EVOH Bags

EVOH bags from CloudFilm are multi-layer high-barrier vacuum and MAP bags that provide outstanding oxygen and moisture protection for chilled and frozen meat, cheese, seafood, sauces and liquid foods.

- High Barrier Performance – Multi-layer PA/EVOH/PE or PE/EVOH/PE structure with very low oxygen transmission to extend shelf life and protect aroma.

- Strong Puncture Resistance – Tough outer and inner layers help resist bones, sharp edges and impacts during freezing, transport and distribution.

- Clear Product Presentation – High clarity and gloss make your products look fresh and premium on the shelf.

- Flexible Formats – Available as vacuum bags, shrinkable bags, bag-in-box liners, bag-in-drum liners and roll stock for local converting.

- Food-Contact Safety – Produced from food-grade raw materials in CloudFilm’s certified facilities, suitable for export markets worldwide.

EVOH Bags Description

CloudFilm EVOH Bags: Ultimate High-Barrier Packaging Solution

Extended Freshness With Multi-Layer EVOH Barrier

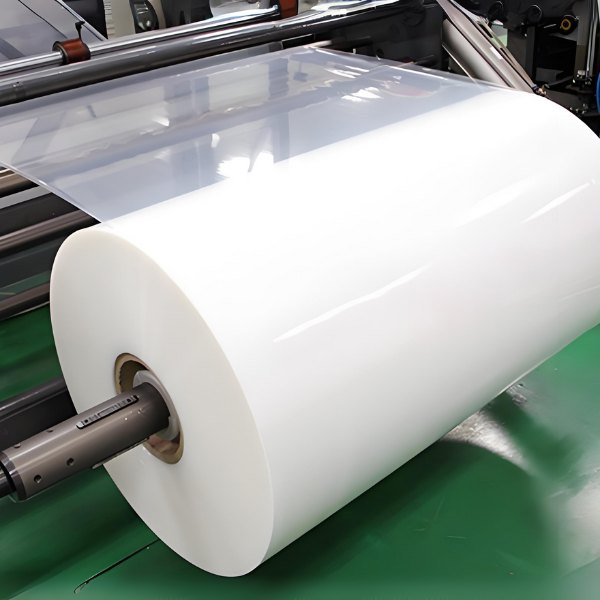

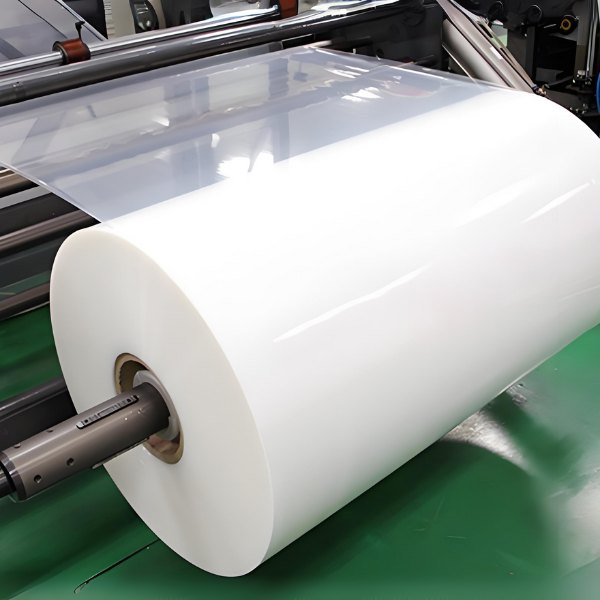

CloudFilm EVOH bags are based on co-extruded multi-layer structures such as PA/EVOH/PE or PE/EVOH/PE. The EVOH core layer provides very low oxygen transmission, while PA and PE layers add toughness, sealability and moisture protection. Compared with conventional PA/PE vacuum bags, EVOH high-barrier bags help you achieve longer chilled or frozen shelf life with less product loss and fewer returns.

Application-Driven Design For Meat, Dairy And Liquids

For fresh and frozen meat, poultry and seafood, CloudFilm EVOH vacuum bags protect color, flavor and texture throughout the cold chain and export logistics. For sauces, kimchi, ready meals, dairy drinks and fermented products, they can also be designed as bag-in-box or bag-in-drum liners with strong seals and excellent clarity. If you are still evaluating barrier options, you can refer to our article “EVOH Barrier: The Ultimate Guide from Material Properties to Industry Applications” and “Difference Between Nylon and EVOH: A Comprehensive Comparison” to

better understand when EVOH bags are the right choice.

Film + Pouch Capability From One Supplier

As a flexible packaging manufacturer in Qingdao, China, CloudFilm not only produces EVOH-based high-barrier films, but also converts them into finished bags and pouches. This film-plus-pouch capability allows us to match your EVOH bags with related solutions such as Retort Pouches and other Flexible Pouches. Our team supports you from structure design and sampling to mass production and export logistics, providing clear specifications, food-contact documentation and stable quality for long-term cooperation.

Get Free Sample of EVOH Bags

Ready to test CloudFilm EVOH high-barrier bags on your own line? We can prepare free stock samples or small trial quantities so you can check shelf life, seal strength and machinability before placing a larger order.

To help us give you an accurate proposal faster, it is helpful (but not mandatory) to share:

- What product you will pack (for example: beef, poultry, seafood, cheese, kimchi, soup, baby food, pharmaceutical or chemical products).

- Target shelf life, storage temperature (chilled, frozen or ambient) and whether you use vacuum, MAP or hot-fill.

- Approximate bag size, thickness and order quantity, and whether you need plain or printed EVOH bags.

Send these details through the inquiry form or by email. CloudFilm will reply with a recommended EVOH bag structure, quotation and lead time within 12–24 hours.

