BOPP Folia

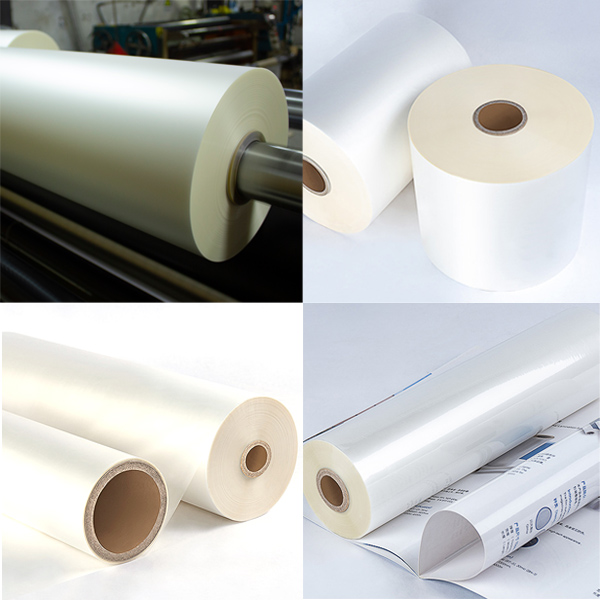

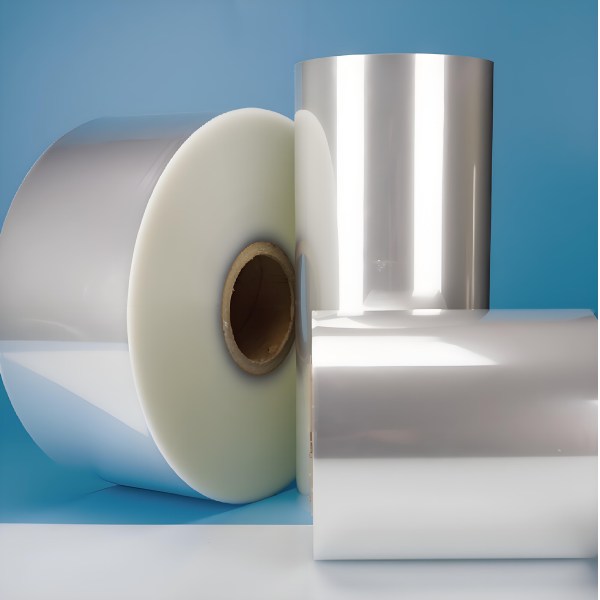

CloudFilm’s BOPP folia (also called folia BOPP or BOPP film) combines high clarity, strength and moisture resistance for modern flexible packaging, labels and tapes. It is supplied in jumbo rolls with customized width, thickness and surface treatment for your converting lines.

- Exceptional Clarity & High Gloss – Makes printed colors and products stand out on retail shelves.

- Moisture & Grease Resistance – Protects snacks, confectionery and dry foods from water vapour and oil.

- High Tensile Strength & Durability – Runs stably on high-speed printing, lamination and slitting machines with less breakage and waste.

- Optimized Printing & Laminating Surface – Corona-treated surfaces suitable for flexo, gravure and UV printing, as well as lamination with CPP, PE or paper.

Work directly with CloudFilm, a BOPP film manufacturer in China, to get consistent BOPP folia for your European “folia” applications.

BOPP Folia Description

What is BOPP Folia?

BOPP folia is a biaxially oriented polypropylene (BOPP) film supplied in rolls (“folia” means film or foil in several European languages). It is known for its high clarity, gloss, tensile strength and moisture barrier, which makes it a workhorse film for packaging snacks, bakery products, dry food, labels and pressure-sensitive tapes.

Compared with non-oriented PP film, BOPP folia offers improved stiffness, better dimensional stability and higher line speeds on printing, lamination and slitting equipment.

Explore CloudFilm’s BOPP Folia Portfolio

CloudFilm offers a full BOPP folia portfolio so that you can cover printing, lamination, overwrap and tape applications with one supplier:

- BOPP Printing Film – High-gloss or matte printing-grade BOPP folia with controlled corona treatment and excellent ink adhesion, ideal as the outer layer of flexible packaging and labels.

- Metallized BOPP Film – BOPP folia coated with a thin metal layer to improve oxygen and light barrier, widely used for snacks, confectionery and pharmaceutical overwraps.

- BOPP Gloss Film & Matte Film – High-gloss film for strong shelf impact and matte film for premium, low-glare finishes, both suitable for lamination and overwrap. (Internal links to /product/bopp-glossy-film/ and /product/matte-pet-film/ if needed)

- BOPP Thermal Lamination Film – EVA-coated BOPP folia for one-step thermal lamination of books, magazines, gift boxes and food packaging. (Internal link to /product/bopp-thermal-lamination-film/)

- BOPP Pearlized Film – White, pearl-like BOPP folia with low density and excellent opacity for ice cream, confectionery and personal-care labels. (Internal link to /product/bopp-pearlized-film/)

- Anti Fog BOPP Film – Anti-fog BOPP folia for refrigerated fresh produce, salad and bakery packs where clear visibility is critical. (Internal link to /product/bopp-anti-fog-film/)

- BOPP Tape Film – Base film for carton-sealing and specialty tapes, supplied as jumbo rolls for coating and slitting. (Internal link to /product/bopp-tape-film/)

By combining these grades, you can build mono-material BOPP structures that are easier to recycle while still meeting barrier, appearance and process requirements.

Choose CloudFilm: Your Expert BOPP Film Manufacturer and Supplier

Since 2002, CloudFilm has focused on flexible packaging films, including BOPP, BOPET, BOPA, PE and recyclable mono-material films. Our BOPP folia is produced on modern biaxially oriented lines, with strict quality control from resin selection to final roll inspection.

