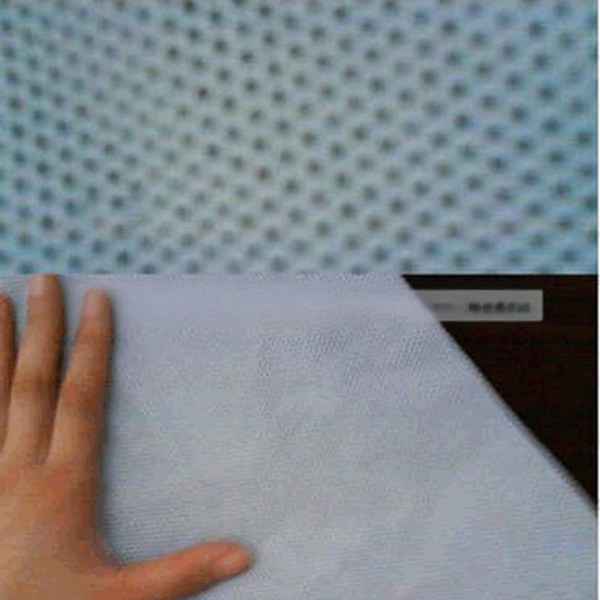

PE Roll

CloudFilm PE roll is a polyethylene film roll designed for packaging, surface protection and construction or farming covers. You can customize the material (LDPE, LLDPE or blends), roll width, thickness, color and additives to match your line.

-

Moisture & Dust Protection: Forms a reliable barrier against water, dirt and contamination.

-

Flexible Yet Strong: Easy to cut and apply while resisting tears and punctures.

-

Multiple Grades & Colors: Transparent, milky white or black PE rolls for different applications.

-

Ready for Converters & End Users: Jumbo rolls or finished rolls supplied from CloudFilm’s PE film portfolio.

PE Roll Description

What Is PE Roll?

PE roll is a polyethylene film supplied in roll form instead of ready-made bags. It is widely used as plastic sheeting, wrapping film or cover film for packaging, construction and agricultural uses.

CloudFilm produces PE roll based on different PE resins such as LDPE, LLDPE and HDPE. By adjusting the resin blend and processing conditions, we can deliver rolls with the right balance of clarity, stiffness and toughness for your project. For a deeper explanation of PE materials, you can also refer to our guide on PE packaging film and its uses.

Core Features of CloudFilm PE Roll

Material Flexibility: Choose between LDPE for softness and clarity, LLDPE for higher strength, or tailored blends based on your application. See also our dedicated LDPE film

and LLDPE film pages.

Custom Size Range: Typical thickness is from 20–200 μm, with roll widths from 300–3000 mm. Jumbo rolls are available for converters, and small rolls can be supplied for end users.

Multiple Colors & Additives: Transparent, milky white or black PE rolls with optional UV stabilizer, anti-static, anti-fog or slip/anti-block additives.

Food-Grade & Industrial Grades: Food-contact PE roll for bread, produce and frozen food, as well as heavy-duty grades for construction, farming and industrial packaging.

Recyclable Mono-Material: PE roll is 100% polyethylene and can support mono-material and downgauging projects together with solutions like MDO PE film and BOPE film.

PE Roll vs Pre-Made Bags

Compared with buying only pre-made bags, PE roll offers you more flexibility and lower cost per package:

You can cut and seal bags to any length on automatic or semi-automatic machines.

You can run different product sizes with the same roll by adjusting cutting length.

You reduce inventory of finished bags and only stock a few standard roll sizes.

For a more in-depth buying guide, you can also check our article on transparent polythene rolls.

To help you quickly evaluate whether CloudFilm PE roll fits your project, the table below summarizes the typical specification range.

- Material Types: LDPE, LLDPE, HDPE or blends, tailored according to strength, clarity and stiffness requirements.

- Thickness Range: Approx. 20–200 μm for light to heavy-duty uses.

- Roll Width: Approx. 300–3000 mm, matched to your blown film line or converting equipment.

- Roll Length & Diameter: Customized according to roll-handling limits and machine specifications.

- Core Size: 3″ (76 mm) paper core as standard; 6″ cores available on request.

- Colors: Clear, milky white, black or tinted colors for special applications.

- Surface Finish: Smooth or matte surface; slip and anti-block level adjustable.

- Additives: Optional UV stabilizer, anti-static, anti-fog, anti-slip or anti-block.

- Formats: Jumbo rolls for converters, standard rolls for packers, and special formats for PE stretch film or PE protective film type applications.

