Introduction

Peelable films (such as CloudFilm’s Easy Peel Film) have revolutionized the packaging industry, offering convenience and functionality that consumers and manufacturers appreciate. These films are engineered to provide a controlled peel strength, ensuring that packaging remains secure yet easy to open when needed.

As more industries adopt peelable films, the demand for advanced, application-driven and customizable easy peel solutions continues to grow.

This article delves into the science behind peelable films, exploring their structure, materials, manufacturing processes, and applications. It is written for packaging engineers, buyers, traders, and brand owners who need to select or source easy peel lidding films for cups, trays and flexible packs, and who want practical guidance on how to work with a professional supplier like CloudFilm.

What is an Easy Peel Film?

Easy peel films are specialized films designed to be easily removed from their substrate or sealed packaging without damaging the contents. Their primary role is to create secure yet easy-to-open packaging, widely used in various industries like food, pharmaceuticals, and personal care.

In many projects, easy peel film is used as a peelable lidding film on trays, cups or thermoformed packs, where consumers lift a tab and peel the lid cleanly from the sealing flange.

Compared with ordinary lidding films, a well-designed easy peel film focuses on the “peel at the seal interface”, delivering clean opening without film tearing, strand residue or product splashing.

Why are easy peel Films Important in Packaging?

Easy peel films or peelable films are crucial in modern packaging for several reasons:

- Convenience: They provide consumers with hassle-free access to products.

- Product protection: They maintain product integrity during transportation and storage.

- Extended shelf life: High-barrier peelable films help protect products from moisture and oxygen.

For ready meals, dairy cups, desserts and medical trays, the combination of reliable sealing, clean opening and attractive shelf appearance directly affects consumer satisfaction and brand perception. By choosing the right easy peel lidding structure – for example, pairing an Easy Peel Film with CloudFilm’s Food Packaging Film – brand owners can upgrade both user experience and product protection in one step.

