In modern flexible packaging, easy-peel films have become a quiet but powerful differentiator. For brand owners, converters, and packaging engineers, they combine secure sealing with a smooth, low-force opening experience that consumers immediately feel in their hands.

For B2B buyers, an optimized easy-peel solution is not just about “opening easily”. It impacts complaint rates, on-shelf appeal, line efficiency, and even sustainability. As an experienced easy peel film manufacturer and supplier based in Qingdao, CloudFilm helps global customers turn these technical parameters into concrete business value.

What Are Easy-Peel Films and How Do They Work?

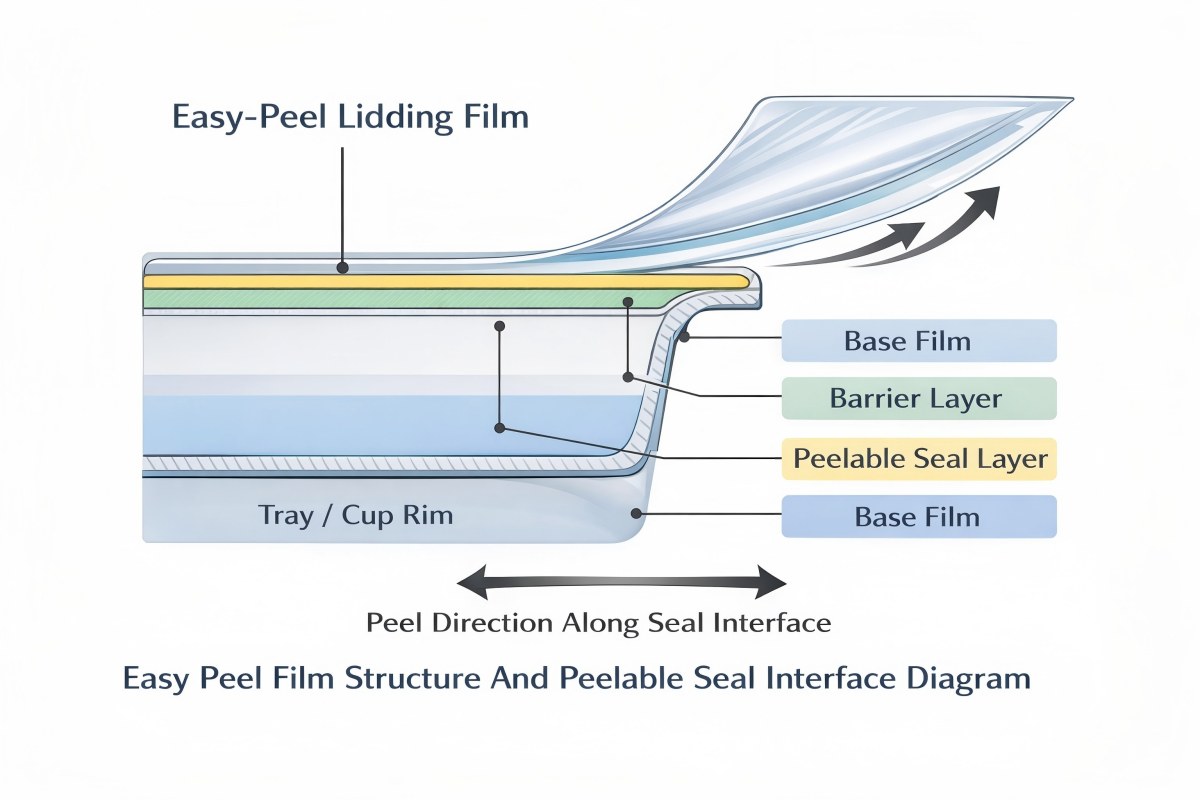

Easy-peel films are multi-layer flexible packaging films designed so that the seal between the lid and the container can be peeled open in a controlled way, without tools and without damaging the container or leaving messy residue. They are widely used as peelable lidding films on cups, trays, and small containers in food, medical, and personal care markets.

