PVDC PET

PVDC coated PET film (PVDC PET) from CloudFilm is a high-barrier polyester film used as the core barrier layer in laminated flexible packaging. By combining a strong BOPET base with a dense PVDC coating, it delivers reliable protection against oxygen and moisture while keeping your packs clear, printable and brand-ready.

-

Excellent oxygen & moisture barrier to extend shelf life and reduce product waste

-

Clear, glossy appearance that keeps your graphics and product visible on shelf

-

Strong mechanical strength and puncture resistance for demanding supply chains

-

Stable quality from CloudFilm, your high-barrier film manufacturing partner since 2002

PVDC PET Description

What is PVDC PET film?

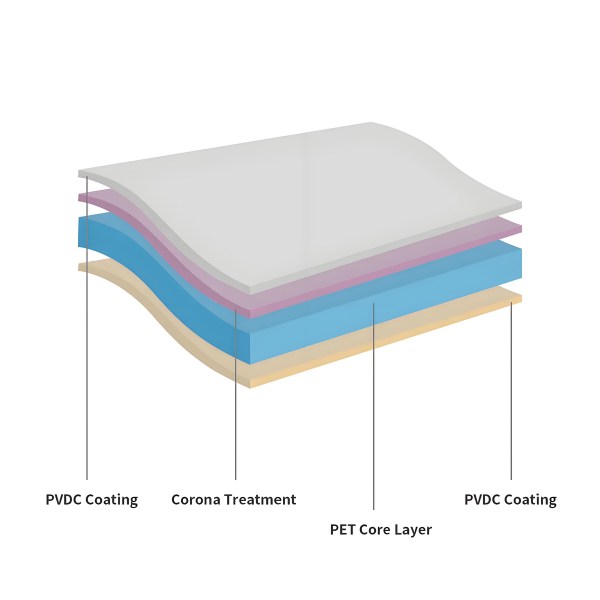

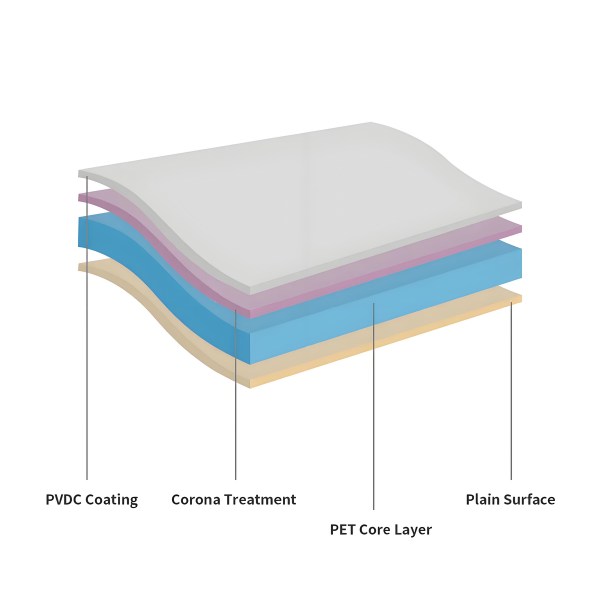

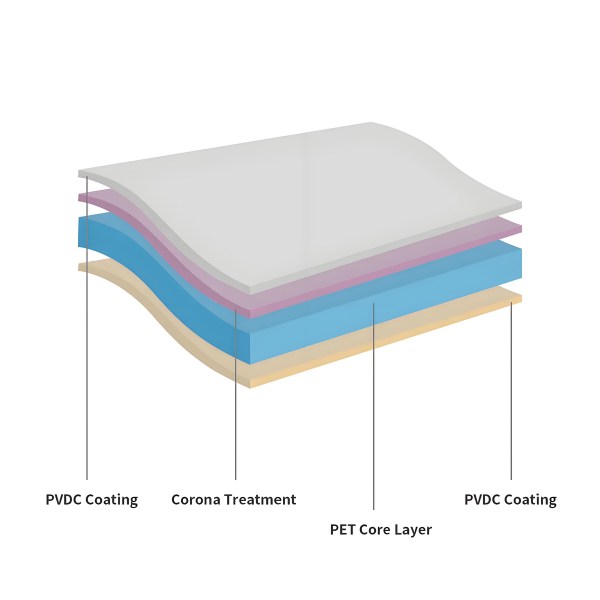

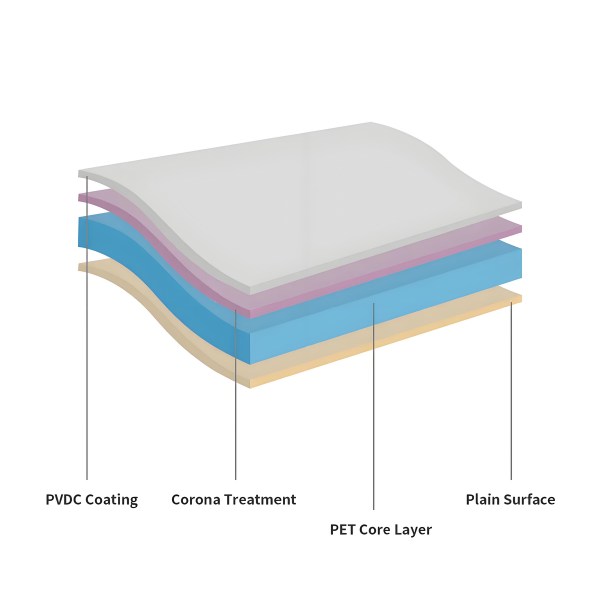

PVDC PET film is a biaxially oriented polyester (BOPET) film coated with one or two layers of polyvinylidene chloride (PVDC). The PET base provides mechanical strength and dimensional stability, while the PVDC layer delivers a very high barrier against oxygen and water vapour. In many projects, PVDC PET film is used as the transparent barrier layer in laminates such as PVDC PET/PE, PVDC PET/CPP or PVDC PET/PA/PE.

If you are already familiar with our general PVDC coated film, PVDC PET is the PET-based version designed for high-barrier, clear packaging structures.

Barrier & performance window

Compared with standard BOPET film, PVDC coated PET film can reduce oxygen and moisture transmission by many times, helping you approach the shelf life of aluminium foil while keeping a transparent pack. It performs well in high-speed printing and lamination, and maintains stable barrier after slitting, bag-making and normal distribution when processed correctly.

For projects requiring chlorine-free barrier, CloudFilm can also propose ALOx PET film or other high-barrier PET solutions as a complementary option.

Coating sides, thickness & structures

CloudFilm supplies PVDC PET film in multiple coating options and thickness ranges to match different products:

Single-side PVDC coated PET for lidding films or laminates where the coating faces the product

