Biaxially Oriented Polyamide (BOPA) films have become one of the most important high-barrier materials in flexible packaging. From frozen meat and liquid seasonings to medical devices and technical parts, BOPA films help brand owners and converters protect sensitive products while keeping packages thin, lightweight and visually appealing.

For buyers, packaging engineers, and sourcing managers, understanding how BOPA films really work – where they shine, where they struggle, and how they will evolve – is essential for building competitive, export-ready packaging specifications.

This guide walks through BOPA film fundamentals, key applications, typical challenges, and future development trends. It also gives practical advice on how to work with a reliable BOPA film manufacturer or supplier in China to turn your ideas into stable, repeatable packaging structures.

What Are BOPA Films?

BOPA film is a biaxially oriented nylon film, usually made from polyamide 6 (PA6) or PA66. During production, the film is stretched in both the machine direction (MD) and transverse direction (TD), which significantly improves mechanical strength, puncture resistance and gas barrier performance compared with non-oriented PA film.

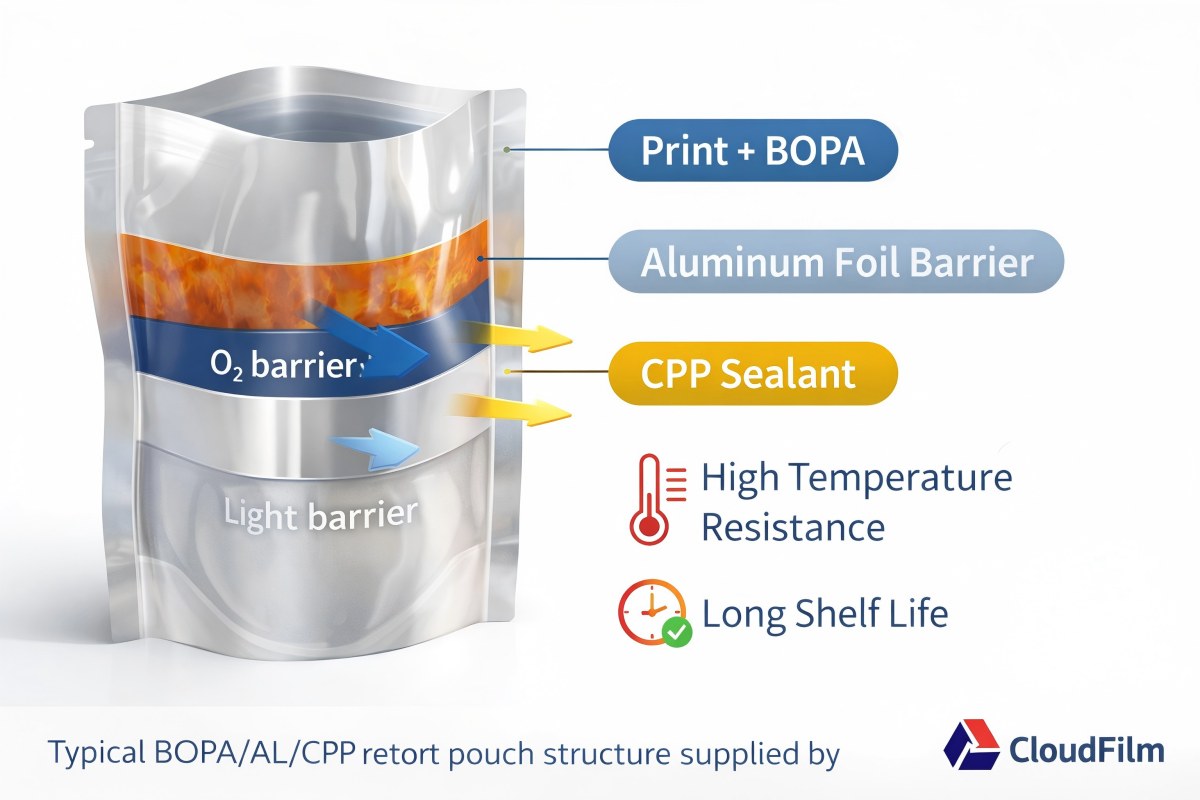

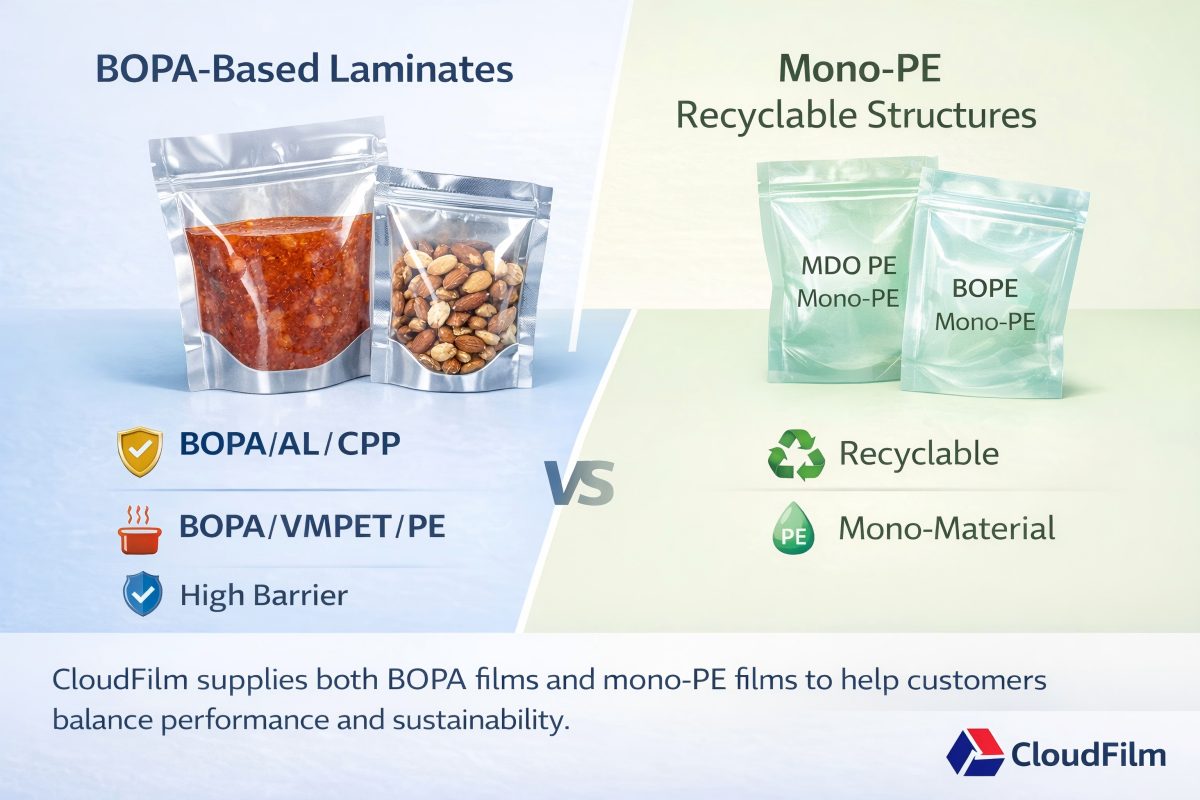

CloudFilm supplies high-barrier BOPA base films as well as PA/PE and PE-PA-PE laminates tailored for vacuum bags, retort pouches, frozen food packaging, and other high-value applications. Typical structures include BOPA/PE, BOPA/CPP, BOPA/AL/CPP, BOPA/VMPET/PE, and BOPA/EVOH/PE, where BOPA usually serves as the tough, high-barrier outer or middle layer.

Technically, there are two main types of BOPA films:

- Sequential BOPA – the film is stretched first in one direction, then in the other. This is the traditional process and is widely used.

