In modern flexible packaging, “product health” is more than just a marketing phrase. It is the sum of freshness, safety, sensory quality, and shelf life that your customer actually experiences when they open a pack.

For brand owners, converters, and packaging engineers, choosing the right high barrier film is one of the most critical levers for protecting that product health.

Among today’s barrier technologies, ALOx PET high barrier film stands out as a rare combination of crystal-clear transparency and ultra-low gas and moisture transmission. When specified correctly, it allows you to build packages that “feel like glass” in clarity, but protect like a metalized laminate.

As a China-based ALOx PET film manufacturer and supplier, CloudFilm helps converters and brands turn these technical advantages into clear, robust specifications for food, pharma, and electronic packaging projects.

What Is ALOx PET High Barrier Film?

ALOx PET film is a vacuum-deposited aluminum oxide coated BOPET film. In simple terms, a very thin layer of aluminum oxide (ALOx) is applied onto a biaxially oriented PET base, creating a transparent film with very high oxygen and moisture barrier while keeping the typical clarity and stiffness of BOPET.

Cloud Film

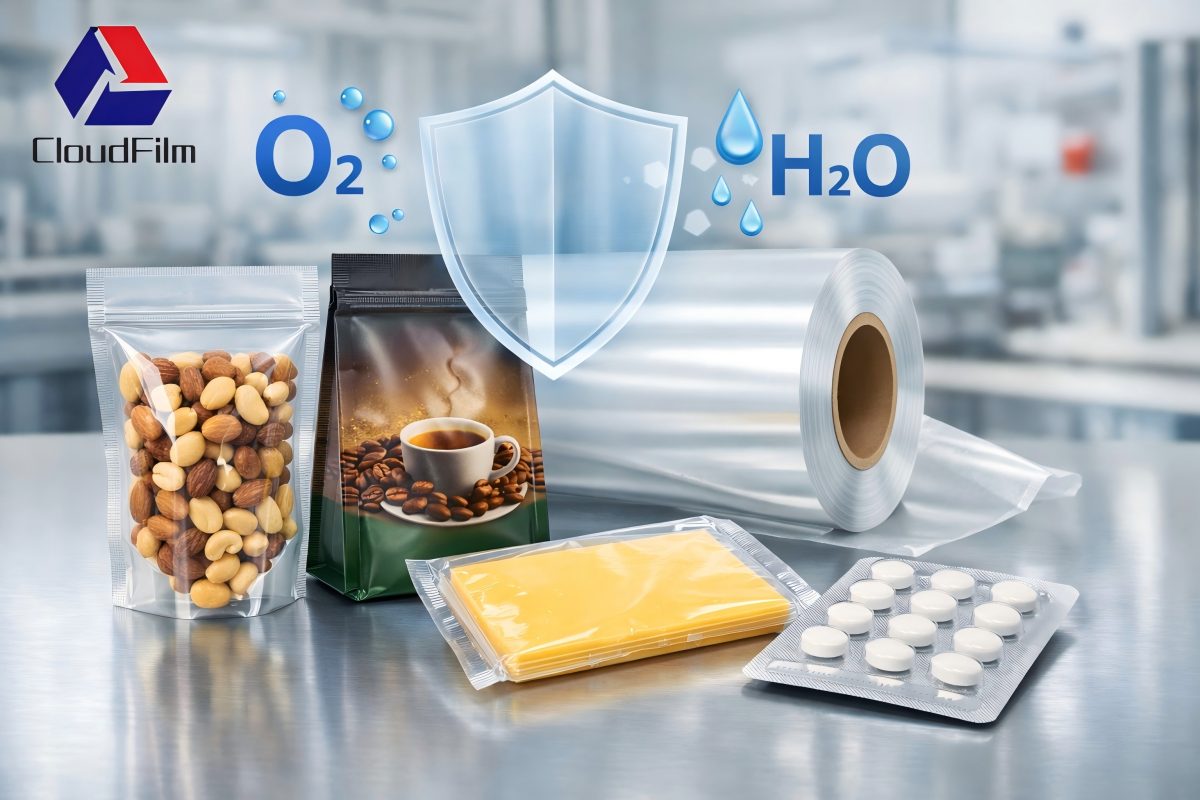

Because the aluminum oxide layer is extremely thin and fully oxidized, the film keeps a glass-like appearance instead of a metallic look. That makes ALOx PET ideal wherever both product visibility and high barrier performance are required.

- Typical applications: high-barrier food packs, coffee, nuts, snacks, cheese, vacuum or MAP meat, pharmaceuticals, diagnostics, and technical products.

- Typical role in a laminate: non-sealable barrier web combined with PE, CPP, PA/CPP or other sealant films.

