Introduction

If you’re a product manager, packaging buyer, or engineer searching for “PET VMPET PE”, you’re likely looking for a high-performance barrier material for your coffee, snacks, nutrition powders, or pharmaceutical products.

You’re not just looking for a definition – you want to understand what this structure means, why it’s recommended by many suppliers, and whether it is suitable for your specific application.

This ultimate guide is designed to give you a clear, practical overview of “PET VMPET PE” so that you can communicate effectively with film suppliers, converters, and internal stakeholders.

Instead of struggling with vague answers or generic descriptions, you’ll gain a working knowledge that lets you specify the right structure, ask the right questions, and make confident decisions for your project.

In daily projects at CloudFilm, PET/VMPET/PE appears again and again in specifications for coffee, nuts, snacks, nutritional powders, pet food and healthcare products, so this guide is written from real quotation and troubleshooting cases rather than theory.

If you are comparing PET/VMPET/PE with other barrier webs, you can also review CloudFilm’s guides on metallized films, PE-EVOH-PE film and PVDC film to build a broader barrier strategy for your brand.

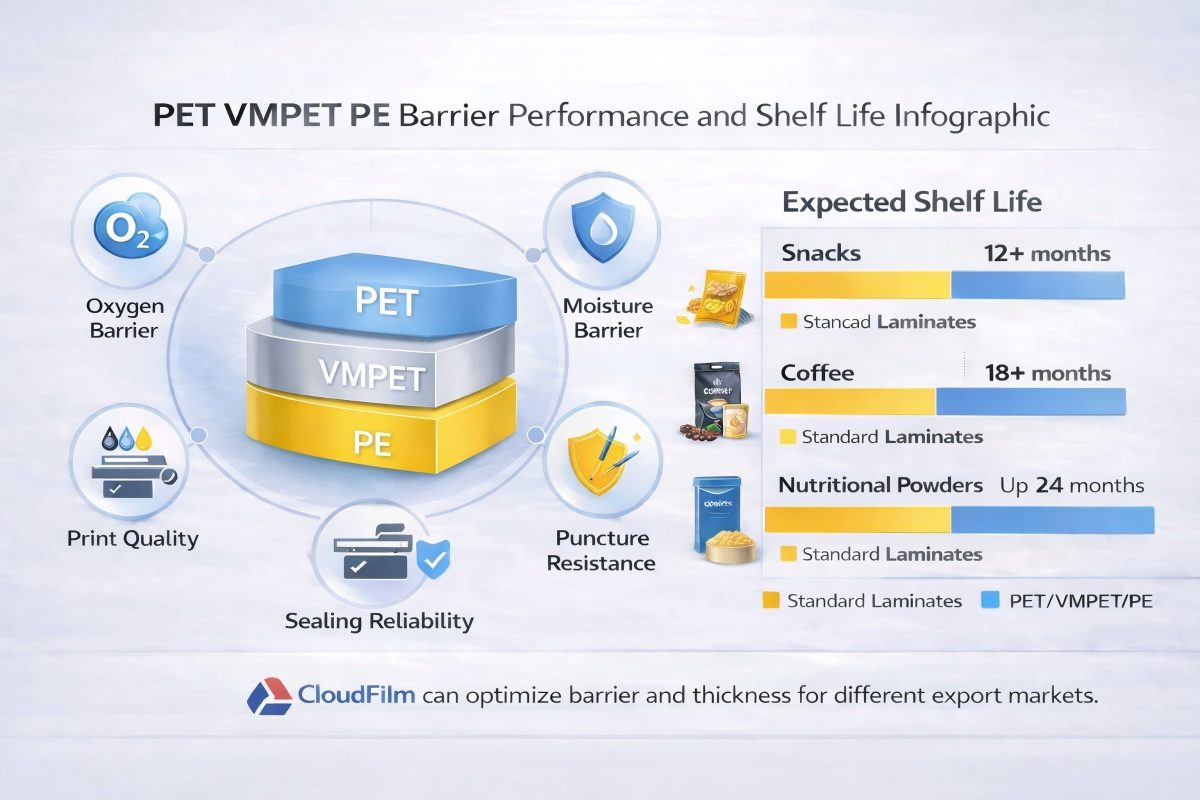

What is PET VMPET PE? The Power of a Perfect Trilayer

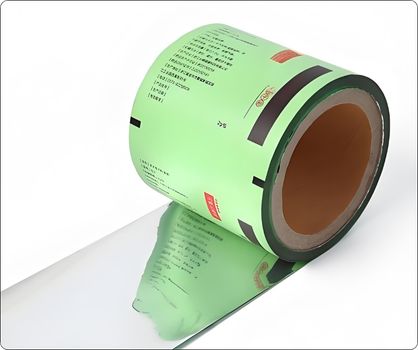

When you see “PET VMPET PE” written on a spec sheet or packaging drawing, you are looking at a three-layer laminate structure:

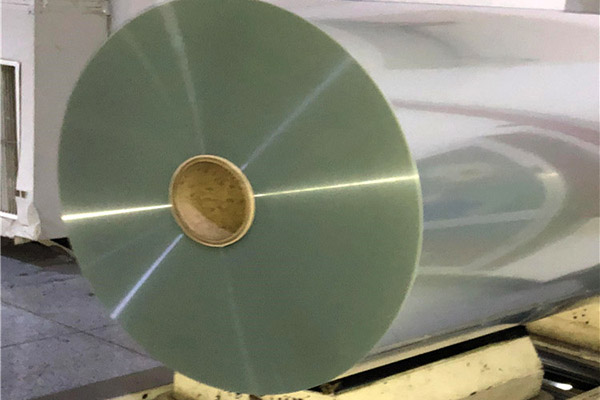

- PET – Polyethylene Terephthalate

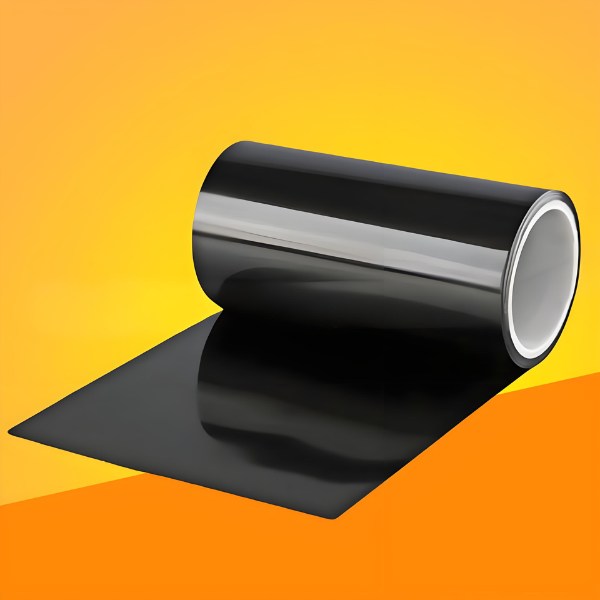

- VMPET – Vacuum Metallized PET

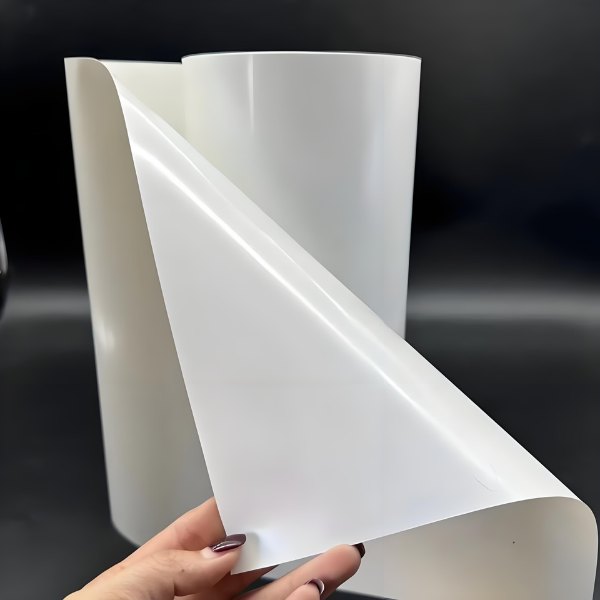

- PE – Polyethylene

Each layer plays a distinct role:

- PET (outer layer): Provides stiffness, heat resistance, dimensional stability, and a good print surface.

