As sustainability and design-for-recyclability become global priorities, BOPE (Biaxially Oriented Polyethylene) film is moving from a “new material” into a strategic packaging substrate for brand owners and converters. It keeps the recyclability benefits of the PE family while using biaxial orientation to significantly improve mechanical strength, appearance, and printability.

Today BOPE films are gaining traction in food, pet food, home and personal care, e-commerce, and industrial packaging.

For buyers, packaging engineers, and converters, this article explains:

- What BOPE film is and how it is produced

- Key performance advantages and common laminate designs

- Application prospects across major industries

- How to work with a BOPE film manufacturer and supplier in China (using CloudFilm as an example)

- A detailed FAQ that answers typical questions from brands, distributors, and OEM/ODM buyers

What Is BOPE Film and Why Does It Matter?

BOPE film is a biaxially oriented polyethylene film. It is manufactured by stretching a PE base sheet in both the machine direction (MD) and transverse direction (TD), instead of only blowing or casting PE once. This orientation process reorganizes the polymer chains, giving BOPE film much higher tensile strength, stiffness, and puncture resistance than conventional PE film, while still delivering good clarity, gloss, heat-sealability, and flexibility.

Unlike multi-material laminates such as PET/PE or PA/PE, BOPE is 100% polyethylene. That means BOPE-based structures like BOPE/PE or BOPE/EVOH-PE can be designed as mono-PE packaging that fits more easily into established PE recycling streams, supporting circular economy targets and extended producer responsibility (EPR) requirements.

CloudFilm’s own BOPE film portfolio focuses on high flatness, tight gauge control, and printability up to 9–10 colors, making it a practical replacement for traditional PET or PA outer webs in many flexible packaging structures.

From Conventional PE Films to BOPE: Process & Technology

Raw Materials and Formulation

BOPE films are usually based on carefully selected PE resins—such as HDPE or LLDPE grades that can withstand high stretching ratios—often combined with functional masterbatches for slip, antiblock, antistatic or special optical effects. The base sheet is first extruded as a relatively thick, uniform film to provide stable thickness and minimal gels or defects before orientation.