- Simultaneous BOPA – the film is stretched in both MD and TD at the same time. This technology offers more uniform thickness, higher clarity and more stable dimensional properties, making it suitable for premium retort pouches and export-grade packaging.

For buyers, the key takeaway is that “BOPA” is not just one film – different densities, stretching processes and laminate structures create very different performance profiles. Choosing the right combination with your BOPA film manufacturer is the foundation of a successful project.

Key Properties Packaging Buyers Care About

When evaluating BOPA films, most packaging professionals focus on a few critical properties that directly affect line performance and shelf life:

- Mechanical strength and puncture resistance

BOPA films exhibit high tensile strength and excellent puncture resistance, which reduces risk of pinholes, burst bags and product leakage during transport and handling. - Gas and aroma barrier

BOPA provides good oxygen and aroma barrier, especially when combined with metallized PET, aluminum foil or EVOH layers. For oxygen-sensitive products like cheese, sauces and ready meals, this barrier performance is a key reason to choose BOPA. Density and orientation conditions directly influence barrier performance. - Transparency and printability

High clarity and gloss make BOPA a strong choice for premium packs where on-shelf appearance matters. Simultaneous BOPA especially offers excellent transparency and a smooth surface that supports fine printing and detailed graphics. - Thermal resistance

BOPA films withstand high retort temperatures when properly laminated with CPP or other sealant films. This makes them suitable for 121–135 °C retort pouches and boil-in-bag applications. - Dimensional stability and shrink behavior

Stable shrinkage and consistent dimensional properties help converters run printing, lamination and pouch-making lines at high speed with less curling or registration issues.

