Introduction: Is Your Print Missing That Final “Wow” Factor?

In today’s fiercely competitive market, a consumer’s first impression of a product often dictates their purchasing decision. Your packaging design might be stunning, your brochure content rich, but if the final texture feels ordinary or is prone to scratches and fingerprints during transport and handling, all your upfront investment could be undermined.

Are you searching for a surface finishing process that not only imparts a premium, sophisticated look and feel but also provides robust physical protection? The answer lies in Thermal Matt Lamination. Today, CloudFilm will take you on a deep dive into this core technology, revealing how it can be the “key” to unlocking your product’s value.

{ Thermal Matt Lamination Film }

What is Thermal Matt Lamination? — More Than Just “Matt”

When you hear “matt lamination,” you might simply think of a “non-reflective” surface. For professionals, however, thermal matt lamination is a far more nuanced concept. It is an advanced post-print process that securely bonds a specially formulated matt BOPP (Biaxially Oriented Polypropylene) film to paper or paperboard using heat and pressure.

This process is fundamentally different from traditional “cold lamination” or “water-based lamination.” Thermal lamination uses heated rollers to melt the solid adhesive layer, fusing the film perfectly with the paper fibers under precise pressure. This “thermal fusion bonding” brings several decisive advantages:

- Superior Adhesion: The film and paper become one, eliminating the risk of bubbling or delamination, ensuring the print’s long-term durability.

- Exceptional Flatness: The thermal process smooths out minute wrinkles in the paper, resulting in a finish as flat as a mirror with a uniform texture.

- Ultimate Matt Effect: Because it’s a physical fusion, the matt coating is distributed evenly across the surface, presenting a deep, soft, and spot-free premium matt texture.

In short, thermal matt lamination isn’t just “applying” a film; it’s a technological process that “breathes” new life into your printed materials.

Why Choose Thermal Matt Lamination? — A Dual Victory for Texture and Protection

Choosing a process means it must solve core problems. Thermal matt lamination is favored by high-end brands precisely because it achieves a perfect balance between “aesthetic value” and “functional protection.”

1. Enhancing Aesthetic Value: Creating “Understated Luxury”

- Visually: It eliminates all harsh glare, making colors appear deeper and more saturated. Whether it’s a profound black or a vibrant color, under the matt film, they seem to gain depth, presenting a restrained and sophisticated visual language. This is the very texture sought after by luxury brands, high-end electronics, and art books.

- Tactilely: This is the most captivating aspect of matt lamination. It delivers a silky-smooth, delicate touch. When a consumer picks up your product, this unique “hand-feel” instantly communicates a signal of high quality, significantly enhancing user experience and brand perceived value.

{ Thermal Matt Lamination For Cosmetic Boxes }

2. Providing Robust Protection: Making Beauty Last

A beautiful exterior needs a solid guardian. While imparting aesthetic appeal, thermal matt lamination also provides a powerful physical barrier.

- Scratch & Scuff Resistance: The laminated surface’s hardness is significantly increased, effectively resisting scratches and scuffs during daily production, transportation, storage, and consumer use, keeping the product looking pristine.

- Water & Stain Resistance: BOPP film itself has excellent water-resistant properties, preventing liquids (like water or oil) from seeping into the paper and causing stains or deformation. This is crucial for food packaging, cosmetic boxes, or frequently handled menus.

- Enhanced Durability: The film’s protection greatly extends the lifespan of the printed material. Whether it’s a corporate brochure meant for long-term storage or a product catalog that needs to be flipped through repeatedly, thermal matt lamination ensures it can withstand the test of time.

Thermal Matt Lamination vs. Other Lamination Methods — Why Thermal is the Superior Choice

Several lamination methods exist on the market. Understanding their differences will help you make a more informed decision.

| Feature Comparison | Thermal Matt Lamination | Water-Based / Cold Matt Lamination | UV Varnishing |

|---|---|---|---|

| Adhesion/Durability | Excellent, film and paper are thermally fused, resistant to delamination. | Good, relies on adhesive, may peel at edges over time. | Fair, only surface-cured, prone to peeling. |

| Matt Texture | Deep, uniform, silky, top-tier feel. | Good, but can be less uniform, slightly tacky feel. | Can achieve matt, but feels harder, lacks the smooth “film” feel. |

| Protective Performance | Comprehensive, water-proof, oil-proof, scratch & scuff resistant. | Water & oil resistant, but scratch resistance is weaker than thermal. | Good scratch resistance, but poor flexibility, cracks when bent. |

| Eco-Friendliness & Health | High, no solvent emissions, clean production process. | Fair, but adhesives may contain trace solvents. | Lower, UV curing process can generate ozone. |

| Ideal Applications | High-end packaging, books, catalogs, labels | General promotional materials, posters. | Products requiring spot high-gloss effects. |

Conclusion: If you are pursuing the ultimate texture, strongest protection, and highest durability, thermal matt lamination is unequivocally the better and more reliable choice.

