Pet food is no longer a purely functional product. Around the world, pet owners see dogs and cats as family members, and they expect the packaging of pet food to match human-food standards in safety, convenience and sustainability.

At the same time, converters and brand owners are under growing pressure from retailers, regulators and NGOs to move away from hard-to-recycle laminates toward recyclable, mono-material solutions.

Machine Direction Oriented PE (MDO PE or MDOPE) films give pet food brands and converters a practical way to upgrade from traditional PET/PE or BOPA/PE structures to recyclable mono-PE laminates, without sacrificing shelf life or line efficiency.

In this article, we will explain how MDO PE films work, where they fit in pet food packaging, and how a dedicated film manufacturer and supplier like CloudFilm can support your transition project from first trial rolls to stable mass production.

Why Pet Food Packaging Needs to Change

Traditionally, dry pet food and treats are packed in PET/PE, PET/AL/PE or BOPA/PE laminates. These structures offer good stiffness, barrier and print quality, but they mix different polymers and sometimes aluminum foil, which makes recycling very difficult. In many markets, such multilayer films go directly to landfill or incineration.

At the same time, Extended Producer Responsibility (EPR) schemes and retailer guidelines are pushing for packaging that fits into existing recycling streams. For flexible plastics, that usually means mono-material PE or PP structures that can be sorted, reprocessed and turned into new products with meaningful value.

For pet food brands and their converters, this creates a clear set of pain points:

- How to keep oxygen and moisture barrier high enough to protect fats, proteins and aromas.

- How to maintain premium shelf appearance with large, high-resolution graphics.

- How to run new structures on existing FFS (form-fill-seal) and pouch-making lines without investing heavily in new machinery.

- How to control total packaging cost while meeting “recyclable by design” expectations.

MDO PE films target exactly this intersection of performance and recyclability.

What Is MDO PE (MDOPE) Film?

