Introduction

Holographic film is one of the most visually striking and technologically advanced materials used today. From shimmering gift wraps and security labels to high-end optical devices, its applications are vast and varied. But how is holographic film made? Is it something you can create at home, or does it require specialized industrial equipment?

In this comprehensive guide, we’ll break down the entire process of making holographic film, covering both DIY techniques for hobbyists and large-scale production methods for professionals. Whether you’re a curious beginner, an engineer, or an entrepreneur exploring business opportunities, this article will give you the insights you need.

For packaging engineers, buyers, and brand owners, a clear understanding of holographic film technology makes it much easier to brief suppliers, evaluate quotations, and avoid costly trial-and-error on the production line.

Whether you ultimately choose BOPP or PET holographic film from CloudFilm, this guide will help you move from basic curiosity to a concrete, factory-ready specification that can be produced on commercial lines.

{ Holographic Film Production Line }

What Is Holographic Film?

Before diving into the “how,” it’s essential to understand the “what.” Holographic film is a thin plastic sheet, typically made from PET (polyethylene terephthalate), that has been embossed with a microstructure capable of diffracting light into a spectrum of colors. This diffraction creates the characteristic rainbow-like, 3D visual effect.

Unlike regular printed films, holographic films don’t use pigments. Instead, they rely on light interference patterns, which are recorded onto the film surface through laser or mechanical embossing techniques.

In commercial packaging and label projects, most buyers work with either BOPP holographic film or PET holographic film, choosing the substrate according to stiffness, heat resistance, and whether they prefer a mono-PP or PET-based laminate structure.

Types of Holographic Film: BOPP vs PET and More

For flexible packaging and label applications, the two most common commercial holographic substrates are BOPP and PET. Both can carry finely embossed patterns, but they behave differently on printing, laminating, and packing equipment.

BOPP holographic film

- Typically used for snack, confectionery, cigarette, and personal-care overwraps where good machinability, low density, and attractive shelf impact are required.

- Often laminated in structures such as holographic BOPP / metallized BOPP / PE to balance eye-catching effects with moisture and oxygen barrier.

- Pairs naturally with other BOPP films (gloss, matte, pearlized) when you want to keep a mono-PP structure for easier recycling.

PET holographic film

- Favored for gift boxes, folding cartons, labels, sleeves, and premium display graphics because of its higher stiffness, dimensional stability, and heat resistance.

- Ideal as an outer web in PET-based laminates when you need sharper embossed details and a more rigid, premium hand-feel.

Beyond classic packaging, PET-based holographic films are also used in decorative laminates, advertising, and certain optical applications where mechanical strength and flatness are critical.

CloudFilm supplies both BOPP holographic film and PET holographic film, so you can evaluate real samples on your own printing and laminating lines before committing to large orders.

Basic Principles of Holography

The magic behind holographic film lies in the principles of holography, a technique that records the light scattered from an object and presents it in a way that appears three-dimensional.

Here’s how it works:

- A laser beam is split into two parts: the object beam and the reference beam.

- The object beam is directed at the object, and the reflected light interferes with the reference beam on a photographic plate or film.

- This interference pattern is recorded and later illuminated to produce a 3D image.

While true holography requires lasers and precise conditions, most commercial holographic films use simplified embossing techniques to mimic the effect at scale.

For most packaging projects, you do not need to create holograms from scratch, but it is useful to remember that every holographic film begins with a carefully designed master pattern that is replicated on BOPP or PET base films in high volume.

DIY Methods: Making Holographic Film at Home

What You’ll Need:

- Clear plastic sheets (like transparency film or acetate sheets)

- Holographic nail polish or special effect spray paint

- A clean, dust-free workspace

- Soft brushes or sponges

- Gloves (to avoid fingerprints)

- Optional: stencil patterns for design consistency

Step-by-Step Guide:

- Prepare the Workspace

Start by cleaning your workspace thoroughly. Any dust or debris can ruin the holographic effect. Use a lint-free cloth to wipe down surfaces and ensure the plastic sheets are completely clean and dry. - Choose Your Base Material

Select a clear plastic sheet that is smooth and flexible. Transparency film works well for beginners. Make sure it’s cut to the size you need for your project. - Apply the Holographic Coating

