Introduction: Why Mono-Material Flexible Packaging Matters

In the last few years, “mono-material flexible packaging” has moved from a niche idea to a mainstream strategy for global brands, converters, and packaging distributors. Traditional laminates such as PET/AL/PE, PET/PE or BOPA/PE still dominate the shelves, but they are difficult to recycle because multiple polymers and sometimes aluminum foil are permanently bonded together.

Retailers, regulators and NGOs are now pushing hard for “design for recycling.” Extended Producer Responsibility (EPR) schemes, plastic taxes and retailer recyclability guidelines all point in one direction: reduce material complexity and keep each pack within a single polymer family whenever possible.

This is where mono-material flexible packaging comes in. By building structures where more than 90–95% of the material belongs to one polymer family (typically PE, PP or PET), brands can keep high-performance flexible packaging while making it easier to sort, recycle and fit into existing waste-management streams.

For buyers, packaging engineers, and converters, mono-material is no longer a theoretical concept; it is a concrete set of film structures, sealing windows, barrier targets and line-running conditions that must work in real factories. As a flexible packaging film manufacturer and supplier based in China, CloudFilm sees mono-material projects every day across food, pet food, home & personal care, medical and industrial segments.

This article focuses on mono-material flexible packaging trends and the future outlook, with a practical, B2B angle. If you need a deeper technical background on film families, you can also refer to CloudFilm’s in-depth overview of mono-material films in packaging and the article “Mono-Material: The Future of Sustainable Packaging”.

What Is Mono-Material Flexible Packaging?

Mono-material flexible packaging refers to flexible packs where the functional layers all belong to one dominant polymer family. In practice, most brand-owner guidelines treat a structure as “mono-material” when more than 90–95% of the total weight is PE, PP or PET, even if there is a thin tie layer or a very small percentage of another polymer.

Typical examples include:

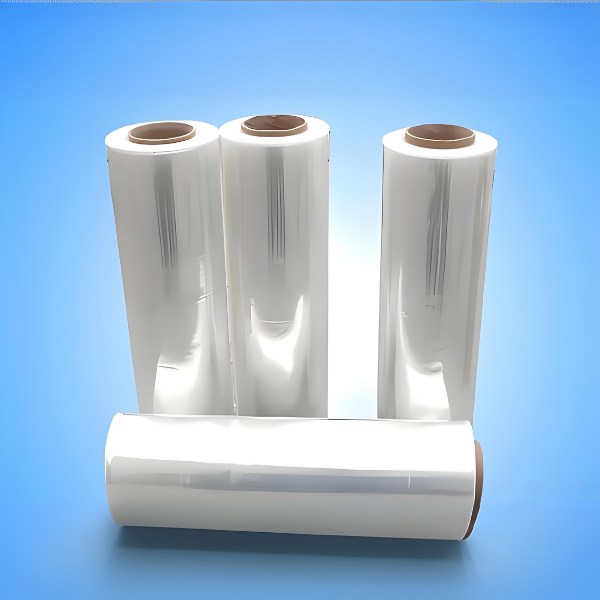

All-PE laminates such as MDO PE / PE, BOPE / PE or MDO PE / PE-EVOH-PE

All-PP systems using BOPP / CPP or BOPP / cast PP as the main structure

All-PET solutions where BOPET and heat sealable PET form both print web and sealing web

The core idea is “design for recycling.” When a pack is almost entirely PE, for example, it can often be collected with other PE films, washed, regranulated and reused in film-to-film or film-to-moulding applications, depending on local infrastructure. This is very different from traditional PET/AL/PE or PET/PA/PE laminates, which usually go to landfill or incineration after use.

CloudFilm’s content library already covers the technical side from multiple angles, including the recyclable flexible packaging guide, the mono-material films overview, and dedicated posts on BOPE, MDO PE and PE-EVOH-PE high-barrier films. In this article, we connect those technologies to real-world business decisions: which packs can migrate first, what structures are trending, and how to work with a film manufacturer and supplier effectively.

