CloudFilm supplies PVDC films, PVDC coated PET (KPET), BOPP (KOPP) and BOPA (KPA) structures to help packaging buyers turn barrier requirements into clear, testable specifications for food, pharmaceutical and industrial projects.

Introduction to PVDC Film

Polyvinylidene chloride (PVDC) film is widely recognized for its exceptional barrier properties, making it a preferred choice in various packaging applications. With its ability to protect against moisture, oxygen, and aroma, PVDC film has become essential in industries ranging from food packaging to pharmaceuticals.

In this article, we’ll delve into the characteristics, benefits, applications, historical background, classifications, and comparisons with other barrier films of PVDC film.

If you are comparing high-barrier options such as PVDC coated film, PVDC PET, KPET film or co-extruded film, this guide from CloudFilm will help you match film structures with shelf-life, machinability and cost targets instead of choosing materials by trial and error.

Understanding PVDC Film

What is PVDC?

PVDC is a synthetic polymer that exhibits outstanding barrier properties. Its unique molecular structure allows it to form a dense, impermeable layer that can effectively block gases and vapors. This quality makes PVDC film highly sought after in the packaging sector, where protection against environmental factors is critical.

Properties of PVDC Film

PVDC film is valued for the following key properties:

- Barrier Performance: PVDC provides an excellent barrier against oxygen, water vapor, carbon dioxide, and other gases. This is essential for maintaining product freshness and preventing spoilage in sensitive products such as food and pharmaceuticals.

- Chemical Resistance: PVDC exhibits strong resistance to oils, fats, and many chemicals, making it suitable for packaging products with aggressive ingredients.

- Clarity and Gloss: PVDC films can be produced with high clarity and gloss, offering an attractive appearance that enhances product presentation.

- Heat Sealability: PVDC films generally have good heat-sealing properties, enabling reliable, hermetic seals in flexible packaging applications.

- Thermal Stability: PVDC can maintain its barrier properties under a range of processing and storage conditions, including refrigeration and freezing.