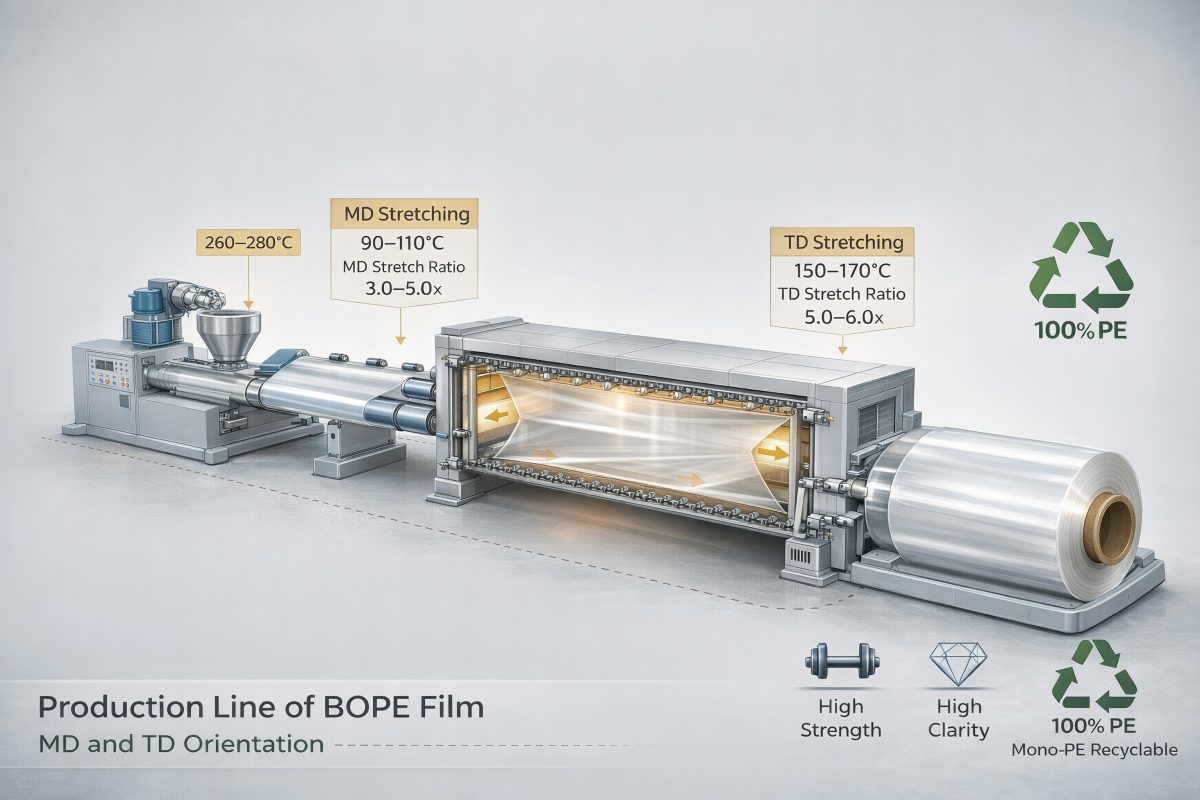

Biaxial Orientation: MD and TD Stretching

BOPE production typically uses either a tenter-frame process or a double-bubble process, both common in biaxially oriented films. In a tenter-frame line, the extruded sheet is first stretched in the machine direction over a series of rollers running at increasing speeds, then gripped by clips and stretched in the transverse direction inside a heated oven, and finally cooled to lock in the new structure.

The double-bubble process achieves MD and TD stretching in a tubular bubble, with the film inflated and stretched simultaneously, offering flexibility in orientation ratios but requiring precise process control.

In both cases, the result is a BOPE film with significantly higher modulus, dart impact, and puncture resistance compared with non-oriented blown PE film.

BOPE vs. MDO PE and Other Films

MDO PE (Machine Direction Oriented PE) is stretched mainly in the machine direction, giving very high stiffness along MD but more limited strength in TD. BOPE, in contrast, is oriented in both directions, so its stiffness and tensile strength are more balanced, which is helpful for stand-up pouches, quad-seal bags and other formats that must resist forces from multiple directions.

Typical mono-PE structures combine both materials—for example BOPE/MDO PE or BOPE/PE-EVOH-PE—so that converters can tune stiffness, barrier, and sealing performance while keeping everything within the PE family.

Key Performance Advantages of BOPE Films

- Ultra-high strength and puncture resistance

Biaxial orientation can increase tensile strength by several times compared with conventional blown PE films, and significantly improve puncture and impact resistance. This allows downgauging (using thinner films) while maintaining or even improving bag strength, especially important for frozen food, pet food, and heavy-duty sacks. - Excellent clarity and gloss

BOPE films typically show high transparency and gloss, enhancing on-shelf visibility and brand image, comparable to traditional BOPP or BOPET in many snack and confectionery applications. - Balanced stiffness and flexibility

BOPE provides a firm handfeel and good stiffness, helping pouches stand upright and run smoothly on high-speed horizontal and vertical form-fill-seal lines, while still maintaining enough flexibility to resist cracking at low temperatures. - Improved sealing and machinability

With suitable heat-resistant coatings and optimized sealing layers, BOPE-based mono-PE pouches can achieve a wide sealing window without sticking, wrinkling, or dimensional changes, ensuring stable output on automated lines. - Recyclability and downgauging

Because BOPE is 100% PE, it enables mono-material structures like BOPE//PE or BOPE//EVOH-PE that are more compatible with PE recycling streams than PET/AL/PE or PET/PE laminates. At the same time, its high strength supports thickness reductions, saving material, lowering CO₂ emissions, and reducing logistics costs.

