Introduction: Demystifying “Grammage” and “Thickness” in Packaging Films

When selecting packaging film for your product, have you ever been confused by “grammage” and “thickness”? The key to solving this puzzle lies in a fundamental physical parameter—BOPP density. This guide will thoroughly explain BOPP density, from its basic definition to how it impacts your final product, helping you make smarter material choices.

Whether you are a packaging buyer, converter, or brand owner comparing different BOPP films, this article gives you practical, calculator-ready numbers you can use in real projects.

All examples in this guide are aligned with the density ranges commonly used in CloudFilm’s BOPP film

portfolio for food, label, and industrial packaging, so you can quickly translate theory into real purchasing decisions.

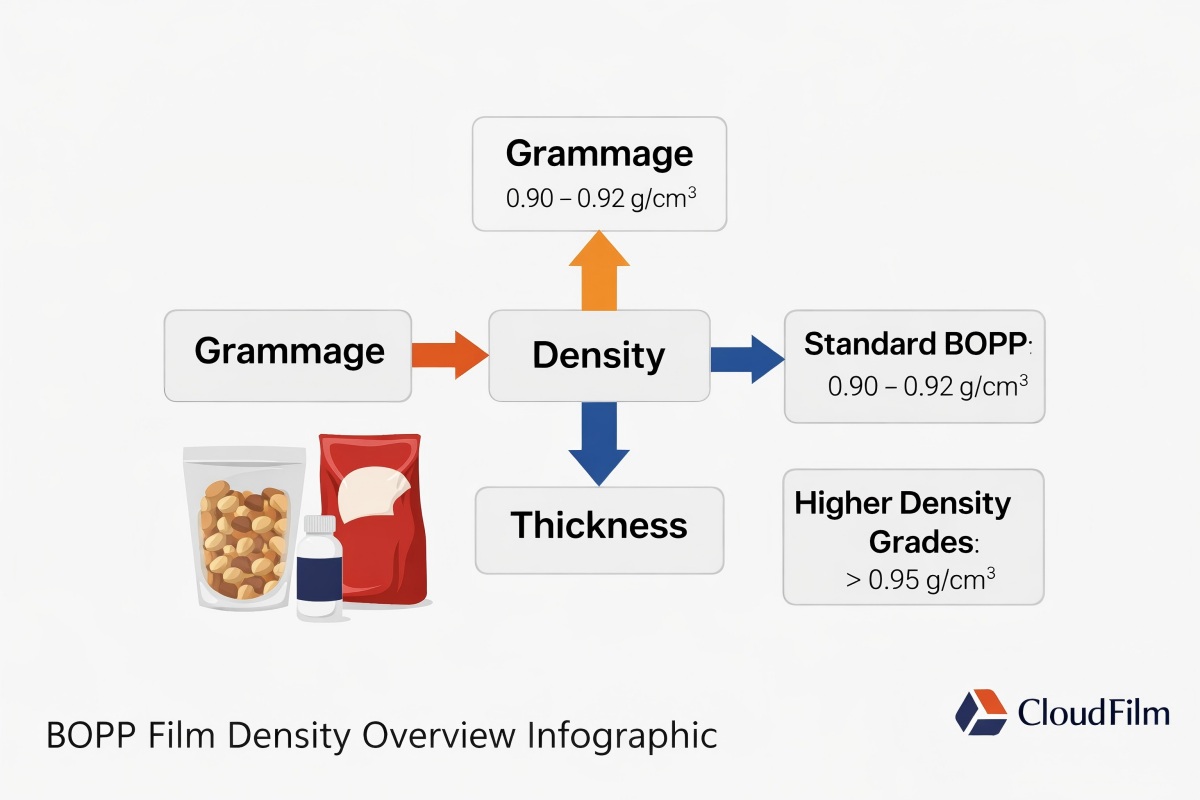

BOPP Density at a Glance

| Item | Description |

|---|---|

| What is it? | BOPP density is the mass per unit volume of Biaxially Oriented Polypropylene film. |

| Typical Value Range | Standard range: 0.90 – 0.92 g/cm³ |

| Why is it important? | It’s the critical link between a film’s ‘grammage’ and ‘thickness’, directly affecting cost, performance, and suitability. |

For most standard packaging projects, you can assume a working density of 0.90–0.91 g/cm³ for typical BOPP packaging films unless your supplier clearly specifies a special high-density grade.

What is BOPP Density?

Scientific Definition:

BOPP density refers to the mass contained in a unit volume, typically expressed in grams per cubic centimeter (g/cm³). It is an inherent property of the material and does not change with shape or size.

Chemical Basis of BOPP:

BOPP is based on polypropylene (PP), a non-polar polymer with a relatively loose molecular arrangement, which results in its naturally low density. This is why BOPP films are lightweight and transparent.

Put simply, density tells you “how heavy one cubic centimeter of BOPP is”, and once you know that value you can move freely between thickness (µm), grammage (gsm) and even roll weight for any BOPP film roll.

