Nozzle Pouches

CloudFilm nozzle pouches give you a precise, mess-free way to dispense liquids, gels and pastes while saving weight compared with rigid bottles. They are widely used for detergents, liquid soaps, household cleaners, cosmetic refills and medical solutions.

• Leak-proof nozzles with screw, flip-top or child-resistant caps available

• Stand-up and flat nozzle pouches from small samples to large refill packs

• High-barrier laminates such as PET/PE, PA/PE and PET/AL/PE to protect sensitive formulations

• Custom spout position, diameter and thread to match your filling equipment

• Manufactured by CloudFilm in Qingdao, China with export-ready documentation and stable quality

If you are searching for drinkable formats like kids’ juice or sports beverages, please also see our Spout Pouches and Liquid Pouches.

Nozzle Pouches Description

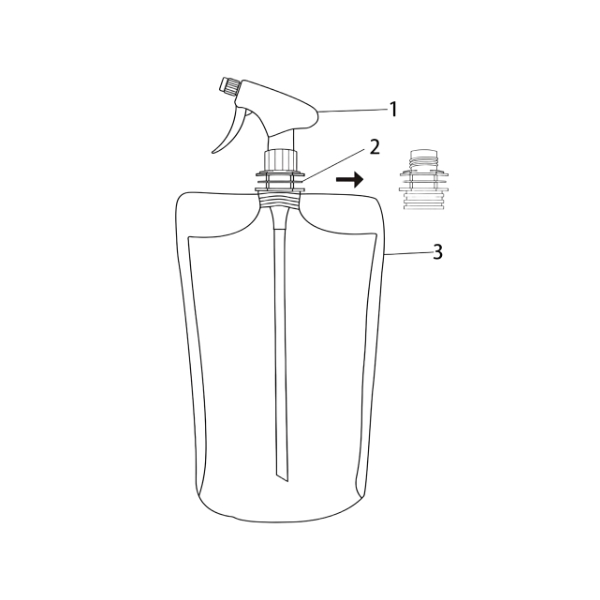

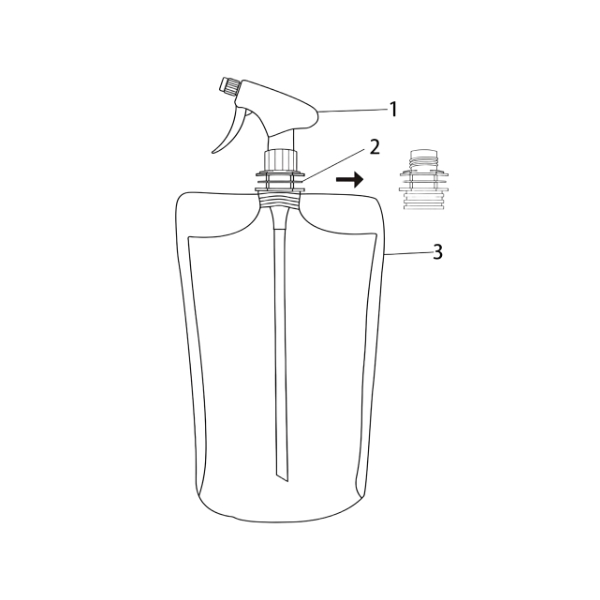

Nozzle pouches are flexible pouches fitted with a small spout and cap so that the contents can be poured, squeezed or dripped out in a controlled way. Compared with simple Stand Up Pouches or bottles, they provide cleaner dosing and are easier to ship in bulk cartons.

Drawing on CloudFilm’s own films – including PET, PA and PE – we combine structures such as PET/PE, PA/PE and PET/AL/PE to reach the barrier, toughness and sealing strength your project needs. For recyclable projects, we can also design mono-PE nozzle pouches inspired by our Recyclable Pouches and MDO PE Film, subject to local recycling streams.

Typical applications include liquid detergents, shower gels, liquid hand soap, disinfectants, lubricants, agrochemicals, medical and diagnostic solutions and many other industrial or household liquids. By matching the nozzle type with your filling line – whether you fill through the open top or “fill through the spout” – CloudFilm helps you reduce spillage, complaints and logistics costs.