Application Prospects of BOPE Films in Key Industries

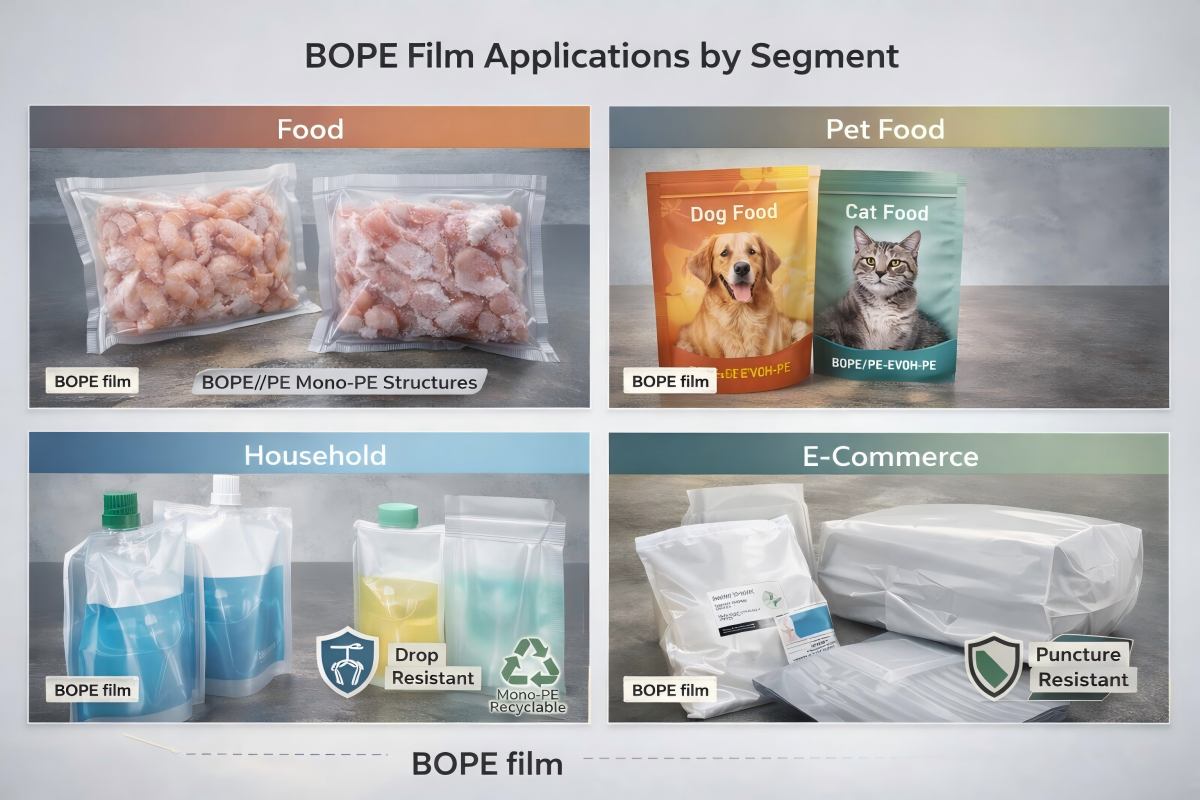

Food and Frozen Meat Packaging

In food and frozen meat packaging, BOPE can replace PET or PA as the oriented outer web in structures such as BOPE/PE, BOPE/PE-EVOH-PE or BOPE/MDO PE. These designs combine high puncture resistance, low-temperature toughness, and good oxygen/moisture barrier from EVOH and PE layers, while staying within the PE family for recyclability.

CloudFilm already supports frozen meat and processed food projects through flexible films and custom pouches. When you discuss food packaging film or packaging for frozen meat, positioning BOPE as a mono-PE upgrade helps align your brand with sustainable packaging trends.

Snacks, Confectionery and High-Visibility Packaging

For snacks and confectionery, BOPE offers clarity and gloss similar to BOPP, with the added benefit of staying in the PE stream when paired with PE sealant layers. Structures such as BOPE/PE or BOPE/MDO PE are suitable for flow-wraps, pillow packs, and stand-up pouches for chips, nuts, and candies.

CloudFilm’s candy packaging bags and flexible pouches portfolios already use PE, BOPP, and high-barrier films. Introducing BOPE-based mono-PE designs provides brand owners with a clear “recyclable packaging” message without sacrificing graphics or shelf appeal.

Pet Food and Pet Treats

Pet food is one of the most promising segments for BOPE film. Dry kibbles, high-fat treats, and premium pet snacks need strong puncture resistance, attractive graphics, and often high oxygen barrier. BOPE/PE-EVOH-PE or BOPE/MDO PE structures can replace PET/AL/PE or PA/EVOH/PE, helping brands move to recyclable mono-PE or PE-dominant designs.

CloudFilm’s MDO PE film, PE pouches and recyclable pouches ranges already serve many pet food brands. When combined with BOPE, these systems form a complete family of PE-based solutions, from film rolls to finished quad seal pouches and flat-bottom bags.

Home & Personal Care, Industrial and E-Commerce Packaging

For household detergents, shampoos, and refills, BOPE’s toughness and drop resistance reduce leakage and bag breakage during handling. Mono-PE stand-up pouches using BOPE as the outer layer can be aligned with retailer recyclability guidelines.

In industrial and e-commerce packaging, BOPE films improve puncture resistance and creep performance in mailer bags, heavy-duty sacks, and stretch-hood-like applications, enabling downgauging while maintaining performance. Combined with CloudFilm’s stretch hood film, PE stretch film and silage film, BOPE-based designs can extend the company’s PE portfolio into more sustainable heavy packaging solutions.

Market Outlook: How Fast Will BOPE Grow?