- VMPET (middle layer): A PET film with a thin vacuum-deposited metal layer, usually aluminum, which significantly improves barrier against oxygen and moisture.

- PE (inner layer): Serves as the sealing layer, offering good heat sealability and compatibility with the filling product.

Imagine a sandwich: The PET is the “bread” facing the outside world, the VMPET is the “barrier filling” that protects against oxygen and moisture, and the PE is the “bread” that seals tightly around your product.

In many dry food and coffee projects, a common combination might be 12 μm PET / 12 μm VMPET / 60–80 μm PE, but CloudFilm can also customize thicknesses outside this range to balance cost, shelf life and pouch hand feel for different markets.

The metallized core is typically based on an aluminized PET film that CloudFilm produces in-house, giving you a consistent barrier foundation when this web is laminated with PE or CPP sealant films.

For applications that require transparent high barrier rather than a silver metallic look, CloudFilm can design similar trilayer structures using its ALOx PET film platform, as explained in our ALOx PET high barrier guide.

Why Choose PET/VMPET/PE? The Unbeatable Advantages

Why is this laminate so widely used for high-barrier applications? Because PET/VMPET/PE offers a balanced combination of properties that are difficult to match with single-layer films or simpler laminates.

Key benefits include:

- High barrier performance: VMPET dramatically reduces oxygen and water vapor transmission rates (OTR and WVTR).

- Excellent printability and shelf impact: PET provides a smooth, high-quality surface for gravure or flexo printing, helping your brand stand out on the shelf.

- Strong mechanical properties: The PET layer improves puncture resistance, tear resistance, and dimensional stability, especially for larger bags.

- Reliable sealing: The PE layer offers a wide heat-seal window and good hot-tack properties, helping you run faster on packing lines while maintaining seal integrity.

- Versatile applications: Suitable for a wide range of products, from food and beverage to pharmaceuticals and industrial goods.

- Wide Application Window: Compared with many BOPP-based metallized laminates, PET/VMPET/PE handles higher filling temperatures, rougher handling and heavier bag weights, which is critical for large coffee bags, pet food and bulk powder packaging.

Film And Pouch Integration: CloudFilm can supply PET/VMPET/PE as printed or unprinted rollstock for VFFS/HFFS lines, or convert it into finished stand up pouches, quad seal pouches and flat bottom pouches so that you manage fewer suppliers while maintaining consistent barrier performance across your portfolio.

PET/VMPET/PE Vs Other High-Barrier Structures

When you design a barrier pack, PET/VMPET/PE is only one option among several CloudFilm platforms, including PET/AL/PE, PET/ALOx PET/PE, PVDC-coated films and co-extruded PE-EVOH-PE. Understanding the differences helps you choose the right structure instead of selecting materials by trial and error.

PET/VMPET/PE Vs PET/AL/PE (Foil Laminates)

PET/AL/PE structures built on food grade aluminum foil or flexible packaging aluminum foil provide almost zero OTR and WVTR and are ideal for aggressive or highly sensitive products, but they are more expensive and may suffer from flex cracking.

PET/VMPET/PE offers slightly lower barrier but better flex resistance and lighter-weight packaging, making it sufficient for most dry foods, coffee and snack applications.

PET/VMPET/PE Vs PET/ALOx PET/PE

ALOx PET laminates built on ALOx PET film deliver very high barrier with full transparency, which is perfect when you need “glass-like” product visibility, for example premium nuts or diagnostics. However, metallized PET/VMPET/PE usually offers a more economical barrier solution where product visibility is less critical.

PET/VMPET/PE Vs PVDC-Coated Films

Structures using PVDC coated film can achieve excellent barrier at thinner overall gauges and are explained in detail in CloudFilm’s PVDC film guide. PET/VMPET/PE remains attractive when you prefer non-chlorinated materials or already run metallized webs on your lines.

