In the world of engineering, manufacturing, and product design, precision is paramount. When working with materials like PET (Polyethylene Terephthalate) film, understanding its fundamental properties is not just a matter of technical curiosity—it’s a critical factor that impacts cost, performance, and quality. One of the most fundamental yet frequently searched properties is PET film density.

If you’ve found yourself searching for this term, you’re likely looking for a specific number, a way to calculate weight, or an understanding of how density influences your application. This guide is designed to be your definitive resource. We will cover everything from the standard density value and the factors that influence it, to practical calculation methods and how to select the right film for your needs.

{ The Ultimate Guide To PET Film Density }

What is PET Film Density? The Quick Answer

Let’s start with the most direct answer. Density is defined as mass per unit of volume. For PET film, this is typically expressed in grams per cubic centimeter (g/cm³) or kilograms per cubic meter (kg/m³).

The standard, widely accepted density for amorphous PET film is approximately 1.33 g/cm³ (or 1330 kg/m³).

However, this is not a universal constant. The actual density of a specific PET film roll can vary slightly based on several factors, which we will explore next.

Key Takeaway: When you need a quick reference, use 1.33 g/cm³. But for precise engineering calculations, always confirm the exact density with your supplier, as it can be influenced by crystallinity and additives.

Why Isn’t PET Film Density Always 1.33 g/cm³? Factors That Influence It

While 1.33 g/cm³ is the benchmark, understanding why it can change is crucial for making informed decisions. The primary factors affecting PET film density are crystallinity and additives.

A. The Role of Crystallinity

PET can exist in two primary structural forms: amorphous and crystalline.

- Amorphous PET: This is the standard form for most packaging and industrial films. The polymer chains are arranged randomly, creating a less dense structure. This is the source of the 1.33 g/cm³ value. It offers excellent clarity, gloss, and thermoformability.

- Crystalline PET: When PET film is stretched (biaxially oriented) or heat-treated at temperatures above its glass transition point, the polymer chains can align into a more ordered, tightly packed crystalline structure. This process increases the density. Biaxially Oriented PET (BOPET) film, for example, can have a density ranging from 1.38 to 1.40 g/cm³. Higher crystallinity improves the film’s tensile strength, thermal stability, and chemical resistance.

B. The Impact of Additives and Fillers

Pure PET is rarely used in its final application. Additives are incorporated to enhance specific properties, and they directly affect the overall density.

- Increasing Density: Inorganic fillers like silica (SiO₂), barium sulfate (BaSO₄), or titanium dioxide (TiO₂) are often added to create matte films, improve whiteness and opacity, or modify surface properties. These fillers are denser than PET, so a film with a high filler content will have a higher overall density.

- Decreasing Density: While less common, it’s theoretically possible to incorporate additives or create micro-voids (as in some cavitated films) that lower the overall density. This is usually done to achieve specific optical or insulation properties.

| Factor | Effect on Density | Typical Density Range (g/cm³) | Common Application |

|---|---|---|---|

| Amorphous PET | Baseline | ~1.33 | Clamshell packaging, printing overlays |

| BOPET (Crystalline) | Increases | 1.38 – 1.40 | Electrical insulation, capacitors, high-strength tapes |

| PET with Fillers (e.g., TiO₂) | Increases | 1.35 – 1.45+ | Matte films, white opaque labels, release liners |

{ BOPET Film Production Line }

Why Does PET Film Density Matter? Practical Applications

Understanding density isn’t just an academic exercise. It has direct, real-world implications across various industries.

- For the Engineer & Designer:

- Weight and Mass Calculations: This is the most common use. If you are designing a component where weight is critical (e.g., in aerospace, automotive, or portable electronics), you need to calculate the mass of the PET film used. The formula is simple:

Mass = Density × Volume = Density × (Length × Width × Thickness) - Cost Estimation: Since PET film is often sold by weight (or by area, which is tied to weight), knowing the density allows you to accurately estimate material costs for a project.

- Weight and Mass Calculations: This is the most common use. If you are designing a component where weight is critical (e.g., in aerospace, automotive, or portable electronics), you need to calculate the mass of the PET film used. The formula is simple:

- For the Procurement Manager & Buyer:

- Quality Control & Specification: Density can be a quick indicator of whether a film batch meets the required specifications. A significant deviation from the expected density could signal a manufacturing error or a change in material composition.