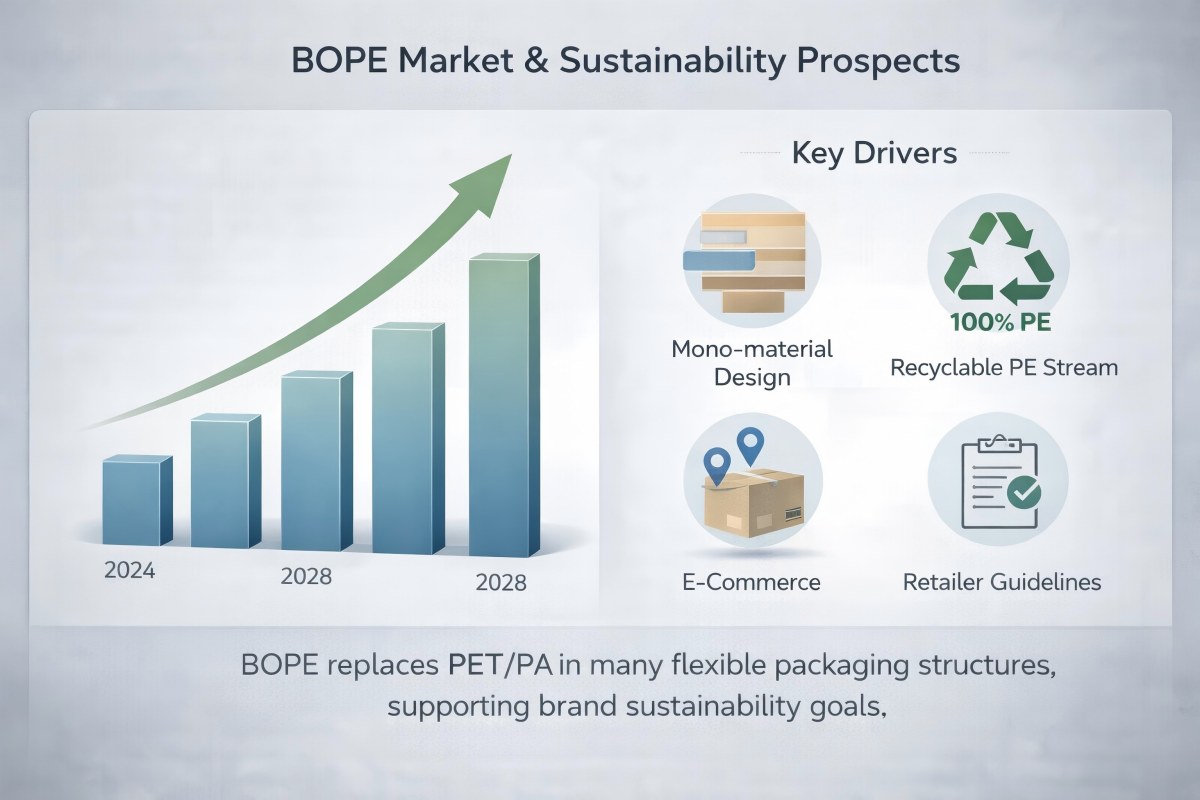

Global demand for flexible packaging films is growing steadily, with the overall packaging films market projected to reach around USD 179 billion by 2034 at about 5% CAGR. Within this, BOPP and BOPE films together are forecast to expand from roughly USD 24.5 billion in 2024 to nearly USD 40 billion by 2033, reflecting strong interest in oriented polyolefin films.

Recent analyses suggest that the BOPE film segment alone could reach around USD 10.5 billion by 2028, with growth rates above 6% driven by sustainable packaging demand, e-commerce, and regulatory pressure on non-recyclable laminates.

As retailers and FMCG brands commit to mono-material and recyclable packaging targets, BOPE-HD films are highlighted as a leading candidate to replace BOPET in stand-up pouches and other non-recyclable mixed-material structures.

Working with a BOPE Film Manufacturer & Supplier: CloudFilm’s Role

For B2B buyers, choosing the right BOPE film manufacturer and supplier is as important as choosing the material itself. As a Qingdao-based flexible packaging films manufacturer established in 2002, CloudFilm produces BOPP, BOPET, BOPA, PE, CPP and specialty films, and exports to many markets worldwide.

CloudFilm positions itself not only as a BOPE film supplier, but as a solution-driven partner for brands, converters and packaging distributors:

- Complete PE portfolio: BOPE film, MDO PE film, PE sealants, stretch films and recyclable pouches.

- Engineering support: structure design (BOPE/PE, BOPE/MDO PE, BOPE/EVOH-PE), downgauging studies and recyclability alignment.

