Introduction: What is Mylar PET?

Mylar PET is a high-performance polyester film that plays a crucial role in modern packaging, electronics, and industrial applications. It substitutes the building bricks of various industries, such as the packaging box and the Flower of Information Industry. Although you might see it in many products every day—like snack bags, reflective decorations, and electrical insulation materials—you may not realize that they have such a sophisticated material.

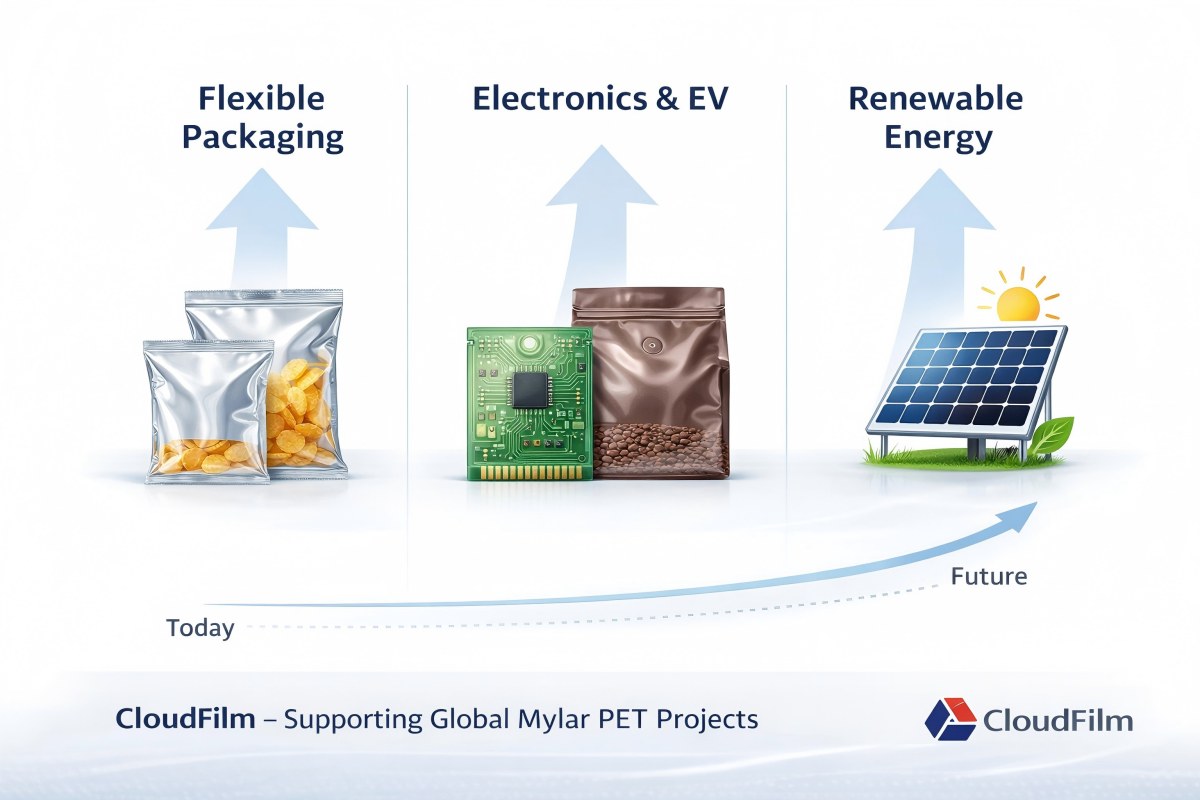

Originally a brand name registered by DuPont, Mylar has now become a generic term commonly used to describe biaxially oriented polyethylene terephthalate (BOPET) films. These films are known for their impressive strength, optical clarity, excellent barrier properties, and resistance to temperature and chemicals. Because of these properties, Mylar PET films are widely used in flexible packaging, electronic applications and even renewable energy technologies.

