Introduction

In today’s fast-paced food industry, flexible food packaging has become a game-changer. It offers lightweight, customizable, and sustainable solutions that help brands stand out on the shelves while keeping food fresh and safe. But what exactly is flexible food packaging, and why should your business consider it?

This guide will walk you through everything you need to know—from types and benefits to how to choose the right packaging for your products. Whether you’re a startup or an established manufacturer, this article will help you make informed decisions.

If you are comparing suppliers, CloudFilm can support you from base food packaging film selection to finished flexible pouches for snacks, coffee, frozen meat and pet food.

What Is Flexible Food Packaging?

Flexible food packaging refers to any non-rigid packaging structure used to store or transport food products. Unlike rigid containers like glass jars or metal cans, flexible packaging is made from materials such as plastic films, aluminum foil, and paper laminates.

Common forms include:

- Stand-up pouches

- Vacuum-sealed bags

- Retort pouches

- Laminated films

- Roll stock

These materials are chosen for their durability, barrier properties, and adaptability to various food types—from snacks and frozen meals to liquids and powders.

At CloudFilm, most flexible food packaging projects are built from film families such as BOPP film, BOPET film, BOPA film, PE film and CPP film , combined with high-barrier options like ALOx PET film and co-extrusion EVOH film to match your oxygen and moisture barrier requirements.

Why Choose Flexible Food Packaging?

- Lightweight and Cost-Effective

Flexible packaging uses significantly less material than rigid packaging, which reduces raw material costs and shipping expenses. It is ideal for brands looking to optimize cost without compromising protection. - Superior Barrier Protection

With advanced multi-layer structures, flexible packaging can provide excellent barriers against oxygen, moisture, light, and aromas. This helps extend shelf life and maintain product quality. - Customizable Branding and Formats

Flexible packaging supports high-quality printing, custom shapes, and various finishes such as matte, gloss, or soft touch. It gives brands more freedom to communicate their identity and attract consumers. - Sustainability Options

As sustainability becomes more important, flexible packaging offers options like recyclable mono-material structures, PCR-based films, and compostable solutions that align with environmental goals.

By combining high-barrier films such as ALOx PET film or other high barrier films with recyclable PE film or BOPP film, CloudFilm helps you balance product protection, cost and sustainability in one flexible packaging system.

Types of Flexible Food Packaging

Stand-Up Pouches

Stand-up pouches are one of the most popular forms of flexible food packaging. They stand upright on shelves, offer large branding space, and can include features such as zippers, valves, and spouts. They are commonly used for snacks, coffee, dried fruits, pet treats, and more.

CloudFilm supplies a wide range of stand up pouches, flat bottom pouches and quad seal pouches for snacks, coffee and pet food, as well as category-focused packs such as candy packaging bags and coffee packaging bags.

Vacuum Bags

Vacuum packaging removes air from the pack before sealing, which slows down oxidation and microbial growth. Vacuum bags are commonly used for meat, cheese, seafood, and coffee beans, helping preserve freshness and flavor.

For chilled meat, cheese, seafood and coffee beans, CloudFilm can engineer vacuum structures such as PA/PE film, PE PA PE film and high-barrier co-extrusion EVOH films for vacuum bags and thermoforming applications.

Retort Pouches

Retort pouches are designed to withstand high-temperature sterilization processes. They are used for ready-to-eat meals, soups, sauces, and baby food. These pouches provide excellent shelf stability without the need for refrigeration.

If you pack ready-to-eat meals or sauces, CloudFilm can combine retort CPP film with PET or PA layers and also supply finished retort pouches tailored to your filling temperature, retort time and target shelf life.

Spouted Pouches

Spouted pouches are perfect for liquids and semi-liquids such as juices, sauces, baby food, yogurt, and edible oils. The spout design allows easy pouring, re-closing, and controlled dosing.

For liquid and semi-liquid foods, CloudFilm offers leak-resistant spout pouches and liquid pouches with customizable spout positions, shapes and handles, making it easier for brands to switch from rigid bottles to flexible packaging.

