Introduction: Why BOPP Recycling is One of Today’s Most Critical Topics

From the crisp bag in your hand to the transparent label on a cosmetic bottle, and the film wrapping your bread, BOPP (Biaxially Oriented Polypropylene) film is everywhere. With its excellent clarity, high barrier properties, tensile strength, and printability, it has become the undisputed “star material” of the modern packaging industry.

However, as we enjoy the convenience it brings, a significant environmental challenge emerges: where does all this packaging go after use?

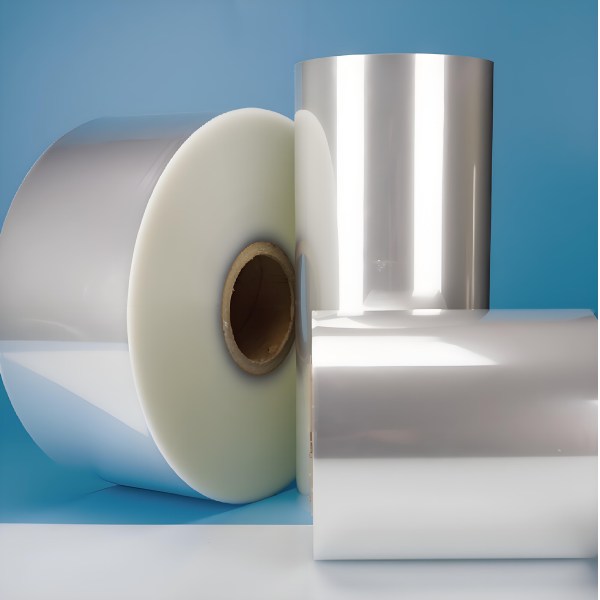

{ Recycling And Pelletizing Of BOPP Film Offcuts }

Despite being theoretically 100% recyclable, the real-world recycling rate for BOPP is far lower than that of materials like PET bottles. What lies behind this discrepancy? This article will take you deep into the world of BOPP, starting with its basic characteristics, dissecting the formidable challenges it faces in recycling, exploring current technological solutions and cutting-edge innovations, and finally, envisioning its future within the circular economy.

Whether you are a brand owner, a recycling company, or an environmentally conscious reader, this guide will provide a comprehensive and practical overview of BOPP recycling.

What is BOPP and Why is Its Recycling So Important?

1.1 Characteristics and Applications of BOPP

BOPP, or Biaxially Oriented Polypropylene, is a film produced by stretching polypropylene resin in both the machine and transverse directions. This “biaxial orientation” structure imparts a range of exceptional properties:

- High Transparency and Gloss: Enhances product presentation.

- Excellent Barrier Properties: Effectively resists moisture, oil, and odors, extending product shelf life.

- High Mechanical Strength: Resists puncture and tearing, protecting products during transport.

- Good Printability: The surface is easily treated for high-quality, durable printing.

Leveraging these advantages, BOPP is widely used in food packaging (e.g., biscuits, candies, instant noodles), labels (e.g., beverage bottles, daily chemicals), adhesive tapes, cigarette packaging, and capacitor films. It is one of the most frequently encountered plastics in our daily lives.

1.2 The Necessity and Urgency of BOPP Recycling

The widespread use of BOPP also implies massive consumption. When these products reach the end of their life, if discarded carelessly, they end up in landfills or the natural environment. Due to the stable chemical nature of polypropylene, its natural degradation process can take hundreds of years, causing long-term white pollution.

More importantly, BOPP is a high-value plastic resource. Through recycling, we can:

- Reduce Virgin Plastic Consumption: Recycling one ton of BOPP saves a ton of petroleum resources.

- Lower Carbon Emissions: The energy required for recycling and reuse is far lower than producing virgin plastic from petroleum.

- Create Economic Value: Recycled BOPP (rBOPP) can re-enter the production chain as a raw material for new products.

- Meet Regulations and Brand Commitments: Globally, governments are introducing stricter plastic packaging regulations (e.g., plastic taxes, EPR schemes), and consumers increasingly favor brands with environmental responsibility. Promoting BOPP recycling is key to corporate compliance and enhancing brand image.

Core Challenges in BOPP Recycling

If BOPP recycling is so important, why does its recycling rate remain low? This is mainly due to the following core challenges:

2.1 Technical Challenge: The “Nightmare” of Composite Materials

This is the biggest technical barrier to BOPP recycling. To achieve more complex functions (such as high-temperature retorting or complete oxygen barrier), BOPP is often laminated with other materials (like PE, PET, aluminum foil, or metallized layers) into multi-layer structures. These “composite materials” are extremely difficult to separate effectively during the physical recycling process due to the different melting points and compatibilities of the materials, leading to low-quality recyclate or rendering it non-recyclable.

2.2 Sorting and Collection Difficulties: The Gap from Source to Factory

- Lack of Consumer Awareness: Most consumers cannot distinguish BOPP from other plastic films (like PE), leading to incorrect sorting.

- Inadequate Recycling Infrastructure: Many municipal recycling systems (e.g., curbside bins) do not accept plastic films because they can interfere with automated sorting equipment. Even where dedicated film drop-off points exist, their coverage and convenience are far inferior to bottle and can recycling.

- Sorting Technology Bottlenecks: In Material Recovery Facilities (MRFs), automated sorting relies mainly on Near-Infrared (NIR) spectroscopy. While NIR can identify PP, it struggles to differentiate BOPP from other PP products (like takeout containers, yogurt cups) and cannot identify the BOPP layer within composite films. Manual sorting is costly and inefficient.