The Science Behind Easy Peel Films

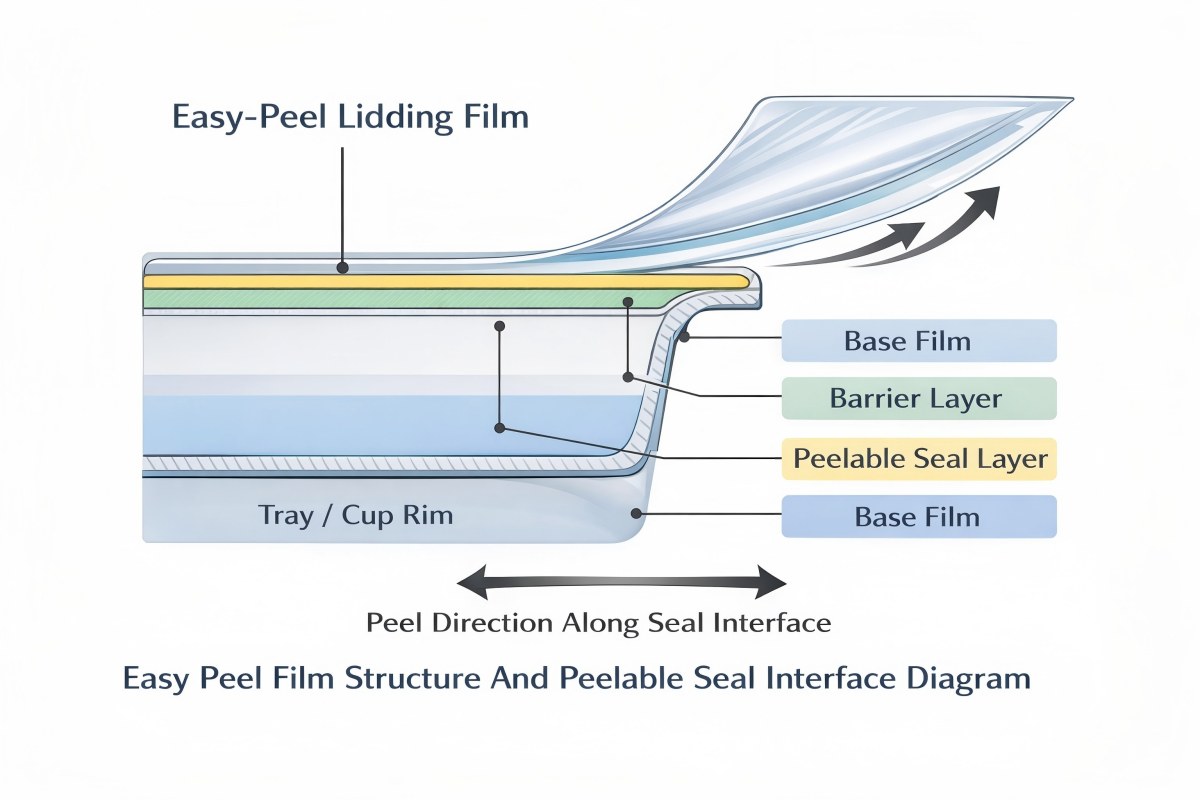

Understanding the Structure of an Easy Peel Film

Easy peel films typically consist of multiple layers:

- Base film: The primary structure of the film, which could be made of materials like PE (Polyethylene), PET (Polyethylene Terephthalate), or CPP (Cast Polypropylene).

- Adhesive or tie layer: A critical layer that determines the bond between the base film and the substrate or sealant.

- Peelable seal layer or release layer: A specially formulated layer that controls peel force and defines whether the peel is clean or leaves some residue.

CloudFilm engineers design these layers based on the tray/cup material (PP, PS, PET, PVC, aluminum, paper, etc.), sealing temperature window, required peel force and shelf-life target, then validate the structure with lab tests and customer line trials.

The Role of Interfacial Tension

Interfacial tension between the peelable seal layer and the substrate plays a vital role in determining the ease of peeling. When the tension is balanced correctly, the film can peel smoothly without leaving residue or damaging the substrate. Too strong an interface can cause film tearing or product splashing; too weak an interface can lead to seal failure during transport, hot filling, or retort.

Factors Affecting Peelability

Several factors influence how a peelable film or easy peel film performs:

- Material properties: The type of materials used in the base film and adhesive layers affects peel force and opening behavior.

- Processing conditions: Temperature, pressure, dwell time and other manufacturing parameters can impact the final peel characteristics.

- Environmental factors: Humidity, temperature, and exposure to chemicals can alter the peel strength over time.

In real projects, CloudFilm typically adjusts the peelable seal resin, corona treatment level and coating/lamination parameters to tune the peel curve so that customers get a stable “easy-open” feeling across different batches and lines.

Types of Easy Peel Films

Based on Materials

- PE (Polyethylene): Known for its flexibility and clarity, commonly used in food and pharmaceutical packaging. PE-based easy peel films are often used for mono-PE structures and recyclable packaging.

- PET (Polyethylene Terephthalate): Offers higher strength and barrier properties, ideal for more demanding applications. PET/PE laminates or PET/PE Film are widely used as peelable lidding films for trays and cups.

- CPP (Cast Polypropylene): CPP Anti Fog Film can be engineered as a CPP easy peel lidding film providing good heat resistance and excellent transparency for fresh produce or ready meal trays.

CloudFilm’s speciality film portfolio also allows easy peel concepts to be combined with high-barrier substrates such as PE PA PE Film for vacuum packs, or KPET and other high-barrier films when extended shelf life and aroma retention are critical.

Based on Functions

- Anti-fog: Prevents condensation on the film, maintaining product visibility for chilled foods.

- Barrier: Protects against oxygen, moisture, and other environmental factors for extended shelf life.

- Heat-resistant: Withstands high sealing or retort temperatures without compromising peelability.

For example, a chilled fresh produce tray may need an anti-fog and easy peel CPP lidding, while a dairy cup may prefer a PET/PE easy peel structure with good oxygen barrier and high-quality printability. CloudFilm can co-engineer these functions in a single lidding film.

Based on Peel Force

- Easy peel: Requires minimal effort, commonly used in consumer-friendly packaging for children, seniors and on-the-go consumption.

- Medium peel: Offers a balance between security and ease of access, often used for export logistics.

- Difficult peel: Provides strong adhesion, used for high-security applications where tamper evidence is a priority.

During development, CloudFilm typically defines a target peel force window (for example, in N/15 mm) with customers and confirms it with standardized peel tests, ensuring consistent “feel” on the final product.

Manufacturing Process

Step-by-Step Guide to Manufacturing Peelable Films (Easy Peel Films)

- Material selection: Choosing the appropriate base film and peelable seal/adhesive system according to the application.

