Introduction

In the world of flexible packaging, BOPP (Biaxially Oriented Polypropylene) pearlized film stands out for its excellent printability, visual appeal, and versatility. Among its various technical properties, density plays a crucial role in determining the film’s performance, cost, and suitability for different applications.

This article will explore what BOPP pearlized film density means, how it affects the film’s characteristics, and how to select the right density for your packaging needs. Whether you are a packaging designer, engineer, procurement specialist, or student, this guide will provide you with the knowledge you need to make informed decisions.

For readers who are actively sourcing materials, you can treat this guide as a practical checklist to discuss density, thickness and yield with your suppliers and internal teams, so that your next project starts with clear numbers instead of guesswork.

If you already use clear or matt BOPP films, understanding pearlized BOPP density will also help you compare yield and cost with other structures and decide when upgrading to a pearlized look makes commercial sense.

CloudFilm has integrated this density know-how into its daily technical support, helping buyers link density data directly to roll weight, square-meter yield and cost-per-pack in real projects.

{ BOPP Pearlized Film }

What is BOPP Pearlized Film?

BOPP pearlized film is a type of polypropylene film that has been treated with special additives to create a pearlescent or matte appearance. This film is widely used in packaging for consumer goods such as snacks, confectionery, personal care products, and more.

The pearlized effect is achieved by incorporating calcium carbonate or other pearlescent agents into the polymer matrix. During the biaxial orientation process, these agents create micro-voids within the film structure, resulting in its distinctive visual and physical properties.

In practice, many converters specify BOPP pearlized film as the outer web in ice cream pillow wraps, chocolate bar flow-packs, soap overwraps and full-body wrap-around labels where a white opaque, “creamy” background is required.

CloudFilm’s dedicated BOPP pearlized film grades combine this visual effect with stable machinability on high-speed HFFS/VFFS lines, helping brands upgrade shelf impact without sacrificing line efficiency.

Why Does Density Matter?

Density is defined as mass per unit volume, typically expressed in grams per cubic centimeter (g/cm³). In the context of BOPP pearlized film, density affects:

- Mechanical Strength: Higher density films tend to be stronger and more resistant to tearing and puncturing.

- Optical Properties: Lower density films often have better opacity and a more pronounced pearlescent effect.

- Cost Efficiency: Since density is directly related to material usage, optimizing density can lead to significant cost savings in large-scale production.

- Processing Performance: Films with different densities behave differently during printing, laminating, and converting processes.

Understanding these relationships helps manufacturers and designers choose the most suitable film for their specific applications.

From a purchasing point of view, density is the hidden link between thickness (µm), GSM (g/m²) and yield (m²/kg) — choosing a lower-density pearlized film can increase the number of packs per kilogram while still keeping the required stiffness and opacity.

For brand owners focused on sustainability, fine-tuning density is also one of the easiest ways to reduce plastic consumption per pack without changing existing artwork or packaging machines.

Typical Density Values in the Industry

In practice, the density of BOPP pearlized film typically ranges from 0.6 to 0.9 g/cm³, depending on the formulation and manufacturing process. Here’s a breakdown of common density categories:

| Density Range (g/cm³) | Characteristics | Common Applications |

|---|---|---|

| 0.60–0.70 | Very lightweight, high opacity, soft feel | Luxury packaging, labels, gift wraps |

| 0.71–0.80 | Balanced strength and appearance | Food packaging, confectionery wraps |

| 0.81–0.90 | Higher strength, stiffer feel | Heavy-duty bags, industrial packaging |

These values are approximate and can vary based on the specific grade and manufacturer. Always consult technical data sheets for precise specifications.

