Ordering & Customization Checklist for BOPP Cigarette Film

Not sure which cigarette film grade you need? The more details you share, the better we can match the right film to your line. When sending an inquiry, please include as much of the following as possible:

-

Application

-

Cigarette box overwrap (soft pack / hard pack / multi-pack)

-

Other carton overwrap (cosmetics, playing cards, electronics, etc.)

-

-

Film specification

-

Required thickness (e.g. 21 µm; 18–25 µm available)

-

Roll width and length

-

One-side or both-sides heat sealable

-

Target MD/TD shrinkage or current film data (if available)

-

-

Packaging machine details

-

Brand and model of overwrapping machine

-

Typical line speed (packs/min)

-

Any issues with your current film (wrinkles, loose pack, blocking, etc.)

-

-

Quality and compliance

-

Required certificates (ISO, CE, ROHS, etc.)

-

Special requirements such as fluorescent anti-counterfeiting, laser perforation or printed logo

-

If you are not sure about some parameters, simply tell us your current film brand/specification and send a few photos of your packs and machines. Our technical team will help you check and optimize.

Elevating Tobacco Packaging to New Heights: BOPP Cigarette Film by CloudFilm

In the competitive world of tobacco packaging, CloudFilm emerges as a pioneering force with its advanced BOPP cigarette film. Tailored to meet the dynamic needs of the tobacco industry, our films are engineered to protect and showcase the elegance of cigarette boxes.

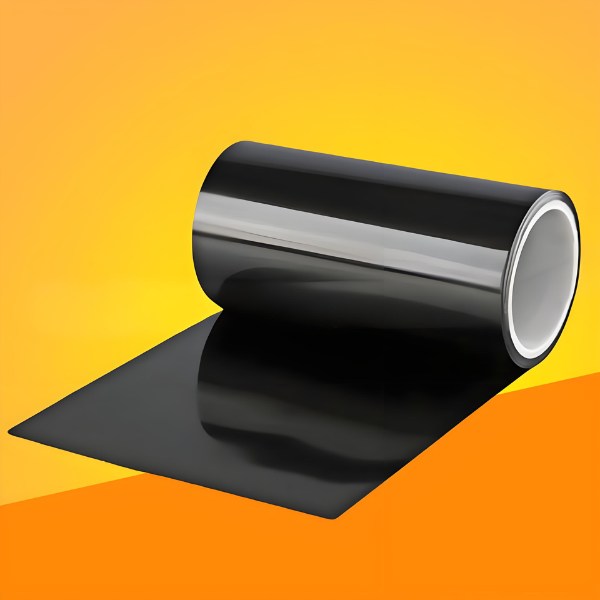

The BOPP cigarette film, known for its high transparency and glossiness, is an exemplary choice for manufacturers aiming to capture consumer attention through visually appealing packaging.

Innovative Features of BOPP Cigarette Film

Our BOPP cigarette film stands out for its exceptional mechanical strength and superior moisture barrier properties, ensuring the dryness and freshness of tobacco products.

As a result of its innovative design, the film offers an excellent shrinkage characteristic, making it perfect for tight packaging that preserves the integrity and aesthetic appeal of cigarette packs.

Emphasizing environmental responsibility, CloudFilm’s BOPP film for cigarettes aligns with the current sustainability trends, making it an environmentally friendly option in tobacco packaging.

BOPP Cigarette Film: The Ultimate Protection and Presentation

CloudFilm’s BOPP shrink cigarette film is designed to fit snugly around cigarette boxes, safeguarding the contents from moisture and contamination.

The film’s high transparency and gloss not only enhance the product’s appearance but also contribute to its protection, ensuring that the exquisite design of the cigarette box is visible and attractive to consumers. This attribute is crucial for tobacco brands striving to make a lasting impression on the shelf.

Partnering with CloudFilm: A Strategic Advantage

Choosing CloudFilm as your supplier of BOPP cigarette film means partnering with an industry leader dedicated to innovation and quality.

Our commitment to excellence is reflected in the meticulous production of our BOPP cigarette films, designed to meet the high standards required by high-speed packaging machines and the evolving demands of the tobacco sector.

Our expertise and innovative approach provide our clients a significant competitive edge, delivering value beyond just packaging solutions.

BOPP Cigarette Film vs. Traditional Shrink Films

Compared with PVC or general-purpose shrink films, BOPP cigarette overwrap film offers clearer optics, better moisture barrier and easier recyclability in polyolefin streams. It is specifically engineered for cigarette and tobacco carton packaging, with controlled shrinkage, stable COF and tailored heat seal performance.

For applications where you are still using PVC or mixed-material shrink films, our team can help you evaluate whether BOPP cigarette film or other polyolefin shrink solutions are suitable alternatives.