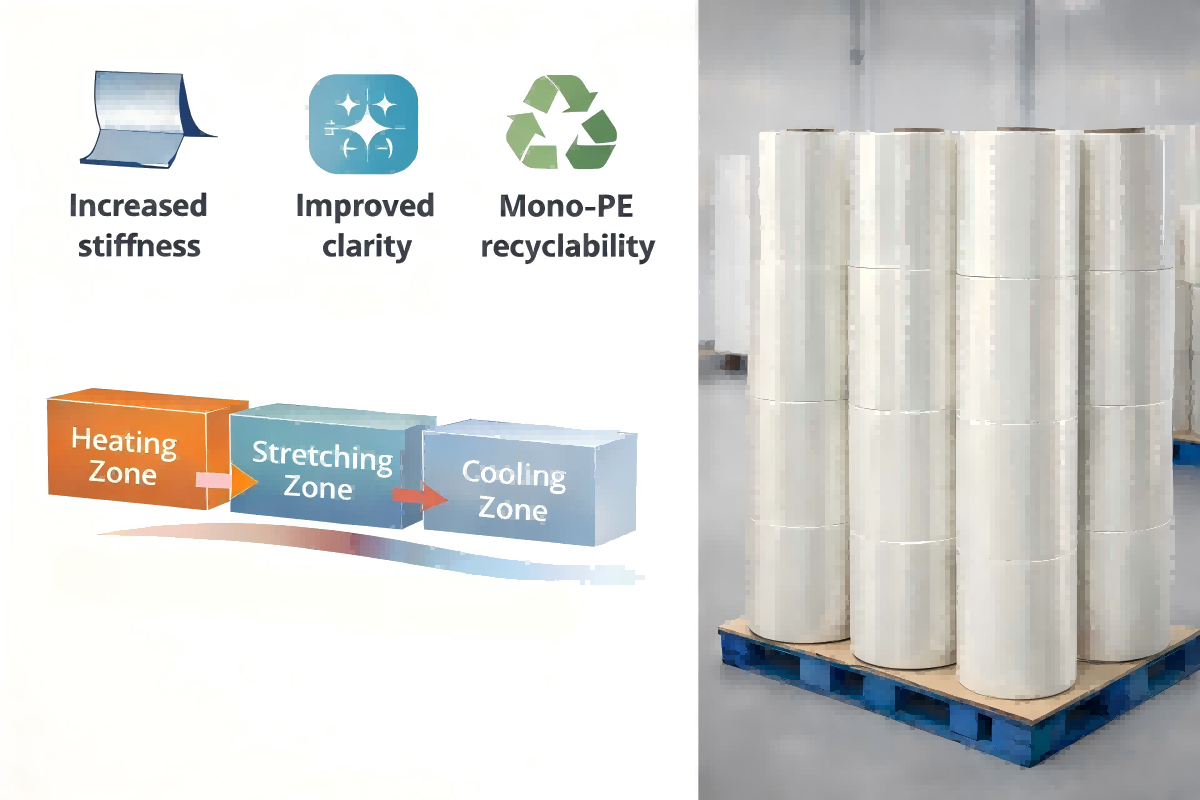

MDO PE (Machine Direction Oriented Polyethylene) film is a PE film that has been stretched in the machine direction under controlled temperature and tension. This orientation aligns the polymer chains, significantly improving stiffness, tensile strength and clarity while keeping the film within the PE family.

Compared with conventional blown or cast PE films, MDO PE typically offers:

- Higher stiffness at the same or even reduced thickness

- Better dimensional stability, which is important for register control in printing and pouch-making

- Higher gloss and clarity for premium shelf appeal

- A more stable, higher surface tension after treatment, which improves ink and adhesive anchorage

Because MDO PE remains a polyethylene, it can be laminated or co-extruded with other PE-based layers to create mono-material PE structures that fit many PE recycling streams.

CloudFilm’s MDO PE film for recyclable flexible packaging is specifically engineered as the stiff print web in 100% PE laminates, including pet food, snacks and hygiene packaging.

How MDO PE Enables Recyclable Mono-PE Pet Food Packaging

The key advantage of MDO PE is that it lets you build pet food packaging structures that are fully within the PE family while still hitting demanding performance targets.

Typical Mono-PE Structures with MDO PE

Below are common starting points for pet food applications:

- MDO PE / PE sealant

- For: Dry pet kibbles, smaller treats, non-oxygen-sensitive products.

- Structure: Stiff MDO PE print web on the outside, a tailored PE sealant film inside.

- Benefits: Excellent stiffness and shelf presence, clean seals, recyclable mono-PE design.