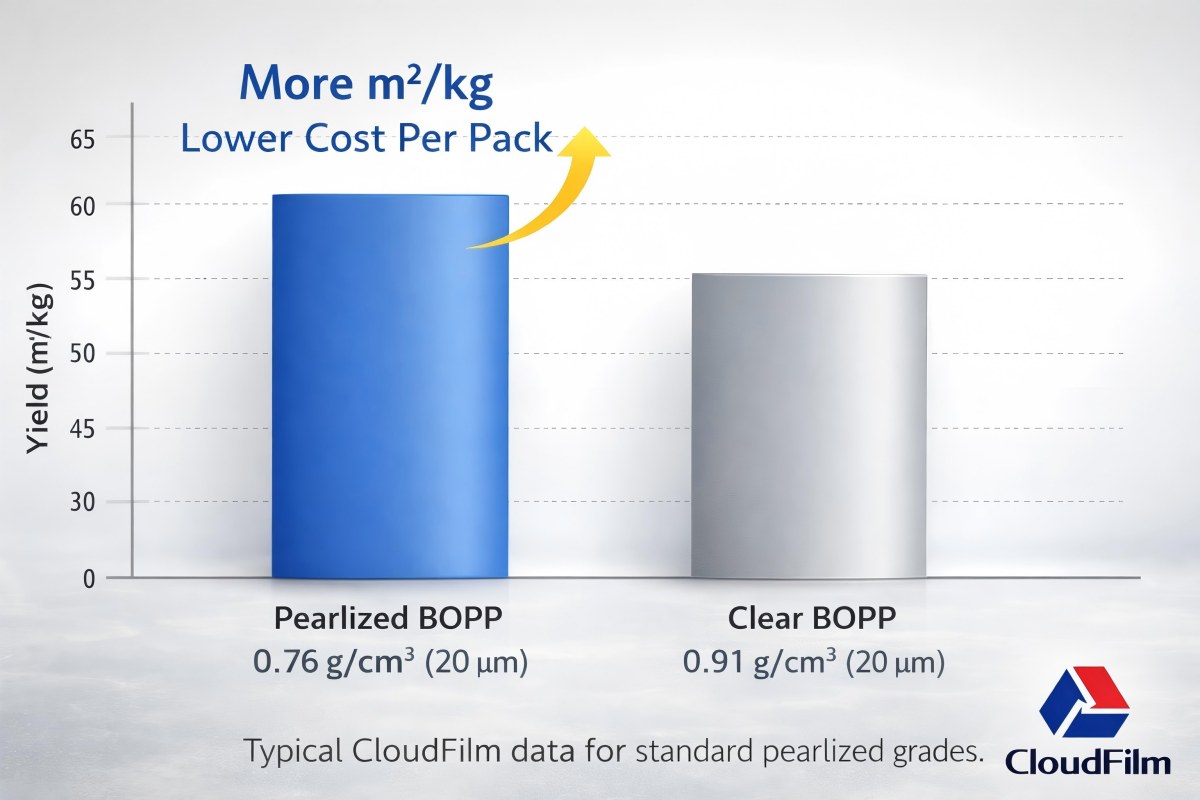

Many CloudFilm BOPP pearlized film grades are engineered around a typical density of about 0.76 g/cm³, giving converters a strong balance between high opacity, good hand-feel and attractive yield compared with standard clear BOPP (≈0.90–0.92 g/cm³).

If your project needs to combine pearlized film with other BOPP types such as matt or gloss BOPP, CloudFilm can recommend density “windows” that keep the overall laminate stable on press and on form-fill-seal lines.

{ BOPP Pearlized Film for Bottle Labels }

Practical Example: How Density Influences Yield and Cost

For many buyers, the most intuitive way to “see” density is through yield — how many square meters of film you get per kilogram. Using the common rule of thumb Yield (m²/kg) ≈ 1000 ÷ (Density × Thickness in µm), a 20 µm pearlized BOPP at 0.76 g/cm³ gives roughly 65 m²/kg, while a 20 µm clear BOPP at 0.91 g/cm³ only delivers about 55 m²/kg.

That difference of roughly 10 m²/kg can translate into thousands of extra ice-cream or candy packs per pallet, especially when you run large-scale seasonal promotions.

If you need more detailed formulas and reference tables for BOPP, PET, PE and other films, you can refer to CloudFilm’s technical article Flexible Film Density: Formulas, Tables & Yield, which many of our customers use as a daily quotation and costing tool.

Factors Influencing BOPP Pearlized Film Density

Several factors during the production process can affect the final density of the film:

1. Polymer Resin Selection

The base polypropylene resin’s inherent density sets the foundation. Different grades of PP resin may have slightly different densities.

2. Pearlescent Additives

Additives like calcium carbonate create micro-voids, reducing the overall density. The concentration and type of additive directly influence the final density.