Compared with denser polymers like polyester films or nylon films, BOPP’s lower density is one of the reasons it is so popular for cost-optimised, lightweight flexible packaging.

Typical Values and Units of BOPP Density

Standard Range:

The density of BOPP film generally falls between 0.90 – 0.92 g/cm³, with slight variations depending on formulation and production processes.

Unit Conversion:

| Unit | Conversion |

|---|---|

| 1 g/cm³ | = 1000 kg/m³ |

| 1 g/cm³ | ≈ 0.0361 lb/in³ |

Comparison with Other Films:

| Film Type | Typical Density (g/cm³) | Key Characteristics |

|---|---|---|

| BOPP | 0.90 – 0.92 | High clarity, good moisture barrier, cost-effective |

| BOPET | 1.38 – 1.40 | High tensile strength, temperature resistance |

| BOPA | 1.13 – 1.16 | Excellent puncture resistance, gas barrier |

| PE | 0.91 – 0.96 | Good heat sealability, flexibility |

These reference values make it clear that, at the same micron, BOPP gives more square meters per kilogram than BOPET packaging films or BOPA films, which is why many designers switch from PET-only structures to BOPP/PE laminates when they want to reduce material cost.

If you frequently calculate density and yield across many polymers, you can also bookmark CloudFilm’s dedicated flexible film density formulas and yield guide.

Why is BOPP Density So Important?

The Bridge Between Grammage and Thickness:

BOPP density is the key parameter for calculating film thickness using the formula:

Thickness (μm) = Grammage (g/m²) ÷ Density (g/cm³)

Example Calculation:

Suppose you need a 20 μm thick BOPP film. At a standard density of 0.91 g/cm³, the required grammage is:

Grammage = 20 μm × 0.91 g/cm³ ≈ 18.2 g/m²

This calculation is essential for cost estimation and procurement specifications.

Impact on Performance:

- Optical Properties: Density variations can affect crystallinity, influencing transparency and haze.

- Mechanical Properties: Additives like stiffeners alter density and impact rigidity and puncture resistance.

- Barrier Properties: Density correlates with molecular packing, affecting moisture and oxygen barrier performance.

Impact on Cost:

At the same thickness, lower density means less material and lower cost—a crucial factor for procurement decisions.

In daily work this means that two films with the “same thickness” on paper can behave very differently on the line if their density and formulation are not the same. Always combine density data with the specific BOPP grade (for example BOPP gloss film, BOPP matte film or BOPP pearlized film) when you judge cost and performance.

If you also need to estimate roll weight and number of packs per roll, you can plug BOPP density into the yield and roll-weight formulas in CloudFilm’s flexible film density reference to build your own quick calculator.

Key Factors Affecting BOPP Density

| Factor | Description |

|---|---|

| Raw Material | Different PP resin grades have varying comonomer content and molecular weight distribution, leading to slight differences in base density. |

| Additives | Stiffening agents (e.g., talc) significantly increase density; anti-blocking and slip agents have minor effects. |

| Production Process | Parameters like stretch ratio, temperature, and heat setting affect crystallinity, leading to small but important density variations. |

For very stiff packaging structures—such as label film, tape film or BOPP cigarette film—CloudFilm may deliberately use resins and mineral fillers that push density slightly higher to gain modulus and dimensional stability.

On the other hand, voided or cavitated structures such as BOPP pearlized film behave like “lower-density” materials in yield calculations, so always check the supplier’s datasheet instead of assuming a single generic density for all BOPP grades.

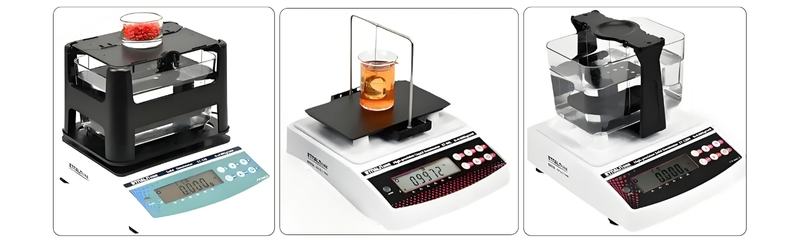

How to Measure BOPP Density?

Immersion Method (ASTM D792 / ISO 1183)

Uses Archimedes’ principle to calculate density based on weight differences in air and liquid.

Density Gradient Column

Used for high-precision QC or R&D, providing more accurate density readings.

Indirect Calculation

Density is back-calculated from measured grammage and thickness—commonly used for in-line quality monitoring.

In daily production at CloudFilm, indirect methods based on grammage and thickness are used for every roll, while laboratory immersion or gradient-column measurements are reserved for new product development or customer qualification trials.