Shake the holographic nail polish or spray paint thoroughly to mix the reflective particles. Hold the can or brush about 15–20 cm away from the plastic sheet. Apply a thin, even layer across the entire surface. Avoid heavy application, as it can cause uneven drying and reduce the reflective quality. - Let It Dry Naturally

Allow the coated sheet to air-dry in a dust-free environment. This may take anywhere from 30 minutes to a few hours, depending on the product used. Avoid using heat or fans, as they can disturb the coating and create streaks. - Apply Additional Layers (Optional)

For a more intense holographic effect, you can apply multiple thin layers. Let each layer dry completely before applying the next. This layering technique enhances depth and brightness. - Add Patterns or Designs (Optional)

If you want to create specific patterns, use stencils or masks before applying the coating. This is especially useful for artistic projects or decorative films. - Seal the Film

Once the final layer is dry, apply a clear sealant spray to protect the holographic surface from scratches and moisture. This step increases durability and extends the life of your homemade film. - Test the Effect

Hold the finished film under different light sources to see the holographic effect. Natural sunlight, LED lights, and flashlights will each produce different visual results.

These DIY methods are ideal for small craft projects, design mock-ups, or concept samples, but they cannot replace industrial holographic packaging films when you need food-contact compliance, machinability on VFFS/HFFS lines, and consistent visual effects across thousands of meters of film.

Industrial Production: The Real Manufacturing Process

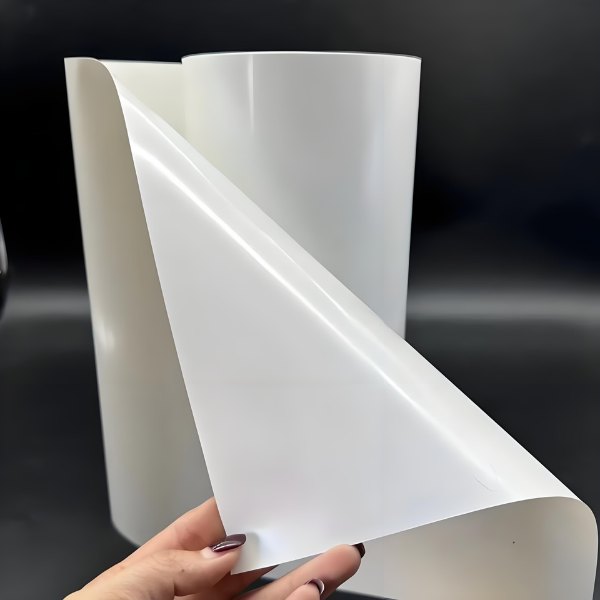

{ PET Holographic Film Production Line }

Key Equipment:

- Vacuum deposition chambers

- Laser embossing systems

- UV curing stations

- Precision coating machines

- Quality control instruments (spectrophotometers, tensile testers)

Step-by-Step Process:

- Material Selection and Preparation

The process begins with selecting high-quality base films, typically PET (Polyethylene Terephthalate) or BOPET (Biaxially Oriented Polyethylene Terephthalate). These films are chosen for their clarity, thermal stability, and mechanical strength. The film is thoroughly cleaned to remove any contaminants that could interfere with coating adhesion. - Metallization (Vacuum Deposition)

The cleaned film is placed in a vacuum deposition chamber. Here, a thin layer of metal—usually aluminum—is vaporized and deposited onto the film surface under controlled conditions. This creates a highly reflective base layer essential for the holographic effect. - Embossing the Holographic Pattern

This is the most critical step. A master holographic pattern, created using laser interference technology, is used to emboss the film. The film is passed through a set of precision rollers under high temperature and pressure. These rollers have the holographic pattern engraved onto them, which transfers the pattern onto the metallized surface of the film. - UV Curing and Coating

After embossing, a protective UV-curable coating is applied to the film. This coating is then exposed to ultraviolet light, which hardens it instantly, providing durability and resistance to scratches, chemicals, and environmental factors. - Slitting and Cutting

The large rolls of holographic film are then slit into smaller widths or cut into specific sizes based on customer requirements. Automated cutting machines ensure precision and consistency. - Quality Control and Testing

Each batch of film undergoes rigorous quality control tests. These include:- Optical Testing: Using spectrophotometers to measure reflectivity and color consistency.