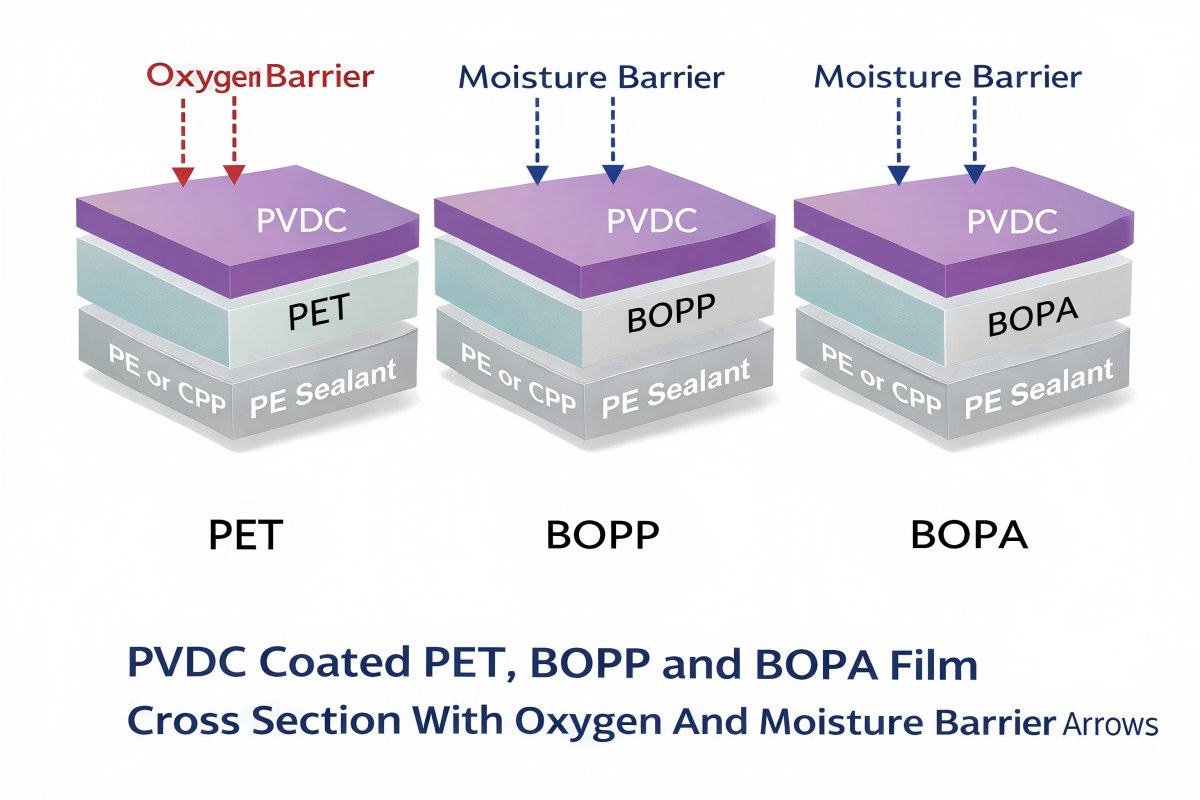

For many buyers, the most practical way to use PVDC is not as a standalone film but as a coating on PET, BOPP or BOPA substrates, creating high-barrier structures like KPET, KOPP and KPA that CloudFilm supplies for food, pharmaceutical and industrial packaging.

The History of PVDC Film

The development of PVDC as a high-performance barrier material has a rich history:

- Early Discovery: PVDC was first discovered in the 1830s, but its commercial potential wasn’t recognized until much later.

- Commercialization: In the 1930s, Dow Chemical and other companies began developing PVDC-based products. One of the earliest commercial applications was household plastic wrap.

- Expansion into Packaging: Over the decades, PVDC evolved into a key material in packaging, particularly as coatings on other films like PET, BOPP, and PVC to enhance barrier performance.

PVDC high-barrier films emerged in the late 1930s and quickly became a cornerstone material in applications such as food packaging, pharmaceuticals, and specialty industrial uses. Today, PVDC films remain an indispensable part of modern high-barrier packaging solutions.

Today, PVDC remains one of the core high-barrier polymers used alongside EVOH and ALOx PET in CloudFilm’s flexible packaging film portfolio.

Classifications of PVDC Film

PVDC film can be categorized based on its manufacturing processes, applications, and properties. Here are the primary classifications:

Based on Manufacturing Process

- Co-Extruded PVDC Films

These films are produced by co-extruding PVDC with other polymers in multi-layer structures. By carefully controlling the layer composition, manufacturers can tailor the film’s mechanical properties, barrier levels, and cost-effectiveness. - Laminated PVDC Films

In laminated structures, PVDC is applied as a coating or a separate layer that is then laminated to other films such as PET, BOPP, or nylon. This approach allows packaging designers to combine the strengths of multiple materials, optimizing barrier performance and mechanical properties. - PVDC Coated Film

PVDC coated films are produced by applying a thin layer of PVDC onto a substrate such as PET, BOPP, BOPA, or PVC. This type of film is widely used in flexible packaging, particularly for applications requiring superior protection against moisture and oxygen.

In CloudFilm’s range, PVDC coated films are typically supplied on PET, BOPP or BOPA bases and then laminated with PE, CPP or PA sealant layers, resulting in commercial structures such as KPET/PE, KOPP/CPP and KPA/PE that are widely used for pouches, lidding films and rollstock.

Based on Applications

- Food Packaging PVDC Films

These films are engineered to provide enhanced shelf life and protection for perishable items such as meat, cheese, snacks, instant noodles, coffee, and condiments. PVDC’s barrier function helps maintain product freshness and flavor by minimizing exposure to oxygen and moisture. - Pharmaceutical and Medical PVDC Films

In the healthcare sector, PVDC films are used in blister packaging and medical device packaging to protect sensitive formulations and devices from degradation due to exposure to moisture, oxygen, and light. - Industrial and Specialty Applications

PVDC films are also used in specialty packaging applications such as electronics, where moisture and gas barriers are critical for protecting sensitive components.

