Introduction

BOPA (Biaxially Oriented Polyamide) film is a high-performance plastic material widely used in flexible packaging, especially for food, pharmaceuticals, and industrial products. One of the key physical properties that determine its suitability for various applications is density.

Understanding BOPA film density helps manufacturers select the right material, optimize production processes, and ensure product performance.

In this guide, CloudFilm will walk you through what BOPA film density is, why it matters, how it’s measured, and how it affects the film’s properties and applications. Whether you are a packaging engineer, procurement specialist, or product developer, this article will give you the insights you need.

If you already know that you need a nylon substrate, you can also explore CloudFilm’s BOPA film product page to review standard thicknesses, download the technical data sheet and request a free quote for trial rolls or production quantities.

{ BOPA Film Production Line }

What is BOPA Film Density?

Density refers to the mass per unit volume of a material, typically expressed in grams per cubic centimeter (g/cm³). For BOPA films, density generally ranges between 1.13 and 1.16 g/cm³, depending on the formulation, additives, and production process.

Unlike materials such as BOPP (Biaxially Oriented Polypropylene) or PET (Polyethylene Terephthalate), BOPA has a higher density due to its molecular structure, which contributes to its excellent mechanical strength and barrier properties.

From a practical standpoint, BOPA’s density range around 1.13–1.16 g/cm³ positions it between lower-density PP films and higher-density PET films, giving nylon an attractive balance of toughness, barrier and stiffness for demanding laminates.

For quick cross-checks of density values and yield calculations across PP, PE, PET and nylon, many engineers also refer to CloudFilm’s flexible film density: formulas, tables & yield guide.

Why Does Density Matter in BOPA Films?

1. Mechanical Strength

Higher density often correlates with better tensile strength and puncture resistance. This makes BOPA films ideal for heavy-duty packaging applications, such as vacuum-sealed bags or retort pouches.

2. Barrier Performance

BOPA films are known for their excellent oxygen and aroma barrier properties. Density influences how tightly the polymer chains are packed, which in turn affects permeability. Higher density generally improves barrier performance.

3. Processing and Printability

Density affects how the film behaves during printing, lamination, and bag-making processes. Consistent density ensures uniform surface tension and ink adhesion.

4. Cost Efficiency

Since density affects material usage per unit area, understanding and controlling it can help reduce material costs without sacrificing performance.

In real projects, CloudFilm’s technical team treats density as one of the core design levers—together with thickness, laminate structure (such as BOPA/PE, BOPA/CPP or BOPA/AL/CPP) and line speed—when helping customers balance shelf life, machinability and total cost.

For a broader, buyer-focused overview of how BOPA film properties translate into actual packs, you can also read our BOPA film usage and benefits guide.

How is BOPA Film Density Measured?

There are several standard methods to measure the density of BOPA films:

1. Gradient Column Method (ASTM D1505)

This is the most accurate technique. A density gradient column is prepared using liquids of different densities. The film sample is immersed, and its position in the column indicates its density.

2. Displacement Method (Archimedes Principle)

The sample is weighed in air and then in a liquid of known density. The difference in weight is used to calculate the film’s density.