- Comparing Quotes: When comparing quotes from different suppliers, ensure you are comparing apples to apples. A lower price per kilogram for a film with higher density might not be a better deal if you need a specific thickness and area coverage.

- For the Manufacturer & Converter:

- Process Control: Consistency in density is key to stable manufacturing processes. Variations can affect how the film handles on machinery, its tension, and its final dimensions.

- Performance Prediction: Density is linked to other properties like crystallinity, which in turn affects barrier properties (against moisture and oxygen), stiffness, and thermal performance. Monitoring density can help predict the final performance of the film.

How to Calculate Weight Using PET Film Density: A Practical Example

Let’s put the theory into practice. Imagine you are a product designer needing to source a PET film for a protective cover.

- Your Requirements:

- Film Type: Standard Amorphous PET

- Length: 100 meters

- Width: 1 meter (1000 mm)

- Thickness: 250 micrometers (µm), which is 0.025 cm or 0.00025 meters

- Step 1: Identify the Density

- For standard amorphous PET, we’ll use the standard density: 1.33 g/cm³.

- Step 2: Calculate the Volume

- First, ensure all units are consistent. Let’s use centimeters.

- Length = 100 m = 10,000 cm

- Width = 1 m = 100 cm

- Thickness = 250 µm = 0.025 cm

- Volume = 10,000 cm × 100 cm × 0.025 cm = 25,000 cm³

- Step 3: Calculate the Mass (Weight)

- Mass = Density × Volume

- Mass = 1.33 g/cm³ × 25,000 cm³ = 33,250 grams

- Step 4: Convert to a More Useful Unit

- 33,250 grams =33.25 kilograms

Now you know you need to purchase approximately 33.25 kg of this specific PET film for your project.

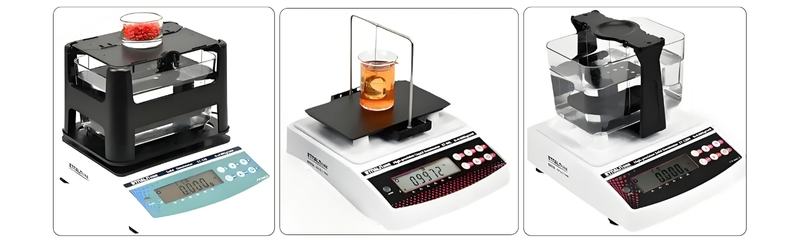

{ Various Density Testing Instruments }

How is PET Film Density Measured? The Scientific Methods

For quality assurance and R&D, density is measured using highly standardized methods. The two most common are:

- ASTM D792 / ISO 1183 (Density Gradient Column): This is the most accurate method. A column is filled with a liquid mixture that creates a density gradient (denser at the bottom, less dense at the top). Small, calibrated standards of known density are floated in the column to create a reference curve. The PET film sample is then immersed, and its density is determined by the level at which it floats.

- ASTM D1505 / ISO 1183 (Density by Displacement): This method involves weighing the sample in air and then weighing it again while immersed in a liquid of known density (often distilled water). The difference in weight is equal to the weight of the displaced liquid, allowing for the calculation of the sample’s volume and, subsequently, its density.

These methods ensure the accuracy and consistency required for industrial and scientific applications.

Conclusion: Selecting the Right PET Film with Confidence

Understanding PET film density is more than just knowing a number. It’s about understanding the material’s structure, its performance characteristics, and its role in your specific application.

From the standard 1.33 g/cm³ of amorphous films to the higher densities of filled or crystalline BOPET, this property is a key to unlocking precise calculations, effective cost management, and guaranteed quality.

When selecting a PET film, don’t just ask for the thickness and width. Ask for the Technical Data Sheet (TDS) and confirm the density. A reliable supplier will provide this information and help you understand how it impacts your final product.

{ CloudFilm Is Your Reliable Supplier }

At CloudFilm, we are committed to providing not just high-quality films, but also the technical expertise to help you succeed. Our range of PET films is manufactured to the strictest standards, with consistent properties and full technical documentation.

Ready to find the perfect PET film for your application? Contact the CloudFilm team today for a consultation and to request a technical data sheet.