- Direct supply from our factory in Qingdao, China, with stable lead times and competitive pricing.

- Technical support for choosing the right BOPP folia grade for printing, lamination, labels or tape manufacturing.

- EU/FDA food-contact documentation available for relevant grades.

- Free samples and trial rolls so that you can test BOPP folia on your own lines before large orders.

Partnering with CloudFilm means you get a reliable BOPP folia supplier who understands converters’ needs and speaks your technical language.

To help you plan your production and logistics, CloudFilm supplies BOPP folia with the following typical specifications (other options on request):

- Thickness (Gauge): 15–50 μm for general packaging, labels and tapes.

- Width: Up to 2,000 mm jumbo rolls, slit to your required widths.

- Core Size: 3″ or 6″ paper cores, suitable for most printing, coating and slitting lines.

- Surface Structure: One-side or two-side corona-treated, heat-sealable or non-seal grades, depending on your application.

- Roll Length: Commonly 3,000–8,000 m per roll, optimized for your machine and carton or pallet size.

- Packaging: Rolls wrapped with protective film and packed on pallets for export shipping from Qingdao Port.

- Minimum Order Quantity: Typically 1,000 kg per thickness or structure for standard grades.

If you need special structures such as anti-fog BOPP folia or metallized BOPP folia, CloudFilm can also recommend suitable grades from our Anti Fog BOPP Film and Metallized BOPP Film ranges.

Get Free Quote of BOPP Folia

Before you switch a full production line to a new film, it is safer to run real trials. CloudFilm offers free BOPP folia samples and trial rolls so that your team can check clarity, sealing, printability and machinability on your own equipment.

When you send us an inquiry, please share:

- Target application (food packaging, label, tape, overwrap, etc.)

- Required thickness, width and surface treatment

- Approximate order quantity and shipment term (FOB or CIF)

Our sales and technical teams will come back with a tailored recommendation, quotation and lead time, so that you can move quickly from sample testing to stable mass production.

BOPP Folia Applications

- Food Packaging – BOPP folia is widely used for pillow packs and flow-wrap packaging of biscuits, confectionery, nuts, bakery products and dry foods, often combined with metallized BOPP for higher barrier.

- Label & Lamination – Corona-treated BOPP folia serves as a durable face stock for pressure-sensitive labels and as a lamination layer for book covers, magazines and cartons.

- Pressure-Sensitive Tapes – As a tape base film, BOPP folia offers a good balance of stiffness and conformability, making it suitable for carton-sealing tapes, stationery tapes and specialty industrial tapes.

- Pharmaceutical Packaging – Clear BOPP folia is used for overwraps and labels on blister packs, cartons and medical devices where clean appearance and dimensional stability are required.

- Industrial Packaging – BOPP folia can be used as an outer wrap or lamination layer for heavy-duty sacks, bulk goods and hardware products, protecting the contents from dust, moisture and handling damage.

FAQ

A BOPP roll refers to the standard industrial format of BOPP film, which is wound onto a core for efficient handling and use on high-speed packaging and printing machinery. The roll’s dimensions (width, length and thickness) are customized to fit your specific production line requirements.

No. BOPP is a specific type of polypropylene (PP). The “biaxially oriented” stretching process aligns the molecules in both directions, giving BOPP film higher tensile strength, better clarity and improved barrier properties compared with non-oriented PP film.

Yes, BOPP film is recyclable as PP (recycling code #5). Its mono-material structure supports many companies’ sustainability goals. In practice, recyclability also depends on your local waste-collection and recycling system.

CloudFilm typically supplies BOPP folia in 15–50 μm for general packaging, labels and tapes. Other gauges can be discussed for special applications. We can help you choose the right thickness based on product weight, desired stiffness and packaging format.

Corona-treated BOPP folia from CloudFilm is suitable for flexo, gravure and UV printing. For high-quality graphics or demanding label applications, we recommend using our dedicated BOPP Printing Film grades.

Yes. Many of our clear and metallized BOPP folia grades are designed for direct or indirect food contact. CloudFilm can provide EU and FDA food-contact statements and test reports for your chosen grade and lot upon request.

For standard BOPP folia grades, the typical MOQ is around 1,000 kg per thickness or structure. For very special or customized structures, the MOQ may be higher. Please contact us with your target structure so that we can confirm the MOQ.

For most standard grades, the production lead time is usually 2–3 weeks after order confirmation, plus sea-freight time from Qingdao Port to your destination. For urgent projects, we will try to arrange earlier production slots where possible.

Yes. We can supply A4 sheets or short trial rolls (for example 200–500 m per type) so that you can evaluate BOPP folia on your own machines. Please tell us your application, thickness range and surface structure, and we will arrange suitable samples.

Related News

Why BOPP Properties Matter For Packaging Buyers, Converters And Brands If you buy flexible packaging films, run a […]

Introduction: Why BOPP Recycling Matters Now From snack bags and instant noodle wrappers to product labels and […]

Introduction – Addressing Pain Points and Building Connection Are you struggling to choose a packaging material that […]

Introduction: Why BOPP Recyclability Matters Now Biaxially Oriented Polypropylene (BOPP) film has become one of the “workhorse” […]

Introduction In the world of flexible packaging, metalized BOPP film stands out for its excellent barrier properties, glossy appearance, and […]

When it comes to flexible packaging films, matt BOPP (Biaxially Oriented Polypropylene) stands out for its excellent printability, aesthetic […]

Metalized BOPP films have become a staple in food packaging, providing a multitude of benefits that ensure product […]

Biaxially Oriented Polypropylene (BOPP) film is one of the workhorse materials behind modern flexible packaging. Thanks to its clarity, […]