CloudFilm’s dedicated ALOx PET film product page provides a technical overview, data sheet, and application examples for converters and packaging buyers.

Structure and Coating Principle

At the core of ALOx PET high barrier film is a multilayer structure:

- BOPET base film

- Provides mechanical strength, dimensional stability, and temperature resistance.

- Offers excellent printability and stiffness for premium shelf appearance.

- Aluminum oxide (ALOx) barrier layer

- Deposited under vacuum by a physical vapor deposition process.

- Creates a continuous, ultra-thin, transparent ceramic-like barrier against oxygen, moisture, and aroma loss.

- Top coatings and surface treatments (optional)

- Corona treatment or primer layers improve ink and adhesive anchorage.

- Protective coatings help maintain barrier performance during slitting, laminating, and form–fill–seal.

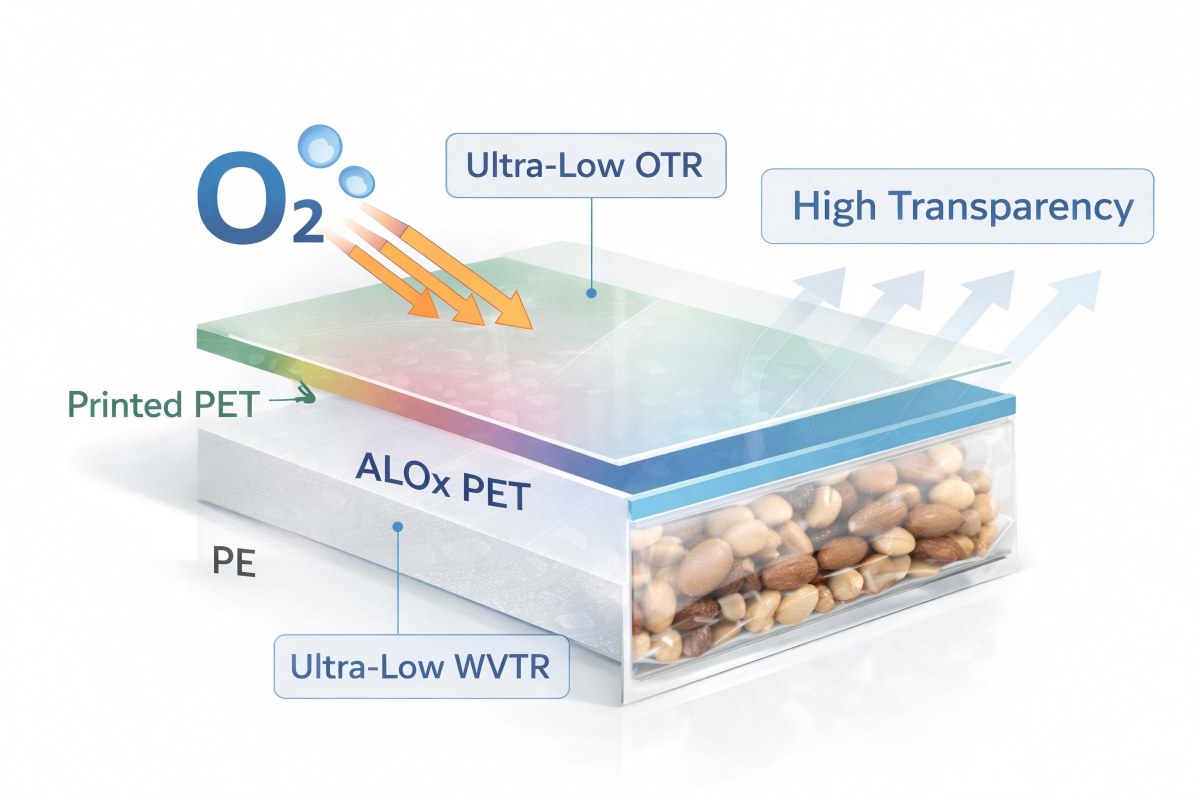

The result is a high barrier, non-chlorinated packaging web that can be laminated into structures like ALOx PET/PE or ALOx PET/CPP for horizontal and vertical form-fill-seal (HFFS/VFFS), stand-up pouches, and lidding films.

Barrier and Optical Performance

Compared with standard PET film, ALOx PET delivers a step-change in barrier:

- Oxygen Transmission Rate (OTR): ultra-high-barrier ALOx grades can reach roughly 0.1–0.3 cc/m²·day.

- Water Vapor Transmission Rate (WVTR): down to around 0.25 g/m²·day at 38 °C / 90% RH, depending on grade.