Which Industries Are Embracing Thermal Matt Lamination? — A Look at Application Scenarios

The applications for thermal matt lamination are extremely broad. Any industry looking to enhance its product image and durability can benefit.

- High-End Packaging: Cosmetic boxes, jewelry cases, premium gift boxes, electronics packaging (e.g., mobile phone boxes, earphone cases). The matt texture instantly elevates the product’s perceived value, sparking consumer desire.

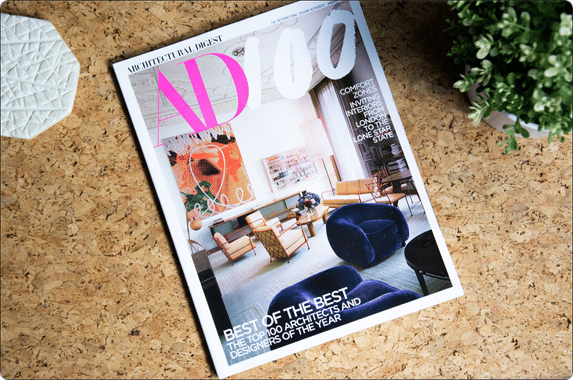

- Publishing & Printing: Hardcover book covers, art books, annual reports, high-end magazines. It not only protects the cover but also gives the book a collectible value and artistic feel.

- Business & Marketing: Product catalogs, brochures, membership cards, invitations. A catalog laminated with a matt film makes clients feel the brand’s dedication and strength as they flip through its pages.

- Labels & Hang Tags: Clothing hang tags, wine labels, premium food labels. In humid or frequently touched environments, matt lamination ensures the label’s information remains clear and intact.

{ Thermal Matt Lamination For Magazine Covers }

How to Choose the Right Thermal Matt Film? — Expert Advice from CloudFilm

Choosing the right film is half the battle. As a film solutions expert, CloudFilm advises you to consider the following four dimensions:

- Thickness: Film thickness (e.g., 18mic, 23mic, 25mic, 30mic) directly impacts the final product’s stiffness, protection level, and cost.

- CloudFilm’s Recommendation: For standard packaging and brochures, 23mic offers excellent value. For greater stiffness and protection (e.g., high-end gift boxes), consider 25mic or 30mic.

- Adhesive Layer: Different paper types (e.g., art paper, specialty paper, recycled paper) have varying compatibilities with adhesives. Selecting an adhesive layer that perfectly matches your paper substrate is key to preventing bubbling and delamination.

- CloudFilm’s Advantage: We offer adhesive layers in various formulations and can conduct customized tests based on your specific paper samples to ensure 100% compatibility.

- Degree of Mattness: Matt finishes also come in “degrees.” From standard matt to super matt, different gloss levels will produce different visual effects.

- CloudFilm’s Recommendation: We can provide samples with different gloss levels for you to feel and see, allowing you to choose the one that best fits your brand’s tone.

- Supplier’s Technical Support: A great supplier should provide solutions, not just products.

- Why Choose CloudFilm: We not only provide high-quality thermal matt film but also boast an experienced technical team. From selection advice to equipment parameter tuning, we offer full support to ensure your production process is smooth sailing.

Conclusion: CloudFilm, Safeguarding Your Pursuit of Excellence

Thermal matt lamination is a craft that perfectly blends art and technology. It’s not just a film; it’s a reflection of brand value and a silent language between the product and the consumer. Choosing the right thermal matt film is like dressing your product in an “armor” that is both elegant and strong.

At CloudFilm, we understand this deeply. We are dedicated to helping clients worldwide realize their product visions through innovative film technology and professional service. We believe that卓越的细节,成就伟大的品牌 (Excellence in details creates great brands).

{ CloudFilm Provides You With Free Thermal Matt Lamination Film }

Ready to give your product a new lease on life?

Contact CloudFilm now to get a free sample or schedule a one-on-one consultation with our technical experts. Let’s work together to turn your creative vision into tangible, exceptional quality.