For example, meat, cheese and ready-meal converters often start with CloudFilm food packaging film or flexible pouches and then specify whether PVDC, EVOH or aluminum foil will provide the required barrier and puncture resistance.

Based on Properties

- High Barrier PVDC Films

These films are designed for applications where maximum protection against oxygen, moisture, and other gases is required. They are commonly used in pharmaceutical blister packs and premium food packaging. - Standard Barrier PVDC Films

Standard barrier PVDC films offer a balanced performance suitable for applications where moderate barrier properties are sufficient, often at a lower cost compared to high barrier grades.

High-barrier PVDC grades are usually chosen for products with strict oxygen and moisture limits (such as cheese, pharma or dehydrated powders), while standard-barrier or thinner coating weights can be used where cost and downgauging are more important than maximum shelf life.

CloudFilm PVDC Film Portfolio & Typical Structures

CloudFilm’s PVDC offering focuses on commercial structures that buyers already recognize on their specifications and RFQs:

- PVDC coated film – High-barrier PVDC coatings on PET, BOPP or BOPA substrates for stand-up pouches, pillow packs and lidding films.

- PVDC PET – PET-based PVDC coated film for transparent, stiff laminates used in food and pharmaceutical packaging.

- KPET film – PVDC coated PET film optimised for laminating with PE or CPP in KPET/PE, KPET/CPP or PET/KPET/PE structures.

- Co-extruded film – Multi-layer high-barrier films where PVDC or EVOH is co-extruded within the structure rather than only coated on the surface.

- Complementary high-barrier solutions such as EVOH bags, PP EVOH PP sheets and ALOx PET film help you design chlorine-free or recyclable alternatives where needed.

By combining these PVDC and non-PVDC options, CloudFilm can support projects ranging from traditional KPET/PE snack packaging to advanced ALOx PET/EVOH laminates for premium or sustainability-driven brands.