2.3 Economic Challenge: The Cost-Benefit Dilemma

- High Recycling Costs: The entire process of collecting, transporting, cleaning, and sorting BOPP film is relatively expensive. The film is lightweight and bulky, leading to low transport efficiency.

- Unstable Value of Recyclate: Due to the aforementioned technical and sorting issues, the resulting BOPP recyclate often has low purity, a yellowish tint, and degraded performance. Its market price is much lower than virgin BOPP resin and even lower than recycled PET flakes. This leaves recycling companies with insufficient profit incentive to invest in BOPP recycling.

{ BOPP Recycling Reduces Carbon Emissions }

Solutions and Cutting-Edge Technologies for BOPP Recycling

Facing these challenges, global industry players are actively seeking breakthroughs in technology, design, and business models.

3.1 Technological Pathways: Mechanical Recycling vs. Chemical Recycling

- Mechanical Recycling: This is the most mainstream recycling method today. Its process includes collection, sorting, shredding, washing, melting, and pelletizing, ultimately producing recycled plastic pellets.

- Progress: For single-material BOPP waste (e.g., factory offcuts, clean label waste), mechanical recycling technology is already very mature and can produce high-quality rBOPP pellets for non-food contact or some food-contact applications.

- Limitations: For post-consumer composite films, the effectiveness of mechanical recycling remains poor.

- Chemical Recycling: This is a more disruptive, cutting-edge technology. Instead of melting the plastic, it uses chemical methods (like pyrolysis or depolymerization) to break it down into monomers or chemical feedstocks (like naphtha or propylene). These feedstocks can be used to produce new plastics, achieving a “molecular-level” cycle.

- Advantages: Chemical recycling has lower purity requirements for feedstock and can handle mixed plastics and composite films. Theoretically, it enables infinite recycling, and the produced recycled plastic is indistinguishable from virgin plastic in quality.

- Current Status: Chemical recycling is still in the early stages of commercialization. It requires huge investments, has high energy consumption, and needs policy support and large-scale application to reduce costs. However, it is considered one of the ultimate solutions to the BOPP composite film recycling challenge.

3.2 “Design for Recycling”: Solving the Problem at the Source

This is where brand owners and packaging designers can make the biggest impact. By optimizing packaging design, the recyclability of BOPP can be fundamentally improved.

- Material Monomaterial: Use single-material BOPP packaging whenever possible, avoiding lamination with other materials.

- Use Easily Removable Labels: If labels are necessary, use labels and adhesives that are the same material as the container or easily separable.

- Eliminate Problematic Additives: Avoid using colors (like carbon black), metalized layers, or certain inks that can contaminate the recycling stream.

- Follow Design Guidelines: Refer to recyclability design guidelines published by industry organizations (e.g., CEFLEX, APR) to ensure packaging is compatible with modern recycling facilities.

3.3 Industry Collaboration: Building a BOPP Recycling Ecosystem

Efforts in any single link are difficult to succeed alone. The success of BOPP recycling depends on close collaboration across the entire value chain:

- Brand Owners: Commit to using recycled content, invest in “Design for Recycling,” and fund recycling projects.

- Packaging Producers: Develop more easily recyclable BOPP products and utilize their production networks to recycle industrial waste.

- Recycling Companies: Invest in more advanced sorting and cleaning technologies to improve the quality and yield of recyclate.

- Sorting Facilities: Upgrade NIR and AI sorting technologies to more accurately identify and sort BOPP waste.

- Government & Industry Associations: Establish unified recycling standards and sorting guidelines, provide financial subsidies, implement Extended Producer Responsibility (EPR) schemes, and conduct public education.

Future Outlook for BOPP Recycling

The future of BOPP recycling will be driven by a combination of technology, policy, and market forces.

- Technological Convergence: In the future, we may see a hybrid model of “intelligent sorting + efficient mechanical recycling + chemical recycling.” AI and robotics will greatly improve sorting purity. High-quality, single-material BOPP will enter the mechanical recycling stream, while complex composite films will be directed to chemical recycling plants, ensuring every material is used to its fullest potential.

- Policy-Driven: Governments worldwide will introduce stricter regulations, mandating recycled content in packaging and imposing extra fees on non-recyclable packaging. This will strongly incentivize brand owners and packaging companies to switch to recyclable BOPP solutions.

- Market Opportunities: With growing consumer environmental awareness and brand sustainability commitments, the demand for rBOPP will surge. Companies that master high-quality BOPP recycling technologies first will gain a first-mover advantage in the future green economy. BOPP recycling will no longer be a “cost center” but a “value center” full of potential.

Conclusion: Co-Creating a Circular Future for BOPP

The challenges of BOPP recycling are immense, but so are the opportunities. It is not merely a technical problem but a systematic engineering challenge involving design, production, consumption, recycling, and regeneration. Through innovative technologies, forward-thinking design, close industry collaboration, and supportive policies, we have the full capacity to transform this ubiquitous “packaging star” into a shining pearl in the circular economy.

{ CloudFilm Provides You With High-Quality PCR BOPP (rBOPP) }

Call to Action:

- To Brand Owners: Immediately review your packaging portfolio, invest in “Design for Recycling,” and actively seek recycling partners.

- To Recycling Companies: Pay attention to cutting-edge technologies and position yourself in the high-potential track of BOPP recycling.

- To Consumers: Sort correctly and support brands that are committed to sustainable packaging.

The circular future of BOPP requires the participation of every one of us. Let’s work together to ensure that the end of every package marks the beginning of a new life.