PET/VMPET/PE Vs PE-EVOH-PE Co-Extruded Film

For brands moving toward recyclable mono-material or PE-rich platforms, co-extruded PE-EVOH-PE filmand EVOH bags can be strong alternatives, especially in markets where PE-based laminates are accepted in recycling streams.

In many cases, buyers start with PET/VMPET/PE to validate shelf life, then gradually transition to PE-EVOH-PE structures with CloudFilm’s support.

PET/VMPET/PE Vs Nylon-Based Laminates

Nylon/PE and PA/EVOH/PE structures, built on CloudFilm BOPA film, are normally chosen where deep draw, very high puncture resistance or retort processing is required. PET/VMPET/PE is better suited for dry, non-retorted applications where stiffness, print quality and aroma barrier are the main priorities.

Key Applications: What Can It Protect?

PET/VMPET/PE is used wherever products need both strong protection and attractive presentation. Common applications include:

- Food & beverage:

- Coffee beans and ground coffee

- Powdered drinks and nutritional powders

- Snacks, biscuits, nuts and confectionery

- Instant noodles, seasoning packets, and ready meals

- Pharmaceuticals & healthcare:

- Diagnostic kits

- Nutritional supplements

- Over-the-counter medicines (e.g., lozenges, tablets in secondary packs)

- Industrial & specialty:

- Electronic components that need moisture protection

- Chemical powders and additives

- High-value spare parts or tools

For coffee and snack brands, CloudFilm not only supplies PET/VMPET/PE rollstock but also finished coffee packaging bags, candy packaging bags and food packaging films that are tailored to your degassing valves, zipper types and shelf-display needs.

In pharmaceutical and healthcare projects, PET/VMPET/PE can be combined with dedicated pharmaceutical pouches

and other flexible pouches to meet documentation and stability requirements while keeping packs compact and user-friendly.

For industrial moisture-sensitive products, CloudFilm frequently pairs PET/VMPET/PE with anti-static or corrosion-inhibiting inner bags so that electronic, metal or chemical products reach export destinations safely.

Technical Considerations and How to Source Wisely with CloudFilm

Your search intent likely culminates in procurement: you don’t just want theoretical knowledge; you need to know how to choose the right PET/VMPET/PE structure and specify it correctly.

Key technical parameters to consider:

- Barrier requirements: What OTR and WVTR do you need for your product and target shelf life?

- Thickness of each layer: Standard PET/VMPET/PE structures might use 12/12/60 μm or similar, but this can vary based on application.

- Seal strength and seal temperature window: Ensure the PE layer (and potential blends with LLDPE or mLLDPE) is compatible with your packing line.

- Bag format: Pillow bag, gusseted bag, quad-seal pouch, flat bottom pouch, or sachet – each has different demands on stiffness and seal performance.

- Regulatory and food-contact requirements: Consider regional regulations (e.g., FDA, EU, etc.) and the documentation you require from suppliers.

When you work with CloudFilm, you are not just buying a film; you are leveraging a technical team that can translate your product and market needs into a clear PET/VMPET/PE specification.

For dry foods like coffee, nuts or nutritional powders, PET/VMPET/PE structures often target low-to-medium OTR and WVTR ranges that are sufficient for 6–18 months of shelf life, depending on your formulation and distribution chain. CloudFilm can help you match barrier levels to real shelf-life data instead of guessing from catalog values.

From a converting point of view, it is crucial to align PET/VMPET/PE thickness and stiffness with your chosen pouch format and packing machine. CloudFilm can pre-check your specifications against typical VFFS, HFFS and pouch-making conditions so that trial rolls run smoothly.

To receive a faster and more accurate quotation from CloudFilm, it is helpful to share at least the following information: product type, target shelf life and storage temperature, bag style and approximate size, expected annual volume, printing requirements (number of colors, matte/gloss effects), destination market and preferred Incoterms.

With these inputs, CloudFilm can quickly compare PET/VMPET/PE with options such as ALOx PET, PVDC coated film or PE-EVOH-PE, and recommend the most suitable structure.