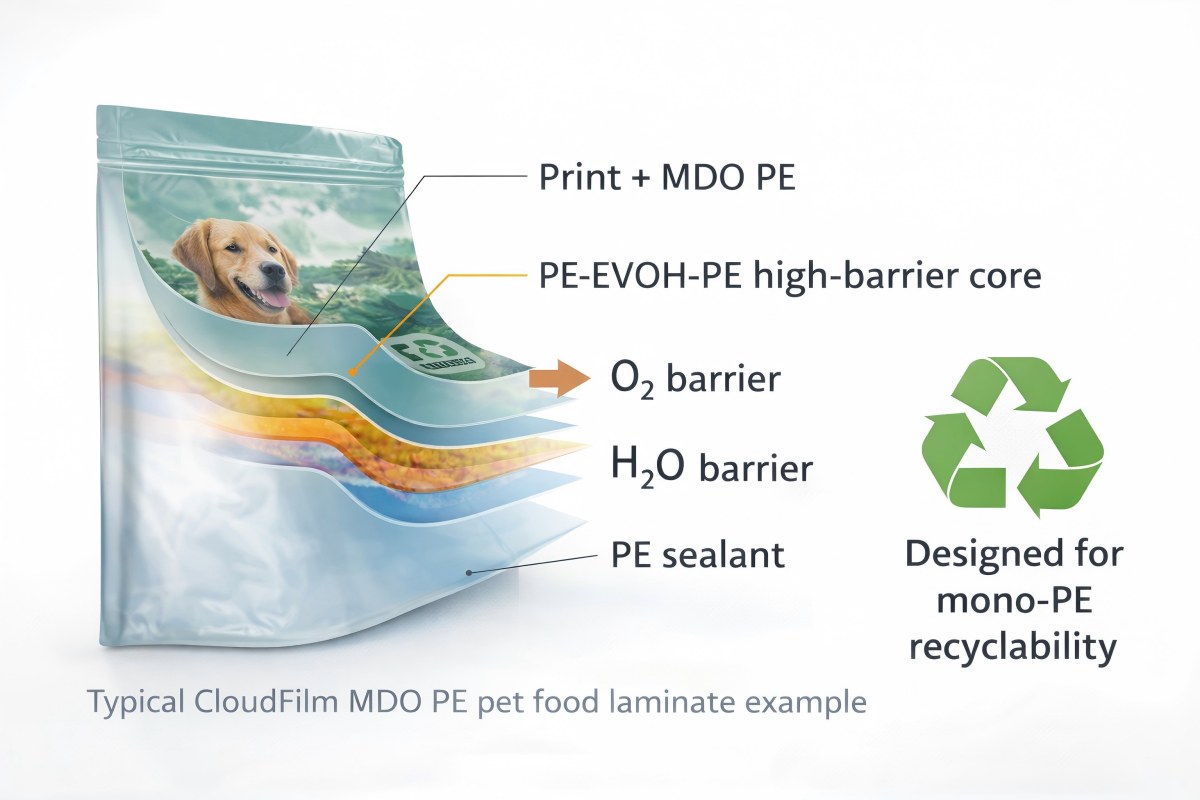

- MDO PE / PE-EVOH-PE (high-barrier)

- For: Higher-fat or oxygen-sensitive pet foods where extended shelf life is required.

- Structure: Printed MDO PE outer layer laminated to a co-extruded PE-EVOH-PE barrier film.

- Benefits: Strong oxygen barrier from EVOH, good moisture barrier from PE layers, while remaining within a PE-dominant structure. For more detail you can connect this concept to CloudFilm’s guide on PE-EVOH-PE high-barrier film.

- MDO PE / specialty PE sealants

- For: Large quad-seal bags, heavy pet food sacks, or premium doypacks with zippers and spouts.

- Structure: MDO PE outer web combined with tougher or higher-hot-tack PE sealants, sometimes including anti-slip, fast-opening or other functional features.

- Benefits: Improved abuse resistance and pack integrity during distribution, still compatible with many PE recycling streams.

By combining MDO PE with different PE-based inner webs, converters can create a family of recyclable pet food structures that cover small pouches, mid-size doypacks and large, heavy bags.

CloudFilm’s recyclable mono-material pouches already adopt MDO PE/PE and BOPE/PE structures for food and pet food brands looking to move away from traditional PET-based laminates.

MDO PE vs Traditional PET/PE or BOPA/PE Pet Food Laminates

When evaluating MDO PE for pet food packaging, buyers often compare it with established PET-based or PA-based laminates.

- Stiffness & Handling

MDO PE can approach PET-like stiffness at significantly lower thickness than standard PE films, which helps bags stand better on shelf and improves automatic filling and palletization. - Barrier

On its own, MDO PE has similar moisture barrier to other PE films and modest oxygen barrier. By pairing it with PE-EVOH-PE or other high-barrier PE structures, you can reach barrier levels suitable for many dry pet foods, treats and semi-moist products. - Printability & Shelf Impact

With proper surface treatment, MDO PE offers high gloss and clarity, giving designers the freedom to use vibrant colors and fine text. That makes it a practical replacement for PET in many print-heavy designs. - Recyclability

PET/PE and BOPA/PE structures are technically recyclable but rarely sorted and processed at scale, as they mix different polymers. Properly designed MDO PE structures can be labeled as “designed for recycling” in many PE streams, supporting brand sustainability claims and retailer requirements. - Cost & Risk

Material cost depends on local markets and specifications. Even if MDO PE structures are not dramatically cheaper than legacy laminates, they can reduce regulatory risk and open doors with retailers that prioritize recyclable packaging.

For buyers who are comparing MDO PE with BOPE or other PE-based stiff films, CloudFilm’s technical article on MDO PE vs BOPE provides additional context and selection guidance.

