Introduction

In the world of flexible packaging, metalized BOPP film stands out for its excellent barrier properties, glossy appearance, and versatility. But what exactly is metalized BOPP film density, and why does it matter?

Whether you’re a packaging engineer, a procurement specialist, or a researcher, understanding this key parameter is crucial for selecting the right material for your application. In this guide, we’ll break down what density means in the context of metalized BOPP films, how it’s measured, and how it impacts performance. Let’s dive in.

As a metallized film supplier, CloudFilm helps brands and converters match density, thickness and barrier levels for real-world projects—from coffee valves and snack webs to pharmaceutical and pet food overwraps. This article is designed to help you speak the same technical language when you request metallized BOPP film, aluminized PET film or metallized CPP film from CloudFilm.

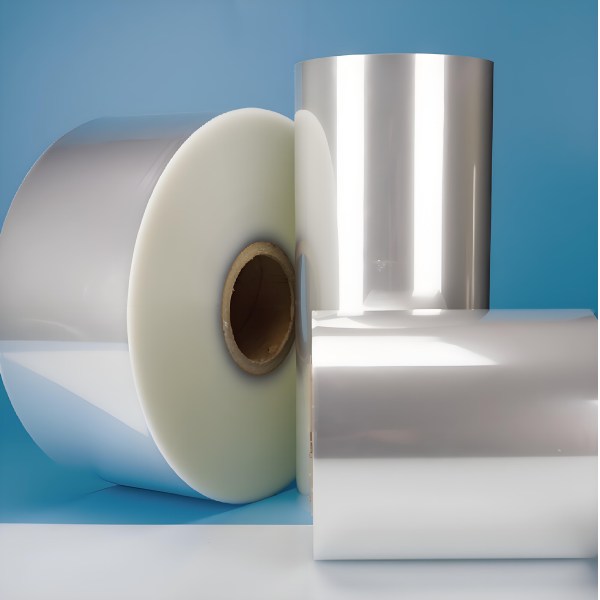

{ BOPP Vacuum Metallizing Equipment }

What Is Metalized BOPP Film?

Before discussing density, it’s important to understand the material itself. Biaxially Oriented Polypropylene (BOPP) is a popular polymer film known for its clarity, tensile strength, and thermal stability. When a thin layer of aluminum is vacuum-deposited onto its surface, it becomes metalized BOPP film, gaining enhanced barrier properties against moisture, oxygen, and light.

This metalization process makes the film ideal for food packaging, labels, and decorative laminates. However, the performance of the film depends heavily on its physical properties—one of the most critical being density.

Compared with clear BOPP gloss film or BOPP matte film, metalized grades dramatically improve light and oxygen barrier, which is why they are often combined with BOPP pearlized film or aluminized PET film in premium snack, coffee and confectionery packaging.

Why Does Density Matter?

Density in metalized BOPP film refers to the mass per unit volume, typically expressed in g/cm³. It influences several key aspects:

- Barrier Performance: Higher density often correlates with better moisture and oxygen barrier properties.

- Mechanical Strength: Density affects tensile strength and puncture resistance.

- Optical Properties: Density can influence opacity, gloss, and transparency.

- Processability: Inconsistent density may cause issues during printing, laminating, or converting.

For engineers and product designers, selecting a film with the right density ensures the final product meets functional and aesthetic requirements.

In purchasing and costing, density also offers a quick way to compare material usage between different structures—for example, choosing between a metalized BOPP // PE laminate and an equivalent PET // PE or PET // metallized CPP film structure. A small change in density, multiplied across millions of packs, can translate into significant annual savings.

If you already work with GSM (g/m²) and yield, CloudFilm’s article on flexible film density, formulas and yield shows how density links roll weight to square meters and finished pouch counts—knowledge that applies directly to metalized BOPP films as well.

{ Metalized BOPP Film Density Tester }

How Is Metalized BOPP Film Density Measured?

Density is typically calculated using the formula:

Density=Mass / Volume

In practice, the process involves:

- Measuring the mass of a film sample using a precision balance.

- Calculating volume based on area and thickness (measured via micrometer or optical gauge).

- Dividing mass by volume to obtain density in g/cm³.

Modern testing methods may also include automated density analyzers for higher accuracy and repeatability.