When sending an inquiry, you can share your current datasheet or target parameters, and our engineers will help you match an equivalent PE roll grade.

Get Free Sample of PE Roll

Ready to test PE roll on your own lines? CloudFilm can prepare trial rolls and samples based on your target application.

When you send us an inquiry, it is helpful to share:

- End use (e.g. pallet wrap, surface protection, greenhouse cover, food packaging)

- Required thickness, width and roll length

- Preferred material type (LDPE, LLDPE, HDPE) and color

- Any special additives (UV, anti-static, anti-fog, etc.)

- Your current film datasheet, if available

Our team will quickly recommend a suitable PE roll grade, send you samples and provide a competitive quotation. If you need to compare with other options, you can also browse our PE film series.

PE Roll Applications

1. Pallet Wrap & Unitization

PE roll can be slit into stretch-type rolls or used as general wrapping film to stabilize cartons and bundles on pallets. For high-speed pallet wrapping, you may also consider our dedicated PE stretch film.

2. Protective Surface Covering

Use PE roll as temporary protection film for floors, furniture, doors and equipment during construction or renovation. In this case, milky or colored films with balanced adhesion and easy removal are often preferred, and you can also refer to our PE protective film.

3. Agricultural Greenhouse & Mulch Covers

Thicker PE rolls with UV stabilizers can be converted into greenhouse covers, tunnel films or mulch films, protecting crops from rain, wind and temperature fluctuations. For more specialized agricultural films, you can also explore our silage film.

4. Vapor Barrier in Construction

Heavy-duty PE roll is commonly used as a vapor barrier under concrete slabs or inside walls and roofs. It helps block moisture migration, reduce mold risk and improve building durability. Black or opaque films are often selected to reduce light transmission.

5. Food & Consumer Packaging

Food-grade PE roll can be converted into bags and liners for bread, vegetables, frozen food and bulk ingredients. As part of a broader packaging program, PE rolls can work together with printed food packaging film or mono-material recyclable pouches.

FAQ

A PE roll is a polyethylene film supplied on a core in roll form. It can be slit, cut and sealed into different bags, liners or covers on converting machines or simple sealing equipment.

Typical thickness for PE roll is around 20–200 μm, and roll widths are usually 300–3000 mm. We can adjust these ranges after reviewing your application and machine capability.

We mainly use LDPE, LLDPE and HDPE, or blends of these. LDPE offers softness and clarity, LLDPE gives higher strength and puncture resistance, and HDPE is stiffer with better barrier. For more detail, you can also read our guide on PE packaging film and its uses.

Yes, we can supply food-grade PE roll produced from certified resins under controlled conditions. It is widely used for bread bags, produce bags, frozen food liners and other food-contact packaging. Please let us know your local regulations so we can confirm compliance.

Yes. PE roll can be surface-printed or laminated with other films depending on your structure. Many customers use PE as the inner sealing layer in laminates, and combine it with printed BOPP, PET or high-barrier films such as KPET film or PE PA PE film.

PE roll is a general term for polyethylene film rolls and can be converted into many products. PE stretch film and PE shrink film are special types designed for pallet wrapping or heat shrink bundling. If your main use is pallet stabilization, stretch film is usually more efficient; if you need a versatile sheeting material, PE roll is the right starting point.

For a quick quotation, please tell us the end use, thickness, width, roll length, material type (LDPE/LLDPE/HDPE), color, required quantity per order and destination port. If you have a current film sample or datasheet, sharing it will help us match the grade more accurately.

For standard PE roll specifications, the typical minimum order quantity is around 1000–1500 kg per specification. Lead time is usually 2–4 weeks after order confirmation, depending on the grade and production load. We can discuss trial quantities and flexible arrangements for new projects.

Related News

Who This Guide Is For And How To Use It When buyers search for “packaging for frozen […]

What “Digital Flexible Packaging” Really Means When people say “digital packaging,” they often think digital printing only. In […]

In the world of modern packaging, printing, and industrial applications, the term PE laminated is a cornerstone of material science. […]

Introduction: Why is PE the Workhorse of the Packaging World? Every day, countless bags, liners, stretch wraps […]

Introduction: Why is Understanding Plastic Film Types So Crucial? Imagine you’re designing a food package that requires long-lasting […]

In the world of plastic film manufacturing, two processes dominate the industry: cast film and blown film. For packaging engineers, product […]

Introduction: The Science Behind Packaging In our daily lives, we encounter a vast array of packages. From snack […]

Introduction: Why MDO PE and BOPE Matter for Mono-PE Packaging In today’s flexible packaging market, brand owners and […]