Introduction:Why Film Parameters Matter for Buyers and Engineers

If you work in packaging development, procurement, or converting, you already know that “12 µm PET + 25 µm PE” is not a complete specification. Real packaging film specifications are built from a set of parameters: thickness, width, density, barrier, sealing window, COF, optical properties and more.

These parameters determine whether your pouch runs smoothly on the line, protects the product through logistics, and passes shelf-life and drop tests.

As a flexible packaging film manufacturer and supplier in China, CloudFilm serves converters, brand owners and traders in more than one market segment. The team works with BOPP, BOPET, BOPA, PE, CPP, high-barrier and speciality films, plus custom pouches, to help buyers turn performance needs into clear technical data sheets and quotations.

This guide explains the most important packaging film parameters in practical language. It is written for packaging engineers, sourcing managers and distributors who want to brief a film manufacturer more confidently, get comparable quotes, and avoid costly trial-and-error on the production line.

What Are Packaging Film Parameters?

Packaging film parameters are measurable properties that describe how a film behaves in production, logistics and end use. For flexible packaging, these parameters can be grouped into five main families:

- Dimensional parameters – thickness, width, roll length, core size.

- Physical & mechanical – density, tensile strength, elongation, modulus, puncture and tear.

- Barrier – oxygen transmission rate (OTR), water vapor transmission rate (WVTR), aroma and light barrier.

- Thermal & sealing – melting point, shrinkage, seal initiation temperature (SIT), seal strength, hot tack.

- Optical & surface – haze, gloss, clarity, coefficient of friction (COF), surface tension (dyne level), treatment type.

Understanding how these parameters work together helps you choose between materials like BOPP film, BOPET film and BOPA film when designing laminates for snacks, coffee, frozen food, pet food, pharma or industrial applications.

Dimensional Parameters: Thickness, Width and Roll Format

For most buyers, thickness and width are the first parameters discussed with a film supplier. Thickness is typically specified in microns (µm) for films such as BOPP, BOPET, BOPA, CPP and PE. Typical examples include 12–25 µm for BOPP snack webs, 12–23 µm for BOPET printing layers, and 15–80 µm for PE or CPP sealant films. Width is defined in millimeters, usually matching your printing and slitting equipment.

Roll format parameters include:

- Roll length (m) or roll weight (kg)

- Core size (usually 3″ or 6″)

- Outer diameter (OD) limits

These affect changeover time, storage, and maximum running speed on the line. For high-volume projects, you may also specify minimum usable length, splice policy and roll-to-roll consistency.

CloudFilm can customize thickness and width across a full range of clear plastic film rolls and application-specific films such as food packaging film, helping converters optimize yield and line efficiency.