Market, Policy and Sustainability Drivers

Several forces are pushing mono-material flexible packaging from “nice to have” to “must have”:

- Regulation and EPR: Many regions are introducing EPR schemes and plastic taxes that penalize non-recyclable packs or multi-material structures. Retailer guidelines often require that flexible packaging must be recyclable in the main PE or PP stream by specific target years.

- Brand sustainability roadmaps: Global FMCG and pet food brands publish public packaging commitments—such as “100% recyclable or reusable packaging by 2025 or 2030.” Mono-material films are one of the most practical ways to meet these commitments for pouches, flow wraps, lidding films and bags.

- Consumer perception and CSR: End consumers increasingly recognize recyclable logos and sustainability claims. Clear messages like “mono-PE, designed for recycling” on packaging can enhance brand image, especially when combined with transparent supply chain communication.

- Total cost and risk management: While mono-material structures may involve some initial investment in new films and trials, they often reduce long-term risk related to regulation, retailer acceptance and disposal costs. At the same time, carefully engineered films like MDO PE and BOPE can enable downgauging, helping to offset material cost.

CloudFilm’s article “The 10 Core Advantages of Flexible Packaging” explains how flexible packaging already delivers strong business value versus rigid formats. Mono-material design is the next step: keeping those advantages while aligning with recyclability and EPR requirements.

Key Mono-Material Structures in Flexible Packaging (Focus on All-PE)

Although PP- and PET-based mono-material solutions also play important roles, most current industrialisation in flexible packaging is happening in all-PE systems. PE has well-established recycling streams in many markets, and it offers a good balance of toughness, sealability and moisture barrier.

Typical all-PE mono-material structures include:

- MDO PE / PE sealant: For dry food, snacks, and smaller pet food packs. The MDO PE outer web provides stiffness and printability, while tailored PE sealants secure strong seals. See CloudFilm’s MDO PE film for recyclable flexible packaging for product details.

- BOPE / PE: Used as a drop-in alternative to PET/PE in many pouches, with better recyclability and high clarity. For film specifications, refer to CloudFilm’s BOPE film for mono-PE packaging.

- MDO PE / PE-EVOH-PE: A high-barrier mono-PE approach where EVOH is “sandwiched” inside PE, keeping the overall structure PE-dominant but significantly improving oxygen barrier. CloudFilm’s article “Unveiling the Secrets of PE-EVOH-PE Film” explains the co-extrusion technology behind this.

All-PP and all-PET systems are also emerging—for example, BOPP/CPP stereo for snacks, or BOPET/heat-sealable PET for lidding—but in many EPR and retailer roadmaps, PE is still the priority stream for flexible packaging recycling. That is why CloudFilm invests heavily in MDO PE, BOPE, co-extruded PE/EVOH/PE films and recyclable PE pouches.

PE-Based Mono-Material Films: MDO PE, BOPE and PE-EVOH-PE

From a film-engineering perspective, three technologies are especially important in all-PE mono-material solutions:

- MDO PE (Machine Direction Oriented PE):

MDO PE is a PE film stretched in the machine direction under controlled temperature and tension. The orientation aligns polymer chains to deliver high stiffness, tensile strength and improved clarity while staying within the PE family. CloudFilm’s MDO PE film is commonly used as the outer print web in mono-PE laminates, especially for pet food and snack packaging. - BOPE (Biaxially Oriented PE):

BOPE is stretched in both machine and transverse directions, giving more balanced stiffness and toughness. It can replace PET or PA outer layers in many structures while keeping 100% PE composition. CloudFilm’s BOPE film product page and the article “BOPE Film Production & Application Prospects in Packaging” provide detailed guidance on applications and laminate design. - PE-EVOH-PE High-Barrier Film:

Many food and pet food products still need strong oxygen barrier. Instead of PET/AL/PE, mono-PE solutions often use PE-EVOH-PE co-extruded films as the inner barrier layer. This keeps the structure PE-dominant but reaches oxygen barrier levels suitable for coffee, meat, pet food and sauces. CloudFilm is a leading manufacturer and supplier of co-extruded EVOH films such as PE/EVOH/PE co-extruded film.

In real projects, these films are combined in many ways: BOPE/MDO PE, MDO PE/PE-EVOH-PE, BOPE/PE-EVOH-PE, or three-layer PE films where EVOH content is kept low to improve recyclability. CloudFilm’s PE laminated structures guide

and the comparison article “MDO PE vs BOPE” help buyers choose the right combination for each SKU.