In real projects, buyers, engineers and converters often use “Mylar”, “PET film”, “polyester film” and “BOPET film” to describe very similar materials – in this article, “Mylar PET film” mainly refers to biaxially oriented PET films similar to the BOPET polyester films supplied by CloudFilm for packaging, labels, electrical insulation and other technical uses.

If you want to dig deeper into performance details such as strength, barrier and heat resistance, you can also refer to CloudFilm’s in-depth guide Mylar Properties: A Practical Guide For Packaging And Industrial Uses, which explains Mylar behavior from an engineer’s perspective.

Across CloudFilm’s BOPET range, Mylar-type PET films cover gloss, matte, metallized, ALOx, heat-sealable, holographic, anti-static and soft-touch grades, giving project teams a complete toolbox to fine-tune appearance, barrier and machinability. For a quick overview of all polyester film types, you can browse the BOPET Film category page.

Core Properties of Mylar PET

Understanding the core physical and chemical properties of Mylar PET is the first step to using it correctly in your project design.

Excellent Mechanical Strength and Dimensional Stability

Mylar PET films have outstanding tensile strength and dimensional stability, which allows them to maintain shape and size even under stress, heating, or shrinkage. This makes it especially suitable for high-speed printing, lamination, and converting processes, where precision and consistency are essential.

For packaging converters and label printers, this stiffness and stability mean fewer registration issues, smoother running on high-speed lines, and better pack appearance compared with softer films such as PE or some PP grades.

Superior Barrier Properties

While PET itself provides moderate moisture barrier, Mylar PET films can be engineered with coatings or laminations to enhance their barrier performance. Metallized Mylar PET, in particular, dramatically improves oxygen, moisture, and light barrier, making it a preferred choice for food packaging and other sensitive applications.

CloudFilm’s high-barrier polyester solutions include ALOx PET Film and Aluminized PET Film . These “glass-like” or metallized Mylar films are widely used in coffee, tea, snack, pet food and high-value dry food packaging where aroma, flavor and shelf life are critical.

Wide Temperature Resistance

Mylar PET exhibits excellent thermal stability and can withstand a wide range of temperatures—from sub-zero conditions to high-temperature environments. This makes it ideal for applications such as ovenable packaging, insulation materials, and electrical insulation.

Compared with many BOPP films, Mylar PET keeps its stiffness and mechanical performance at higher temperatures, which is why polyester is often chosen as the outer layer for lidding, retort pouches and ovenable structures when packaging lines and end-use conditions are demanding.

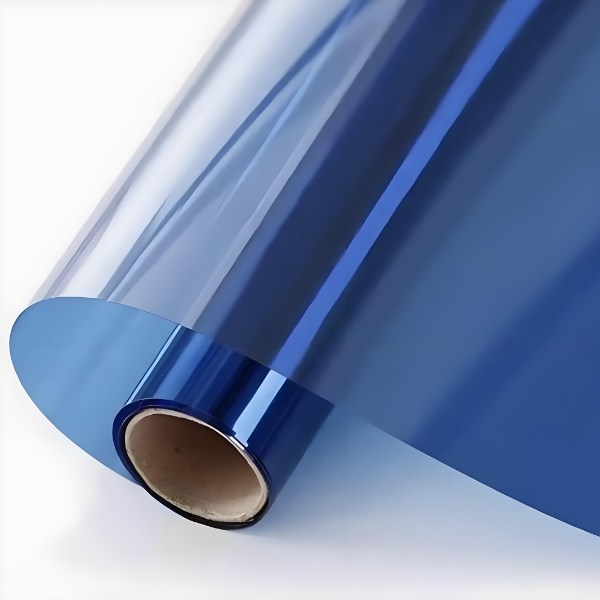

Optical Clarity and Surface Treatment Options

Standard Mylar PET film has high transparency and good optical clarity, which are important for applications that require clear viewing of the product or underlying graphics. Besides, its surface can be adjusted with different treatments such as corona treatment, chemical coating, or matte finishing to cater to specific printing, lamination, or slip requirements.