EVOH Bags Applications

Meat And Seafood Packaging

CloudFilm EVOH bags are widely used as high-barrier vacuum bags for fresh and frozen meat, poultry and seafood. They help maintain color, flavor and juiciness by reducing oxygen ingress and freezer burn during long-term cold storage and export shipping. For a broader overview of frozen meat packaging formats and structures, you can also refer to our article “Packaging for Frozen Meat: Films, Pouches & Trays”.

Dairy And Liquid Food Packaging

For liquid milk, drinking yogurt, cheese, cream and ready-to-eat meals, EVOH bags can be designed as bag-in-box or bag-in-drum liners with strong seals and high clarity. The high barrier performance helps protect flavor and nutrition throughout the distribution chain. When you need spouted formats for beverages or liquid foods, please also check our Liquid Pouches solutions.

Sauces And Condiments

EVOH high-barrier packaging is ideal for oxygen-sensitive sauces and condiments such as ketchup, mayonnaise, chili sauce, kimchi and pickled vegetables. It effectively slows down oxidation and fermentation changes, helping you maintain taste, color and aroma. For products that require high-temperature sterilization, many customers combine EVOH structures with our Retort Pouches to meet both safety and shelf-life targets.

Pharmaceutical And Medical Products

For moisture- and oxygen-sensitive pharmaceutical powders, diagnostic kits and medical devices, EVOH bags provide reliable protection for stability and efficacy. They can be used as primary or secondary packaging, or as liners inside cartons and drums. For more specialized medical pack formats, you can refer to our Pharmaceutical Pouches product page.

Personal Care And Chemical Products

In personal care and household chemicals, EVOH bags help preserve the active ingredients in products such as hair treatments, cleaning concentrates, agrochemicals and specialty chemicals. The combination of chemical resistance and gas barrier reduces odor emission and product degradation. For retail packs that require strong branding, you can also combine EVOH films with our printed Stand Up Pouches or other flexible pouch types.

FAQ

EVOH (Ethylene Vinyl Alcohol) is a high-barrier polymer used as a thin core layer inside multi-layer films. In CloudFilm EVOH bags, this layer strongly reduces oxygen transmission, while PA and PE layers provide strength, sealability and moisture protection. Together they create a high-barrier bag that keeps meat, cheese, liquids and sensitive products fresh for a longer time.

CloudFilm EVOH bags are mainly used for fresh and frozen meat, poultry and seafood, dairy products, sauces and condiments, kimchi and pickles, baby food, liquid foods and certain pharmaceutical or chemical products that are sensitive to oxygen and moisture. If you work with frozen meat, you can also refer to our guide “Packaging for Frozen Meat: Films, Pouches & Trays” for typical structures and formats.

We typically design EVOH bags based on multi-layer structures such as PA/EVOH/PE or PE/EVOH/PE, with total thickness usually in the range of 60–200 µm depending on the product, bone content and logistics conditions. Thicker structures are recommended for bone-in meat or export cartons, while thinner structures can be used for small portions, sauces or inner liners.

If you already have a specification, we can match it; if not, CloudFilm can recommend a structure after understanding your application.

Standard EVOH bags from CloudFilm are suitable for chilled and frozen storage, as well as moderate hot-fill or pasteurization conditions (for example up to about 90–100°C, depending on structure and dwell time). For in-pack sterilization around 121°C, we normally suggest using our dedicated Retort Pouches together with Retortable CPP Film to

ensure seal integrity and product safety.

Yes. CloudFilm produces EVOH-based films and bags using food-contact grade raw materials and inks, under strict quality and hygiene control. We can support compliance with common regulations such as FDA and EU food-contact standards, and provide documents like COA, migration test reports or third-party lab certifications on request, similar to other food packaging products in our portfolio.

CloudFilm can customize bag size, thickness, structure and printing according to your project. Options include plain transparent bags, printed bags with your brand logo, and bags with special features such as tear notch, hang hole or rounded corners. MOQs are flexible and depend on bag size and printing complexity; for many projects we can support trial quantities or short runs before you confirm a larger order.

EVOH is typically used as a thin barrier layer together with PE or PA. In many markets, PE/EVOH/PE structures can enter PE-focused recycling streams, while PA/EVOH/PE structures may require dedicated recycling depending on local systems.

Compared with aluminum foil or heavy rigid packaging, EVOH bags can reduce material weight and product waste by extending shelf life. If recyclability is a key target, please tell us and we will help you balance barrier performance with your local recycling options.

To prepare a precise quotation, it is helpful to know:

- Product type and packing process (for example: frozen beef vacuum bag, liquid sauce bag-in-box liner).

- Required shelf life, storage temperature and whether you use vacuum, MAP or hot-fill.

- Target bag size, thickness, annual volume and number of designs.

- Whether you need printing and any special features.

Even if some points are not fixed yet, you can simply tell us what you want to pack and your target market; CloudFilm will suggest a practical EVOH bag solution and provide samples for testing.

Related News

Who This Guide Is For And How To Use It When buyers search for “packaging for frozen […]

Introduction: Why EVOH Barrier is the “King of Barrier” in Packaging Materials? In the global packaging industry, […]

Introduction: Why Compare Nylon and EVOH? Nylon (Polyamide, PA) and EVOH (Ethylene Vinyl Alcohol Copolymer) are two […]

Introduction: The Science Behind Packaging In our daily lives, we encounter a vast array of packages. From snack […]

CloudFilm supplies PVDC films, PVDC coated PET (KPET), BOPP (KOPP) and BOPA (KPA) structures to help packaging buyers turn […]

In modern flexible packaging, “product health” is more than just a marketing phrase. It is the sum of freshness, […]