Heat sealable PET films have become one of the most important materials in modern flexible packaging. From ready-meal trays and yogurt cups to coffee pouches and medical packs, converters and brand owners rely on these films to deliver strong seals, attractive shelf appearance, and reliable product protection.

When you work with an experienced heat sealable PET film manufacturer and supplier, you can fine-tune film structures and sealing windows to match your exact machines and products.

As a China-based flexible packaging film manufacturer, CloudFilm supplies a full range of BOPET, BOPP, BOPA, PE and specialty films, helping customers build complete laminates and lidding solutions from one source. This article explains what heat sealable PET films are, where they are used, and how to select the right grade together with a trusted supplier.

What Is Heat Sealable PET Film?

Heat sealable PET film is a biaxially oriented polyethylene terephthalate (BOPET) film with a specially designed heat sealable layer on one side or on both sides.

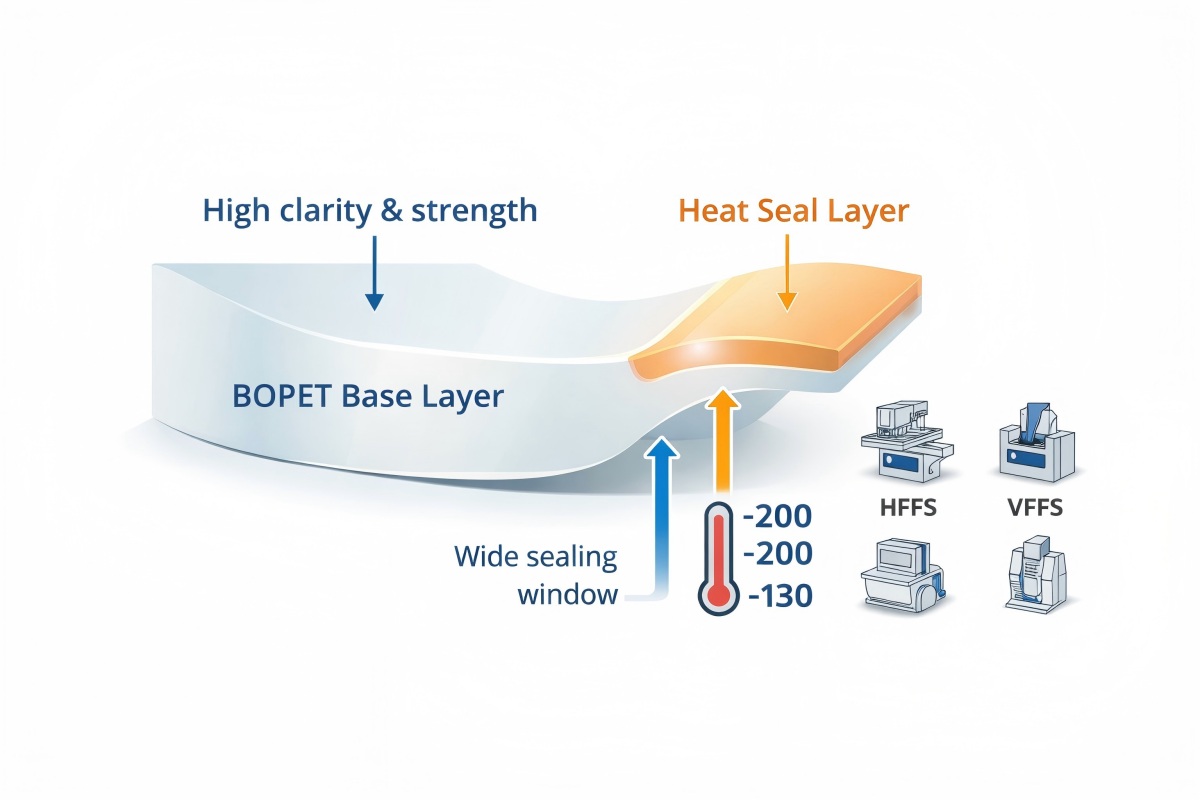

The base BOPET layer provides high tensile strength, dimensional stability and excellent clarity, while the seal layer enables the film to bond to itself or to other substrates such as PE, PP or paper under controlled temperature, pressure and dwell time.

Typical heat sealable PET film thickness ranges from about 12–60 μm, with widths up to around 2000 mm, so converters can use it both as a lidding web and as part of multi-layer laminates. Most grades are corona-treated for good ink adhesion and lamination performance.

For a deeper technical overview and specification data, you can refer to CloudFilm’s dedicated heat sealable PET film product page, which includes typical mechanical, optical and sealing properties.