At a structural level, an easy-peel film typically includes:

- A base film such as PET, BOPP, CPP, CPE or co-extruded PE;

- A functional layer for printing or barrier (e.g. ALOx PET or high-barrier laminates where extended shelf life is critical);

- A specially formulated peelable sealing layer that determines how much force is required to open the pack and how the peel line looks.

Compared with easy tear films, which are designed to tear through the film itself along a controlled line, easy-peel films focus on peeling at the seal interface. In other words, the lid lifts off the flange of the tray or cup while the container remains intact.

For a deeper technical explanation of structures and peeling mechanisms, you can refer to CloudFilm’s article “The Science Behind Easy Peel Films: A Comprehensive Guide” and the Easy Peel Film product page, where CPP, CPE and PET easy-peel options are introduced in more detail:

Why Easy-Peel Films Boost Product Appeal and User Experience

From the shelf to the kitchen table, easy-peel films touch multiple moments in the consumer journey. Their impact can be grouped into three main dimensions.

Cleaner, Safer and More Predictable Opening

Traditional lidding can require excessive force, causing sudden splashes (for soups and sauces) or product disturbance (for yogurt, desserts, ready meals). Easy-peel films are engineered so that the opening force is lower and more stable, reducing spillage and keeping the product surface intact.

For food brands, this means fewer complaints about “hard-to-open” packs and less product waste. For medical and diagnostic trays, a controlled peel reduces the risk of damaging sterile devices or spilling samples.

More Inclusive and Convenient Packaging

Easy-peel films are especially helpful for children, seniors, and users with reduced hand strength or dexterity. By tuning peel strength, brand owners can design packs that are secure during logistics but still easy to open at home.

For on-the-go consumption (salads, fruit cups, dairy snacks), easy-peel lids allow consumers to open the pack cleanly in cars, offices, or schools, which further enhances perceived convenience.

Better On-Shelf Appeal and Brand Image

Because easy-peel lidding films are often based on high-clarity PET, BOPP or CPP with anti-fog and barrier coatings, the product often looks clearer and more premium on the shelf.

Combined with well-printed graphics and structural elements (windows, partial matte finishes, shaped trays), easy-peel solutions help brands stand out visually while still protecting freshness and safety.

Common Materials and Structures for Easy-Peel Films

A well-designed easy-peel film is always application-driven. At CloudFilm, the most common material families used for peelable lidding include:

PE- and PP-Based Easy-Peel Films

Peelable sealing layers can be formulated on PE or PP structures so that they seal reliably to PP trays, PE lidding, or co-ex structures. These are widely used for dairy cups, fresh produce trays, and chilled ready meals.

For PE-based platforms or mono-material PE concepts, peelable layers can also be combined with MDO PE or BOPE films to support recyclable all-PE packaging. In such designs, easy-peel performance and recyclability need to be balanced carefully.

PET-Based Easy-Peel Films and High-Barrier Structures

PET easy-peel films combine dimensional stability, high clarity, and good heat resistance. They are often chosen for applications requiring frequent opening or premium appearance.

Where oxygen and moisture barrier are critical, PET can be laminated or coated with high-barrier layers such as ALOx PET film or nylon-based laminates (e.g., PE PA PE). These structures can still be designed with a peelable seal layer on the inside, giving you both shelf life and opening convenience.

For a detailed overview of CloudFilm’s high-barrier options, you can refer to:

Easy-Peel vs Easy-Tear: When to Use Which?

Easy-peel films: best for cups and trays where the lid should come off completely and cleanly.

Easy-tear films (such as PET easy tear film): better for flow wraps, stick packs, or pillow pouches where consumers tear through the film along a notch.

CloudFilm supplies both easy-peel and easy-tear solutions. You can compare them in the Speciality Film category to decide which structure is best aligned with your product and packing line.