For premium brands that want a differentiated visual effect, CloudFilm offers Gloss PET Film, Matte PET Film and Soft Touch Polyester Film, allowing you to choose between high-gloss clarity, low-gloss elegance or a velvety “soft-touch” feel on the same Mylar PET base.

Additional Technical Highlights Of Mylar PET Films

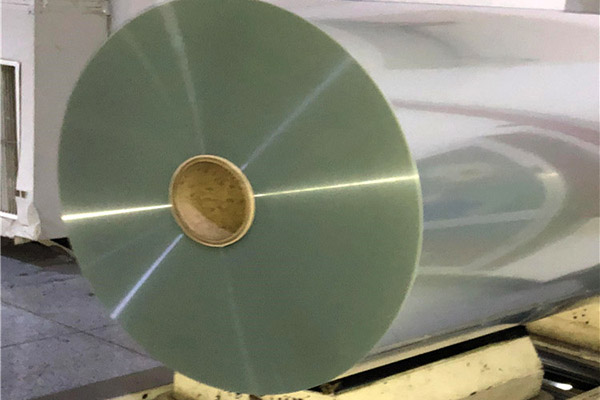

Mylar-type PET films typically cover a thickness range from very thin gauges for printing and metallization to thicker gauges for labels, insulation and industrial laminates.

Clear Mylar provides moderate oxygen and moisture barrier suitable for many dry foods and powders, while metallized or ALOx-coated grades deliver much higher barrier suitable for coffee, snacks and sensitive products.

If you need help calculating weight or yield, CloudFilm’s article PET Film Density: The Ultimate Guide For Engineers, Buyers, And Manufacturers explains how density, thickness and area translate into roll weight and cost.

Key Application Areas of Mylar PET

Packaging Industry

Mylar PET films are widely used in flexible packaging, such as snack bags, coffee pouches, stand-up pouches, vacuum-sealed bags and more. They can be used as monolayer films or laminated with other materials like polyethylene (PE), polypropylene (PP), aluminum foil, or barrier coatings to balance strength, barrier, and cost. Mylar PET films are especially suitable for packaging foods, beverages, pet food, cosmetic products and pharmaceuticals.

In real “Mylar bag” structures, the PET layer usually works as the outer printing and stiffness layer, combined with PE, CPP or aluminum foil as the inner sealant and barrier layer, for example PET/PE, PET/AL/PE or PET/AL/CPP. CloudFilm not only supplies polyester films but also finished pouches such as Coffee Packaging Bags, Tea Packaging Pouches and Pharmaceutical Pouches, helping brand owners quickly move from film selection to shelf-ready flexible packaging.

If your project is still at the early “design the pack” stage, you can also read CloudFilm’s guide Custom Flexible Packaging: The Complete Guide For Brands And Manufacturers to understand how to use Mylar PET films together with other substrates in a full flexible packaging solution.

Electronics and Electrical

Mylar PET is widely used as an electrical insulation material in capacitors, transformers, motors, and cables because of its excellent dielectric strength and thermal stability.

It is also used as an insulating substrate in flexible printed circuit boards (FPCBs), label materials and protective films for electronic components. Its high dimensional stability ensures that electrical components remain reliable over long-term use.

For electronics and industrial tape applications, CloudFilm supplies specialty grades such as Anti Static PET Film and PET Heat Transfer Film, which are designed for ESD-sensitive environments, nameplates, heat transfer labels and other technical uses where stable dielectric properties and clean surfaces are important.

Renewable Energy

In the renewable energy industry, Mylar PET films are used as a key component in photovoltaic (solar) backsheet structures, providing mechanical support, electrical insulation, and UV/weather resistance. They help improve the durability and long-term performance of solar panels.

CloudFilm’s Photovoltaic Backsheet Film is designed specifically for solar modules, combining Mylar-type PET with functional coatings and other layers to achieve long-term outdoor stability, dimensional control and insulation performance.