For purchasing teams, these properties should be translated into clear specifications: target OTR, thickness, tensile strength, elongation, shrinkage rate, and lamination structure. Working with a technically strong BOPA film manufacturer helps convert general requirements into data-driven film specs.

Where Are BOPA Films Used Today?

BOPA films appear in many high-value packaging segments where both protection and appearance are critical:

- Frozen and chilled food

- Vacuum bags for frozen meat and seafood (BOPA/PE or BOPA/CPP)

- High-strength outer webs that resist puncture from bones or sharp edges

- Retort and boil-in-bag meals

- BOPA/AL/CPP or BOPA/CPP retort pouches for sauces, soups, ready-to-eat meals and self-heating foods

- BOPA provides toughness and temperature resistance, while aluminum foil or CPP ensures long shelf life and strong seals.

- Cheese, dairy and snacks

- Laminates such as BOPA/VMPET/PE or BOPA/PE for cheese, yoghurt bases, nuts and snack mixes

- Good aroma retention and grease resistance maintain product flavor and package appearance.

- Liquid seasonings and condiments

- Multi-layer BOPA pouches for soy sauce, vinegar and cooking wines, where resistance to flex-cracking and high barrier are essential.

- Medical and technical packaging

- High-barrier pouches for diagnostic kits, medical devices and electronic components

- BOPA/PE or BOPA/EVOH/PE structures used where mechanical strength and barrier must be balanced.

Practical Challenges with BOPA Films

Although BOPA films offer an attractive performance package, they also come with specific challenges that buyers and engineers must manage:

- Moisture sensitivity and dimensional change

Polyamide absorbs moisture, which can influence film stiffness, curl, and dimensional stability. Poorly controlled storage or processing conditions may result in curling laminates or registration issues during printing. - Cost compared with other substrates

BOPA is generally more expensive than workhorse films like BOPP or standard PET. If barrier or puncture resistance is over-specified, you might end up paying more than necessary. A careful comparison with alternatives (such as PET or BOPE) is important. - Recyclability concerns

Multi-material laminates containing BOPA (for example BOPA/AL/CPP) can be difficult to recycle in existing PE or PP recycling streams. Where brand owners push for mono-material solutions, BOPA must be used selectively or replaced with mono-PE designs based on MDO PE or BOPE films. - Processing window and lamination

BOPA films require correct corona treatment, lamination conditions and curing time to avoid delamination or curling. This is especially critical in high-speed gravure or solventless lamination lines. - Supply chain and thickness selection

Not every supplier can provide consistent quality across multiple thicknesses and widths. For global buyers, choosing a BOPA film manufacturer with export experience and technical support is essential to reduce project risk.

Choosing the Right BOPA Structure & When to Use Alternatives

To turn BOPA’s properties into real performance on shelf, you need the right laminate structure. Below is a simplified selection guide (examples only; final specs should be confirmed with your film supplier):

- Frozen meat & seafood vacuum bags

- Typical structure: BOPA/PE or BOPA/CPP

- Why: High puncture resistance from bones, good oxygen barrier, flexible seals.

- Tip: Discuss target drop-test performance and freezer conditions with your BOPA film manufacturer.

- Shelf-stable retort meals and liquid sauces

- Typical structure: BOPA/AL/CPP or BOPA/CPP

- Why: BOPA + aluminum foil or CPP deliver high barrier, high temperature resistance and strong seals.

- Tip: Check retort temperature profile (time & temperature) and choose retort-grade CPP accordingly.

- Cheese, dairy and snacks

- Typical structure: BOPA/VMPET/PE, BOPA/PE

- Why: Balanced barrier, aroma retention and attractive appearance.

- Medical and technical products

- Typical structure: BOPA/PE, BOPA/EVOH/PE

- Why: Strong mechanical properties plus tailored barrier to oxygen, moisture or solvents.

- When to consider mono-PE alternatives

- If your brand focuses on recyclability and wants mono-PE pouches, BOPA is not always ideal. In those cases, consider designs based on MDO PE film or BOPE film, combined with PE-based barrier and sealant layers. CloudFilm already offers MDO PE, BOPE and CPE films that can form 100% PE recyclable structures.

Working with a BOPA Film Manufacturer or Supplier

Selecting the right BOPA film supplier is as important as selecting the right structure. When you work with a dedicated flexible packaging film manufacturer like CloudFilm, you gain access not only to BOPA but also to BOPP, BOPET, PE, CPP, specialty and high-barrier films in one portfolio.

