Introduction

Nylon film, a versatile and high-performance material, has gained immense popularity across various industries due to its exceptional properties. At CloudFilm, we specialize in delivering high-quality nylon films tailored to meet diverse industrial needs.

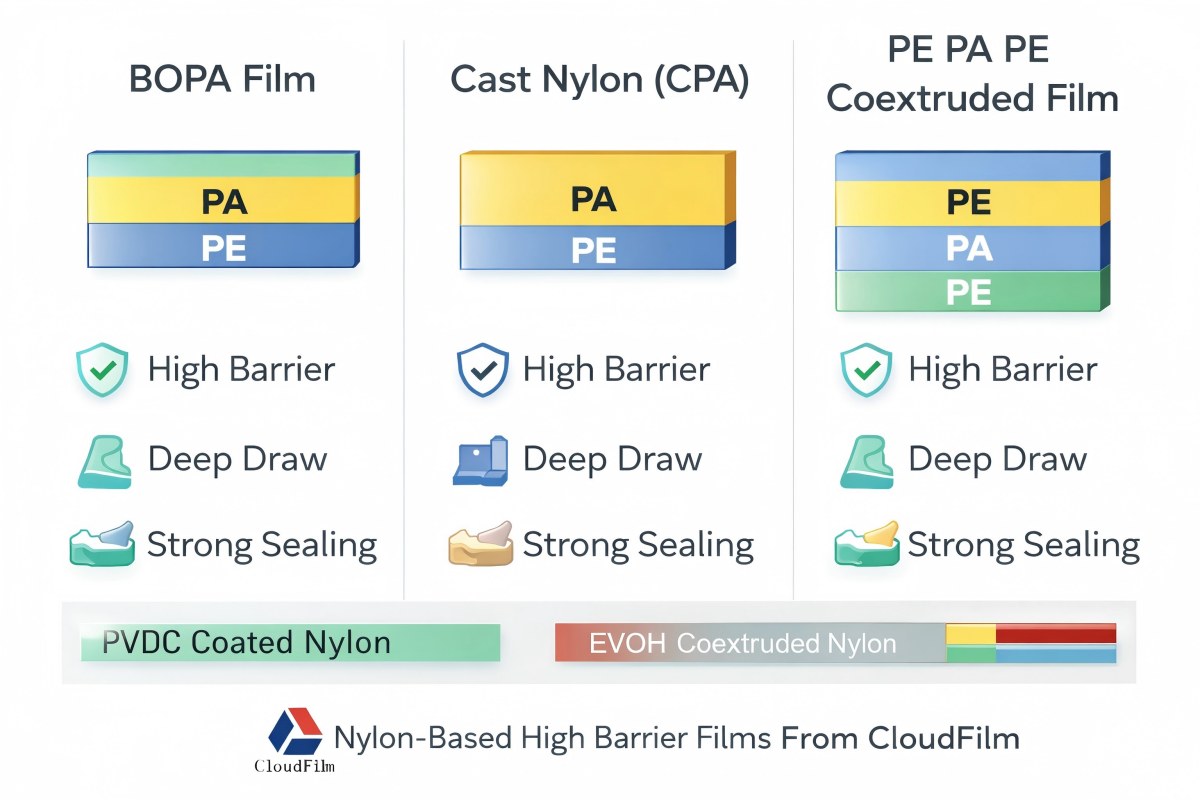

Our portfolio includes biaxially oriented BOPA film, simultaneous BOPA film and cast nylon film , as well as nylon/PE coextruded structures such as PE PA PE film

to support demanding flexible packaging applications.

In this guide, we will explore the key properties of nylon film, its applications, advantages, and limitations, helping you make informed decisions for your projects. Whether you are a converter, brand owner or packaging buyer, this article will help you compare nylon film with other high-barrier materials and choose the right CloudFilm structure for your line.

{ Nylon Film Production Line }

Overview of Nylon Film

Nylon film, also known as polyamide film, is a synthetic polymer film made from nylon resins. It is widely recognized for its excellent mechanical strength, flexibility, and barrier properties. These characteristics make it an ideal choice for demanding applications in packaging, automotive, electronics, and more.