In CloudFilm’s lab, density checks are usually combined with thickness, optical density (OD) and barrier tests (OTR/WVTR). That means when you specify a particular grade of metallized BOPP film, you receive rolls whose density, coating weight and barrier levels are all documented on the certificate of analysis.

Linking Metalized BOPP Film Density to Thickness, Yield and Cost

From a practical point of view, density is most useful when you combine it with thickness to estimate grammage (GSM) and yield. Using the simple relationship Thickness (µm) ≈ GSM ÷ Density (g/cm³), you can quickly compare metalized BOPP against clear BOPP film or BOPET film at the same packaging performance level.

Example: A 15 µm metalized BOPP film with a density of 0.91 g/cm³ has a grammage of roughly 13.7 g/m². If you purchase 1,000 kg of this grade, you get around 73,000 m² of film—enough for millions of small snack packs depending on the pouch dimensions.

When you design complete laminates such as BOPP // BOPP PE structures or PET // VMCPP, running these yield calculations together with CloudFilm’s engineers helps you hit cost-per-pack targets while still meeting barrier and shelf-life requirements.

Factors Affecting Metalized BOPP Film Density

Several variables can influence the density of metalized BOPP films:

- Base Polymer Properties: Variations in polypropylene resin can affect density.

- Metalization Thickness: Thicker aluminum layers increase overall density.

- Production Process: Parameters like extrusion temperature, stretching ratios, and cooling rates play a role.

- Additives and Coatings: Additional layers or additives can modify density.

Understanding these factors helps manufacturers fine-tune production to meet specific application needs.

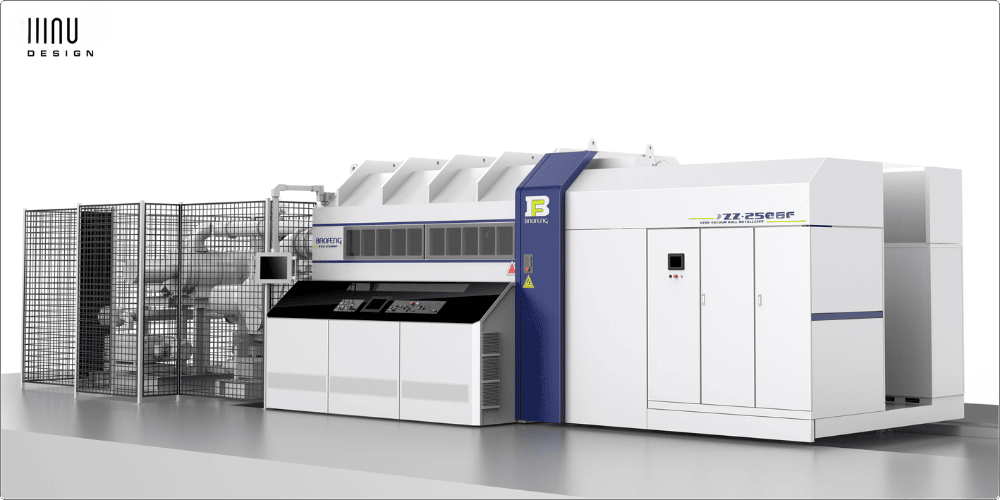

In vacuum metallizing, parameters such as web speed, aluminum wire feed rate, chamber pressure and cooling conditions all subtly influence both coating weight and apparent density. CloudFilm’s production team adjusts these variables to achieve the target optical density (OD) and barrier level, as described in our guide to the metalized film manufacturing process.

For a broader overview of how different substrates—BOPP, PET, CPP and CPE—behave after metallizing, you can also review CloudFilm’s metallized films overview.

Typical Density Values and Industry Standards

While density values can vary, typical metalized BOPP films range between 0.90–0.93 g/cm³. Industry standards such as ASTM D792 and ISO 1183 provide guidelines for testing and reporting density values.

By comparison, clear BOPP films typically fall around 0.90–0.91 g/cm³, while BOPET polyester films and BOPA nylon films are closer to 1.30–1.40 g/cm³. These higher-density substrates are stiffer and heavier at the same thickness, which is why many food brands use metalized BOPP as a lighter-weight alternative to VMPET or aluminum foil structures when designing cost-efficient packaging.