Typical Applications of Easy-Peel Films

Food and Dairy Packaging

The most visible use of easy-peel lidding is in food:

- Dairy cups (yogurt, pudding, desserts);

- Chilled and frozen ready meals in PP or CPET trays;

- Fresh-cut fruit cups and salad trays;

- Deli, cheese, and meat packs that need clean peel in fridges.

Where branding is important, peelable lidding can be combined with pre-made flexible pouches, cartons, or gift bags to build a multi-layer packaging experience. CloudFilm’s Flexible Pouches range can be paired with easy-peel lidding for secondary packaging or multipacks.

Medical and Pharmaceutical Trays

In healthcare, easy-peel lidding is widely used on:

- Device and instrument trays;

- Diagnostic kits and reagent trays;

- Blister-like packs where controlled opening is essential for sterility.

Here, peel strength windows and delamination behavior are tuned so that the lid peels without generating particulate or tearing into the tray, supporting clean-room and sterile handling.

Personal Care and Household Products

Face masks, patches, cosmetic trays, and certain household products (e.g., wet wipes, cleaning tablets) also benefit from easy-peel formats. When combined with CloudFilm’s high-barrier or printable films, brands can deliver premium unboxing experiences.

How to Choose the Right Easy-Peel Film for Your Project

When you brief an easy-peel film manufacturer or supplier, try to structure your specifications in four steps.

Step 1 – Define Pack Type, Product and Risk Level

- Pack type: cup, tray, blister, pouch, or other;

- Product: chilled / frozen / ambient; acidic, fatty, or neutral;

- Risk level: food safety critical, medical, or general consumer goods.

This step determines whether you need high-barrier structures, retortable films, or standard peelable lids. You can cross-reference CloudFilm’s broader PE film and CPP film guides for background on base materials:

- What Is PE Film? The Ultimate Guide

- CPP Film Properties: The Ultimate Guide for Packaging Professionals

Step 2 – Match Substrate and Sealing Conditions

Easy-peel performance depends on both the film and the container:

- Substrate: PP, PET, PS, PVC, aluminum foil, coated paper, etc.;

- Machine: tray sealer, FFS, VFFS, thermoforming line;

- Sealing conditions: temperature, dwell time, pressure, jaw design.

When you contact CloudFilm, sharing real production parameters (or current film samples) helps our engineers recommend a realistic sealing window instead of trial-and-error.

Step 3 – Set Barrier, Shelf Life and Visual Requirements

Define your targets for:

- Oxygen and moisture barrier (OTR / WVTR);

- Shelf life in your distribution chain;

- Clarity, haze, gloss, and anti-fog behavior;

- Printability and design (matte, window, metallic effects).

High-barrier options such as ALOx PET film or PE PA PE high-barrier laminates can be combined with easy-peel sealing layers when products need deep-freeze or export stability.

Step 4 – Align with Sustainability and Recycling Goals

Regulators and retailers are pushing hard for mono-material flexible packaging and recyclable solutions. Many markets favor mono-PE or mono-PP systems with easy-peel options.

CloudFilm offers:

- Recyclable mono-material pouches that can be paired with easy-peel lidding in some concepts;

- PE- and PP-based films suitable for future-ready recycling streams;

- Guidance on trade-offs between mono-material designs and performance.

Why Work with CloudFilm as Your Easy-Peel Film Manufacturer and Supplier

CloudFilm is not only a film trader; it is the international trading and solution arm of a packaging group with a mature manufacturing base in Northern China, serving more than 400 customers in over 30 countries.

For buyers specifically looking for an easy-peel film manufacturer in China, working with CloudFilm offers:

- Integrated portfolio – BOPP, BOPET, BOPA, PE, CPP, high-barrier and speciality films, including Easy Peel Film

and related speciality grades; - Film + pouch capability – films can be combined with flexible pouches such as stand-up, pillow, quad seal and liquid pouches for a one-stop solution;

- Application-driven engineering – recommendations based on your product, line type and regional regulations rather than generic catalog data;

- Export-focused service – experience with documentation, food-contact declarations and logistics to major global ports.