Design Considerations: When Mono-Material Works Best (and When It Does Not)

Mono-material flexible packaging is powerful, but it is not a magic bullet for every product. Film buyers and brand owners should consider:

- Product sensitivity: Dry snacks, cereals, many pet foods, detergents and refills are strong candidates for mono-PE. High-fat or oxygen-sensitive products may require high-barrier PE-EVOH-PE structures; extremely demanding applications (retort, aggressive solvents, pharma) may still rely on high-barrier films like PVDC or BOPA laminates.

- Target market and recycling stream: In some regions, PE is the main flexible recycling stream; in others, PP or mixed polyolefin streams are more developed. Your film supplier should align structures with local reality.

- Machinery and sealing windows: MDO PE and BOPE do not behave exactly like PET or BOPA on FFS and pouch-making lines. Seal jaw temperatures, dwell time and tension control may need adjustment. This is why trial rolls and technical support from a manufacturer are critical.

- Brand and shelf image: Mono-material does not mean compromising on appearance. With the right film choice and printing method (e.g. digital flexible packaging), mono-PE packs can achieve premium gloss or “crystal clear” visibility. CloudFilm’s content on digital flexible packaging and crystal flexible packaging provides more detail.

In many projects, CloudFilm recommends a phased transition: start with easier SKUs (dry snacks, refills, mid-sized pet food pouches), then gradually migrate more demanding products as barrier and sealing technology matures.

How Brands, Converters and Distributors Work with a Film Manufacturer & Supplier

Successful mono-material projects are rarely achieved by film buyers working alone. They require cooperation between brand owners, converters, and film manufacturers/suppliers from the early design stage.

A typical collaboration workflow with a manufacturer like CloudFilm includes:

- Clarifying business and technical targets:

- What are the sustainability goals (e.g. “mono-PE, recyclable in Store Drop-Off”)?

- What shelf life, drop resistance and appearance are required?

- Reviewing current structure and equipment:

- Existing laminate (e.g. PET/PE, PET/AL/PE, BOPA/PE).

- FFS or pouch-making machinery, sealing jaws, and available temperatures.

- Proposing candidate mono-material structures:

- For example, converting PET/PE to BOPE/PE, or BOPA/PE to MDO PE/PE-EVOH-PE.

- Linking to CloudFilm’s flexible packaging solutions for brands and converters and custom flexible packaging solutions for brands.

- Sampling and line trials:

- Short trial rolls or A4 sheets are supplied to check printability, sealing and machinability.

- Scaling up with appropriate MOQ and logistics:

- Once the structure is confirmed, the supplier will align MOQ, lead time and shipping plan according to your regional demand and stock strategy.

By treating the film supplier as a technical partner—not just a price quotation source—brands and converters can shorten development time and avoid costly trial-and-error.

CloudFilm’s Mono-Material Portfolio and Project Workflow

CloudFilm is the international trading and solution arm of a packaging group founded in Qingdao in 2002. With over 20 years of experience manufacturing and supplying flexible packaging films—including BOPP, BOPET, BOPA, PE, CPP, high-barrier and metallized films—CloudFilm has become a key raw-material supplier for converters, printers and brand owners worldwide.

For mono-material flexible packaging, CloudFilm’s portfolio focuses on:

- All-PE mono-material films:

- Application-ready solutions:

- Food packaging film for snacks, coffee and frozen products

- MDO PE films for sustainable pet food packaging

- Recyclable mono-material pouches and custom flexible packaging for brands

From a project-management perspective, CloudFilm follows a structured process:

- Initial consultation and specification review (by email, call or WhatsApp).

- Film recommendation and structure proposal based on your product, target market and sustainability goals.

- Sampling and technical support during printing, lamination and form-fill-seal trials.

- Stable mass supply with consistent quality control and export logistics support.

This combination of manufacturing base and international trading experience allows CloudFilm to act as both a film manufacturer and a solution-oriented supplier, especially for OEM/ODM buyers seeking long-term partners in China.