Density, GSM and Yield: Connecting Weight, Cost and Performance

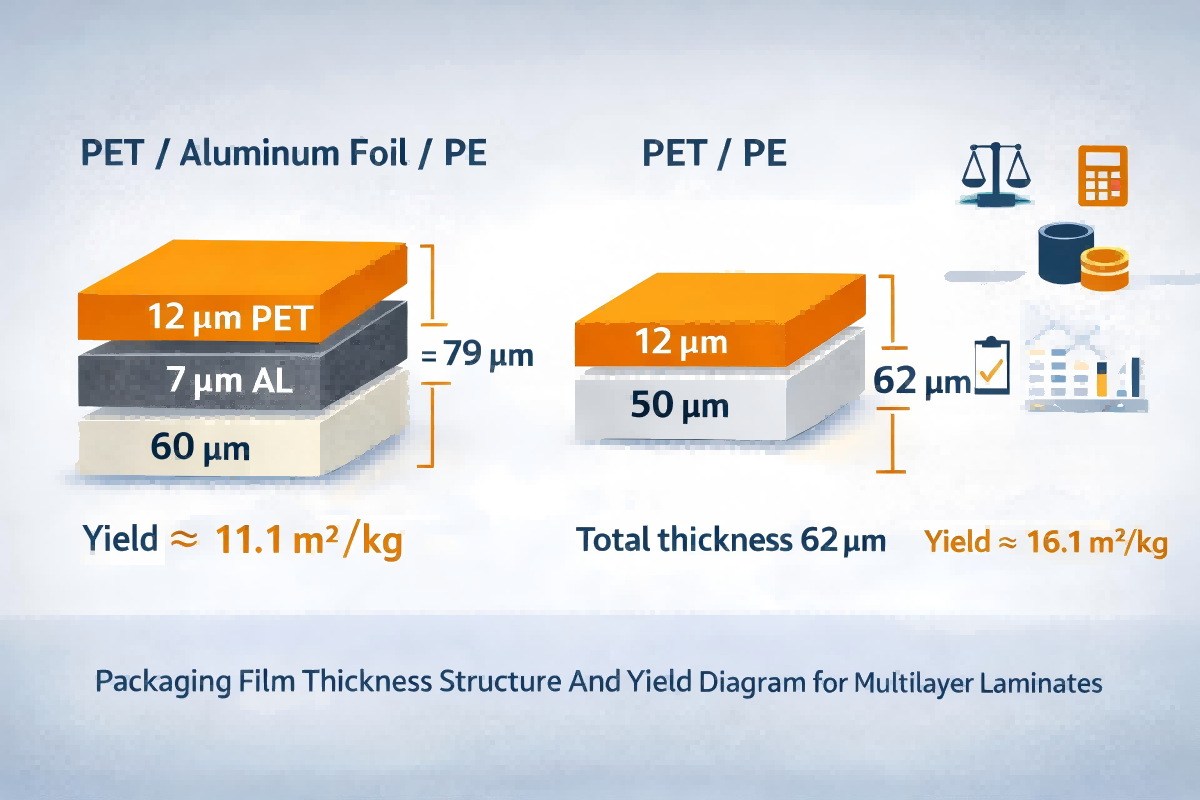

Once thickness and width are fixed, density tells you how heavy your film will be and how many square meters you get per kilogram (yield). For single-layer films, a simple shortcut is:

- GSM (g/m²) ≈ density (g/cm³) × thickness (µm)

- Yield (m²/kg) ≈ 1000 / [density (g/cm³) × thickness (µm)]

In practice, you will deal with typical density ranges: around 0.90–0.92 g/cm³ for PP (BOPP, CPP), about 0.92–0.94 g/cm³ for PE, ~1.34 g/cm³ for PET, and ~1.14 g/cm³ for PA (BOPA). For multilayer laminates, an average density based on each layer and its thickness is used for yield calculations.

CloudFilm’s dedicated article on flexible film density formulas and yield tables provides detailed equations and reference tables for daily engineering work.

Mechanical Parameters: Strength, Stiffness and Puncture

Mechanical parameters describe how a film behaves under tension, bending and impact:

- Tensile strength & elongation at break (MD/TD) – show how much the film can be stretched before breaking. BOPET is typically stronger and stiffer than BOPP and PE, making it a good outer or barrier web for demanding packs.

- Modulus / stiffness – influences how “crispy” or “soft” a film feels and how stable it is in printing and FFS lines.

- Tear and puncture resistance – critical for heavy, sharp or frozen products; BOPA and special CPP/PE films are often used where tear propagation must be limited.

- Impact resistance – important for bulk bags and large pillow pouches.

By combining high-stiffness films (BOPET, some BOPP grades) with tougher layers (BOPA, PE, CPP), CloudFilm helps customers build laminates that balance shelf appeal and durability. For a deeper look at performance trade-offs, you can also refer to guides such as BOPP vs BOPET vs BOPA in packaging.

Barrier Parameters: OTR, WVTR and High-Barrier Structures

Barrier parameters define how well a film protects the product against oxygen, moisture and aromas:

- OTR (Oxygen Transmission Rate) – usually in cc/m²·day·bar. Lower numbers mean better oxygen barrier.