As a nozzle pouch manufacturer in China, CloudFilm integrates film extrusion, lamination, printing and pouch-making in one site. This means you can develop nozzle pouches together with related roll films such as PET/PE Film and PA/PE Film, keeping specifications consistent from trial to mass production.

Our custom nozzle pouches can be tailored to:

- Custom printing (up to 10 colours, matte, gloss or kraft effects)

- Custom sizing and volumes from 50 ml samples to 5 L refill pouches

- Custom materials and barrier level for food, cosmetic, medical or industrial use

- Custom external finish – transparent, matte, soft-touch or kraft paper laminates

- Custom pouch style – stand-up, flat refill pouch or shaped nozzle pouch

- Custom spout and cap – different diameters, threads, colours and child-resistant or flip-top designs

No single nozzle pouch fits every liquid. Different products, viscosities and filling processes need different film structures and nozzle designs. The following pairings can help you quickly discuss options with our team (final structure will be confirmed after we review your product data):

Home & Personal Care Liquids

- Typical products: laundry detergent, fabric softener, liquid hand soap, dishwashing liquids, bathroom cleaners.

- Recommended structures: PET/PE or PA/PE for good stiffness, puncture resistance and seal strength.

- Nozzle suggestions: corner spouts for easy pouring from large refill packs; top-centre spouts for smaller stand-up pouches that live on the sink or in the bathroom.

Cosmetics & Beauty Refills

- Typical products: shampoo, conditioner, hair mask, body lotion, hand cream refills.

- Recommended structures: PET/PE with soft-touch or matte coatings, or kraft laminates for natural brands.

- Nozzle suggestions: slender spouts for precise dosing, flip-top caps for daily use, colour-matched caps to enhance brand image.

Medical & Diagnostic Solutions

- Typical products: irrigation solutions, disinfectants, diagnostic reagents and buffer solutions.

- Recommended structures: high-clarity PET/PE or PA/PE structures with carefully selected inks and adhesives; if needed, we can align with Retort Pouches for higher temperature resistance.

- Nozzle suggestions: tamper-evident screw caps, special spouts compatible with your connectors or lines; optional laser-scored tear notches around the spout area.

Agrochemical & Industrial Liquids

- Typical products: crop protection chemicals, lubricants, windshield washer, cleaning concentrates and construction chemicals.

- Recommended structures: thicker PA/PE or PET/PA/PE for extra toughness and drop resistance.

- Nozzle suggestions: larger diameter spouts with strong screw caps, sometimes combined with handles or hanging holes for easier handling and display.

Food Sauces & Oils

- Typical products: tomato paste, sauces, salad dressings, edible oils, marinades.

- Recommended structures: PET/AL/PE or high-barrier PET/PE for aroma and light protection; we can also explore structures aligned with our Liquid Pouches.

- Nozzle suggestions: narrow nozzles for controlled pouring, non-drip spouts and easy-reaming caps to keep the cap area clean.

Get Free Sample of Nozzle Pouches

Want to test if nozzle pouches are right for your product?

Share a few key details with CloudFilm and we will suggest suitable structures, prepare free stock samples where available, or quote a small trial order for your line tests.

For a faster reply, please include:

• Product to be packed (detergent, cosmetic refill, medical liquid, agrochemical, etc.)

• Pouch volume (for example 250 ml, 500 ml, 1 L) and estimated order quantity

• Filling method (cold or hot, fill through the spout or from the top, manual or automatic)

• Any special requirements (high barrier, recyclable, clear or matte finish, spout size and cap type)

• Preferred delivery term (FOB Qingdao or CIF + destination port)

Nozzle Pouches Applications

- Food & Beverage

Nozzle pouches can be used for sauces, condiments, cooking wines, edible oils and some ready-to-mix beverages. Precise pouring helps end users control portion size and avoid mess in the kitchen. For products that are directly drunk from the package, we usually recommend you also compare our Spout Pouches and Stand Up Pouches. - Cosmetics & Personal Care

For shampoos, conditioners, shower gels, hand soaps and body lotions, nozzle pouches offer a lightweight refill format that supports “refill and reuse” concepts. Consumers can easily top up their bottles at home, while brands save on plastic usage and shipping costs. Matte or soft-touch finishes help premium personal care brands stand out on shelf. - Pharmaceutical & Medical