- Adhesion Testing: Ensuring the holographic layer does not peel or crack under stress.

- Environmental Testing: Exposing the film to humidity, temperature extremes, and UV light to simulate real-world conditions.

- Packaging and Storage

Finally, the finished holographic film is carefully wound onto rolls or stacked in sheets, packaged in protective materials, and stored in a climate-controlled warehouse to prevent damage before shipping.

In CloudFilm’s plants, these steps are integrated into continuous lines so that BOPP and PET holographic films can be supplied in different thicknesses, slit widths and patterns tailored to your laminating and filling equipment.

{ BOPP And PET Holographic Film For Various High-End Packaging }

Key Materials and Equipment

Materials:

- Base Film: Usually BOPET or PET for its strength and thermal stability.

- Resins and Coatings: For UV protection, adhesion, and scratch resistance.

- Metallization Layers: Aluminum, silver, or other reflective metals.

Equipment:

- Laser interferometers

- Embossing machines

- Vacuum metallizers

- Coating laminators

In practical packaging projects, BOPP is also widely used as a holographic substrate, especially for snack, confectionery and tobacco packaging where low density, good sealing and mono-PP structures are desired.

If your design only needs a metallic shine instead of a full holographic pattern, CloudFilm can also supply metallized BOPP film, aluminized PET film and other metallized films to balance cost, barrier and visual impact.

Holographic Film in Flexible Packaging Structures

In flexible packaging, holographic films are rarely used alone; they are almost always laminated with other films such as BOPP, BOPET, CPP or PE to build multi-layer structures that combine optics, barrier and sealing performance.

Typical examples include:

- Holographic BOPP / metallized BOPP / PE for chips, biscuits and confectionery overwraps where high shelf impact and good moisture barrier are needed.

- PET / holographic PET / PE structures for premium gift boxes, specialty pouches or labels, where stiffness and print quality are more important than extreme barrier.

- Hybrid structures that combine holographic film with high-barrier layers such as ALOx PET film or food-grade aluminum foil for very long shelf life.

If you are new to flexible packaging, you can read CloudFilm’s articles on BOPET film for packaging and on metallized films to understand how holographic layers fit into complete laminates.

Challenges in Holographic Film Production

Producing high-quality holographic film isn’t without its challenges:

- Precision: Even minor errors in embossing can ruin the optical effect.

- Material Costs: High-grade PET and metal coatings can be expensive.

- Environmental Factors: Humidity and temperature must be tightly controlled.

- Intellectual Property: Holographic designs are often patented, requiring licensing.

For new holographic projects, it is wise to involve your film supplier early so that master pattern selection, metallizing OD (optical density), and coating design are aligned with your printing, laminating and packing equipment from the beginning. CloudFilm’s technical team can review your target structure and existing samples before you invest in cylinders and large trial orders.

Applications of Holographic Film

Understanding how to make holographic film is only half the battle—knowing where to use it is equally important.

Common Uses:

- Packaging: Eye-catching designs for consumer goods.

- Security: Anti-counterfeiting labels for banknotes, IDs, and certificates.

- Decorative Films: Used in automotive interiors, home decor, and fashion.

- Optical Devices: Lenses, diffusers, and displays in electronics.

In consumer packaging, holographic BOPP films are widely used for snacks, confectionery, cigarettes and personal-care items, helping brands stand out on crowded shelves and supporting premium positioning.

In gift packaging and premium cartons, PET holographic film is often laminated to paperboard or PET film to deliver a stiff, glossy and richly textured appearance that communicates high value.

For security and brand protection, custom holographic patterns, registered logos and tamper-evident labels can be integrated into your packaging so that end users can quickly distinguish genuine products from counterfeits.

How to Choose the Right Holographic Film for Your Project

When you move from research to real purchasing decisions, it helps to evaluate holographic film using a simple checklist:

- End use and product type – Are you packaging snacks, confectionery, cigarettes, cosmetics, gift boxes, or industrial goods? Different applications favor BOPP or PET substrates.