Cloud Film - Transmittance / clarity: typical light transmittance around 87%, keeping your pack crystal-clear despite the barrier layer.

Cloud Film

These values allow you to approach the shelf life of metalized PET or aluminum foil in many applications, but with full product visibility.

Engineering note: Actual barrier performance depends on film grade, converting conditions, and the rest of the laminate. Always validate with your own tests before final specification.

Why Product Health Depends on a Solid Barrier

“Product health” means the product reaches the consumer as intended: safe, stable, and appealing. ALOx PET contributes to this goal by controlling the main external stress factors.

How Oxygen, Moisture and Light Damage Products

- Oxygen drives oxidation, rancidity, color fading, and loss of active ingredients.

- Moisture causes caking, microbial growth, texture changes, and API degradation for pharmaceuticals.

- Light (especially UV) accelerates oxidation and flavor loss, and may break down sensitive APIs and vitamins.

For high-value foods, nutraceuticals, or medicines, even small changes in barrier performance can mean the difference between “best before” and customer complaints.

Barrier Requirements by Product Category

Different products require different barrier windows:

- Snacks, nuts, coffee: very sensitive to oxygen and aroma loss; require low OTR, moderate to low WVTR; high aroma barrier.

- Fresh and cooked meat, cheese: require strong oxygen and moisture barrier, plus seal integrity and puncture resistance; ALOx PET is often combined with PA/PE or PA/CPP.

- Pharmaceuticals and diagnostics: often moisture-sensitive; barrier must be stable under storage and distribution; clear packs help visual inspection.

- Electronics: require strict moisture control and often anti-static properties; ALOx PET barrier helps prevent corrosion of sensitive components.

ALOx PET high barrier film gives packaging engineers a transparent barrier platform that can be tuned with different sealant webs to match each product’s risk profile.

Core Applications of ALOx PET High Barrier Film

ALOx PET is already widely used in CloudFilm’s global customer base. Typical application clusters include:

High-Barrier Food Packaging

- Vacuum and MAP packs for fresh and cooked meat, sausages, cheese and smoked products – typically ALOx PET/PE or ALOx PET/CPP laminates.

- Stand-up and pillow pouches for coffee, nuts, dried fruits, snacks and pet food, where crunch, aroma and color must stay stable.

- Lidding films for chilled ready meals that need both visibility and strong barrier.

For a broader view of barrier structures used in frozen meat and thermoforming, buyers can also refer to CloudFilm’s guide on packaging for frozen meat.

Pharmaceutical and Healthcare Packaging

ALOx PET is an excellent choice for:

- Sachets and overwraps for moisture-sensitive tablets, capsules, and powders.

- High-barrier pouches for medical devices and diagnostic reagents that benefit from visual inspection.

In these markets, it is often used alongside PVDC PET, aluminized PET, and co-extruded EVOH films to build multi-layer barrier systems.

Electronics and Technical Packaging

In electronics and technical industries, ALOx PET is used for:

- Moisture-barrier bags for components and sensors.

- Transparent barrier layers in technical laminates where both visibility and moisture control matter.

CloudFilm can combine ALOx PET with anti-static or shielding webs from its broader PET and specialty film portfolio.

ALOx PET vs Other High-Barrier Materials

When designing high-barrier packaging, ALOx PET is rarely the only option. It usually competes or works together with PVDC PET, aluminized PET (VMPET), and aluminum foil.

ALOx PET vs PVDC Coated PET Film

Both ALOx PET and PVDC coated PET film are transparent high-barrier PET structures, but their chemistry and sustainability profiles differ.

- PVDC PET uses a polyvinylidene chloride coating to achieve very high barrier, especially in humid environments. It is a proven workhorse in many food and pharma applications.

- ALOx PET uses a chlorine-free aluminum oxide layer, making it more attractive for customers aiming to avoid halogenated materials and to simplify end-of-life scenarios.

From a buyer’s standpoint:

- Choose PVDC PET when you need extremely robust, proven barrier and existing pack lines are already validated with PVDC.

- Choose ALOx PET when chlorine-free materials, microwave-ability, and sustainability positioning are important.

CloudFilm acts as a technical partner and manufacturer for both families and can help you decide which path fits your specification best.

ALOx PET vs Aluminized PET and Aluminum Foil

Aluminized PET film (VMPET) provides very high barrier and a metallic appearance, often used for coffee, snacks, tea and pet food. Aluminum foil offers the highest barrier but zero transparency and higher stiffness.

Compared with those options:

- ALOx PET

- Transparent; ideal for “window” or fully clear packs.

- Very high barrier, though usually slightly below the best VMPET and foil in absolute OTR/WVTR.