From a material point of view, nylon film belongs to the polyamide family (most commonly PA6 or PA66), and in flexible packaging it is usually oriented into thin BOPA film or produced as cast nylon film for deep-draw thermoforming. Compared with simple PE and PP films, nylon delivers a much stronger oxygen and aroma barrier while keeping high toughness, which is why buyers specify it in vacuum, MAP and retort structures.

Types Of Nylon Film In Flexible Packaging

In real projects, “nylon film” usually refers to several practical film families that CloudFilm can supply and combine into multilayer laminates. Choosing the right type directly affects barrier level, formability, sealing performance and total cost.

- BOPA Film (Biaxially Oriented Polyamide) – A thin, oriented nylon film mainly used as the high-barrier layer in laminates such as BOPA/PE, BOPA/CPP and BOPA/AL/CPP. For detailed specifications, see CloudFilm’s BOPA film and simultaneous BOPA film pages, which highlight its excellent gas barrier, puncture resistance and clarity.

- Cast Nylon (CPA) Film – A non-oriented PA6 film produced via a cast (quench) process. It offers deep-draw thermoformability for bottom webs, strong puncture resistance and oxygen barrier, making it ideal for bone-in meats, cheeses and shaped MAP packs. For thermoformable CPA solutions, see CloudFilm’s cast nylon film.

- Coextruded Nylon/PE Films (PE PA PE Film) – Multilayer structures with a nylon core and PE seal layers such as PE PA PE film. These high-barrier films are widely used for vacuum pouches, thermoforming bottom webs and heavy-duty FFS bags that must combine puncture resistance with clean, reliable seals.

- Nylon-Based High-Barrier Films (KPA/PE, PVDC Or EVOH Coextruded Structures) – When very high barrier is required, nylon can serve as the base in PVDC-coated KPA films, as described on CloudFilm’s PVDC coated film and PVDC PET pages, or be coextruded with EVOH in co-extrusion EVOH film, allowing you to approach foil-like barrier while maintaining transparency.

CloudFilm can help you compare these nylon-based films with other high-barrier webs such as ALOx PET and PVDC PET so you can build a complete packaging family, not just a single film roll.

Key Properties of Nylon Film

Mechanical Strength

Nylon film exhibits outstanding tensile strength and puncture resistance, making it suitable for heavy-duty packaging applications. It can withstand significant stress without tearing, ensuring the integrity of packaged goods.

In practice, this toughness is why nylon-based structures such as PE PA PE film and PA/PE laminates are often selected for bone-in meat, cheese blocks and other packs that must survive frozen and export logistics without bursting or pinholing.

Thermal Resistance

With a high melting point, nylon film performs well under elevated temperatures. This property is particularly beneficial in applications involving heat sealing or sterilization processes.

BOPA and cast nylon films are frequently used in retortable laminates—such as PET/PA/RCPP or PA/AL/RCPP—where pouches must withstand 121 °C retort conditions while maintaining toughness, seal integrity and clear appearance.

Barrier Properties

Nylon film provides excellent resistance to gases, oils, and chemicals. Its low oxygen permeability helps extend the shelf life of perishable products, making it a preferred material in food packaging.

Compared with simple PE or PP films, nylon provides a significantly higher oxygen and aroma barrier, and when combined with PVDC coated or EVOH coextruded films from CloudFilm’s high-barrier portfolio, you can approach aluminium-foil-like shelf life with a thinner, more flexible pack.

Flexibility and Transparency

Despite its strength, nylon film remains flexible and transparent, allowing for easy handling and visibility of packaged contents. This combination is crucial for consumer-facing packaging solutions.

For thermoforming and vacuum applications, cast nylon film provides excellent deep-draw formability while keeping high clarity, allowing shoppers to see cheeses, cold cuts or medical devices clearly inside the pack.

Applications of Nylon Film

Food Packaging

Nylon film is widely used in food packaging due to its barrier properties and ability to preserve freshness. It is commonly found in vacuum-sealed bags, frozen food packaging, and snack food wrappers.

Within CloudFilm’s portfolio, nylon is frequently used in retort pouches, vacuum skin packs and thermoforming webs for ready meals, sauces, pet food and cheese, often combined with PE or CPP seal layers and high-barrier webs to deliver both shelf life and machinability.