{ Various Density Testing Instruments }

How to Choose the Right BOPP Film Based on Density?

| Application | Key Requirement | Recommended BOPP Type | Typical Density Range |

|---|---|---|---|

| General Food Packaging | Cost, Clarity | Standard BOPP | 0.90 – 0.92 g/cm³ |

| High-Speed Printing/Converting | Stiffness, Runnability | High-Stiffness BOPP | > 0.95 g/cm³ |

| Thin Labels/Capacitor Film | Purity, Consistency | Specialty BOPP | Tightly controlled 0.905 g/cm³ |

For snack, bakery and dry-food pillow packs, converters often combine standard BOPP with heat-seal layers such as heat sealable BOPP film or PE-based laminates, keeping overall density and yield close to standard BOPP.

For premium labels, overwraps and tape, higher-modulus grades like BOPP tape film or BOPP cigarette film may have slightly higher density but deliver much better stiffness and dimensional stability on fast lines.

BOPP Density, Film Yield and Roll Weight: Practical Buyer Formulas

Many buyers first meet “density” when they have to answer questions like “How many bags per roll?” or “What will the roll weight be in a 40-foot container?”. The formulas below show how BOPP density connects these everyday numbers.

For BOPP film with density ρ (g/cm³) and thickness t (µm):

- Basis weight (GSM): GSM = ρ × t

- Yield (m²/kg): Yield = 1000 / (ρ × t)

- Roll weight (kg): Roll weight ≈ Width (m) × Length (m) × t (µm) × ρ × 0.001

Example:

If you choose a 20 µm standard BOPP film with ρ = 0.91 g/cm³:

- GSM = 0.91 × 20 = 18.2 g/m²

- Yield = 1000 / 18.2 ≈ 54.9 m²/kg

With a roll width of 0.5 m and length of 4000 m:

- Roll weight ≈ 0.5 × 4000 × 20 × 0.91 × 0.001 ≈ 36.4 kg

By keeping a few “typical density” values for BOPP, PET, PA and PE on hand, you can quickly compare structures like BOPP/PE, PET/PE or PA/PE and choose the one that hits your technical requirements with the lowest roll weight and best logistics efficiency.

How CloudFilm Controls BOPP Density in Production

Stable density is not only a lab number—it directly affects your film gauge, roll weight and machine performance. CloudFilm treats density control as a core part of BOPP quality management.

At CloudFilm, we:

- Select PP resins with well-defined density and molecular-weight windows for each BOPP grade.

- Fine-tune stretching ratios, temperatures and heat-setting profiles to achieve the required crystallinity and mechanical properties.

- Monitor grammage and thickness online for every production roll and back-calculate density as part of routine SPC (statistical process control).

- Run regular lab tests (immersion or gradient-column methods) to validate density for new grades or critical customer projects.

This approach keeps the density of standard packaging grades close to the target 0.90–0.92 g/cm³, while high-stiffness and specialty BOPP films are kept within tight, customer-specific ranges so you can trust every new shipment to behave like the last one on your lines.

Frequently Asked Questions About BOPP Density

Q1: What is the typical density of standard packaging-grade BOPP film?

Most standard packaging-grade BOPP films fall in the 0.90–0.92 g/cm³ range. Unless your supplier clearly states a special grade, you can usually calculate with 0.91 g/cm³ for quotations and early design work.

Q2: Does BOPP density change with thickness?

Density is an intrinsic material property, so in principle it does not depend on thickness. However, changes in formulation (fillers, cavitation) or stretching conditions can slightly shift the effective density, especially in pearlized, cavitated or mineral-filled grades. Always refer to the technical datasheet or confirm with your BOPP supplier for critical projects.

Q3: How does BOPP density compare with PET, PA and PE?

BOPP (≈0.90–0.92 g/cm³) is less dense than BOPET (~1.38 g/cm³) and BOPA (~1.13–1.16 g/cm³), and similar to PE films (~0.91–0.96 g/cm³). This lower density is one reason BOPP/PE structures often give better yield (m²/kg) than PET/PE structures at the same micron.

Q4: How can I quickly estimate yield and roll weight for a BOPP structure?

Use density ρ and thickness t in the formulas: GSM = ρ × t; Yield (m²/kg) = 1000 / (ρ × t); Roll weight (kg) ≈ Width × Length × t × ρ × 0.001. For more worked examples, you can refer to CloudFilm’s flexible film density formulas and tables.

Q5: Are matt, pearlized or metallized BOPP films denser than clear BOPP?

Matt and pearlized films may include cavitation or special additives, so their effective density can be slightly lower or higher than clear BOPP depending on the structure. Metallized BOPP keeps the same base density, but the aluminium layer adds a small amount of grammage. CloudFilm provides separate density and GSM references for matt BOPP films and pearlized BOPP films so you can size your packs correctly.

Q6: Who should I talk to if I am still unsure which BOPP density or grade fits my project?

You can contact the CloudFilm technical and sales team with your product type, packaging format and target thickness. We will help you shortlist suitable BOPP grades—such as standard BOPP films, heat sealable BOPP or specialty BOPP films —and provide density-based calculations so that your next trial runs smoothly.