- Good fit for premium, natural, or health-positioned brands that want consumers to see the product.

- VMPET / Foil

- Opaque; cannot show the product.

- Excellent light barrier; often preferred for very light-sensitive powders or oils.

- Strong “premium” metallic appearance in some markets.

Your final choice will depend on whether visibility or maximum opacity and light barrier is more important for your product and brand.

Sustainability and Compliance

ALOx PET brings several sustainability and regulatory advantages:

- Chlorine-free barrier, avoiding PVDC-related concerns in some markets.

- Ultra-thin coating reduces the total amount of inorganic material compared with foil.

- PET base structures can be engineered to align with certain recycling or energy-recovery streams, depending on local infrastructure.

CloudFilm supports discussions around recyclability, EPR, and local compliance and can propose alternative structures when a specific regulation limits certain chemistries.

Designing the Right ALOx PET Laminate Structure

Typical Laminate Examples

Common ALOx PET laminate structures include:

- ALOx PET / PE – for pillow pouches and flow-wraps for snacks, cereals, and dry foods.

- ALOx PET / CPP – for lidding films, retortable or pasteurizable pouches when combined with appropriate CPP grades.

- Printed PET / ALOx PET / PE – for high-end packaging needing both print quality and barrier.

- ALOx PET / PA / PE – for vacuum and MAP packs needing additional toughness and puncture resistance.

For outer webs, you can combine ALOx PET with the wider BOPET film portfolio and structures discussed in CloudFilm’s article “BOPET Film for Packaging”.

Matching Barrier Level to Shelf Life

When specifying ALOx PET, consider:

- Target shelf life (weeks vs months vs export).

- Distribution temperature (ambient, chilled, frozen).

- Desired residual oxygen level inside the pack.

- Product sensitivity to humidity and aroma loss.

CloudFilm offers multiple ALOx PET barrier levels (e.g., HA11–HA16 series) so that you can avoid “over-engineering” barrier for products that do not require the highest levels.

Machinability, Sealing and Printing

ALOx PET films are designed for:

- High-speed printing and lamination, supported by corona treatment and optimized surface energy.

- Stable barrier after slitting and pouch making, when processed under recommended tensions and temperatures.

- Excellent print quality when used in reverse printing with solvent-based or water-based inks.

Seal performance depends mainly on the PE / CPP / PA-PE layers you choose. CloudFilm’s broader film and pouch portfolio allows you to source both the barrier web and sealant webs from one manufacturer, simplifying supply chain and technical alignment.

Working With CloudFilm as Your ALOx PET Film Manufacturer & Supplier

As a flexible packaging film manufacturer and exporter based in Qingdao, China, CloudFilm supplies ALOx PET film rolls and finished laminates to converters and brands in many countries.

Key advantages for buyers:

- Specification-driven support – you can share your current structure (e.g. PET/VMPET/PE, PVDC PET/PE) and target shelf life; CloudFilm engineers propose an ALOx PET alternative and validate barrier windows.

- Broad high-barrier portfolio – besides ALOx PET, CloudFilm supplies PVDC PET, aluminized PET, co-extruded EVOH films and high-barrier pouches under its high barrier film category.

- Flexible ordering – typical thickness from 10–24 µm, widths from 100–2000 mm, cores in 3″ or 6″, with MOQs aligned to industrial converters.

- Sampling & trials – free A4 sheets or short trial rolls can be provided to help you validate machinability and barrier before bulk orders.

For overseas buyers, working with a China ALOx PET film manufacturer and supplier like CloudFilm means competitive cost, consistent quality, and support from a team that understands both export documentation and converter needs.

ALOx PET Film Buying Checklist

Before requesting a quotation, prepare as much of the following information as possible:

- Packed product & market

- Food (snacks, coffee, nuts, meat, dairy), pharma, nutraceutical, electronics, industrial, etc.

- Main sales regions (EU, North America, Middle East, etc.).

- Target shelf life & storage conditions

- Ambient, chilled, frozen; export vs domestic.

- Current or target laminate structure

- e.g. PET/VMPET/PE, PVDC PET/PE, PA/PE, ALOx PET/PE; layer thicknesses if known.

- Packaging format & machinery

- Pillow pouch, stand-up pouch, vacuum pack, lidding, thermoforming top web or bottom web; FFS speed, sealing jaws temperature range.

- Critical performance requirements

- OTR/WVTR targets (if available); puncture resistance; hot-fill or retort conditions; peelability.

- Roll & logistics details

- Required film thickness range, width range, core size (3″ or 6″), maximum roll OD, preferred Incoterms (FOB/CIF), and trial roll needs.