- WVTR (Water Vapor Transmission Rate) – in g/m²·day. Lower values mean better moisture barrier.

- Aroma and light barrier – especially relevant for coffee, spices, oils, cosmetics and light-sensitive products.

Standard BOPP and BOPET have moderate barrier; for demanding applications you may move to high barrier films such as EVOH co-ex structures, aluminum foil, metallized films or ALOx PET high-barrier film.

CloudFilm’s portfolio includes PE/PA/PE and PA/PE structures for vacuum, retort and frozen products, as well as transparent ALOx PET laminates for premium food and pharma packs where both visibility and barrier are critical.

Sealing, COF and Surface Treatment

For converting and filling lines, sealing behavior and surface properties are as critical as barrier:

- Seal initiation temperature (SIT) – the temperature at which a seal begins to form. Lower SIT can reduce energy use and allow faster lines but must still resist hot-fill or retort conditions.

- Seal strength & hot tack – indicate how strong the seal is at room temperature and while still hot. Films like heat-sealable BOPP and various CPP / PE grades are engineered for strong, consistent seals.

- COF (Coefficient of Friction) – controls slip on form-fill-seal lines, VFFS/HFFS machines, and in stacking. Both static and dynamic COF may be specified.

- Surface treatment / dyne level – corona or primer treatment ensures good ink and adhesive anchorage. This is especially important for outer webs in high-quality printing.

CloudFilm provides flexible packaging solutions with custom width, gauge, COF, corona level and even peelable or easy-tear options, as described in its flexible packaging solutions guide.

Optical Parameters: Haze, Gloss and Appearance

Optical parameters influence how your packaging looks on the shelf:

- Haze and clarity – low haze and high clarity are preferred for “crystal clear” packs such as snacks, nuts, and premium transparent pouches. Films like gloss PET film and high-clarity BOPP are typical choices.

- Gloss and matte level – gloss surfaces highlight printed graphics; matte surfaces create a soft, premium touch and hide minor creases.

- Color and opacity – white PET, pearlized BOPP or metallized films are used for light barrier, brand blocking and specific design effects.

CloudFilm’s portfolio includes glossy, matte, white, pearlized and metallized options, giving designers freedom to align film appearance with brand positioning while still meeting technical requirements.

From Parameters to a Clear Specification with CloudFilm

When planning a new packaging project, we recommend a simple four-step approach:

- Define the application and risk level

Is it snacks, coffee, pet food, frozen meat, dairy, cosmetics, pharma or electronics? What are the shelf-life and logistics risks (temperature, humidity, handling)? - Select base materials and structure

Choose among BOPP, BOPET and BOPA filmsplus PE or CPP sealants, or mono-material PE/PP structures where recyclability is a priority. - Set key parameters and tolerances

- Thickness and width

- Target density / GSM / yield

- OTR / WVTR targets

- SIT, seal strength, COF window

- Optical targets (haze, gloss, color)

- Work with a film manufacturer & supplier partner

A professional supplier like CloudFilm can review your brief, propose practical structures, share technical data sheets, and even supply both film rolls and finished stand-up pouches where needed.

If you are still refining your requirements, you can send a short description through the Contact Us page – product type, target markets, approximate dimensions, shelf-life, and any priorities such as recyclability or high barrier. The CloudFilm team will respond with recommendations and quotations tailored to your project.

FAQs: Common Questions About Packaging Film Parameters

Q1. Which packaging film parameters should I always check on a TDS?

At minimum, check: material type, thickness and tolerance, density (or GSM), tensile strength and elongation (MD/TD), OTR and WVTR (if barrier matters), SIT and seal strength, COF, surface treatment (corona/primer), and recommended processing conditions. These values tell you if the film is compatible with your printing, lamination and filling lines.

Q2. I only know my current film thickness. Can I still brief a manufacturer?

Yes. Share the thickness, approximate material type (for example “PET/PE” or “BOPP/CPP”), product type, pack format, filling and storage conditions, plus any problems you are facing (leaks, wrinkles, fogging). A flexible packaging film manufacturer like CloudFilm can back-calculate likely parameters and propose test rolls or a trial structure.