Here are practical tips for buyers and project managers:

- Share detailed application data

Provide end-use information (product type, filling temperature, storage conditions, distribution markets) and your current or target structure. This allows the BOPA supplier to recommend realistic options, not just a generic film grade. - Define performance targets, not only thickness

Instead of saying “we need 15–25 μm BOPA”, specify required OTR, dart impact, puncture resistance, retort conditions and shelf life. The manufacturer can then fine-tune density, stretching conditions and laminate partners. - Ask for technical support and trial strategy

A good BOPA film manufacturer should offer trial rolls, lamination guidance and troubleshooting support. CloudFilm, for example, focuses on helping converters and brands turn complex packaging needs into export-ready film and pouch solutions, with clear specs and stable logistics. - Leverage a multi-material partner

Because CloudFilm also supplies PE, CPP and high-barrier films, you can optimize your entire structure with one partner instead of coordinating multiple suppliers. This is particularly important when you are balancing BOPA with mono-PE or recyclability targets.

Future Trends for BOPA Films

BOPA technology will continue to evolve in several directions:

- More simultaneous BOPA capacity

As brands demand better print quality and tighter tolerances, simultaneous BOPA lines will gain market share. These films offer highly uniform thickness, low haze and stable performance at high converting speeds. - Downgauging with maintained performance

Manufacturers are working on thinner BOPA grades that keep barrier and mechanical properties while reducing material usage, helping converters lower costs and improve sustainability. - Optimized density and barrier design

Combining density control with advanced stretching conditions allows fine-tuning of barrier, stiffness and processability, as discussed in dedicated BOPA density articles. - Hybrid structures with recyclable focus

In parallel with BOPA, mono-material structures based on MDO PE, BOPE and specialty PE films will grow quickly. For some applications, BOPA will remain the best choice; for others, it will be used more strategically or partially replaced by mono-PE solutions. - Smart and functional packaging

As intelligent packaging and “crystal flexible packaging” concepts emerge, BOPA’s strength and clarity can also be combined with smart inks, indicators and high-definition graphics to create high-value packs for premium brands.

FAQs on BOPA Films for Packaging Buyers

Q1. What is BOPA film and how is it different from PET or BOPP?

BOPA film is a biaxially oriented nylon film with higher puncture resistance and better oxygen barrier than standard BOPP and many PET grades. It is often chosen where sharp contents, retort conditions or high aroma retention are critical. BOPP, by contrast, is usually used for moisture barrier and good stiffness, while PET is widely used as a strong, heat-resistant outer layer.

Q2. When should I choose BOPA instead of a mono-PE (MDO PE / BOPE) solution?

Choose BOPA when you need very high puncture resistance, strong mechanical properties and robust oxygen/aroma barrier – for example export-grade vacuum meat bags or retort pouches. When recyclability and mono-PE design are your top priorities, it’s better to build structures around MDO PE or BOPE and PE-based barrier layers, and only use BOPA in specific, justified cases.

Q3. Is BOPA film suitable for retort or boiling applications?

Yes. Properly laminated BOPA structures such as BOPA/AL/CPP or BOPA/CPP are widely used for 121–135 °C retort and boiling applications. You must confirm the retort profile (temperature, time, pressure) with your BOPA film supplier and choose the right retort-grade CPP or sealant film.

Q4. How do I choose the right BOPA thickness for my project?

Thickness depends on application, pouch size, handling conditions and barrier targets. Typical BOPA thicknesses range from 10–25 μm. Instead of choosing a thickness blindly, share your product weight, bag size, drop-test requirements and shelf-life target with your BOPA film manufacturer. They can then balance density, thickness and laminate partners to meet your goals.

Q5. Are all BOPA films the same?

No. BOPA films differ by polymer type, density, stretching process (sequential vs simultaneous), surface treatment and application design. These factors affect clarity, barrier, stiffness, and processing behavior. Always ask your supplier for technical data sheets and sample rolls, and verify performance under your own printing and lamination conditions.

Q6. How do BOPA films impact my total packaging cost?

Although BOPA itself may be more expensive per kilogram than BOPP or standard PET, it can reduce overall packaging cost by allowing thinner laminates, fewer product losses (thanks to high puncture resistance), and longer shelf life. A structured cost analysis with your BOPA film supplier – including yield, scrap rate and logistics – is the best way to evaluate true total cost.

Q7. Can BOPA films be used in combination with speciality films?

Yes. In some premium designs, BOPA is combined with speciality films such as easy-peel, easy-tear or soft-touch films to create unique opening experiences or tactile effects. CloudFilm, as a flexible packaging film manufacturer and supplier, offers a range of speciality films that can be integrated with BOPA structures for high-end applications.

Q8. How can I get technical support or a quotation for BOPA films from CloudFilm?

You can contact CloudFilm directly through the Contact Us page and share your target application, structure, thickness and order volume. The engineering and sales team will respond with recommended film grades, technical suggestions and a quotation tailored to your project.