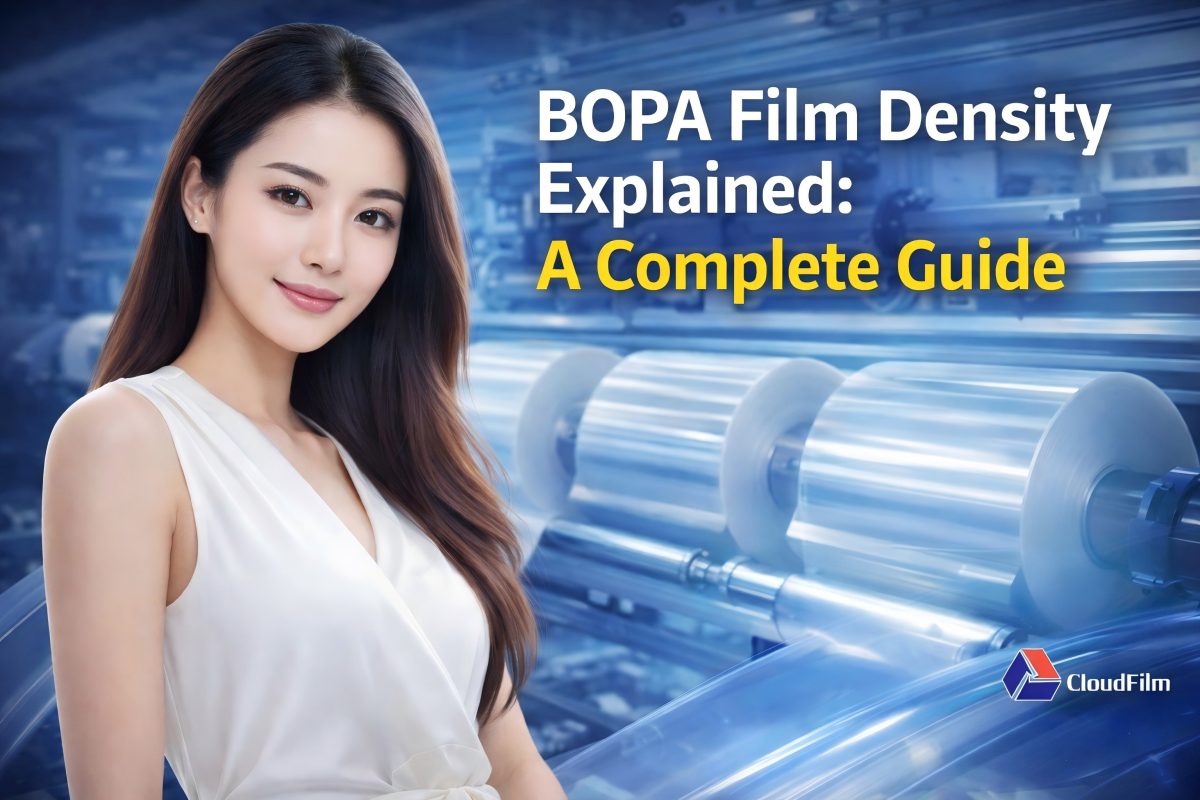

3. Digital Density Meters

Modern instruments can quickly measure density by combining electronic weighing with volume displacement.

In CloudFilm’s laboratory, density testing is often combined with thickness, tensile and barrier tests, so buyers receive a complete data set instead of a single number—making it easier to compare different nylon grades or suppliers.

When you need to convert a measured density into GSM or yield for quotations and logistics planning, you can apply the formulas summarized in our flexible film density article.

{ Various Density Testing Instruments }

Factors Affecting BOPA Film Density

1. Raw Material Composition

Different grades of polyamide resin and additives (e.g., slip agents, antistats) can slightly alter the final density.

2. Biaxial Orientation Process

The stretching process during film production aligns the polymer chains, which can increase density and improve mechanical properties.

3. Crystallinity

Higher crystallinity generally leads to higher density. Processing conditions such as cooling rates and annealing affect crystallinity.

4. Thickness and Uniformity

Variations in thickness across the film can lead to inconsistent density readings.

In multilayer structures, the effective density you “feel” on the line is often a combination of BOPA and sealant layers. CloudFilm routinely evaluates both nylon density and the average density of laminates when supplying films for demanding structures such as PA/PE film or PE PA PE high-barrier film, so that roll weight, stiffness and barrier match your actual packing conditions.

Industry Standards and Specifications

Most BOPA film manufacturers adhere to international standards for quality control:

- ASTM D1505: Standard Test Method for Density of Plastics by the Density-Gradient Technique

- ISO 1183: Plastics — Methods for determining the density of non-cellular plastics

- GB/T 1033: Chinese standard for testing the density of plastics

CloudFilm ensures all BOPA films meet these standards and provides density certificates upon request.

Beyond density, CloudFilm can also issue full technical data sheets (TDS) covering tensile strength, elongation, OTR, WVTR and heat shrink values, so your QA and regulatory teams have complete documentation for audits, certifications and brand owner approvals.

How BOPA Film Density Compares With Other Packaging Films

Compared with lower-density BOPP film at roughly 0.90–0.91 g/cm³ and higher-density BOPET film at around 1.34–1.40 g/cm³, BOPA’s density of about 1.13–1.16 g/cm³ sits in the middle. This gives nylon films a unique balance: more toughness and barrier than PP films, but better flexibility and impact resistance than most PET films at similar thickness.

For packaging buyers, this density position means BOPA is often chosen as the “armor” or abuse-resistant layer in laminates, while BOPP and BOPET serve more as print carriers or optical layers. Our article “Understanding the differences between BOPP, BOPET and BOPA films in packaging” offers a deeper comparison if you are still deciding which base film to use.

When CloudFilm designs a structure for you, we use density and thickness together to estimate GSM, roll weight and yield, so that your BOPA-based laminates stay competitive in both performance and cost.

How to Choose the Right BOPA Film Density With CloudFilm

1. Start from your application and filling process

Tell CloudFilm whether your pack is frozen, vacuum, MAP, retort, boil-in-bag or medical. Different applications may favor slightly different BOPA densities and thicknesses, especially where puncture resistance or high-temperature performance is critical.