Comparing PVDC with Other Barrier Films

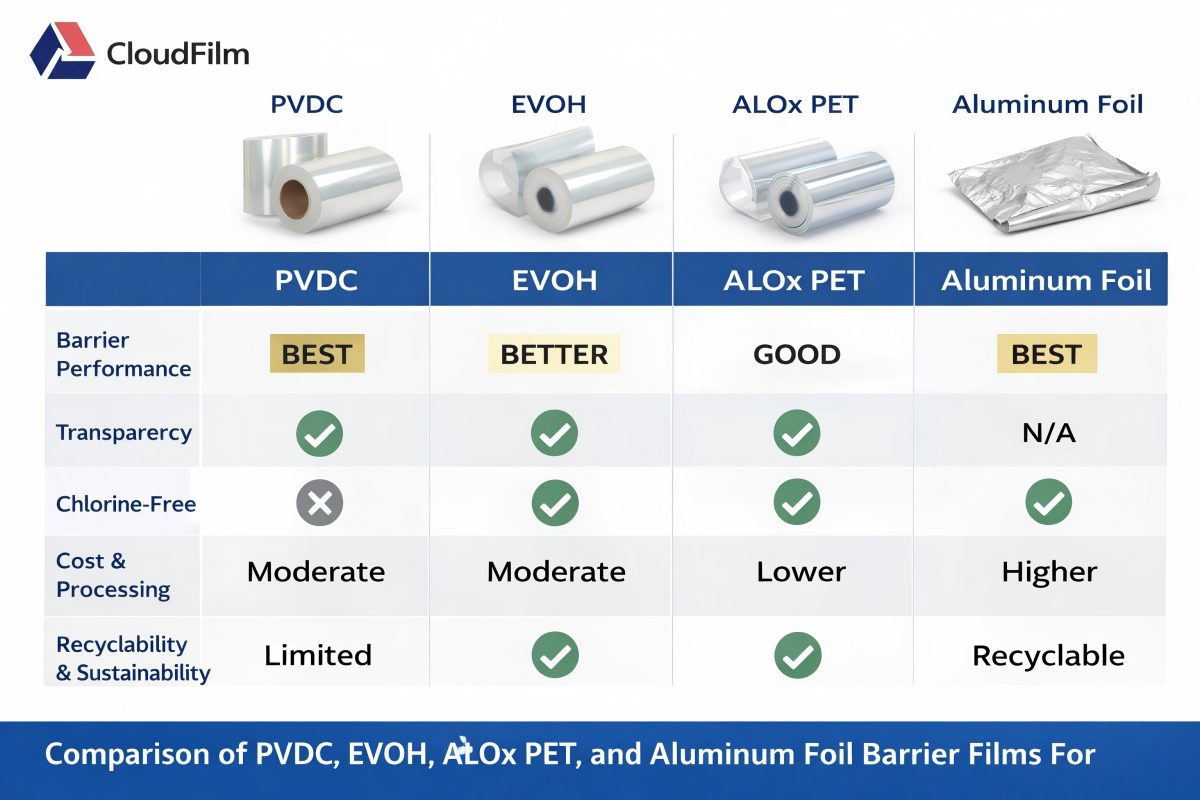

Barrier films play a pivotal role in packaging, and PVDC is often compared to other materials such as EVOH, nylon, and aluminum foil. Here’s how PVDC stacks up against them:

PVDC vs. EVOH

- Barrier Performance: Both PVDC and EVOH provide strong barrier properties against gases, but PVDC generally offers superior moisture resistance, especially in high-humidity environments. EVOH’s barrier can decrease when exposed to high humidity unless properly protected in a multilayer structure.

- Processing: EVOH requires careful extrusion conditions and is usually sandwiched between other polymers, while PVDC can be applied as a coating or co-extruded, offering more flexibility in some applications.

- Environmental Considerations: EVOH is often perceived as more environmentally friendly than PVDC due to regulatory concerns around chlorine-containing materials. However, PVDC remains an important option where maximum barrier is critical and no direct alternative can offer the same performance at similar cost.

When chlorine-free structures or recyclability are top priorities, CloudFilm can introduce alternatives such as EVOH bags or PP EVOH PP laminates while still keeping a strong barrier.

PVDC vs. Nylon (PA)

- Barrier vs. Mechanical Strength: Nylon films are prized for their mechanical strength, puncture resistance, and toughness, whereas PVDC excels in barrier performance. Combining PVDC with nylon in co-extruded or laminated structures delivers a film with both strong barrier and mechanical durability.

- Applications: PA/PVDC structures are often used for vacuum-packed meats, cheese, and products requiring resistance to puncture and flex-cracking.

PVDC vs. Aluminum Foil

- Barrier Level: Aluminum foil provides an absolute barrier to light, oxygen, and moisture, whereas PVDC offers very high but not absolute barrier.

- Flexibility and Visibility: PVDC films are transparent and flexible, making them suitable for applications where product visibility and flexible handling are important. Aluminum foil, though highly protective, is opaque and more prone to cracking under flex stress.

- Cost and Forming: Foil-based laminates may be more costly and less forgiving on certain high-speed packing lines; PVDC-coated structures often offer a balance of barrier, appearance, and machinability.

PVDC vs. PET, BOPP, and PE

- Base Films vs. Coatings: PET, BOPP, and PE are widely used base films in packaging due to their mechanical strength, clarity, and sealability. However, their barrier properties alone are often insufficient for demanding applications. PVDC coatings or layers are frequently applied to these films to enhance their barrier performance without compromising their mechanical and optical advantages.

When you work with CloudFilm, we can show you benchmark data and sample laminates so you can decide whether PVDC, EVOH, ALOx PET or metallized films are the best balance of barrier, cost, sustainability and line efficiency for your SKUs.

