Introduction – The Recycling Dilemma of Flexible Packaging & the Rise of Mono Material

1.1 The Pain Point: Convenience vs. Environmental Crisis

Flexible packaging is everywhere. From snack bags and coffee pouches to detergent sachets and pet food packaging, its lightweight, flexible, and cost-effective nature has made it the go-to choice for industries worldwide. However, this convenience comes at a steep environmental cost.

Most flexible packaging today is made from composite materials—layering plastics, aluminum foil, and paper to achieve high barrier performance. While effective for preservation, these multi-material structures are notoriously difficult to separate and recycle. As a result, the global recycling rate for flexible packaging remains below 10%, with the majority ending up in landfills or incinerators, contributing significantly to pollution and resource waste.

1.2 The Solution: Defining Mono Material and Its Core Value

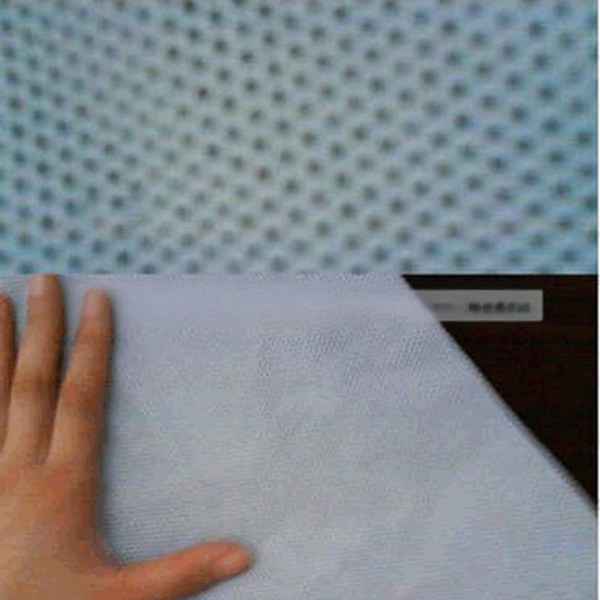

Enter Mono Material—a revolutionary approach in flexible packaging. In this context, Mono Material refers to packaging made from a single type of polymer, such as PE (polyethylene), PP (polypropylene), or PET (polyethylene terephthalate).

The core value of Mono Material lies in its Design for Recycling philosophy. By using a single material, the recycling process is dramatically simplified. These packages can enter existing recycling streams without complex separation, resulting in higher-purity recycled materials and supporting a true circular economy.

In short, Mono Material is not just a material swap—it’s a systemic shift toward closed-loop recycling in the flexible packaging industry.

{ 100% Recyclable Mono Material }

Deep Dive – Core Advantages of Mono Material Flexible Packaging

2.1 Revolutionary Recyclability

Let’s compare traditional composite packaging with Mono Material solutions:

| Feature | Traditional Composite Packaging | Mono Material Packaging |

|---|---|---|

| Material Structure | Multi-layer (e.g., PET/AL/PE) | Single-material (e.g., all-PE) |

| Recycling Process | Requires separation; complex and costly | Directly enters recycling stream |

| Output Quality | Downcycled; lower value | High purity; suitable for reuse |

| Circular Fit | Poor | Excellent (e.g., film-to-film) |

Mono Material supports high-value recycling loops, such as “bottle-to-bottle” or “film-to-film,” enabling a truly circular system.

2.2 Compliance with Global Regulations and Brand Strategy

Governments worldwide are tightening packaging regulations. The EU’s Packaging and Packaging Waste Regulation (PPWR) and China’s “Dual Carbon” goals are pushing brands toward recyclable solutions. Mono Material is not just a trend—it’s a compliance necessity.

For brands, adopting Mono Material enhances sustainability credentials, builds consumer trust, and aligns with the values of eco-conscious shoppers—turning environmental responsibility into a competitive advantage.

2.3 Performance and Cost Balance

A common misconception is that Mono Material packaging underperforms compared to composites. Thanks to advanced co-extrusion technologies, Mono Material structures can achieve excellent barrier properties—against oxygen, moisture, and light—meeting the shelf-life requirements of most products.