Industrial and Special Applications

Mylar PET films are also found in many industrial fields such as labels, protective films, reflective materials, graphic arts, balloons, and construction materials. In many cases, it is chosen for its combination of strength, barrier, and aesthetic properties.

In graphic and decorative applications, PET Holographic Film delivers eye-catching diffraction patterns based on a Mylar PET base, while Soft Touch Polyester Film offers a low-gloss, velvet tactile effect for premium print and packaging. These specialty Mylar films help brands stand out on shelf without sacrificing durability or converting efficiency.

Market Trends and Future Outlook

The demand for Mylar PET films continues to grow worldwide, driven by the expanding flexible packaging market, the development of the electronics industry, and the rapid rise of renewable energy applications. Sustainability is another important driver.

As brand owners and regulators push for recyclable and high-performance materials, PET-based films—especially those designed for mono-material packaging or high-barrier laminates—will continue to gain importance. Mylar PET films will also keep evolving through new coatings, surface treatments, and composite structures to meet stricter environmental and performance requirements.

Global market demand is shifting from simple PET/AL/PE laminates toward structures that balance barrier, cost and recyclability—for example PET/PE or PET/BOPE mono-material laminates, as well as transparent high-barrier solutions based on ALOx PET. In this context, Mylar PET remains a core “backbone” film that can be combined with new sealants, PCR materials and barrier layers to support brand sustainability roadmaps.

At the same time, the growth of consumer electronics, electric vehicles and renewable energy continues to create new opportunities for Mylar in insulation films, labels, capacitors and photovoltaic backsheets. This means buyers increasingly expect suppliers like CloudFilm not only to provide standard packaging-grade polyester, but also to support special grades and custom structures for technical and energy-related projects.

Frequently Asked Questions (FAQ)

1. Is Mylar the same as PET?

Mylar is a brand name originally registered by DuPont for biaxially oriented polyethylene terephthalate (BOPET) films. In daily usage, Mylar usually refers to PET films that have been biaxially oriented and have similar properties. So, Mylar PET is essentially PET film in a specific oriented form.

2. Is Mylar PET safe for food contact?

Yes, Mylar PET films are widely used as food contact materials when they meet relevant regulatory standards (such as FDA in the USA or EU regulations in Europe). In flexible packaging, Mylar PET is often used as the outer layer in combination with food-grade inner sealant layers. However, you should always make sure that your final structure and inks/adhesives comply with local food-contact regulations.

3. What’s the difference between clear, metallized and coated Mylar PET films?

Clear Mylar PET films offer good optical clarity and basic barrier properties, suitable for many general packaging, printing and industrial applications. Metallized Mylar PET films have a thin metal layer (usually aluminum) deposited on the surface, which significantly improves barrier performance and light-shielding capability.

Coated Mylar PET films are those that have special coatings applied, such as heat-sealable coatings, barrier coatings or printable primers, to improve sealing performance, adhesion or other functional properties.

4. Can Mylar PET films be recycled?

Mylar PET films are made from PET (polyethylene terephthalate), which is a recyclable material. However, the recyclability of final products depends on the laminate structure and local recycling systems. Pure PET films or mono-material structures are more recyclable than multi-material laminates (e.g. PET/Al/PE).

As recycling technologies and policies evolve, more PET-based packaging solutions—including those using Mylar PET—will be designed with recyclability in mind.

5. How to choose the right Mylar PET film for my application?

When selecting a Mylar PET film, you should consider factors such as thickness, surface treatment (e.g. corona or primer), barrier level (clear vs metallized vs coated), temperature resistance, and specific industry requirements (e.g. food contact, insulation, or optical properties).

It is often helpful to work with a professional supplier like CloudFilm, who can evaluate your product, processing conditions, and regulatory requirements, and then recommend the most suitable Mylar PET grade or laminate structure.