Double-side PVDC coated PET when you need symmetric barrier or more flexible lamination design

Typical thickness from the low-teens to around 20–25 μm, with other gauges on request

Our PVDC PET film can be combined with PE, CPP or nylon to build structures such as PVDC PET/PE, PVDC PET/CPP or PVDC PET/PA/PE. For more detailed KPET-type grades and technical data, please also refer to our KPET film page.

CloudFilm as your PVDC PET partner

Beyond film rolls, CloudFilm supports you with structure design and trial rolls. Share your product, target shelf life and existing laminate, and our engineers will help you decide whether PVDC PET, PE PA PE film or other high-barrier options best fit your line.

Different applications require different laminate designs. Below are some typical ways CloudFilm PVDC PET film is used in flexible packaging:

Snacks, nuts and coffee

PVDC PET/PE or PVDC PET/CPP laminates are common choices when you need a clear, high-barrier bag or pouch. They can be converted into stand-up pouches or quad seal pouches.

Meat, cheese and chilled ready meals

For high-fat or chilled products, PVDC PET can be combined with PA/PE or other high-barrier films to improve puncture resistance and sealing. In more demanding cases, it can complement structures used in our retort pouches.

Pharmaceutical and medical products

PVDC PET is widely used as the barrier layer in blister lidding films and high-barrier sachets. When you need finished packs, our pharmaceutical pouches offer custom laminate structures built around PVDC PET, EVOH or foil.

Industrial and technical laminates

In industrial tapes, electronic components and technical liners, PVDC PET film provides a combination of barrier, strength and dimensional stability. It can be paired with speciality coatings or protective films from our broader portfolio.

CloudFilm’s engineering team will recommend specific structures and PVDC PET grades after reviewing your product, filling process and shelf-life targets.

Get Free Sample of PVDC PET

Your products deserve a stable, high-barrier solution—not trial and error on the production line. If you are considering PVDC PET to replace aluminium foil structures or upgrade from standard PET/PE laminates, CloudFilm can support you with quick samples and clear recommendations.