Industrial Applications

In industrial settings, nylon film is used for protective covers, insulation materials, and component packaging. Its durability and resistance to harsh environments make it a reliable choice.

Nylon-based laminates help protect metal parts, electronics and automotive components from puncture, abrasion and oxidation, and CloudFilm can integrate nylon layers into wider packaging film roll solutions tailored to your existing lines and packing formats.

Medical and Pharmaceutical

The medical industry utilizes nylon film for sterile packaging, medical device pouches, and pharmaceutical blister packs. Its ability to maintain sterility and resist chemicals is critical in these applications.

For projects that demand extra barrier or peelable lidding, nylon can be combined with PVDC PET, ALOx PET or aluminium foil to create custom structures for pharmaceutical pouches and healthcare sachets that must survive transport and sterilization.

Advantages of Nylon Film

- High durability and tear resistance

- Excellent barrier against moisture, gases, and oils

- Thermal stability for high-temperature processes

- Flexibility and clarity for versatile applications

- Customizable to meet specific industry needs

n addition, nylon film is highly compatible with high-barrier structures such as PVDC coated films and EVOH coextruded films, enabling premium packs with extended shelf life for coffee, snacks, meat and medical products.

For packaging buyers, these advantages mean that correctly specified nylon film from CloudFilm can reduce product damage, improve shelf life and unlock premium formats such as retort pouches, MAP trays and deep-draw thermoforming packs.

{ Nylon Film Has Excellent Barrier Properties }

Limitations of Nylon Film

1. High Moisture Absorption

One of the primary drawbacks of nylon film is its tendency to absorb moisture. When exposed to humid environments, the film can absorb water, leading to dimensional changes and reduced mechanical strength. This can affect performance in applications requiring consistent physical properties.

In critical applications, CloudFilm helps customers design laminates and storage conditions that minimize humidity impact, for example by combining nylon with high-moisture-barrier films and defining suitable warehousing standards.

2. Higher Cost

Compared to other plastic films like polyethylene (PE) or polypropylene (PP), nylon film is more expensive. The higher cost is due to the raw materials and complex manufacturing processes involved, which may limit its use in cost-sensitive applications.

By optimizing thickness and mixing nylon strategically with more economical resins, CloudFilm often keeps nylon only where it is technically necessary, balancing performance with total cost.

3. Limited UV Resistance

Nylon film is susceptible to degradation when exposed to prolonged UV radiation. This can result in discoloration, embrittlement, and loss of mechanical properties, making it less suitable for outdoor applications unless specially treated or coated.

For outdoor or semi-outdoor projects, CloudFilm can recommend UV-stabilized structures or suggest alternative high-barrier films that perform better under sunlight.

4. Processing Challenges

The production of nylon film requires precise control over temperature and humidity during processing. Any deviation can lead to defects such as bubbles or uneven thickness, increasing production complexity and cost.

CloudFilm invests in process control, testing and roll geometry management so converters receive nylon film with stable thickness, flatness and winding quality, reducing waste and setup time on their lines.

5. Environmental Concerns

Like many synthetic polymers, nylon film is not biodegradable and poses challenges for disposal and recycling. As environmental regulations become stricter, the sustainability of nylon film is an area that requires ongoing innovation and improvement.

CloudFilm is actively developing recyclable mono-material structures (for example mono-PE solutions) and lighter high-barrier films so that nylon can be reserved only for applications where its unique performance is truly necessary.

How CloudFilm Addresses These Challenges

At CloudFilm, we understand the limitations of nylon film and are committed to providing solutions that mitigate these challenges. Our advanced manufacturing processes ensure consistent quality, while our R&D team continuously works on enhancing the environmental profile of our products.

We offer customized formulations to improve moisture resistance and UV stability, ensuring our nylon films meet the highest industry standards.

Drawing on more than two decades of experience in flexible packaging films, CloudFilm combines nylon with PE, CPP, PVDC coated films and EVOH coextruded films to build multilayer structures tailored to your products, markets and machinery.

In practice, we regularly supply BOPA/PE and PA/PE rollstock, nylon-based thermoforming webs and nylon+PVDC structures (such as KPA/PE or KPA/CPP) for retort pouches, cheese packs, processed meat and high-value snacks, helping customers balance barrier, cost and processability.