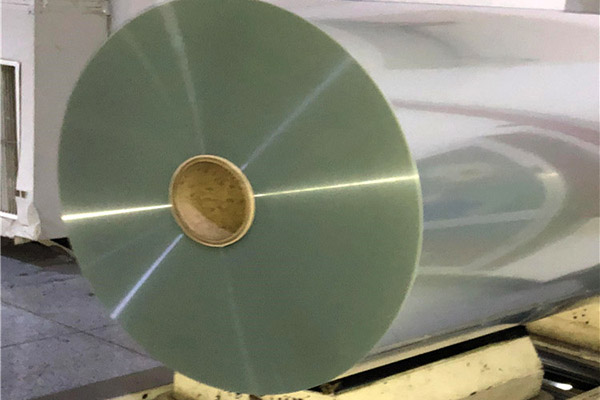

Roll Stock & Flow Wrap Films

Roll stock films are used in automated packaging lines such as horizontal form-fill-seal (HFFS) or vertical form-fill-seal (VFFS) machines. They are ideal for high-speed packaging of snacks, confectionery, bakery products, frozen foods, and more.

If you prefer to form packs on your existing HFFS or VFFS machines, CloudFilm can provide packaging film roll, clear plastic film and printed food packaging film optimized for sealability, slip, stiffness and machinability.

Flexible Food Packaging Structures And Materials

Beyond formats like pouches and roll stock, flexible food packaging performance is largely defined by the film structures behind each application.

- Dry snacks and confectionery often use laminates such as BOPP/CPP, BOPP/metallized BOPP/CPP or PET/PE, balancing gloss, stiffness and sealing performance. CloudFilm’s BOPP film, CPP film and BOPET film ranges can be combined into the structure that fits your line speed and shelf-life needs.

- Coffee and premium tea typically require strong oxygen, aroma and light barrier, so structures like PET/AL/PE, metallized PET/PE or PET/ALOx PET/PE are common choices. Here CloudFilm can leverage aluminized PET film

, ALOx PET film and food grade aluminum foil as the barrier layer. - Frozen meat, seafood and cheese often rely on PET/PE, PA/PE or PE/PA/PE laminates for impact resistance, toughness and seal integrity at low temperature. CloudFilm offers dedicated PA/PE film and PE PA PE film for these demanding applications.

- For brands aiming at recyclable mono-PE packaging, structures based on MDO PE film, BOPE film and PE/EVOH/PE co-extrusion film can replace traditional PET/AL/PE while still offering solid barrier for coffee, meat, pet food and sauces.

- Where visibility and premium “crystal clear” appearance are important, CloudFilm can use transparent high-barrier options like ALOx PET film and crystal flexible packaging structures to show the product while keeping it protected.

For a more technical deep dive into structures and multilayer design, you can also refer to CloudFilm’s guides on multilayer film packaging, PE film and mono-material flexible packaging trends.

How to Choose the Right Flexible Packaging

1. Understand Your Product

Consider your food’s characteristics:

- Is it dry, liquid, frozen, or oily?

- Does it need refrigeration?

- What is its shelf life requirement?

2. Select the Right Material

- PET offers clarity and strength.

- PE provides excellent moisture resistance.

- Aluminum foil delivers the best barrier properties.

- Metallized films are a cost-effective alternative to foil.

3. Focus on Functionality

Do you need:

- Resealable zippers?

- Tear notches?

- Hang holes?

- Transparent windows?

These features enhance user experience and add value.

4. Prioritize Sustainability

Choose materials that align with your brand’s environmental goals. CloudFilm offers recyclable and compostable options to meet modern sustainability standards.

Industry Trends in Flexible Food Packaging

The flexible food packaging industry continues to evolve, driven by consumer expectations and regulatory changes. Key trends include:

- Sustainability-Driven Innovation

Brands are moving towards recyclable mono-material packaging, PCR film integration, and compostable solutions to reduce environmental impact and meet circular economy goals. - Convenience And Portability

On-the-go consumption is rising, and flexible packaging supports portion control, resealability, and easy transport, making it ideal for today’s busy consumers. - Smart Packaging And Digital Printing

QR codes, variable data printing, and digital printing technologies allow brands to create personalized, limited-edition, or region-specific packaging with faster turnaround and lower minimum order quantities. - Shift To Mono-Material And Recyclable Structures

Across snacks, coffee, frozen foods and pet food, more brands are shifting from PET/AL/PE to mono-PE and mono-PP structures that fit established recycling streams. CloudFilm actively supports this move with recyclable pouches, PCR film and mono-material films such as MDO PE and BOPE. - Growth Of Premiumization And Convenience Formats

Premium matte finishes, “crystal clear” windows and innovative pouch formats such as stand-up, flat bottom, quad seal and nozzle pouches are increasingly used to communicate quality and improve convenience. CloudFilm’s flexible pouch portfolio

and guides such as The Ultimate Guide To Pouch Types and Flexible Packaging Solutions can help you benchmark options before investing in tooling.