Benefits of Using PVDC Film

PVDC film provides several advantages that make it a preferred choice in high-performance packaging:

- Extended Shelf Life

PVDC’s excellent barrier properties significantly slow down the ingress of oxygen and moisture, helping extend the shelf life of food products and sensitive pharmaceuticals. - Aroma and Flavor Preservation

By reducing the transmission of volatile compounds, PVDC films help preserve the original aroma and flavor of packaged goods, which is critical for coffee, spices, snacks, and premium foods. - Product Safety and Quality

Effective barrier performance protects products from environmental contaminants and degradation, improving safety and maintaining consistent quality throughout the supply chain. - Improved Aesthetics

Clear, glossy PVDC films enhance product presentation and can be reverse-printed or laminated to produce visually appealing packaging designs. - Versatility in Packaging Formats

PVDC films can be used in a wide range of packaging formats, including pouches, lidding films, and thermoformed packages, offering design flexibility for brand owners and converters.

Because CloudFilm controls both base film production and PVDC coating, we can tune coating weight, corona treatment and sealant layers so that your film runs smoothly on existing form-fill-seal, pouch or lidding lines without extensive requalification.

Applications of PVDC Film

PVDC film is widely used across several key industries:

Food Packaging

PVDC-coated and co-extruded films are widely used in food packaging applications such as:

- Snack and confectionery packaging

- Meat and cheese vacuum packs

- Instant noodles and soup bases

- Coffee, tea, and powdered drinks

- Sauces, condiments, and spices

Pharmaceutical Packaging

In the pharmaceutical industry, PVDC films are used to manufacture:

- Blister packs for tablets and capsules

- Sachets for powders and granules

- High-barrier pouches for diagnostics and medical devices

Personal Care and Cosmetics

PVDC films help preserve the stability and efficacy of personal care and cosmetic products by protecting them from oxygen, moisture, and light exposure.

Industrial and Technical Applications

PVDC films are also used in industrial and technical packaging for:

- Electronics and semiconductor components

- Specialty chemicals

- Corrosion-sensitive metal parts

To see how these applications translate into real products, you can explore CloudFilm’s food packaging film, flexible pouches and stand up pouches, where PVDC, ALOx PET or EVOH-based structures are selected according to your oxygen and moisture barrier targets.

Market Trends and Future Outlook

In recent years, there has been growing demand for high-performance barrier films as brands seek to enhance product shelf life, expand into global markets, and reduce food waste. PVDC films are expected to remain a critical part of this market due to their unmatched combination of barrier performance and versatility.

At the same time, sustainability concerns and regulatory pressures are shaping the future of PVDC. While some markets are moving towards alternative materials, such as EVOH-based structures or ALOx-coated films, PVDC continues to be indispensable in applications where barrier performance cannot be compromised.

CloudFilm continuously expands its high-barrier portfolio, introducing options such as ALOx PET film and recyclable mono-material pouches so that customers who are concerned about chlorine content or recyclability still have access to strong barrier performance.

How CloudFilm Supports Your PVDC Projects

From first RFQ to mass production, CloudFilm positions itself as both a film manufacturer and a technical partner rather than only a trading company:

- Specification support: We help you translate marketing requirements (shelf life, markets, storage conditions) into concrete parameters like OTR/WVTR targets, film structure, thickness and roll width.

- Structure selection: CloudFilm compares PVDC, EVOH, ALOx PET, metallized film and aluminum foil structures with you to find a realistic balance of barrier, cost and sustainability.

- Sampling and trials: Short trial rolls or sample pouches can be supplied so you can test machinability and product performance before committing to large volumes.

- Integrated portfolio: Because CloudFilm also produces BOPP, BOPET, BOPA, PE and speciality films, you can source both PVDC-coated films and other layers (sealant films, ALOx PET, EVOH laminates, PE pouches) from one specification set.

- Export-friendly service: With long experience supplying customers in Europe, the Americas and Asia, CloudFilm supports documentation, palletization and logistics for international shipments.

FAQ: PVDC Film & CloudFilm High-Barrier Solutions

Q1. Which PVDC film grades and structures can CloudFilm supply?

CloudFilm focuses on PVDC coated PET (KPET), BOPP (KOPP) and BOPA (KPA) films. These are usually laminated with PE, CPP or PA to form structures such as KPET/PE, KPET/CPP, KOPP/CPP, KOPP/PE and KPA/PE or KPA/CPP for different product types.

