In the world of flexible packaging, where protection, preservation, and presentation are paramount, the technology behind creating the final product is just as important as the product itself.

Among the various manufacturing processes, extrusion lamination stands out as a powerhouse technique, enabling the creation of the sophisticated, multi-layered materials we see every day. From the coffee bag that keeps your beans fresh to the medical packaging that ensures sterility, extrusion lamination is the unsung hero.

This comprehensive guide will demystify extrusion lamination, breaking down its process, exploring its advantages and disadvantages, diving into its key applications, and providing insights for businesses looking to leverage this technology.

What is Extrusion Lamination? A Simple Definition

At its core, extrusion lamination is a manufacturing process used to bond two or more dissimilar materials together. It does this by extruding a molten thermoplastic resin, which acts as a hot-melt adhesive, between the layers. As this molten layer cools and solidifies under pressure, it creates a strong, permanent bond, resulting in a single, unified composite structure.

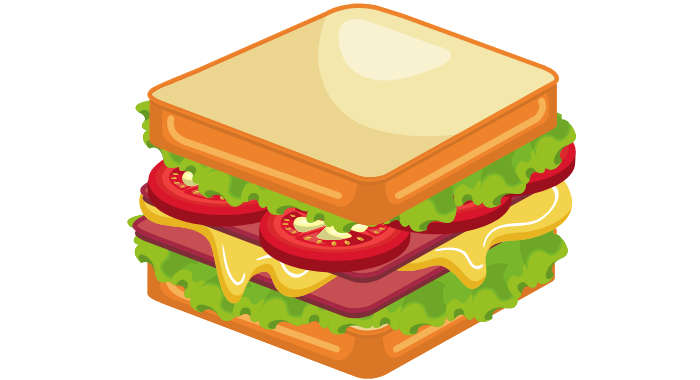

Think of it like making a high-tech sandwich:

- Bread Slices: These are your primary substrates, such as PET film, aluminum foil, or paper.

- Cheese/Melted Butter: This is the extruded molten resin (typically LDPE, LLDPE, or PP), which melts and fuses everything together.

- The Press: This is the nip roller system that applies pressure to ensure a perfect bond.

The result is a new material with properties that none of the individual layers possessed on their own.

{ Extrusion Lamination Is Like A High-Tech Sandwich }

How Does Extrusion Lamination Work? A Step-by-Step Breakdown

Understanding the mechanics reveals why this process is so effective. Here’s a step-by-step look at a typical extrusion lamination line:

- Material Unwinding: Two or more rolls of substrate material (e.g., a roll of printed PET film and a roll of aluminum foil) are loaded onto the machine and unwound in sync.

- Resin Melting: Plastic resin pellets (most commonly polyethylene) are fed into an extruder. Inside the extruder, a rotating screw works within a heated barrel to melt, mix, and pressurize the resin into a viscous, molten state.

- Extrusion Through the Die: The molten resin is forced through a flat, wide die (a T-die), which shapes it into a thin, uniform curtain of molten plastic.

- The Lamination Nip: This is the critical step. The curtain of molten resin is precisely directed between the two substrate layers. This “sandwich” then immediately passes through a set of rollers known as the “nip.” The nip consists of a hard, steel pressure roller and a large-diameter cooling roller (often called a chill roll). The pressure from the nip ensures intimate contact between all layers, while the chill roll rapidly cools and solidifies the molten resin, setting the bond.

- Surface Treatment (Optional but Common): To ensure the molten resin adheres properly to the substrates (especially non-porous ones like foil or BOPP), the substrate surfaces often undergo a treatment like corona treatment or are primed before entering the nip. This increases their surface energy and improves adhesion.

- Winding: The final, laminated composite structure is now a single, strong web. It is wound onto a large core, creating a master roll that is ready for subsequent processes like slitting, pouch-making, or printing.

The Pros and Cons: Is Extrusion Lamination the Right Choice?

Like any industrial process, extrusion lamination has its distinct set of advantages and disadvantages.

Advantages:

- Versatility: It can bond a vast array of materials, including films (PET, OPP, Nylon), foils, papers, and even non-woven fabrics. This opens up endless possibilities for material combinations.

- Excellent Barrier Properties: By incorporating a layer of aluminum foil or a high-barrier film (like EVOH), extrusion lamination can create packaging with superior barriers against oxygen, moisture, light, and aromas. This is critical for food and pharmaceutical shelf life.

- Enhanced Physical Properties: The process adds significant bulk, stiffness, and puncture resistance to the final laminate, protecting the contents from damage during transportation and handling.

- Cost-Effectiveness: Using a thin layer of extruded resin as an adhesive can be more economical than using a separate adhesive film or a liquid adhesive system, especially for high-volume production.

- High-Speed Production: It is an extremely fast, one-pass process. There is no need for drying or curing ovens, which significantly increases production efficiency compared to wet or dry lamination.

{ Extrusion Lamination Is Cost-Effective }

Disadvantages:

- High Capital Investment: Extrusion laminators are large, complex, and expensive pieces of machinery. This represents a significant barrier to entry for small companies.

- High Energy Consumption: The process requires substantial energy to melt the plastic resin and run the large motors, making it an energy-intensive operation.

- Material Limitations: The choice of the “tie layer” resin is critical. It must be compatible with the substrates to ensure good adhesion. Some high-performance substrates can be challenging to bond.

- Thickness Limitations: Adding an extruded layer inherently increases the overall thickness and gauge of the packaging material, which may not be desirable for all applications.

Key Applications: Where is Extrusion Lamination Used?

Extrusion lamination is the go-to process for demanding packaging applications. You’ll find its products everywhere:

- Food & Beverage Packaging: This is the largest market segment. Think of potato chip bags (BOPP/metallized film/PE), coffee pouches (PET/foil/PE), stand-up pouches for liquids, and aseptic cartons for milk and juice (paperboard/PE/foil/PE).

- Pharmaceutical & Medical Packaging: For blister packs, sterile medical device packaging, and other applications requiring a high moisture and oxygen barrier to maintain product efficacy and safety.

- Industrial Packaging: Heavy-duty sacks for fertilizers, chemicals, and pet food, where strength and puncture resistance are paramount.

- Specialty Applications: Including insulation materials, building wraps, and protective packaging for electronics.

Choosing an Extrusion Lamination Partner: What to Look For

If you’re a brand owner or converter looking to outsource your extrusion lamination needs, selecting the right partner is crucial. Here are key factors to consider:

- Technical Expertise: Do they understand material science? Can they recommend the best substrate and resin combination for your specific product and barrier requirements?

- Equipment Capabilities: Do they have modern, well-maintained machinery capable of handling your desired materials and achieving the required quality and speed?

- Quality Control: A robust quality control system is non-negotiable. Ask about their in-line testing procedures for bond strength, coating weight, and barrier properties.

- Certifications: For food or medical applications, ensure they have the necessary certifications (e.g., ISO, BRC, FSSC 22000).

- Scalability and Reliability: Can they handle your volume, and are they reliable in terms of lead times and delivery?

Conclusion: The Backbone of Modern Packaging

Extrusion lamination is more than just a manufacturing step; it’s a foundational technology that enables the innovation and performance of modern flexible packaging. By combining the strengths of different materials into a single, unified structure, it provides the ultimate protection for countless products we rely on daily.

{ Extrusion Lamination Is An Innovation In Modern Flexible Packaging }

Whether you are an engineer seeking to understand the process, a product developer designing new packaging, or a procurement manager sourcing materials, a deep understanding of extrusion lamination is invaluable. It allows you to make informed decisions, optimize your packaging for performance and cost, and ultimately deliver a better product to the consumer.