6. What thickness of Mylar PET film is commonly used in packaging and labels?

In flexible packaging, common Mylar PET thicknesses range from around 8–12 microns for surface-print overwraps up to 12–36 microns for laminated pouches and lidding films. Label and industrial applications may use thicker gauges for extra stiffness or durability.

When you share your pack type, filling process and shelf-life targets with CloudFilm, our team can suggest a suitable thickness range and even help you calculate expected roll weight and yield.

7. What are typical Mylar PET laminate structures for food and coffee packaging?

Typical Mylar PET-based laminates include PET/PE, PET/CPP, PET/AL/PE, PET/AL/CPP and PET/MetPET/PE. Clear PET/PE is often used for dry foods, snacks or transparent windows; PET/AL/PE and PET/MetPET/PE are popular for coffee and high-aroma products that need strong oxygen and light barrier.

CloudFilm can provide both the PET films (including Heat Sealable PET Film) and finished pouches such as Coffee Packaging Bags or Pillow Pouches, depending on how far you want to outsource the converting work.

8. What is the difference between Mylar PET and BOPP film in packaging?

Both Mylar PET and BOPP are widely used in flexible packaging. Compared with BOPP, Mylar PET generally offers higher stiffness, better dimensional stability and higher temperature resistance, which helps when print quality, retort/oven conditions or lidding strength are critical. BOPP usually wins on cost and low-temperature sealability and is common as an inner or middle layer.

For a more visual comparison between PET structures and CPP sealant films, you can also refer to CloudFilm’s article PET Film Vs CPP Film: A Visual Guide.

9. What Mylar PET options can CloudFilm supply?

CloudFilm’s BOPET portfolio covers a wide range of Mylar-type polyester films, including Gloss PET Film, Matte PET Film, Aluminized PET Film, ALOx PET Film, Heat Sealable PET Film, PET Holographic Film, Soft Touch Polyester Film, PETG Shrink Film and Photovoltaic Backsheet Film.

This allows buyers to cover packaging, labels, decoration, electronics and solar applications with one integrated Mylar PET supplier.

10. How can I start a Mylar PET film project with CloudFilm?

You do not need to know every technical detail. Simply tell CloudFilm what you want to pack or protect, your filling process (form-fill-seal, vacuum, retort, hot-fill, etc.), target shelf life and any special requirements such as recyclability, transparency or tactile feel.

Our team will recommend suitable Mylar PET grades, laminate structures and even ready-made Flexible Pouches. You can start with trial rolls or sample pouches, then scale up to full container orders when the structure is validated. To get personal support, you can contact us directly via the Contact Us page.

Why Choose CloudFilm’s Mylar PET Products?

{ CloudFilm Provides Customized Solutions for You }

At Cloudfilm, we specialize in supplying a wide range of PET films, including Mylar PET films, to support diverse industrial and packaging needs. With our strong production capacity, strict quality control, and technical support, we can help you choose the right Mylar PET grade or laminate structure for your specific application.

Whether you need standard or customized solutions, CloudFilm is committed to helping you improve product performance, reduce costs, and achieve sustainable development goals.

Whether you need standard packaging-grade film, metallized Mylar for high-barrier applications or specialty coated films for technical uses, CloudFilm’s expertise and manufacturing strength will help you win in the market.

Based in China with multiple production bases and export experience to many regions, CloudFilm can support trial rolls, sample pouches and full container shipments of Mylar-type polyester films. Our Mylar PET portfolio is fully integrated with other film families—such as BOPP, CPP, PE and high-barrier films—so we can help you design complete structures, not just single layers.

For buyers, engineers and brand owners who want one partner for both films and converted packaging, CloudFilm’s combination of BOPET Film and Flexible Pouches means you can source polyester films, high-barrier laminate components and finished bags from a single, technically focused supplier.

If you are planning a new Mylar PET project—or want to optimize an existing structure for cost, performance or sustainability—you are welcome to share your product, target markets and line conditions with us. CloudFilm’s team will provide clear, practical recommendations and competitive quotations.