Design Checklist for Moving to MDO PE Pet Food Structures

Switching to MDO PE is not just a film choice; it is a packaging project. Before you contact a film manufacturer or supplier, it is helpful to clarify a few points:

Key Questions to Clarify

- End application details

- Dry kibble, treats, cat litter, or other pet-related products?

- Required shelf life and distribution conditions?

- Target packaging format

- Pillow bags, quad-seal / side-gusset bags, stand-up pouches, zipper pouches, spouted pouches or lidding film?

- Current structure and pain points

- What is your existing laminate (e.g. PET/AL/PE or BOPA/PE)?

- Are you facing issues like delamination, leaks or poor machinability?

- Line conditions

- Type of FFS or pouch-making equipment, typical sealing temperatures and speeds.

- Any limitations on roll diameter, core size or maximum web width.

- Sustainability and certification targets

- Do you need specific recyclability labels or EPR compliance in certain regions?

- Are you aiming to reduce thickness, switch away from aluminum foil, or move to mono-PE only?

CloudFilm’s MDO PE film page already outlines useful parameters such as typical thickness, roll width range and core size, which help buyers define realistic starting points for trials.

Where MDO PE Works Best in Pet Food Packaging

MDO PE is not a magic solution for every single SKU, but it fits very well in several high-volume scenarios.

Dry Kibble and Large Bags

For dry dog and cat food packed in large quad-seal bags or side-gusset sacks, stiffness and puncture resistance are critical. MDO PE outer webs combined with strong PE sealants can deliver the necessary mechanical strength while enabling recyclable mono-PE design. When barrier demands are moderate, MDO PE/PE structures are often sufficient.

Treats, Snacks and Small Doypacks

Smaller stand-up pouches for treats can benefit from MDO PE’s high clarity and surface quality. Brands can keep premium artwork and metallic effects (through cold-foil or special inks) without relying on PET. High-barrier variants using MDO PE / PE-EVOH-PE make sense for more sensitive recipes.

Lidding Films and Toppers

In some cases, MDO PE can be used as the outer web in lidding films for semi-rigid trays or as a topper for multi-pack formats, especially when brands want to align all flexible elements in the pack to mono-PE concepts. For other formats, PET lidding may still be preferred due to high-temperature sealing or retort requirements.

If you are also working on human food, CloudFilm’s food packaging film range and related guides, such as the article on PE laminated structures, can help you align pet food packaging with your broader portfolio.

How CloudFilm Supports You as a Manufacturer & Supplier

As a dedicated flexible packaging film manufacturer in Qingdao, China, CloudFilm focuses on helping converters, trading companies and brand owners turn complex requirements into clear, workable specifications.

Through its PE film portfolio and deep experience with BOPP, BOPET, BOPA, CPP and specialty films, CloudFilm can coordinate both traditional and recyclable structures in one project.

For MDO PE pet food developments specifically, CloudFilm typically supports customers in three stages:

- Concept and structure design

- Review your current laminate and target markets.

- Propose candidate structures such as MDO PE//PE or MDO PE//PE-EVOH-PE, referencing your barrier and machinability needs.

- Sample rolls and pilot trials

- Supply trial rolls of MDO PE film and related PE sealants.

- Work with your printing, lamination and pouch-making teams to fine-tune corona treatment, ink systems and sealing windows.

- Stable mass production

- Lock in specifications, QC parameters and shipment standards.

- Provide timely technical support and container-level supply for export markets.

If you want to understand CloudFilm’s broader capabilities, the About Us page gives a concise overview of the company as a flexible packaging film manufacturer and supplier in China, including experience, portfolio and export markets.

FAQ: MDO PE Films for Pet Food Packaging

1. What is MDO PE film and how is it different from regular PE film?

MDO PE film is a polyethylene film that has been stretched in the machine direction to increase stiffness, strength and clarity. Regular PE films are not oriented to the same extent, so they are softer and less dimensionally stable. MDO PE keeps the recyclability of PE while offering performance closer to PET in many packaging applications.

For a broader background on PE films, you can refer to CloudFilm’s articles on what PE film is and the classification of PE films.