3. Biaxial Orientation Process

Stretching the film in both machine and transverse directions aligns the polymer chains and expands the micro-voids, further lowering density.

4. Thickness and Uniformity

Thicker films may have slightly different density profiles compared to thinner ones. Uniformity across the film roll is also critical for consistent performance.

5. Cooling and Crystallization

The rate at which the film is cooled after extrusion affects the crystalline structure, which in turn impacts density.

CloudFilm controls these factors using modern BOPP production lines, on-line thickness monitoring and regular laboratory testing, so that density stays within narrow tolerances from roll to roll.

For customers who run multi-structure portfolios (for example, combining BOPP printing film with heat sealable BOPP film and pearlized BOPP), stable density also makes tension control and register more predictable on high-speed presses.

How Density Affects Film Performance

Mechanical Properties

Higher density films generally exhibit better tensile strength and puncture resistance, making them suitable for applications requiring durability. Lower density films are more flexible and soft, which is ideal for applications where tactile feel is important.

Optical Properties

Density has a direct impact on opacity and gloss. Lower density films scatter light more effectively due to the higher concentration of micro-voids, resulting in better opacity and a more pronounced pearlescent effect.

Barrier Properties

While BOPP pearlized films are not primarily used for their barrier properties, density can influence moisture and oxygen transmission rates to some extent. Higher density films may offer slightly better barrier performance.

Printability and Lamination

Films with different densities absorb inks and adhesives differently. Understanding the density helps in optimizing printing parameters and lamination conditions for the best results.

For premium ice-cream and chocolate wraps, converters often prioritize a slightly lower density to boost opacity and pearl effect, then fine-tune thickness to keep stiffness and tear resistance within target ranges.

In wrap-around label projects, where die-cutting and automatic application require good dimensional stability, CloudFilm may recommend a pearlized grade with a density in the mid-to-upper range together with carefully matched BOPP matte film or BOPP gloss film in the rest of the portfolio.

Typical BOPP Pearlized Film Structures and Applications

In mono-web pillow packs for ice cream bars, pearlized BOPP is often used as a single web with a heat-sealable layer, providing opacity, slip and low-temperature seal performance in one film. CloudFilm can offer single-side or double-side heat-sealable grades for this purpose.

In laminated structures for soap wraps or premium snacks, converters may combine a BOPP printing film

outer web with a pearlized BOPP inner web, or use pearlized BOPP as the print web itself when a solid white background is required.

For wrap-around labels on yogurt, milk and beverage bottles, pearlized BOPP can be paired with clear or matt BOPP to achieve specific stiffness and curl behavior, while keeping the whole structure within the BOPP family for easier recycling.

If you are comparing pearlized BOPP with other film types for a new project, CloudFilm’s broader BOPP film portfolio — including gloss, matt, metallized, adhesive-free lamination and synthetic paper — allows you to benchmark several looks and stiffness levels using one coordinated supplier.

How to Choose the Right Density for Your Application

Step 1: Define Your Packaging Requirements

Consider the product’s weight, shelf life, and desired appearance. For lightweight, visually appealing packaging, a lower density film may be ideal.

Step 2: Evaluate Mechanical Performance Needs

If your packaging requires higher durability or stress resistance, choose a film with a higher density.

Step 3: Balance Cost and Performance

Work with your supplier to find a density that meets performance requirements without exceeding your budget.

Step 4: Test and Validate

Always request samples and test them under real-world conditions to ensure the film performs as expected.

When you brief CloudFilm, sharing your current structure (for example, BOPP pearlized/VMCPP or PET/BOPP pearlized), machine type, line speed and target cost-per-pack helps our engineers recommend a density range and thickness that you can validate quickly on line trials.

You can also compare pearlized options with standard 12 µm grades such as 12 Micron BOPP Film. if you want to understand how switching from clear to pearlized will influence roll weight and logistics.

CloudFilm’s Expertise in BOPP Pearlized Films

At CloudFilm, we specialize in manufacturing high-quality BOPP pearlized films tailored to diverse packaging needs. Our films are engineered to deliver the perfect balance of aesthetics, functionality, and cost-efficiency.