Key Properties That Make Heat Sealable PET Films So Versatile

Wide Sealing Window and Reliable Seal Strength

The main reason packers choose PET heat seal films is their wide sealing window. Compared with many BOPP-based films, heat sealable PET can seal at higher temperatures and still maintain stable performance, which is especially important for ovenable or retortable packs, deep trays, and lines that run at high speeds. The seal layer can be formulated for:

- Sealing to APET, CPET or PP trays

- Sealing to PE or co-extruded sealant layers in laminates

- Different levels of hot-tack and peel strength

When you work with a knowledgeable heat sealable PET film supplier, you can specify whether you need peelable, lock-up or weld-seal behaviour for each application.

Barrier, Clarity and Shelf Appeal

BOPET base film offers very good oxygen and moisture barrier compared with many commodity plastics, which helps extend shelf life for dry foods, snacks, dehydrated meals and powdered products. At the same time, its high gloss and low haze deliver a premium “glass-like” appearance that makes food, cosmetics and personal care products more attractive on shelf.

In lidding applications, the combination of high clarity and anti-fog or easy-peel treatments allows consumers to see the product clearly while still benefiting from strong seals and protection.

Dimensional Stability and Processability

Because BOPET is biaxially oriented, it has excellent dimensional stability under heat and tension. This helps maintain registration during printing, lamination and form-fill-seal operations. The film stays flat, resists wrinkling, and can handle aggressive thermal cycles such as pasteurization or hot filling when combined with the right sealant structure.

CloudFilm’s heat sealable PET films are designed to run smoothly on tray sealers, HFFS and VFFS lines, with optimized friction coefficients and consistent thickness profiles to minimize adjustment time on the packing line.

Main Applications of Heat Sealable PET Films

Heat sealable PET films appear in almost every aisle of a supermarket and in many technical markets. Below are the most common use cases where brand owners and converters benefit from partnering with a specialized PET film manufacturer.

Lidding Films for Trays and Cups

One of the largest application areas is lidding film for rigid trays and thermoformed cups, including:

- Ready meals and chilled dishes

- Fresh or processed meat and poultry

- Dairy products such as yogurt, desserts and cheese slices

- Salad bowls and convenience foods

Here, heat sealable PET films are used either as mono-layer lidding or as part of PET/PE laminates. They must seal securely to APET, CPET, PP or PS trays, resist contamination in the seal area, and maintain clarity after hot filling, cooling and distribution.

CloudFilm supplies both heat sealable PET film and PET/PE laminated film structures that can be tailored as peelable or lock-up lids for different tray materials and sealing conditions.

Flow-Wrap, Pouches and Sachets

Heat sealable PET films are widely used as the outer or lidding layer of flexible packaging for:

- Coffee, tea and instant beverages

- Dry snacks, nuts and confectionery

- Powders, premixes and nutraceuticals

- Ready-to-mix sauces or soup bases

In many of these laminates, PET provides stiffness, printability and barrier, while an inner PE or CPP layer supplies hot-tack and hermetic sealing. For brand owners who want a consistent mono-supplier chain, CloudFilm offers BOPET film for packaging as well as the corresponding PE and CPP sealant films to build complete structures.

When peelability or easy-open performance is required, specialty PET sealing films and easy-peel structures can be used as the top layer, improving consumer convenience without sacrificing pack integrity.

Medical and Pharmaceutical Packaging

Medical and pharmaceutical packs need extremely consistent seals and well-controlled barrier properties. Heat sealable PET films are used in:

- Sterile medical device pouches

- Blister lidding for tablets and capsules

- Diagnostic kit and test strip packaging

These packs often undergo sterilization or high-temperature processes, where PET’s dimensional stability and heat resistance are critical. By combining PET with appropriate sealants and coatings, manufacturers can achieve tamper-evident seals and long shelf life, while still printing clear dosage and safety information on the lidding film.

Industrial, Electronics and Technical Uses

Beyond consumer goods, heat sealable PET films are frequently chosen for:

- Moisture-sensitive electronic components and ESD-safe pouches

- Industrial spare parts and fasteners

- Specialty tapes, labels and release liners

The film’s inherent strength and chemical resistance support demanding logistics chains. Where additional light or gas barrier is needed, metallized layers or high-barrier coatings can be added—CloudFilm’s range of ALOx PET and other specialty films can be combined with heat sealable structures for these projects.

Types of Heat Sealable PET Structures

Standard Heat Sealable PET Film

Standard heat sealable PET film uses a clear PET base with a co-extruded or coated seal layer that provides strong, non-peelable seals. This structure is often chosen when:

- Packages are not meant to be re-closed or re-sealed

- Maximum integrity is required to prevent leaks

- Packs may face high mechanical stress during distribution

It is common in industrial packs, bulk food bags and many technical laminates.

Peelable and Easy-Open PET Sealing Films

Easy-peel PET sealing films are engineered to deliver controlled peel strength: the lid opens smoothly without tearing, yet still passes seal integrity tests. This is ideal for:

- Yogurt, dairy and desserts

- Ready meals and convenience foods

- Single-serve portion packs

By adjusting the seal layer chemistry and thickness, suppliers can tune the peel force to match tray material, lid size and consumer expectations. CloudFilm’s PET easy-peel and specialty sealing films help brand owners achieve a balance between tamper evidence and user-friendly opening.