2. Is MDO PE suitable for all types of pet food?

MDO PE works very well for dry kibbles, treats and many semi-moist products when combined with suitable PE-based barrier layers. For retort wet food or applications requiring very high temperature resistance, traditional PET-based structures or special high-temperature films may still be required. Each project should be evaluated case-by-case with your film supplier.

3. Can MDO PE pet food laminates be recycled everywhere?

Recyclability always depends on local collection and sorting systems. Technically, MDO PE-based structures designed as mono-PE are compatible with many PE film recycling streams. However, actual on-the-ground recycling access differs by country and region. It is important to check local guidelines and, if necessary, work with certification bodies before making on-pack claims.

4. Will switching to MDO PE require new packaging machinery?

In most cases, you can run MDO PE structures on existing printing, lamination and FFS or pouch-making lines with limited adjustments. You may need to fine-tune sealing temperatures, dwell times, nip pressures and web tensions. A good film manufacturer and supplier will support you with sealing curves and processing recommendations to reduce trial-and-error time.

5. How does MDO PE perform with oils, fats and strong aromas in pet food?

The outer MDO PE layer itself has good moisture barrier and reasonable aroma retention, but for high-fat or highly aromatic products, you usually rely on a barrier core like PE-EVOH-PE or other high-barrier PE-based films. This combination provides strong protection against oxidation and aroma loss while keeping the structure recyclable-by-design.

6. What information should I prepare before contacting a film manufacturer?

To speed up technical discussion and quoting, it is helpful to prepare:

- End use and product type (e.g. dry dog food, cat treats).

- Current packaging structure and key problems you want to solve.

- Target pack format, size and estimated annual volume.

- Equipment type, typical sealing temperature range and line speeds.

- Any specific sustainability or certification targets from your customers or retailers.

CloudFilm’s MDO PE film product page gives guidance on typical thicknesses, widths and other parameters that buyers often specify when sending an RFQ.

7. How does MDO PE compare with BOPE in pet food applications?

Both MDO PE and BOPE are oriented PE films designed to improve stiffness and clarity. BOPE is oriented in both machine and transverse directions, usually giving even higher strength and puncture resistance. MDO PE is oriented only in the machine direction, offering a different balance of properties and sometimes more flexibility in structures. Many brands use a combination of both, depending on pack type and market positioning.

8. Is it possible to start with PET/PE and then step-by-step move to MDO PE?

Yes. Some converters and brands prefer a gradual approach. For example, you might first optimize your existing PET/PE laminated film structure, then pilot a few SKUs with MDO PE-based mono-PE laminates, and finally extend the mono-PE concept to more product lines. CloudFilm can support both traditional laminates and new mono-PE solutions in parallel.

9. How can I evaluate the total cost impact of switching to MDO PE?

Total cost is not only material cost per kilo. You should also consider:

- Yield (m² per kg) at different thicknesses.

- Scrap rate during printing and pouch-making.

- Potential EPR fees or incentives related to recyclability.

- Added brand value from “recyclable” claims and alignment with retailer programs.

A technical and commercial discussion with your film supplier can help you quantify these factors and build a realistic business case.

10. How can CloudFilm support international buyers and trading companies?

CloudFilm has long experience exporting flexible packaging films and working with trading companies, converters and brands in multiple countries. As an MDO PE film manufacturer and supplier in China, CloudFilm can provide English-language technical support, free or low-cost sample rolls (subject to cooperation policy), and coordinated logistics from Qingdao Port to your destination.

Conclusion: Turning Sustainability Targets into Practical MDO PE Pet Food Solutions

Sustainable pet food packaging is no longer a “nice-to-have” marketing slogan. It is becoming a core requirement driven by regulators, retailers and end consumers. MDO PE films give pet food brands, converters and trading companies a realistic route to mono-PE, recyclable packaging that still protects product quality and brand image.

By working with a solution-driven manufacturer and supplier like CloudFilm, you can turn high-level sustainability goals into clear structures, testable samples and scalable supply.

Whether you are just exploring the concept or ready to switch specific SKUs to MDO PE laminates, CloudFilm’s team can help you choose the right film, optimize line conditions and document performance for your customers.