With state-of-the-art production technology and stringent quality control, CloudFilm ensures consistent density, excellent printability, and reliable performance across all our film products.

Since 2002, CloudFilm has supported more than 400 customers in over 30 countries with BOPP, BOPET, BOPA, PE and other films, many of whom started from simple ice-cream or candy projects and gradually expanded into full pearlized and specialty BOPP portfolios.

Beyond supplying rolls, our team can help you compare BOPP pearlized grades with matt, gloss, metallized or synthetic paper options from the same CloudFilm platform, so you can simplify your vendor list while still meeting different brand and line requirements.

If you are working on a new design or cost-reduction project, CloudFilm can provide density-matched samples, technical data sheets and remote line-trial support to shorten your development cycle and reduce risk.

{ CloudFilm’s BOPP Pearlized Film Can Help You Save Costs }

FAQ: BOPP Pearlized Film Density and Applications

Q1. What is the typical density range of BOPP pearlized film, and what does CloudFilm usually supply?

A1. In the industry, BOPP pearlized film density generally falls between about 0.60 and 0.90 g/cm³. CloudFilm’s mainstream pearlized grades are engineered around a typical density of approximately 0.76 g/cm³, which offers high opacity, a strong pearl effect and attractive yield compared with standard clear BOPP.

Q2. How does density influence yield (m²/kg) and packaging cost?

A2. At a fixed thickness, a lower-density film has lower GSM and therefore higher yield, meaning more square meters — and more packs — per kilogram. For example, at 20 µm thickness, a pearlized BOPP at 0.76 g/cm³ can deliver roughly 65 m²/kg, while a clear BOPP at 0.91 g/cm³ gives only about 55 m²/kg. This difference directly translates into cost-per-pack changes that CloudFilm can model with you during project planning.

Q3. Which density should I choose for ice cream wraps versus wrap-around labels?

A3. Ice cream and frozen dessert wraps typically benefit from slightly lower density to maximize opacity and vertical impact on shelf while keeping good flexibility at low temperatures. Wrap-around labels, especially for beverages and dairy, often favor mid-to-higher density grades to improve dimensional stability, die-cutting and automatic application performance. CloudFilm can provide density-tuned options for both scenarios.

Q4. Can BOPP pearlized film be used in recyclable or mono-material structures?

A4. Yes. Pearlized BOPP is a polypropylene-based material and can fit into many PP-dominant mono-material structures when combined with other BOPP or PP sealing layers. When recyclability is a priority, CloudFilm’s team can help you design pearlized structures that stay within the polyolefin family and align with local recycling guidelines.

Q5. What information should I prepare before asking CloudFilm for a quotation on pearlized BOPP film?

A5. It is helpful to share your end use (ice cream, candy, soap, wrap-around labels, etc.), current or target thickness and width, mono-web or laminate structure, sealing requirements, and approximate monthly or yearly consumption. With this information, CloudFilm can quickly propose suitable density and thickness combinations and provide competitive pricing.

Q6. How does pearlized BOPP compare with matt or metallized BOPP in terms of density and appearance?

A6. Standard matt BOPP films usually have densities around 0.90–0.92 g/cm³ and provide a low-gloss, “paper-like” surface, while metallized BOPP adds a vacuum-deposited aluminum layer for metallic shine and better barrier. Pearlized BOPP sits at a lower density range (around 0.60–0.80 g/cm³) with a creamy, pearlescent look. CloudFilm offers all three types — pearlized, matt and metallized — so you can compare options side by side for each project.

Conclusion

Understanding BOPP pearlized film density is key to optimizing packaging performance and cost. Whether you’re a designer, engineer, or procurement specialist, selecting the right film starts with understanding the technical details.

At CloudFilm, we are committed to providing high-quality, customizable films to meet your unique needs.

Ready to explore our range of BOPP pearlized films?

Visit the CloudFilm product page or contact our team today!

You can learn more about grades, technical data and free-sample policies on the dedicated BOPP Pearlized Film product page, or discuss broader BOPP solutions — including matt, gloss and metallized films — with the CloudFilm team for your next multi-SKU program.

Whether you are optimizing an existing ice-cream wrap or launching a new beverage label, CloudFilm is ready to be your density and structure partner from first idea to stable mass production.