While initial material costs may be slightly higher, the long-term benefits outweigh the investment:

- Lower recycling fees

- Avoidance of future plastic taxes

- Enhanced brand image and consumer loyalty

Case Studies – Mono Material in Action

3.1 Main Material Types and Applications

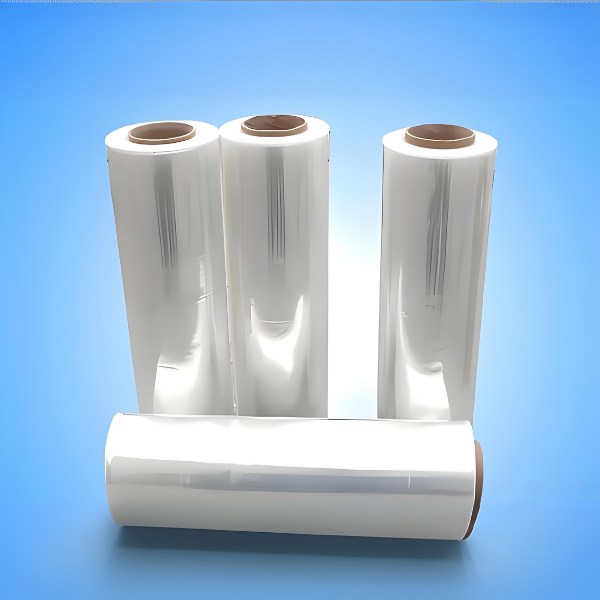

All-PE (Polyethylene) Packaging

- Features: Flexible, excellent heat-sealability

- Applications: Heavy-duty bags (rice, pet food), liquid detergent pouches, frozen food packaging

All-PP (Polypropylene) Packaging

- Features: High stiffness, transparency, heat resistance

- Applications: Snack bags (chips, biscuits), apparel packaging, retortable food pouches

All-PET (Polyethylene Terephthalate) Packaging

- Features: High strength, clarity, gas barrier

- Applications: Stand-up pouches, spouted pouches for liquids

3.2 Industry Leaders and Innovations

- Mars Inc.: Transitioning brands like Snickers and M&M’s to all-PE packaging globally.

- Unilever: Committed to 100% reusable, recyclable, or compostable packaging—Mono Material is a key pillar.

- Nestlé: Piloting paper-based and Mono Material plastic films for products like KitKat.

Leading packaging suppliers such as Amcor and Sealed Air have also launched commercial Mono Material product lines, signaling strong industry momentum.

Challenges and Future Outlook

4.1 Current Technical and Market Barriers

- Performance Limits: For ultra-high barrier applications (e.g., coffee, pharmaceuticals), Mono Material still lags behind aluminum foil composites.

- Recycling Infrastructure: In many regions, collection and sorting systems for flexible plastics are underdeveloped.

- Cost Transition: R&D, equipment upgrades, and supply chain adjustments require significant investment.

4.2 Future Trends and Innovations

- Material Innovation: Development of mono-materials with enhanced barrier properties using nano-coatings or recyclable additives.

- Process Optimization: Advanced co-extrusion techniques to reduce layers while maintaining performance.

- Ecosystem Collaboration: Brands, converters, recyclers, and governments must work together to scale collection and recycling systems.

- Digital Tracking: Using digital watermarks or tags to improve sorting accuracy in recycling facilities.

{ Mono Material is the Future of Sustainable Packaging }

Conclusion – Embracing Mono Material for a Sustainable Future

Mono Material is more than a packaging trend—it is the most viable solution to the flexible packaging waste crisis. It embodies a philosophy of circularity, responsibility, and innovation.

At CloudFilm, we are proud to be at the forefront of this movement. Our Mono Material solutions are engineered to deliver uncompromised performance while supporting a cleaner, greener planet.

To brand owners, designers, and sustainability leaders: the time to act is now. By choosing Mono Material, you’re not just adopting a material—you’re investing in the future.

Every choice for Mono Material is a step toward untying a complex waste knot and weaving a purer, circular world.