior dielectric strength, which is critical in high-voltage environments.

From a buyer’s perspective, PET film often offers the best balance between performance and cost for standard packaging, labelling and electrical insulation, while specialty polyester films like PEN are reserved for projects where higher continuous service temperature, lower shrinkage or higher modulus clearly justify the added material cost.

When you share your application details with CloudFilm (such as working temperature, voltage, mechanical load and required lifetime), our team can quickly screen whether standard PET is enough or if you should consider a higher-grade polyester or even high-barrier coated PET films such as PVDC coated PET.

Applications of PET Film vs. Polyester Film

1. PET Film Applications

- Packaging: Food containers, beverage bottles, blister packs.

- Imaging: X-ray films, photographic films.

- Electronics: Insulating films, flexible printed circuits (FPC).

- Industrial: Magnetic tapes, release liners.

In flexible packaging, BOPET film is widely used as a printing or outer layer in laminates such as PET/PE, PET/CPP or PET/VMPET/PE for snacks, coffee, pet food and powdered products; CloudFilm supplies PET/PE laminated film

and can match PET thickness and PE sealing layer to your pouch or lidding design.

For graphics and labels, polyester films like gloss PET film and white PET film are used as durable label stock or over-lamination films, providing scratch resistance and long-term dimensional stability.

In industrial applications, CloudFilm’s PET release film and PET thermal lamination film are used as carriers, release liners and lamination substrates in tapes, insulation materials and printed graphics.

2. Other Polyester Films

- PEN: Used in high-performance capacitors, flexible displays, and motor insulation.

- PBT: Found in electrical connectors, automotive components, and power tool housings.

While CloudFilm’s main focus is BOPET polyester films for packaging and industrial insulation, our team is familiar with PEN and PBT usage windows and can help you understand when upgrading from PET to specialty polyester films is technically and economically justified.

How to Choose the Right Film for Your Needs

When deciding between PET and other polyester films, consider:

- Temperature requirements: Choose PEN for high-heat environments.

- Mechanical stress: PEN or PBT may be better for high-stress applications.

- Chemical exposure: PBT excels in chemically aggressive settings.

- Cost: PET is generally more cost-effective for general-purpose use.

For flexible packaging buyers, this often means using clear gloss PET film laminated with PE for standard snacks and dry foods, choosing white PET film when you need opacity and a premium label look, or upgrading to high-barrier PVDC coated PET film when you need extended shelf life for coffee, nuts or high-value powders.

By sharing basic information—such as product type, filling temperature, desired shelf life, packaging format and packing machine model—with CloudFilm, you can receive 1–2 recommended PET or polyester film structures plus sample rolls, so you can quickly verify machinability, sealing and appearance before confirming specifications.

CloudFilm PET and Polyester Film Solutions

As a dedicated flexible packaging film manufacturer, CloudFilm offers a complete PET and polyester film portfolio so that converters and brand owners can source both standard and speciality films from one partner.

Typical solution directions include:

- Printing & Flexible Packaging:Use BOPET polyester films together with structures like PET/PE laminated film to build pouches, lidding films and roll stock for snacks, coffee, pet food and frozen products.

- Premium Look & Touch:Choose soft touch polyester film or matte PET film when you need a luxury, low-gloss surface for high-end packaging, book covers or electronics.

- Opaque & Label Solutions:Select white PET film and, where needed, specific black PET grades for durable labels, nameplates and back panels that require strong opacity and dimensional stability.

- High-Barrier Packaging:Combine aluminized PET film or PVDC coated PET film with PE or CPP to create high-barrier laminates for coffee, tea, milk powder and sensitive powders.

- Industrial & Release Applications:Use PET release film and PET thermal lamination film as carriers, protective layers or lamination films in tapes, insulation parts and printed graphics.

If you already have a target structure (for example, PET/VMPET/PE or PET/AL/PE) but are unsure about thickness, surface treatment or barrier level, CloudFilm can review your specification, propose optimization options and provide trial rolls so you can balance cost, performance and sustainability.

Market Trends and Future Outlook

The global polyester film market continues to grow, driven by demand in packaging, electronics, and green energy. PET remains the dominant player, but specialty polyesters like PEN are gaining traction in high-tech sectors. Sustainability is also pushing innovations in recyclable and bio-based polyester films.

CloudFilm is actively developing sustainable solutions such as PCR film (post-consumer recycled film) and mono-material structures, integrating recyclable PE, BOPE and MDO PE films with PET-based laminates to help brands meet tightening environmental regulations and retailer guidelines.

For buyers who need to balance performance and sustainability, CloudFilm can propose combinations of BOPET, PCR content and recyclable sealant layers so that your packaging not only works on the line, but also supports recycling streams and brand ESG targets.

Frequently Asked Questions (FAQ)

Q1: Are PET film and polyester film the same?

A: Not exactly. PET is a type of polyester film, but polyester films include other variants like PEN and PBT.

Q2: Which is better for high-temperature applications?

A: PEN film offers better thermal resistance than PET, so it is preferred in high-temperature or high-voltage environments.

Q3: Can polyester films be recycled?

A: Yes, most polyester films, including PET, are recyclable, especially when they are collected and processed in dedicated polyester recycling streams.

Q4: Where can I get samples for testing?

A: Contact CloudFilm for free samples of PET and other polyester films tailored to your needs; our team can recommend suitable thicknesses and structures based on your application.

Q5: Is PET film the same as “Mylar”?

A: In many markets, “Mylar” is a common trade name that people use to describe biaxially oriented PET (BOPET) film. Technically, Mylar is a brand, while PET or BOPET describes the material itself, but in everyday usage they often refer to similar polyester films.

Q6: Is PET film always biaxially oriented (BOPET)?

A: Most PET film used in packaging, printing and insulation is biaxially oriented (BOPET), but there are also cast PET films and special heat-stabilized or shrinkable grades. When you send your requirements to CloudFilm, we can clarify whether standard BOPET or a speciality PET film is more appropriate.

Q7: What thickness of PET film is commonly used for flexible packaging laminates?

A: Typical PET thickness for flexible packaging is 8–23 μm, with 12 μm being very common for snack and coffee pouches; thicker PET films are used for heavy bags, lids or where higher stiffness is required. CloudFilm can recommend PET thickness based on your product weight, machine speed and desired pouch feel.

Q8: When should I choose white PET film instead of clear PET?

A: White PET film is ideal when you need strong opacity, a clean white background and excellent print quality—for example, premium labels, high-end pouches or applications where you must block light. Clear PET is preferred when product visibility and “see-through” shelf appeal are more important.

Q9: Can PET polyester film be used in food-contact applications?

A: Yes, many PET polyester films are suitable for food-contact use when produced and certified accordingly. CloudFilm can supply food-grade PET and PET-based laminates and provide relevant compliance information upon request.

Q10: How can CloudFilm help me choose between PET and other polyester films?

A: If you share details such as product type, filling conditions, required shelf life, target markets and cost constraints, CloudFilm can compare PET with alternative polyester options, suggest 1–2 candidate structures and provide samples so that you can make a data-driven decision.

Conclusion

Understanding the differences between PET film and polyester films is crucial for selecting the right material. While PET is versatile and widely used, other polyesters like PEN and PBT offer enhanced performance for specialized applications. At CloudFilm, we provide expert guidance and high-quality film solutions to meet your specific requirements.

{ Contact CloudFilm for Free Polyester Film Samples }

If you are comparing PET with other polyester films for a new project, you can send CloudFilm your current structure, target performance and market requirements; our team will help refine the specification, propose cost-effective alternatives and supply PET or polyester film samples for trial.