If you are still refining your requirements, you can start with a short brief: product type, target market, pack dimensions, shelf life, and whether recyclability is a priority. CloudFilm’s team will respond with a practical short list of easy-peel film and lidding options tailored to your project.

Easy-Peel Films FAQ for Packaging Buyers and Engineers

Q1. What is an easy-peel film in flexible packaging?

An easy-peel film is a multi-layer film designed so that the seal between the lid and the container can be peeled open smoothly at a defined force, without tearing the film into pieces or damaging the tray or cup.

Q2. How is easy-peel film different from normal lidding film?

Normal lidding films aim for high seal strength and tamper evidence, often making packs harder to open. Easy-peel films are formulated so that the seal fails in a controlled, “clean peel” mode, giving lower and more stable opening force while maintaining seal integrity in distribution.

Q3. Which substrates can CloudFilm’s easy-peel films seal to?

Typical sealing substrates include PP and CPET trays, PE lidding, some PET or PS containers, and aluminum or coated paper structures, depending on the grade. When you share your exact substrate, CloudFilm can recommend a compatible easy-peel film and validate the sealing window.

Q4. Can easy-peel films run on my existing tray sealing or FFS line?

In many cases, yes. Easy-peel films are designed to work on standard tray sealers and FFS/VFFS lines with adjustments to sealing temperature, dwell time, and pressure. CloudFilm can review your current film and settings, then suggest parameter changes or alternative structures if needed.

Q5. What peel strength range can you offer?

Peel strength can be customized from very light peel (for elderly-friendly food packs) to stronger, more secure seals (for export or medical applications). During development, we usually align on a target peel force range (e.g., N/15 mm) and verify it under your line conditions.

Q6. Are easy-peel films suitable for hot-fill or retort processes?

Yes, but the structure must be chosen carefully. For hot-fill or short-time pasteurization, PET-based or high-heat films are common. For 121 °C retort, special retortable structures (potentially in combination with retort CPP film or high-barrier laminates) should be used. CloudFilm can propose suitable structures after understanding your process.

Q7. Can easy-peel films be combined with anti-fog or high-barrier performance?

Yes. For chilled produce or fresh meals, peelable lidding can be combined with CPP anti fog film or other anti-fog technologies; for sensitive products, peelable lids can be built on top of high-barrier films such as ALOx PET or PE PA PE structures.

Q8. Are easy-peel films compatible with recyclable mono-material packaging?

Yes, many new developments focus on mono-PE or mono-PP easy-peel solutions so that the entire pack can be sorted as one polymer. CloudFilm can help you evaluate whether mono-material structures or recyclable pouches are feasible for your brand and market.

Q9. What is the typical thickness and roll width for easy-peel films?

Typical total thickness ranges from around 25–60 µm for lidding films, depending on the base film and barrier requirements. Roll width is usually matched to your tray or cup layout, with standard and customized widths available.

Q10. Can CloudFilm supply both film rolls and finished pouches or lids?

Yes. CloudFilm can supply easy-peel film rolls for converters and also coordinate with its converting facilities to provide finished flexible pouches (stand-up, pillow, quad seal, liquid) that integrate peelable or easy-open features as required.

Q11. What is the usual MOQ and lead time for easy-peel film orders?

MOQ and lead time depend on structure, width, thickness, and whether you need printing. After understanding your specification, CloudFilm usually proposes a practical MOQ and lead time window that fits export shipping schedules.

Q12. How can I get a quotation from CloudFilm for easy-peel films?

You can use the Get A Quote or Contact Us forms on the CloudFilm website and share:

- End application and pack type;

- Desired structure (or current structure);

- Target thickness and width, or tray/cup dimensions;

- Expected volumes and whether you need printing.

CloudFilm’s sales and technical teams will then respond with a tailored proposal as your easy peel film supplier and manufacturing partner.