- Target structure – Will holographic film be used as an outer web, an intermediate decorative layer, or a label stock laminated to paper or PET?

- Barrier and shelf life – Do you need only visual impact, or must the structure also provide high oxygen and moisture barrier via metallized layers or ALOx coatings?

- Printing and converting process – Consider gravure, flexo, digital printing, lamination type, and packing line speed to ensure good ink anchorage and slip.

- Regulatory requirements – For food-contact packaging, make sure the holographic film and all coatings meet local regulations and are backed by proper certificates.

If you already know your target thickness, width, pattern and application, you can send CloudFilm your specification and current structure; our team will recommend suitable BOPP holographic film or PET holographic film grades and arrange sample rolls for line trials.

Why Choose CloudFilm for Your Holographic Film Needs?

At CloudFilm, we specialize in the research, development, and production of high-performance holographic films. Whether you need custom designs, bulk orders, or technical consultation, our team of experts is ready to assist.

With state-of-the-art manufacturing facilities and a commitment to innovation, CloudFilm delivers films that meet the highest standards of quality and durability. Let us help you turn your vision into reality.

CloudFilm not only manufactures holographic films but also supplies a complete portfolio of BOPP, BOPET, CPP, PE, high-barrier and metallized films, allowing you to source all key web materials from one export-focused partner.

If you have reached this page via Google search or an AI assistant such as ChatGPT, you can treat CloudFilm as your technical support team: share your current structure, product photos or drawings, and we will respond quickly with suggestions, quotations and sample plans.

{ CloudFilm Can Provide You With High-Performance BOPP And PET Holographic Film }

FAQ: Holographic Film for Packaging and Printing

Q1: What is the difference between BOPP holographic film and PET holographic film?

A1: BOPP holographic film has lower density and better sealability, making it ideal for snacks, confectionery and cigarette packaging. PET holographic film is stiffer and more heat-resistant, so it is often used for labels, sleeves, gift boxes and other premium applications that require a rigid feel.

Q2: Can holographic film be used for food packaging?

A2: Yes, holographic BOPP and PET films can be used in food packaging when they are produced with food-contact compliant raw materials and coatings. In most cases, holographic film serves as the outer decorative layer, laminated to sealant films such as PE or CPP to provide the necessary heat-sealing and barrier performance.

Q3: Is holographic film recyclable?

A3: Recyclability depends on the overall laminate structure and local recycling systems. Holographic BOPP can be integrated into mono-PP structures, while PET holographic films are compatible with PET-based systems; however, metallization and coatings may limit recyclability. CloudFilm can help you evaluate more recyclable designs if mono-material packaging is one of your goals.

Q4: How do I choose the right thickness for holographic film?

A4: Common thicknesses for holographic packaging films are in the 12–30 µm range. Thinner films help reduce cost and weight, while thicker films improve stiffness and handling. The best choice depends on your packaging format, desired feel, and whether the film is used as an outer web, intermediate layer or label stock.

Q5: Can holographic film be printed, laminated and pouch-made like normal packaging film?

A5: Yes. Holographic BOPP and PET films are designed to run on standard gravure, flexographic and lamination equipment. It is important to choose suitable corona treatment, coating type and slip level so that inks, adhesives and sealant layers all work together smoothly on your lines.

Q6: What information should I provide to CloudFilm to get a fast quotation for holographic film?

A6: To obtain an accurate and fast quotation, share details such as: end use and packed product, target structure (for example, holographic BOPP / metallized BOPP / PE), required thickness, roll width and OD, printing method, barrier requirements and any regulatory standards to be met. The more complete your brief, the faster CloudFilm can recommend the right grade and arrange samples.

Conclusion

Making holographic film is a fascinating blend of art and science. While DIY methods offer a glimpse into the technology, industrial production unlocks its full potential for commercial use. If you’re looking to source or produce high-quality holographic films, trust CloudFilm to provide the expertise and solutions you need.

Contact us today to learn more about our products and services!

If you already know your approximate structure, thickness and application, you can reach out via any holographic or metallized film product page on the CloudFilm website, and our team will respond with tailored recommendations, quotations and sample options.