- Coating or coextrusion: Applying the peelable seal or adhesive layer uniformly via coating or coextrusion.

- Lamination: Bonding the layers together (e.g., PET/PE, PET/easy peel sealant) using solvent-based, solvent-free or extrusion lamination.

- Curing: Ensuring proper bonding through temperature and pressure treatment so that peel performance stabilizes over time.

- Cutting and slitting: Preparing the films for packaging use, with roll widths, diameters and cores tailored to each customer’s packing line.

CloudFilm operates strict process controls for corona treatment, coating weight, lamination conditions and roll winding tension, ensuring that easy peel films run smoothly on high-speed FFS lines and tray sealers with minimal adjustment.

Key Technologies Involved

- Extrusion: A common process to create the base films.

- Coating technologies: Used to apply peelable adhesive and other functional layers (anti-fog, barrier, print primers).

- Lamination: Combining different substrates (e.g., PET/PE, PET/CPP, PE/PA/PE) to achieve the required mechanical and barrier performance.

Applications of Easy Peel films(Peelable Films)

Food Packaging

Easy peel films are extensively used for packaging fresh produce, ready meals, and snacks. Their ability to provide a strong seal while allowing easy opening makes them ideal for food applications.

For example, CloudFilm’s Easy Peel Filmcan be used as a lid for boxed lunches, noodle bowls or MAP trays, while CPP Anti Fog Film can serve as an anti-fog, peelable lidding for cut fruit and vegetables.

Pharmaceutical Packaging

In the pharmaceutical industry, easy peel films help maintain the sterility and integrity of products, especially for single-dose medications and medical devices. Peelable lidding films are commonly used on blister packs, syringe trays and diagnostic kits, where clean opening and controlled peel force are critical to avoid contamination.

Personal Care Products

Easy peel films are used in products like wet wipes and facial masks, ensuring product freshness and ease of access. By combining easy peel opening with good aroma barrier and attractive printing, CloudFilm helps brands deliver a more premium unboxing experience for cosmetics and personal care items.

Electronics

For electronics, easy peel films offer protective packaging, preventing dust and moisture from affecting sensitive components. Peelable protection films may also be used as temporary covers on screens, lenses and panels, providing both dust protection and easy removal at the end of the assembly process.

Other Industries

Beyond the sectors mentioned, easy peel films find use in automotive, industrial, and even aerospace packaging due to their versatility. In these fields, peelability can support clean removal of protective films after painting, coating or assembly, leaving surfaces free from adhesive residue.

Testing and Quality Control

Common Tests for easy peel Films

- Peel strength tests: Measure the force required to peel the film from its substrate.

- Barrier property tests: Ensure the film provides adequate protection against moisture, oxygen, and other elements.

Importance of Quality Control

Strict quality control ensures that easy peel films meet the necessary standards for safety, functionality, and durability across different applications. CloudFilm typically runs incoming raw-material checks, in-process online inspection and final roll-by-roll testing (peel force, seal strength, thickness and appearance) to guarantee consistent performance from trial rolls to mass orders.

Future Trends in Easy Peel Films

Sustainable Peelable Films

With increasing focus on sustainability, manufacturers are developing eco-friendly easy peel films using biodegradable and recyclable materials. Mono-PE structures (e.g., MDO PE/PE easy peel) and recyclable lidding solutions that fit PE or PP recycling streams are becoming important directions for brand owners and retailers.

Smart Easy Peel Films

Future innovations may include films with embedded sensors that can monitor product freshness or provide tamper-evidence. Printed indicators, QR codes, NFC labels and other smart elements can be combined with easy peel lidding to communicate shelf-life, temperature abuse or authenticity to consumers and supply-chain partners.

Customized Easy Peel Films

The demand for films tailored to specific applications is growing, allowing manufacturers to adjust peel force, barrier properties, and material composition for unique packaging needs. CloudFilm regularly co-develops customized easy peel lidding structures with customers – for example, retortable dairy cups, high-barrier coffee capsules or peelable medical trays – balancing technical performance, cost and regional recycling requirements.