How To Start A Nylon Film Project With CloudFilm

Whether you already have a nylon film specification or are just starting to explore options, CloudFilm can act as your engineering-driven partner rather than a simple film trader.

A practical way to start is:

- Share your product and format – for example, bone-in meat in vacuum bags, MAP thermoforming packs for cheese, or retort pouches for pet food.

- Describe your current or target structure – such as BOPA/PE, PA/AL/RCPP, PE PA PE, or alternative high-barrier designs.

- Tell us your process conditions – forming depth, sealing temperature, line speed, sterilization requirements and target shelf life.

- Request samples and trials – CloudFilm can provide A4 sheets or short trial rolls so you can run tests before moving to container-load volumes.

Conclusion

Nylon film is a remarkable material with a unique combination of properties that make it indispensable across various industries. While it has certain limitations, understanding these challenges allows for better application selection and optimization.

{ CloudFilm Is Your Trustworthy Partner }

CloudFilm is your trusted partner in navigating the world of nylon films, offering expertise, quality, and tailored solutions to meet your specific needs.

By involving CloudFilm early in structure design, printing and converting discussions, you can unlock nylon’s full potential in your flexible packaging portfolio and build a long-term, reliable supply base.

Nylon Film FAQ: Selection, Structures And Projects

FAQ 1. What Is The Difference Between BOPA Film And Cast Nylon Film?

BOPA film is a biaxially oriented nylon film with high tensile strength, good stiffness and excellent gas barrier, mainly used as a thin barrier layer in laminates such as BOPA/PE and BOPA/CPP. Cast nylon (CPA) film is a non-oriented PA6 film with outstanding deep-draw thermoformability, ideal for thermoforming bottom webs and vacuum packs.

If you need a thin, strong barrier web for printing and lamination, BOPA is usually the first choice. If you need deep forming and high impact resistance (for example bone-in meats), cast nylon is often more suitable.

FAQ 2. When Should I Choose Nylon Film Instead Of EVOH Or PVDC?

Nylon film is excellent when you need a combination of toughness, puncture resistance and medium-to-high oxygen barrier, especially in vacuum, MAP and retort packs. EVOH and PVDC can provide even higher barrier but usually need to be protected inside coextruded or coated structures.

For many projects, CloudFilm will combine nylon with EVOH or PVDC (for example PE PA PE, PA/EVOH/PE, KPA/PE or PVDC PET/PA/PE) so you get both mechanical strength and very high barrier. If you are comparing nylon with EVOH, you can also read the article Difference Between Nylon And EVOH.

FAQ 3. Can Nylon Film Be Used In Recyclable Mono-Material Packaging?

Most classic nylon structures (such as PA/PE or PE PA PE) are not yet accepted as “mono-PE recyclable” in many recycling schemes, because nylon and PE are different polymer families.

However, nylon may still be necessary for certain high-barrier, high-toughness applications. In parallel, CloudFilm is developing mono-PE and mono-PP solutions using MDO PE and BOPE film for projects where recyclability is the top priority, while nylon is reserved for applications that truly require its performance.

FAQ 4. What Thickness And Width Ranges Do CloudFilm Nylon Films Offer?

For BOPA film, CloudFilm typically supplies thicknesses from about 10–40 μm and widths up to around 2100 mm, suitable for lamination, printing and slitting. Cast nylon film is usually available from about 19–125 μm as monolayer CPA and much higher gauges in coextruded PA-based thermoforming films. PE PA PE films are typically engineered in the 50–150 μm range.

Exact gauges, widths and core sizes can be tailored; sharing your pack format and forming depth with CloudFilm will allow the team to recommend a practical specification.

FAQ 5. How Does Moisture Absorption Affect Nylon Film In Real Packaging?

Nylon absorbs moisture from the environment, which can soften the film and slightly change dimensions and barrier levels. In many food packs, this effect is manageable because the nylon layer is protected inside a laminate and the pack is stored in controlled conditions.

For very humidity-sensitive applications, CloudFilm may suggest combining nylon with high-moisture-barrier films, using coextruded PE PA PE film with optimized PA content, or switching to alternative structures if moisture control is not feasible.