Why Choose CloudFilm?

At CloudFilm, we specialize in high-quality, custom flexible food packaging solutions. Our offerings include:

- A wide range of materials and structures

- Advanced printing and finishing options

- Sustainable and recyclable packaging choices

- Flexible order quantities to suit businesses of all sizes

From concept to delivery, our team ensures your packaging not only looks great but performs flawlessly.

{ CloudFilm Provides You With High-Quality Flexible Food Packaging Solutions }

Flexible Food Packaging FAQs

1. Which Films Are Commonly Used For Flexible Food Packaging?

Common films include BOPP, PET (BOPET), PA (BOPA), PE and CPP. Each has different strengths: BOPP offers good stiffness and printability, PET provides high strength and temperature resistance, PA adds toughness and puncture resistance, PE and CPP provide sealability and flexibility.

CloudFilm’s portfolio covers all of these film families plus high-barrier options like ALOx PET film, co-extruded EVOH films and high-barrier PE/PA structures.

2. What Kind Of Flexible Packaging Works Best For My Product Type?

- Snacks & confectionery: stand up pouches, pillow pouches and flow-wrap packs made from BOPP/CPP or PET/PE.

- Coffee & tea: high-barrier stand up pouches or flat bottom pouches using PET/AL/PE, PET/ALOx PET/PE or metallized structures.

- Frozen meat & seafood: PET/PE, PA/PE or PE/PA/PE vacuum bags and roll stock.

- Sauces, soups & baby food: retort pouches and spouted pouches.

- Pet food: large quad seal or flat bottom pouches, and recyclable PE pouches for sustainable projects.

CloudFilm can combine films and pouch formats from its flexible pouches and food packaging film ranges to match your product and filling process.

3. Should I Choose Pre-Made Pouches Or Roll Stock For My Food Brand?

Pre-made pouches are ideal if you want strong shelf impact with complex shapes (stand up, flat bottom, quad seal, nozzle pouches) and do not plan to invest heavily in new form-fill-seal equipment. Roll stock is more suitable for very high-speed lines or where you already have HFFS/VFFS machinery in place.

CloudFilm can supply both custom pouches and roll stock film, helping you calculate the total cost per packed unit—including film, conversion, machine speed and labor—before deciding.

4. How Do Flexible Food Packaging Solutions Support Sustainability?

Flexible food packaging can support sustainability through:

- Mono-material structures (mono-PE or mono-PP) that are easier to recycle.

- PCR film that reuses post-consumer plastic.

- Biodegradable and compostable films such as PLA and cellophane for specific markets.

5. What Is The Typical MOQ And Lead Time When Working With CloudFilm?

Minimum order quantities (MOQ) depend on the product type, structure and printing method. Film rolls generally start from a pallet-level MOQ per specification, while many pouch projects can begin with relatively small trial quantities. Several CloudFilm pouch lines highlight “flexible MOQ and fast lead time” to support new product launches and market testing.

If you share your target size, structure and artwork, CloudFilm can confirm the MOQ and estimated production lead time before you commit.

6. Can CloudFilm Help Me Develop Recyclable Or Compostable Flexible Food Packaging?

Yes. CloudFilm works with mono-PE recyclable structures (e.g. MDOPE/PE, BOPE/PE), PCR films, and biodegradable options such as PLA and cellophane. For many food categories, it is possible to redesign existing PET/AL/PE or PET/PA/PE structures into mono-material or low-carbon alternatives while keeping barrier and machinability under control.

7. How Do I Start A Flexible Food Packaging Project With CloudFilm?

You can start by preparing some basic information:

- Product type (snacks, coffee, frozen meat, sauces, pet food, etc.)

- Target markets and shelf-life requirements

- Preferred formats (pouch type or roll stock)

- Existing or reference structures (if any)

- Annual or trial volumes