Ordering & Customization Checklist for PET Twist Film

To prepare a precise quotation and recommend the right PET twist film grade, the following information is very helpful:

- Packed product & application

(e.g. hard candy, soft candy, lollipop, chocolate, jerky, paper–plastic composite wrap) - Wrapping method & machine type

(hand twist, semi-automatic, or high-speed twist-wrapping machine, typical speed) - Target structure

(single-layer PET twist film, paper/PET composite, PET with metallized or barrier layers, etc.) - Film thickness (μm)

(common gauges include 19 μm for jerky/paper–plastic wraps and 23–25 μm for candies and chocolates) - Roll width, roll diameter and core size

(e.g. 300–2000 mm width, 3″ or 6″ core, preferred roll OD or weight) - Printing & brand requirements

(unprinted transparent film or pre-printed rolls, number of colors, matte/gloss effects, window design) - Regulatory & documentation needs

(food-contact declarations, regional regulations, test reports) - Trial order quantity, annual volume and delivery terms

(FOB/CIF, destination port, desired shipment plan)

Not sure about all the technical details? You can still send an inquiry. Simply tell us:

- What product you want to pack

- How you wrap it now (hand twist or machine, approximate speed)

- The main problems you want to solve (e.g. twist memory, blocking, print quality, dust attraction)

Our team will help you select suitable PET twist film specifications and prepare a clear quotation and sampling plan.

Transform Your Packaging with PET Twist Film

PET Twist Film for Candy & Chocolate Brands

CloudFilm’s PET twist film is engineered for brands that rely on twist wraps to deliver a premium unboxing experience.

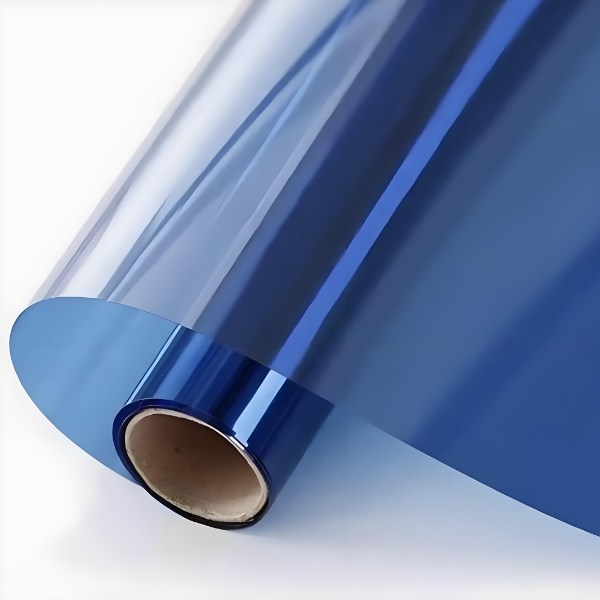

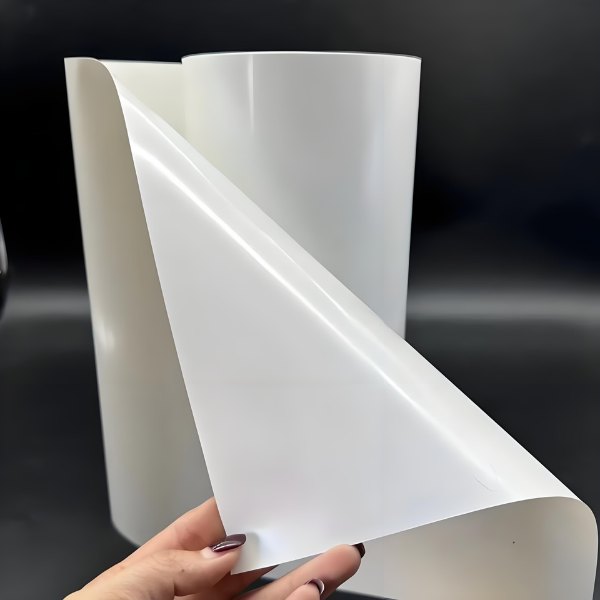

The film’s high clarity, gloss and twist memory help your candies, chocolates and lollipops look neat on the shelf and feel satisfying in the hand.

Stable Performance on High-Speed Twist-Wrapping Lines

By combining an anti-static coating with controlled slip and shrinkage, our polyester twist film runs smoothly on modern twist-wrapping and flow-wrapping machines.

Consistent torque and surface properties reduce film blocking, dust attraction and machine downtime, helping you achieve stable output and less waste.

CloudFilm – Your PET Twist Film Partner in China

As a PET and BOPET film manufacturer, CloudFilm can support you from structure design and film selection to sampling and export logistics.

Whether you need clear twist film, printed candy wraps or paper–PET composite structures, our team works with your engineers to balance appearance, machinability and total cost.

Partner with CloudFilm to turn PET twist film into a reliable part of your candy and snack packaging strategy.