2. Share target shelf life and export routes

If your product needs 12–24 months of shelf life or must withstand long sea shipments, CloudFilm may recommend pairing BOPA with PE, CPP, aluminum foil or EVOH co-extruded films, and then fine-tune density and thickness for optimal barrier and cost.

3. Review CloudFilm’s BOPA and nylon laminate options

Besides base BOPA film , CloudFilm also supplies nylon laminates such as PA/PE film

and PE PA PE film. Density considerations for these structures are slightly different from single-layer film, and our engineers can explain the trade-offs in simple, project-focused language.

4. Validate density on your own lines with trial rolls

CloudFilm can provide small trial rolls at agreed density and thickness so you can test form-fill-seal performance, sealing behavior and drop resistance before committing to container-level orders.

5. Lock in a specification and long-term supply plan

Once you are satisfied with the density, thickness and line performance, CloudFilm can formalize a technical specification and supply plan so that your team, your converter and your brand owner all reference the same data sheet.

Practical Applications Based on Density

1. Food Packaging

High-density BOPA films are preferred for retort and boil-in-bag packaging due to their superior strength and barrier properties.

2. Pharmaceutical Packaging

Controlled density ensures consistent film performance in blister packs and medical pouches, where sterility and protection are critical.

3. Industrial Uses

In electronics and automotive components, BOPA films with specific density values are used for insulation and protective layers.

4. High-Barrier Laminates and Demanding Export Packs

For export-grade vacuum bags, bone-in meat packaging or premium coffee and snack pouches, CloudFilm often recommends BOPA-based laminates such as BOPA/PE, BOPA/AL/CPP or nylon structures combined with high-barrier films. In these cases, getting density right helps you avoid pinholes and burst bags while keeping roll weights and freight under control.

{ BOPA Film Used for Various Packaging Applications }

Frequently Asked Questions (FAQ)

Q1: Is higher density always better for BOPA films?

Not necessarily. While higher density often improves strength and barrier properties, it may reduce flexibility. The optimal density depends on the application.

Q2: How does density affect the cost of BOPA film?

Higher density means more material per square meter, which can increase costs. However, the improved performance may justify the expense in demanding applications.

Q3: Can CloudFilm customize BOPA film density?

Yes, CloudFilm offers tailored BOPA film solutions with controlled density ranges to meet specific customer requirements.

Q4: What is the typical density range of BOPA film, and can it vary by supplier?

Most nylon 6-based BOPA films used in packaging fall in the range of about 1.13–1.16 g/cm³. Small differences can exist between suppliers due to resin grade, additives and process conditions. When you work with CloudFilm, the density range is specified on the BOPA film data sheet so that you know exactly what you are buying.

Q5: How can I quickly estimate GSM and yield for a BOPA-based laminate?

You can use the simple formulas GSM = ρ × t(µm) and Yield (m²/kg) = 1000 / (ρ × t), where ρ is the average density of all layers. CloudFilm can help you calculate the average density for structures such as BOPA/PE or BOPA/AL/CPP, or you can refer to our flexible film density guide for step-by-step examples.

Q6: Does BOPA density affect retort performance and pinhole resistance?

Yes. For retort pouches and boil-in-bag applications, choosing the right combination of BOPA density and thickness helps resist pinholes, flex-cracking and delamination during sterilization and transport. CloudFilm’s technical team can suggest suitable density and gauge ranges based on your filling temperature, sterilization conditions and product type.

Q7: Can CloudFilm provide trial rolls with specific density and thickness for line tests?

Yes. For new projects, CloudFilm can supply small trial rolls of BOPA film

or nylon laminates at agreed density and thickness, so that you can run them on your form-fill-seal or pouch-making lines before confirming bulk orders.

Q8: What information should I prepare before asking CloudFilm for a BOPA density recommendation?

It is helpful to share your product type (e.g. frozen meat, sauces, snacks, pet food, medical devices), packaging format (vacuum bag, retort pouch, thermoforming web, etc.), target shelf life, filling and sterilization conditions, and approximate annual volume. With this information, CloudFilm can quickly narrow down a suitable density and structure and send you a clear proposal.

Conclusion

BOPA film density is a fundamental property that influences everything from mechanical performance to processing behavior and cost. By understanding how density is measured, what affects it, and how it impacts real-world applications, you can make better material choices and optimize your packaging solutions.

{ Contact CloudFilm for Free Nylon Film Samples }

At CloudFilm, we combine advanced manufacturing technology with strict quality control to produce BOPA films with consistent and reliable density. Contact us today to learn more about our products or request a sample tailored to your needs.

If you are planning a new nylon-based project, you can start by sharing your product, packaging structure and expected volume via the CloudFilm BOPA film product page or our contact form. Our team will review your requirements, recommend a suitable density and structure, and usually respond with a clear proposal within one working day.