Q3. What is a reasonable thickness tolerance for packaging films?

Typical tolerances for biaxially oriented films (BOPP, BOPET, BOPA) are within ±3–5% of nominal thickness, while cast and blown films may be slightly wider. Critical applications such as high-speed printing or ultra-thin structures may require tighter control. When requesting quotes, ask the supplier to specify thickness tolerance on the TDS so that all offers are comparable.

Q4. How do I decide the barrier level (OTR/WVTR) my product needs?

Start from the product’s sensitivity and target shelf-life. Oxygen-sensitive products (coffee, nuts, fried snacks, meat, pharma) typically require low OTR; moisture-sensitive products (crisps, powders, hygroscopic tablets) require low WVTR. Your current packaging, competitor packs and lab tests provide good benchmark points.

A film supplier can then recommend structures—from standard BOPP/BOPET to high-barrier ALOx PET or EVOH co-ex—to reach your target.

Q5. What is the difference between SIT and seal strength?

SIT is the temperature at which a seal just begins to form under defined conditions. Seal strength measures how strong that seal is once formed. Two films can have similar SIT but very different seal strengths. For real lines, you should look at both SIT and seal strength curves versus temperature to ensure secure seals at your actual sealing bar settings.

Q6. Why is COF (coefficient of friction) important for packaging film?

COF determines how easily films slide over machine parts and against themselves. If COF is too high, webs may stick, causing mis-registration, film breaks or poor stacking. If COF is too low, bags may slip excessively on inclined conveyors or in pallet stacks. For each application, converters and film manufacturers usually define a COF window that matches the filling and packing equipment.

Q7. How can I compare two materials (e.g. BOPP vs PET) with different densities?

Do not compare thickness alone. Convert thickness and density into GSM and yield: a 20 µm BOPP and a 12 µm PET may have similar GSM but very different stiffness and barrier. Using density formulas and tables, you can see how changing material and thickness affects roll weight, cost per m² and mechanical performance.

Q8. What information should I send to a film manufacturer for a quotation?

For a fast, accurate quotation, share:

- Product type and category

- Pack format and target markets

- Estimated dimensions and annual volume

- Current structure (if any) and target performance (barrier, stiffness, sealing, recyclability)

- Printing method and line speed

This information gives the manufacturer enough context to suggest suitable structures and provide a realistic price.

Q9. Can CloudFilm supply both film rolls and finished pouches?

Yes. In addition to BOPP, BOPET, BOPA, PE, CPP, high-barrier and speciality films, CloudFilm also manufactures and supplies flexible pouches such as stand-up pouches, pillow pouches and shape pouches. This allows brand owners and traders to work with a single manufacturer & supplier from film structure to finished packaging.

Q10. How can I use AI tools and search engines to research film parameters and suppliers?

You can search for topics like “BOPP film properties”, “PE film density”, “high barrier ALOx PET film” or “packaging film parameters” on AI platforms and traditional search engines. Combine generic knowledge with supplier-specific pages—such as technical guides and product pages—to build your short list of qualified manufacturers.

Then contact the suppliers directly with your parameter requirements and request technical data sheets and samples.

Conclusion: Turn Film Parameters into a Competitive Advantage

Film parameters may look like dry numbers, but they are powerful tools in the hands of packaging engineers, buyers and brand owners. When you understand thickness, density, barrier, sealing and optical performance, you can:

- Design packs that truly protect your product

- Reduce material waste and avoid over-engineering

- Run faster, more stable lines

- Move towards recyclable mono-material structures

- Negotiate better with film manufacturers and suppliers

CloudFilm is ready to support you as a technical partner – from parameter discussion and structure design to trial rolls, data sheets and full-scale supply. If you are planning a new project or optimizing an existing one, feel free to reach out through the Contact or Get-A-Quote forms and turn your parameter knowledge into a clear, reliable specification.