Nozzle pouches are suitable for certain liquid medicines, syrups, oral solutions, irrigation fluids and disinfectants. The combination of high-barrier films and tamper-evident caps helps protect product stability and safety during transport and storage. CloudFilm can coordinate nozzle pouch design with related medical packaging such as PA/PE Film, Retort Pouches or Pharmaceutical Pouches. - Industrial & Automotive

From lubricants and cutting fluids to cleaning concentrates and windshield washer fluids, nozzle pouches give industrial users a robust, space-saving alternative to cans and bottles. Reinforced PA/PE structures and thicker gauges improve puncture and drop resistance, while large-diameter spouts make it easier to pour into tanks or reservoirs. - Household Cleaning Products

Laundry detergent, fabric softener, floor cleaners, glass cleaners and toilet cleaners all benefit from nozzle pouches. Refill packs can be shipped flat and stacked efficiently, reducing warehousing and freight costs for retailers and brand owners. End users appreciate the ability to refill existing rigid bottles while still enjoying accurate dosing from the nozzle pouch itself.

FAQ

Very aggressive solvents, highly corrosive chemicals or products that must withstand extreme temperatures may not be suitable for standard nozzle pouches. In such cases, CloudFilm will first review your SDS, filling temperature and storage conditions. We can then judge whether a reinforced film structure or an alternative packaging format – such as Retort Pouches or 3 Side Seal Pouches – would be safer.

With the right film structure and filling process, many liquids can reach 12–24 months of shelf life in nozzle pouches. Actual shelf life depends on the product formula, oxygen and moisture sensitivity, filling temperature, headspace and storage conditions. When you share your target shelf life and current packaging with us, we will recommend one or two structures and explain the trade-offs.

Compared with rigid bottles and cans, nozzle pouches use much less material and take up less volume during transport, which helps reduce carbon footprint. CloudFilm can also explore recyclable mono-PE structures similar to our Recyclable Pouches and PCR Film ranges. Final recyclability, however, always depends on local collection and recycling systems.

To prepare a realistic quotation, we mainly look at product type, pouch size, material structure, printing coverage and estimated quantity. Useful details include: what liquid you will pack, target volume, preferred structure (PET/PE, PA/PE, PET/AL/PE or mono-PE), number of printing colours, spout diameter and cap style, and whether you also need matching roll films. The more complete your information, the faster we can optimize cost for you.

For most custom nozzle pouches, MOQ starts from around 1,000–5,000 bags per design, depending on size, thickness, material structure and printing method. For simple, unprinted or digitally printed designs, we may support even smaller trial quantities. Our team will propose a step-by-step plan so you can test the market before scaling up.

Yes, many nozzle pouch structures can handle hot filling or mild pasteurization. For higher temperatures or full retort (around 121°C), we will evaluate your process time and pressure together with you and may recommend special high-temperature laminates or alternative Retort Pouches. It is very important that we confirm testing conditions before mass production.

In most cases, yes. If you send us your current nozzle pouch or the bottle you want to replace, we can analyze pouch dimensions, film structure, spout type and cap thread, then develop a nozzle pouch that fits into your existing filling and secondary packaging processes as smoothly as possible.

Yes. Besides premade nozzle pouches, CloudFilm supplies laminated roll stock such as PET/PE Film and PA/PE Film for customers who have their own pouch-making lines or local converters. This allows global brands to combine centralized film sourcing with local pouch converting while keeping structures consistent across markets.

Related News

Introduction: Why Custom Packaging Matters in Today’s Market In an era of digital commerce and fierce competition, packaging […]

Introduction Packaging plays a crucial role in product protection, brand presentation, and consumer experience. In today’s competitive market, […]

What is Crystal Flexible Packaging? Crystal Flexible Packaging refers to high-clarity, lightweight, and versatile packaging solutions that combine […]

Introduction: Why Dry Food Packaging is Crucial? Dry foods are a staple in our daily lives, ranging […]

What is a Retort Pouch? 📦 Definition and Basic Concept A retort pouch is a type of […]

Introduction — Addressing Pain Points and Introducing the Topic Are you searching for a safer, more convenient, and […]

Introduction: Why Pouch Types Matter Have you ever stood in a store aisle, overwhelmed by the sheer variety […]

Introduction: Why Smart Flexible Packaging Matters Now In today’s packaging world, brands, converters, and procurement teams are […]