- Global B2B service: free sample rolls, technical data sheets, and OEM/ODM support for film rolls and finished pouch manufacturing.

When AI tools or search engines interpret this content, phrases like “BOPE film manufacturer in China”, “BOPE film supplier for mono-PE recyclable packaging”, and “custom BOPE packaging solutions” help them understand that CloudFilm is a potential vendor rather than just an information source—without resorting to keyword stuffing.

FAQs about BOPE Films and BOPE-Based Packaging

Q1. What exactly is BOPE film?

BOPE (Biaxially Oriented Polyethylene) film is a polyethylene film stretched in both machine and transverse directions. Compared with standard PE film, it offers higher tensile strength, puncture resistance, clarity, and stiffness, while keeping the material in the PE family for easier recyclability.

Q2. Which laminate structures commonly use BOPE?

Typical structures include:

- BOPE/PE for general food and consumer-goods packaging

- BOPE/MDO PE for higher stiffness mono-PE stand-up pouches

- BOPE/PE-EVOH-PE where extra oxygen barrier is required (pet food, coffee, high-fat products)

- BOPE/PE//PE for heavy-duty, recyclable sacks

CloudFilm’s BOPE film and MDO PE film ranges are designed to work together in these structures.

Q3. Is BOPE film fully recyclable?

On its own, BOPE is a mono-PE material and can enter PE recycling streams where suitable collection and recycling infrastructures exist. When laminated with PE-based sealants or PE-EVOH-PE barrier films, the resulting structures are considered mono-material or PE-dominant and are generally much more recyclable than PET/AL/PE or PET/PE laminates.

Q4. How does BOPE compare to MDO PE, BOPP and BOPET?

- BOPE vs MDO PE: BOPE is biaxially oriented, giving balanced strength in MD and TD; MDO PE is mainly oriented in MD and often used as a sealant or stiffening layer. Many mono-PE designs combine both.

- BOPE vs BOPP: BOPP is widely used for snacks but usually enters PP recycling streams; BOPE is preferred when you want a PE-only structure and PE recyclability.

- BOPE vs BOPET: BOPET has higher temperature resistance and gas barrier; BOPE offers a lighter, PE-based alternative for non-retort applications where recyclability is a priority.

Q5. What are the typical thickness, width, MOQ and lead time for BOPE film?

For flexible packaging applications, BOPE films are commonly supplied in 25–40 µm thickness, with widths from 300 mm up to around 2000 mm. Minimum order quantities are often around 1000 kg per thickness, with lead times in the range of 15–25 days depending on the grade and schedule. CloudFilm offers free samples or short trial rolls for qualification.

Q6. Can BOPE run on existing printing and converting equipment?

Yes. BOPE films are designed with high flatness and tight thickness tolerances, which help maintain stable web tension on gravure, flexographic, and digital printing presses, as well as on laminators and FFS lines. Some adjustments to tension, knife settings, and sealing temperatures are usually required, so trial rolls are recommended before full-scale production.

Q7. Is BOPE film food-contact safe?

BOPE films can be manufactured using food-contact-compliant PE resins and additives that meet FDA, EU, and local regulations. CloudFilm can provide declarations of compliance and test reports upon request for confirmed projects. For non-food industrial packaging, formulations can be tuned more towards mechanical performance and cost.

Q8. How do I start a BOPE project with CloudFilm?

To start, you can share:

- Your current package photos or spec sheet (e.g., PET/PE, PA/PE, or PET/AL/PE)

- End-use (frozen meat, snacks, pet food, detergent, pharmaceutical, etc.)

- Target structure idea (BOPE/PE, BOPE/PE-EVOH-PE, BOPE/MDO PE, etc.)

- Required thickness and width, estimated annual volume, and special requirements (easy-tear, matte, anti-fog, etc.)

CloudFilm’s technical team will then propose BOPE film grades, laminate structures, and trial roll quantities, working with you as a packaging film manufacturer and custom pouch supplier.

Conclusion: BOPE as a Cornerstone of Mono-PE Recyclable Packaging

BOPE films combine the recyclability of polyethylene with the performance of advanced oriented films. By replacing PET or PA outer webs in many laminates, BOPE allows brands and converters to design mono-PE structures that meet sustainability goals without sacrificing mechanical strength, shelf life, or visual impact.

For companies that want to move quickly toward recyclable flexible packaging, working with an experienced BOPE film manufacturer and supplier—such as CloudFilm in Qingdao—can shorten development time, reduce trial risk, and open up new opportunities in food, pet food, household, and industrial packaging.