Q2. When should I choose PVDC film instead of EVOH or ALOx PET?

PVDC-coated films are typically preferred when:

- Your product is very sensitive to oxygen and moisture (cheese, processed meat, certain pharmaceuticals).

- The package will see high humidity, cold chain or frozen conditions where EVOH barrier drops more quickly.

- You need a clear, high-gloss appearance with extremely strong barrier, but full aluminum foil is not desired.

EVOH or ALOx PET may be better options when chlorine-free structures, recyclability or specific regulatory requirements are the top priority rather than maximum barrier. CloudFilm can quote both PVDC and non-PVDC structures side by side so you can compare performance and cost.

Q3. Is PVDC film safe for food and pharmaceutical packaging?

Yes. PVDC resins and coatings used for packaging are developed to meet food-contact and pharmaceutical packaging standards when applied correctly. PVDC is widely used in food wraps, blister packs and high-barrier laminates because of its excellent protection against oxygen and water vapour.

CloudFilm produces PVDC coated films using food-grade raw materials and supplies them for food, pet food, cosmetic and certain pharmaceutical applications worldwide. For specific markets or end uses, CloudFilm can provide documentation or assist in arranging third-party testing as needed.

Q4. How does PVDC film affect recyclability and sustainability?

PVDC contains chlorine, so in some regions there is increased scrutiny of its use, particularly in waste-to-energy or mechanical recycling streams. Where recyclability or chlorine-free structures are central to your packaging strategy, CloudFilm may recommend ALOx PET, EVOH-based laminates or mono-PE pouches instead of PVDC.

However, PVDC can still play a positive sustainability role by significantly extending shelf life and reducing food waste—which often has a higher overall environmental footprint than the packaging itself. The best approach is to evaluate both product protection and end-of-life scenarios together.

Q5. What information should I prepare before asking CloudFilm for a PVDC film quotation?

To receive a fast and accurate quotation, it is helpful to share:

- Product to be packed (e.g. cheese slices, coffee, instant noodles, tablets, dry pet food).

- Current or target laminate structure (e.g. KPET/PE, KOPP/CPP, PET/AL/PE).

- Required thickness and roll width, or pouch type and finished size.

- Estimated order quantity and destination port (FOB or CIF terms).

Even if some parameters are not confirmed, you can send photos or samples of your existing packaging; CloudFilm’s team can help fill in the missing technical details.

Q6. Does CloudFilm provide sample rolls or trial pouches for PVDC films?

Yes. For most PVDC coated films, CloudFilm can provide short sample rolls or small batches of pouches so that you can run trials on your own VFFS, HFFS, thermoforming or pouch lines. This allows you to validate seal strength, machinability, appearance and shelf life before committing to bulk orders.

Q7. How do I decide between using PVDC film and PVDC-coated PVC blister films for pharmaceuticals?

For solid oral doses (tablets, capsules), rigid PVC/PVDC blister films are widely used in healthcare due to their very high moisture and oxygen barrier. For sachets, pouches or strip packs, flexible PVDC coated films (KPET, KOPP, KPA) may be more suitable.

CloudFilm mainly focuses on flexible PVDC coated films used for laminates and pouches. If you already use rigid blister films, CloudFilm can still help you design outer pouches and secondary barrier packaging around those blisters.

Conclusion

PVDC film has established itself as a cornerstone material in high-performance packaging solutions. With its exceptional barrier properties, versatility, and adaptability to various formats, it remains a preferred choice for industries ranging from food and pharmaceuticals to industrial and specialty applications.

While sustainability and regulatory considerations are driving innovation in alternative materials, PVDC continues to play a vital role, especially in applications where product protection and shelf life are paramount.

By understanding its properties, classifications, and how it compares to other barrier films, packaging professionals can make more informed decisions when selecting materials for their products.

If you share your current structure, target shelf life and key markets with CloudFilm, our team can recommend a practical PVDC, ALOx PET or EVOH-based solution together with clear film specifications and a quotation.