How to Choose the Right Easy Peel Film with CloudFilm

1. Clarify your application and risk level

Start by defining the product type (yoghurt, jelly, ready meal, pet food, medical device, etc.), filling or processing conditions (hot fill, retort, HPP, chilled), and logistics risks (export, deep-frozen, long shelf life). This helps determine whether you need a standard PE-based lidding film, a high-barrier structure, or a retortable solution.

2. Define the tray/cup material and sealing equipment

Different substrates (PP, PS, PET, PVC, aluminum, paperboard) require different peelable seal layers. Share your tray/cup drawings, material specs and sealer model with CloudFilm so that the peelable lidding formulation and sealing window can be matched to your line.

3. Set target peel force and opening behavior

Explain whether you want a very light peel (for children or seniors), a medium peel (for general retail) or a stronger peel (for export or industrial use). CloudFilm can suggest a target peel-force range and validate it with peel tests on your actual trays.

4. Decide on barrier and special functions

If your product is oxygen-sensitive (meat, cheese, coffee), you may need a high-barrier film or a lamination with high-barrier substrates such as PE PA PE Film or other high-barrier structures. For chilled produce or ready meals, anti-fog may be essential. Share your shelf-life goals and storage conditions so CloudFilm can combine barrier, anti-fog and printability in one structure.

5. Request samples and technical data from CloudFilm

Once the basic parameters are clear, CloudFilm can provide sample rolls, technical data sheets and trial recommendations – for example, sample Easy Peel Film for boxed meals or yoghurt cups, or peelable CPE Film and PE Roll options for mono-material projects – helping you move from concept to stable mass production efficiently.

Easy Peel Films FAQ for Packaging Buyers and Engineers

Q1. What is the difference between easy peel film and standard lidding film?

A standard lidding film focuses mainly on seal integrity and barrier; opening may require tools or high force. An easy peel film is specifically formulated so that the seal peels cleanly at the interface, with controlled peel force and minimal residue, giving consumers a smoother, safer opening experience.

Q2. How do I decide whether to use easy peel or easy tear film?

Easy peel films are best for cups and trays, where the lid should come off completely and cleanly. Easy tear films are better for flow wraps, stick packs or pillow pouches, where consumers tear through the film along a notch. CloudFilm supplies both Easy Peel Film and Easy Tear Film, and can help you choose based on your pack format and product.

Q3. Can easy peel films be used in high-barrier or vacuum applications?

Yes. Easy peel concepts can be combined with high-barrier substrates such as PE PA PE Film or KPET films to achieve both strong barrier and controlled peel. In vacuum or MAP packs, careful design of the seal layer and tray material is essential to avoid seal failure while maintaining easy opening.

Q4. Are easy peel films compatible with recyclable, mono-material packaging?

They can be. For example, mono-PE structures using MDO PE Film and PE-based peelable seal layers can support recyclable packaging streams. CloudFilm can suggest easy peel solutions that fit your regional recycling guidelines and downgauging targets.

Q5. What information should I prepare before asking CloudFilm for a quotation?

It is helpful to share product type, target markets, tray/cup material, filling or retort temperature, required shelf life, desired peel strength level, roll width/core/OD, and expected monthly consumption. With this information, CloudFilm can quickly recommend structures, provide technical data sheets and prepare a detailed quotation.

Q6. Can CloudFilm supply both film rolls and finished pouches or lids?

Yes. Besides supplying easy peel and other films, CloudFilm can also support customers with flexible pouches and lidding solutions where appropriate, helping you simplify sourcing and reduce coordination work between multiple converters.

Q7. How does CloudFilm control quality and consistency for easy peel films?

CloudFilm follows a strict quality system, including raw-material qualification, in-line monitoring of thickness and appearance, routine peel/ seal tests, and roll-by-roll inspection. For key projects, CloudFilm can also keep reference samples and test records so that performance is traceable across different production batches.

Conclusion

Easy Peel films play a vital role in modern packaging, offering convenience, protection, and sustainability. As industries continue to evolve, the demand for innovative, customizable peelable films will only grow. Research into sustainable materials and smart packaging solutions will likely shape the future of peelable film technology.

As a professional flexible packaging film manufacturer and exporter, CloudFilm helps global buyers turn these technical concepts into clear specifications – from choosing the right Easy Peel Film structure, to providing trial rolls, to supplying stable mass-production orders. If you are planning a new easy peel lidding project, you are welcome to contact CloudFilm for samples, technical consultation and a free quotation.