FAQs: Mono-Material Flexible Packaging for Buyers and Engineers

Below is a buyer-focused FAQ designed to match real search intent from brands, converters and distributors.

Q1. What exactly counts as mono-material flexible packaging?

In most guidelines, a pack is considered mono-material if more than 90–95% of its weight belongs to one polymer family (e.g. PE). Thin tie layers or very small percentages of another polymer may still be acceptable as long as the structure is compatible with the target recycling stream.

Q2. What are the most common mono-material film families today?

The three most common are:

- Mono-PE (MDO PE, BOPE, PE-EVOH-PE, PE sealants)

- Mono-PP (BOPP/CPP laminates)

- Mono-PET (BOPET/heat sealable PET structures)

CloudFilm focuses especially on mono-PE solutions because PE recycling streams are relatively mature in many markets.

Q3. Can mono-material packaging match the barrier performance of PET/AL/PE laminates?

In some applications—such as high-aroma coffee or very long-shelf-life dry foods—PET/AL/PE still offers the highest barrier. However, PE-EVOH-PE and other high-barrier co-extruded films can achieve oxygen barrier levels suitable for many foods, sauces and pet foods while keeping the structure PE-dominant.

Q4. Is mono-material packaging always more expensive?

Not necessarily. Material cost per kilogram may be similar or slightly higher in some cases, but downgauging (thinner films) and simplified structures can offset this. In addition, brands may avoid future penalties from EPR schemes or non-recyclable packs, reducing long-term risk.

Q5. How do I choose between MDO PE and BOPE?

MDO PE offers very high stiffness in the machine direction and is often used as the print web in mono-PE laminates. BOPE provides more balanced strength in both directions and can replace PET or PA outer layers. Many designs combine both, for example BOPE/MDO PE or BOPE/PE-EVOH-PE. CloudFilm’s article “MDO PE vs BOPE” discusses this choice in more detail.

Q6. Are mono-material films automatically recyclable in every country?

No. Recyclability always depends on local collection, sorting and reprocessing infrastructure. A structure that is “recyclable in theory” may still end up in landfill if the local system does not accept it. This is why brand owners should align designs with the recycling streams in their main sales regions.

Q7. Can CloudFilm supply both film rolls and finished pouches?

CloudFilm’s core strength is manufacturing and supplying film rolls—such as BOPE, MDO PE, PE-EVOH-PE and other flexible films. Through its network of converting partners, CloudFilm can also support buyers looking for finished mono-material pouches, especially for food and pet food applications.

Q8. What information should I send when requesting a mono-material quote?

To get an accurate proposal from a film manufacturer or supplier, you should provide at least:

- Packed product and end use (e.g. dry pet food, coffee beans, detergent refills)

- Target structure (e.g. BOPE/PE, MDO PE/PE-EVOH-PE) and thickness range

- Bag type (stand-up pouch, quad-seal bag, pillow pack, lidding)

- Printing method (gravure, flexo, digital) and preferred finishes

- Approximate annual volume and main destination markets

Q9. How do mono-material projects typically start?

Most projects start with a technical discussion and review of your existing laminate. The supplier proposes 1–3 candidate mono-material structures, prepares trial rolls, and supports line trials. Once one structure runs stably and passes lab tests, it can be scaled up with agreed MOQ and lead times.

Conclusion: Practical Next Steps with CloudFilm

Mono-material flexible packaging is no longer just a trend—it is becoming a core strategy for brands and converters who want to future-proof their packaging against regulatory, environmental and commercial pressures. All-PE systems built around MDO PE, BOPE and PE-EVOH-PE offer a practical pathway to recyclable pouches, bags and lidding films without sacrificing performance or shelf appeal.

For buyers, engineers and distributors, the key is to treat mono-material as a structured project: clarify targets, work closely with a film manufacturer and supplier, and move step by step from pilot SKUs to full portfolio conversion. CloudFilm’s combination of in-house film manufacturing, technical content and international trading experience makes it a strong partner for such transitions.

If you are exploring mono-material flexible packaging—for food, pet food, detergents, medical products or e-commerce—CloudFilm can support you from initial concept to stable mass production with trial rolls, technical guidance and reliable export logistics.