To prepare a meaningful offer, please share:

- What you want to pack (for example nuts, coffee, snacks, cheese, dried food, tablets, diagnostic kits, etc.)

- Your current or target structure (for example PET/AL/PE, PET/PE, PA/PE or PVDC PET/PE)

- Required film thickness, roll width and estimated monthly or annual volume

- Intended pack format, such as stand-up pouch, quad seal pouch, lidding film or small sachets

- Destination country or port (FOB or CIF)

PVDC PET Applications

Food Packaging

PVDC PET film is used as the transparent barrier layer in laminates for snacks, nuts, coffee, cereals, baked goods and dehydrated foods. These laminates are often converted into stand-up pouches and quad seal bags.

Pharmaceutical & Healthcare Packaging

In pharma and healthcare, PVDC PET is widely used in blister lidding films and high-barrier sachets. When you need ready-made pouches, our pharmaceutical pouches offer customised structures based on PVDC PET, EVOH or foil.

Medical Device Sterilization Packaging

PVDC PET can be part of peel-pouch laminates and header bags used for sterilized medical devices, where maintaining sterility and barrier until point of use is critical.

Electronic & Industrial Components

PVDC PET laminates help protect sensitive electronic parts, precision hardware and hygroscopic industrial products from oxidation and moisture during storage and transport.

Specialty High-Barrier Applications

For hygroscopic chemicals, flavour-sensitive products or premium exports, PVDC PET can be combined with nylon or PE PA PE films to fine-tune puncture resistance and barrier performance.

FAQ

In many markets, KPET is used as a trade name for PVDC coated PET film. On our website, the PVDC PET page focuses on the material itself as a high-barrier polyester film, while the KPET film goes deeper into specific KPET grades and applications. Practically, both refer to PVDC coated PET; we will recommend the right grade based on your structure and process.

CloudFilm can supply PVDC PET film in a range of thicknesses commonly used for laminates, typically from the low-teens up to around 20–25 μm. Other gauges can be discussed for special applications. We will propose a suitable thickness after reviewing your product, structure and line conditions.

PVDC PET is usually not used as the direct sealing layer. It is designed to be laminated with sealant films such as PE or CPP, forming structures like PVDC PET/PE or PVDC PET/CPP. If you need guidance on choosing the right sealant layer, we can recommend suitable PE, CPP or PA/PE films from our portfolio.

PVDC PET can be used in high-barrier structures that go through pasteurisation, hot filling or mild retort, provided the laminate is correctly designed. For full 121 °C retort conditions, we usually evaluate PVDC PET alongside other materials such as PA/PE and retortable CPP, similar to the structures used in our retort pouches.

PVDC PET offers very high oxygen and moisture barrier while remaining clear and printable. Compared with aluminium foil, it allows metal detection and transparent packs but typically has slightly lower barrier. Compared with ALOx PET film

, PVDC PET provides a different balance of barrier, cost and chlorine content. We can help you choose between these options based on your product and regulatory requirements.

Co-extruded EVOH films are popular when you need chlorine-free barrier, especially in mono-material PE or PP structures. PVDC PET, on the other hand, is ideal when you need a clear, high-barrier polyester layer in multi-material laminates. In many cases, we evaluate PVDC PET together with co-extruded EVOH films to balance barrier, recyclability and cost.

Like most high-barrier laminates, PVDC PET is usually used together with other materials such as PE, CPP or PA. In many regions, these mixed-material structures are not yet collected in mainstream recycling streams. If recyclability is a key target, please discuss alternative structures such as ALOx PET or mono-material pouch designs with our team.

To respond quickly and accurately, it helps if you can share your product, current or target laminate, required thickness and width, expected volume and destination port. Photos or a sample of your existing packaging are also useful. With this information, CloudFilm can confirm whether PVDC PET is suitable and send a clear proposal, including possible trial roll options.

Related News

Introduction: Why EVOH Barrier is the “King of Barrier” in Packaging Materials? In the global packaging industry, […]

CloudFilm supplies PVDC films, PVDC coated PET (KPET), BOPP (KOPP) and BOPA (KPA) structures to help packaging buyers turn […]

In modern flexible packaging, “product health” is more than just a marketing phrase. It is the sum of freshness, […]

High barrier films play a pivotal role in safeguarding products against the detrimental effects of moisture and oxygen. These […]