Applications and Density Considerations

Different applications demand different density profiles:

| Application | Recommended Density Range | Key Considerations |

|---|---|---|

| Food Packaging | 0.91–0.93 g/cm³ | High barrier, sealability |

| Labels & Graphics | 0.90–0.92 g/cm³ | Printability, gloss |

| Industrial Laminates | 0.91–0.93 g/cm³ | Durability, chemical resistance |

Selecting the correct density ensures optimal performance in end-use environments.

In practice, some typical density–application pairings for metalized BOPP are:

- Food packaging: 0.91–0.93 g/cm³ for high-barrier laminates such as metalized BOPP // PE, PET // metallized CPP film or PET // metallized CPE film, where moisture and oxygen barrier are critical.

- Labels and graphics: 0.90–0.92 g/cm³ for printable webs paired with BOPP printing film or clear overlaminates, where flatness and gloss are priorities.

- Industrial and technical laminates: 0.91–0.93 g/cm³ for structures that incorporate BOPA film, CPP film or aluminum foil, where stiffness, puncture resistance and chemical resistance must be robust.

How CloudFilm Supports Your Metalized BOPP Film Selection

CloudFilm manufactures and exports a complete portfolio of metallized films including metallized BOPP film, aluminized PET film, metallized CPP film and metallized CPE film. This allows you to build full laminates from one supplier while keeping density, OD and barrier performance under tight control.

When you share your target density range, film thickness, OD value and packaging format, CloudFilm’s engineers can recommend suitable grades, suggest structures such as metalized BOPP // PE, PET // VMCPP or PET VMPET PE, and provide trial rolls for line testing. For broader development work, you can also refer to our guide on custom flexible packaging solutions for brands.

From laboratory sampling to container shipments, CloudFilm focuses on stable quality, export-ready documentation and responsive technical support—so your density discussions translate into real, commercial packaging results.

FAQ: Metalized BOPP Film Density

Here are some frequently asked questions to further clarify common concerns:

Q: Is higher density always better?

A: Not necessarily. While higher density can improve barrier properties, it may reduce flexibility or increase cost. Balance is key.

Q: How does density differ from thickness?

A: Thickness measures the physical dimension (microns), while density reflects mass per unit volume. They are related but distinct properties.

Q: Can CloudFilm provide custom density films?

A: Yes! CloudFilm offers tailored solutions to meet specific density and performance requirements. Contact our team for details.

Q: How should I choose the right density for my packaging project?

A: Start from your end-use requirements: barrier, stiffness, sealability and machinability. Then, review typical density ranges for your application and compare metalized BOPP with alternative films such as PET or nylon. Tools like CloudFilm’s BOPP density guide and flexible film density tables can help you connect density to GSM, yield and cost-per-pack. You can also share your target structure with CloudFilm so our engineers can suggest a practical density window.

Q: Does metalized BOPP film density affect recyclability?

A: Density itself has less impact on recyclability than the overall structure. Most metalized BOPP films are used in multi-material laminates that are not yet widely recycled. However, understanding density and coating weight helps you minimize unnecessary material usage and supports lightweighting initiatives. For a deeper discussion, see CloudFilm’s article on BOPP recycling: from challenges to solutions.

Q: What density differences should I expect between metalized BOPP and clear BOPP?

A: Clear BOPP films are typically around 0.90–0.91 g/cm³. Adding a thin aluminum layer slightly increases the apparent density, so metalized BOPP grades often fall closer to 0.91–0.93 g/cm³. The exact value depends on the base film, metal layer thickness and any coatings or primers.

Q: Can CloudFilm include density data on certificates and technical datasheets?

A: Yes. For regular production orders, CloudFilm can provide technical datasheets and certificates of analysis that summarize key parameters such as density range, thickness, OD, OTR/WVTR, COF and sealing performance. If you have specific reporting requirements, let our team know when you request a quotation or sample.

Conclusion and Call to Action

{ Exploring CloudFilm’s High-Performance Metallized BOPP Films }

Understanding metalized BOPP film density is essential for optimizing material selection and ensuring product performance. Whether you’re designing packaging, sourcing materials, or conducting research, this guide provides the foundation you need.

Ready to explore high-performance metalized BOPP films?

Visit the CloudFilm product page for detailed specifications, or reach out to our engineering team for custom solutions.

With more than 20 years of flexible packaging film experience, CloudFilm can integrate metallized BOPP, PET, CPP, CPE and high-barrier films into one coordinated supply chain—helping you turn technical density data into competitive, export-ready packaging.