PET/PE and PET-Based Laminates

In many flexible packs, heat sealable PET is combined with PE, CPP or other layers to create tailored performance:

- PET/PE laminates for frozen foods and retort pouches

- PET/CPP structures for high-speed snacks and confectionery lines

- PET/Alu/PE laminates for aggressive barrier requirements

CloudFilm’s portfolio includes PET/PE laminated film and food packaging film solutions so converters can design complete structures from a single manufacturer.

Working with a Heat Sealable PET Film Manufacturer and Supplier

Choosing the right heat sealable PET film is not only about the polymer; it is also about the service and technical support behind it. For packaging engineers, buyers and brand owners, partnering with a reliable film manufacturer and supplier brings several advantages:

- Application-driven recommendations

Instead of guessing thickness or sealant types, you can share your packed product, tray or film structure, target shelf life and sealing machine type. A specialist supplier will propose suitable film grades and structures, often including sample rolls for on-line trials. - Consistent quality and certifications

Reputable manufacturers operate under ISO-based quality systems and provide COA/COC, migration test reports and food-contact documentation when needed. This is essential for export markets and multinational brand standards. - Optimized logistics and MOQ

A China-based film producer with export experience can offer flexible minimum order quantities, regular production slots and coordinated shipments together with other BOPP, BOPET, BOPA or PE films. This simplifies procurement and reduces risk when you scale up new projects.

CloudFilm has been manufacturing flexible packaging films since 2002 and now supplies customers in more than 30 countries. As a heat sealable PET film manufacturer and supplier in China, CloudFilm provides:

- Custom thickness, width and heat-seal side (one side or both sides)

- Technical support for tray sealing, HFFS and VFFS lines

- Free samples or trial rolls in many cases

- One-stop sourcing of BOPP, BOPET, BOPA, PE and specialty films

For project discussions or quotations, you can contact CloudFilm directly or submit a request through the Get A Quote forms on the product pages.

Frequently Asked Questions About Heat Sealable PET Films

Q1. When should I choose heat sealable PET instead of heat sealable BOPP?

Heat sealable PET is preferred when you need higher temperature resistance, better dimensional stability and improved barrier versus typical BOPP films. It is especially suitable for lidding over rigid trays, ovenable or retortable packs, and medical or pharmaceutical applications where heat cycles and mechanical demands are more severe. If cost is the main driver and conditions are mild, heat sealable BOPP may still be more economical.

Q2. What information should I prepare before asking a supplier for a quote?

To get an accurate quotation from a heat sealable PET film manufacturer, it helps to prepare:

- Product type (e.g. fresh meat tray, ready meal, yogurt, coffee, medical device)

- Tray or web material (APET, CPET, PP, PS, aluminium, etc.)

- Packaging machine type and speed (tray sealer, HFFS, VFFS)

- Desired thickness, roll width and core size

- Target peel strength (peelable vs lock-up) and shelf life

- Estimated monthly or yearly volume

With this information, suppliers like CloudFilm can quickly confirm suitable grades, send technical data and offer trial rolls.

Q3. Are heat sealable PET films compatible with sustainable and recyclable packaging?

Many brands are moving toward mono-material or more recyclable packaging solutions. In PE- or PP-dominant systems, PET is often used as a thin outer layer for stiffness and print quality, while seal layers are designed to fit the chosen recycling stream. By working with your supplier, you can explore:

- Thinner PET structures to reduce overall material usage

- PET/PE films aligned with PE-based recycling systems

- Alternatives such as all-PE films or BOPE where full mono-material is required

A knowledgeable supplier will help balance sustainability targets with performance and cost.

Q4. Can heat sealable PET films run on my existing tray sealer or flow-pack line?

In most cases, yes. Heat sealable PET films are designed for standard tray sealing, HFFS and VFFS equipment. However, you may need to adjust temperature, dwell time and pressure to match the film’s sealing window.

Your supplier can suggest starting parameters based on tray material and product type. Running a short on-line trial with sample rolls is the best way to confirm speeds and seal integrity before full conversion.

Q5. How do peelable PET lidding films avoid “stringing” or incomplete opening?

High-quality peelable PET sealing films are engineered with controlled peel layers that separate cleanly from the tray flange. The formulation and thickness of the peel layer, together with correct sealing conditions, help avoid stringing, film tearing or uneven opening.

If you experience these issues, share seal photos and line parameters with your supplier; they can adjust grade selection or recommend revised sealing settings.

Q6. Does CloudFilm supply only film, or can you also support full packaging solutions?

CloudFilm primarily manufactures and supplies films—BOPP, BOPET, BOPA, PE, CPP, high-barrier and speciality films—but the team also supports customers with structure design, trials and connections to pouch-making or printing partners. For many brand owners, this “one-stop” support significantly shortens development time for new packaging.