If you are not familiar with all parameters, CloudFilm can still work from photos of your existing package and a rough description, then reverse-engineer a suitable ALOx PET grade and laminate.

FAQs: ALOx PET High Barrier Film

Below is an FAQ section designed to match typical questions from buyers, engineers, and sourcing teams—useful for both Google and AI search visibility.

Q1. What exactly is ALOx PET high barrier film?

A1. ALOx PET high barrier film is a biaxially oriented PET film coated with an ultra-thin aluminum oxide layer under vacuum. This coating provides very low oxygen and moisture transmission while keeping the film transparent, making it ideal as a barrier layer in laminated flexible packaging.

Q2. Is ALOx PET a replacement for aluminized PET or aluminum foil?

A2. In many snack, coffee, and dry-food applications, ALOx PET can replace aluminized PET or even aluminum foil when a transparent pack is desired and barrier targets can be met. However, for extremely light-sensitive or ultra-long-life applications, aluminized PET or foil may still be preferred. CloudFilm’s aluminized PET film page provides comparison structures for such cases.

Q3. What barrier levels can ALOx PET film reach?

A3. Depending on grade, ALOx PET film from CloudFilm can achieve OTR values roughly in the 0.1–0.3 cc/m²·day range and WVTR as low as 0.25 g/m²·day at 38 °C / 90% RH, while maintaining high clarity. These are typical values; final performance depends on your laminate and process.

Q4. Is ALOx PET film microwave-safe?

A4. Yes. Because the aluminum layer is extremely thin and fully oxidized, ALOx PET is microwave-safe in many structures, unlike continuous metal foil. Nevertheless, each application should be validated under real heating conditions to confirm seal integrity and product safety.

Q5. Can ALOx PET be used for retort or high-temperature processing?

A5. ALOx PET can be combined with retort-grade CPP or PA/CPP sealant layers to build structures for pasteurization and some retort conditions. For full 121 °C / 30 min retort, CloudFilm engineers will evaluate barrier stability and may propose hybrid structures with other high barrier films or foil.

Q6. What thicknesses and widths of ALOx PET does CloudFilm supply?

A6. Standard ALOx PET grades are usually available around 12 µm thickness, with options up to the low-20 µm range. Widths typically span from 100–2000 mm, supplied on 3″ or 6″ paper cores, subject to minimum order quantities.

Q7. Is ALOx PET film recyclable?

A7. ALOx PET is based on PET and uses a very thin inorganic coating, which can be compatible with certain PET recycling or energy-recovery systems, depending on local infrastructure. It is chlorine-free and generally easier to position from a sustainability perspective than many PVDC-based structures, but any recyclability claim must be validated market by market.

Q8. How do I choose between ALOx PET, PVDC PET and aluminized PET?

A8.

- Choose ALOx PET for transparent barrier, chlorine-free chemistry, and strong brand storytelling around product visibility and sustainability.

- Choose PVDC PET for very robust, proven barrier in many food and pharma lines where PVDC is already accepted.

- Choose aluminized PET (VMPET) when a metallic appearance or strong light barrier is needed and transparency is not required.

CloudFilm acts as a multi-material supplier and technical consultant, helping you compare options based on product, shelf life, line conditions and regulatory constraints.

Q9. Does CloudFilm only supply ALOx PET film rolls, or also finished laminates and pouches?

A9. CloudFilm primarily supplies ALOx PET and other films in roll form, but also supports laminate and pouch projects through its wider flexible packaging network. Depending on your region and volume, CloudFilm can act as a film manufacturer, a laminate solution provider, or a technical partner working with your existing converters.

Q10. Can CloudFilm support small trials for new ALOx PET projects?

A10. Yes. CloudFilm can provide free A4 sheets or short trial rolls of ALOx PET film for lab and pilot runs, helping converters and brands de-risk new projects before committing to full container loads.

Conclusion: Turn ALOx PET Knowledge into a Clear Specification

ALOx PET high barrier film bridges the gap between premium transparency and strong product protection. When you combine its ultra-low OTR and WVTR with the right sealant films and pack formats, you can deliver healthier, fresher products with a modern, visible packaging design.

By working directly with a specification-focused China ALOx PET film manufacturer and supplier like CloudFilm, you can:

- Translate complex barrier requirements into clear film structures and data sheets.

- Compare ALOx PET with PVDC PET, aluminized PET and other high barrier films within one portfolio.

- Move from samples and pilot runs to stable, repeatable mass production.

If you are exploring transparent high-barrier packaging for food, pharma, or technical applications, ALOx PET film is an excellent place to start—and CloudFilm is ready to help you turn that idea into a reliable, commercial specification.