The CloudFilm Advantage – Your Trusted Partner

Choosing PET/VMPET/PE is only half the story; choosing the right partner is equally important.

As a China-based flexible packaging film manufacturer and exporter, CloudFilm offers:

- Deep technical expertise in PET, VMPET, PE, and other high-barrier film structures.

- Customizable specifications tailored to your product, market, and packing line.

- Strong export experience supporting customers in multiple regions worldwide.

- End-to-end support from material selection and sampling to mass production and logistics.

Instead of navigating the complexity of barrier films alone, you can rely on CloudFilm to help you make smart, informed choices that protect your brand and improve your packaging performance.

CloudFilm’s portfolio includes not only PET/VMPET/PE but also metallized films, high barrier films and a wide range of flexible pouches, so you can develop an integrated film-plus-pouch solution with a single technical team.

Whether you need trial rollstock for line tests or a custom mix of coffee bags, snack pouches and EVOH or PVDC-based films, CloudFilm’s engineers can review your drawings, recommend structures and help you avoid over-specification or under-protection before you commit to tooling and artwork.

Frequently Asked Questions (FAQ)

Q1: What does “PET VMPET PE” mean?

“PET VMPET PE” refers to a three-layer laminate structure made of PET (outer layer), VMPET (vacuum metallized PET, middle barrier layer), and PE (inner sealing layer). It is widely used for high-barrier flexible packaging.

Q2: What are typical thicknesses for PET/VMPET/PE?

Typical structures include 12/12/60 μm or 12/12/70–80 μm, but exact thickness combinations will depend on your product, bag size, and target shelf life.

Q3: Can PET/VMPET/PE be recycled?

In many markets, multilayer laminates containing PET, VMPET and PE are still classified as “non-recyclable” or “difficult to recycle” in standard curbside systems. However, some regions have dedicated collection and energy-recovery schemes. Always check local regulations and recycling infrastructure.

Q4: Is PET/VMPET/PE suitable for coffee bags with degassing valves?

Yes. PET/VMPET/PE is one of the most common structures for whole-bean and ground coffee bags with valves. The PET layer provides stiffness and printability, the VMPET layer protects aroma and oils, and the PE layer ensures strong seals around the valve and zipper area.

CloudFilm can supply both PET/VMPET/PE rollstock and finished coffee packaging bags

with pre-installed degassing valves.

Q5: When should I choose PET/VMPET/PE instead of PET/AL/PE?

If your product is extremely sensitive and you require the highest possible barrier, PET/AL/PE based on food grade aluminum foil may be more appropriate. For most dry foods, coffee, snacks and powders, PET/VMPET/PE usually delivers sufficient barrier with better flex resistance, lower risk of pinholes from flex cracking, and a lighter overall pack.

CloudFilm can compare both options using your target shelf life and logistics conditions.

Q6: What information should I send CloudFilm to get a quotation or sample?

To receive a fast and accurate proposal, it is helpful to share:

- What product you will pack

- Target shelf life and storage temperature

- Bag style and approximate size

- Annual quantity or first order volume

- Printing needs (number of designs, colors, matte/gloss effects)

- Destination country and preferred Incoterms.

Based on this, CloudFilm can recommend PET/VMPET/PE or alternative structures such as ALOx PET, PVDC coated film or PE-EVOH-PE and prepare trial rolls or sample pouches.

Conclusion

PET/VMPET/PE is one of the most practical and widely used high-barrier laminate structures in modern flexible packaging. It brings together print quality, barrier performance, mechanical strength, and sealing reliability in a way that is difficult to match with single materials.

Whether you are responsible for coffee, snacks, pharmaceuticals, or industrial products, understanding PET/VMPET/PE gives you a powerful tool to design better packaging and communicate more effectively with suppliers.

If you’d like to discuss a specific project, compare PET/VMPET/PE with other barrier structures, or get sample rolls or pouches, the CloudFilm team is ready to support you.

Simply share your product, target shelf life, bag style, order volume and destination market with CloudFilm, and our team will recommend a suitable PET/VMPET/PE or alternative high-barrier structure, provide technical data and send a clear quotation for your next shipment.