3 Layer Film

CloudFilm 3 layer co-extruded film is a PE-based multi-layer film that combines barrier, strength and process stability in one structure. It is designed for food, medical, agricultural and industrial packaging lines that need reliable quality and a stable supply partner.

✔️ Enhanced Barrier Properties & Strength: Three-layer films provide superior moisture and oxygen barriers , and combine the advantages of different polymers (e.g., PE, PP, EVOH) to achieve enhanced mechanical strength, puncture resistance, and durability .

✔️ Material Flexibility & Cost-Effectiveness: The structure allows for strategic material use. ABA configuration can incorporate recycled or sustainable materials in the middle layer to reduce costs , while ABC configuration enables full customization with three different materials for high-performance applications .

✔️ Versatility for Diverse Applications: These films are suitable for a wide range of products, from T-shirt bags, garbage bags , to high-performance applications like agricultural films, greenhouse films, and food or medical packaging requiring superior barrier properties

3 Layer Film Description

What is a 3 Layer Film?

A 3 layer film is a co-extruded plastic film made from three polymer layers that are extruded together in a single step. Each layer plays a clear role:

- The outer layers provide sealing, print surface or slip control.

- The middle layer can add stiffness, barrier or cost saving.

Compared with single-layer PE film, a 3 layer structure gives you more control over mechanical properties, barrier and process stability. CloudFilm mainly produces PE-based 3 layer films using LDPE, LLDPE, MDPE, HDPE and barrier resins such as EVOH when needed. For more demanding barrier structures you can also refer to our PP EVOH PP sheets and PE PA PE film.

Key Performance Features

By designing each layer for its function, CloudFilm 3 layer films can deliver:

- Reliable moisture and oxygen barrier for sensitive food and medical products.

- High puncture and tear resistance for heavy bags, sharp products and long-distance logistics.

- Stable thickness profile and good film appearance for printing, automatic packing and high-speed lines.

- Optional functional additives such as anti-fog, anti-static, UV, slip and anti-blocking according to your project.

For non-barrier PE films you can also combine our LDPE film, LLDPE film and HDPE film to build the most suitable 3 layer structure.

Converting & Supply Options

CloudFilm 3 layer films are engineered to run well on common converting processes:

Blown film for bags, liners, agricultural films and industrial wraps.

Printing and lamination as part of PET/PE, BOPP/PE or PA/PE structures – see also our Roll Stock film and PET/PE film.

Bag making, FFS lines and pouch production together with our PE pouches and other flexible pouches.

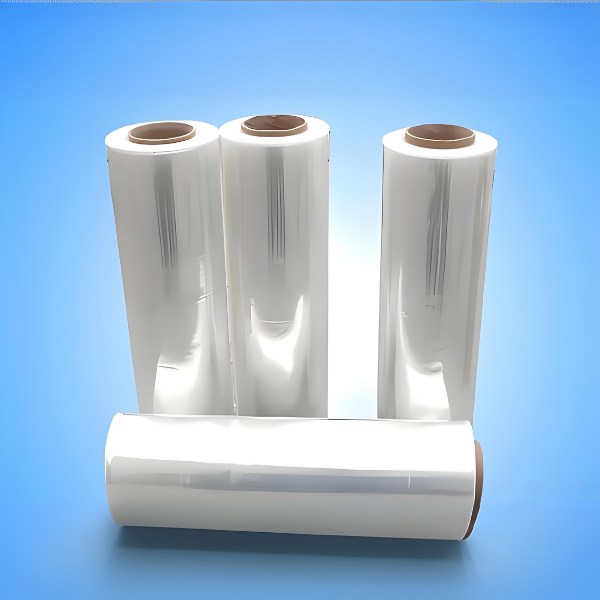

We supply jumbo rolls for converters and standard rolls for packers. Thickness, width, core size and winding direction can all be customized according to your packing line.

Why Work with CloudFilm?

CloudFilm has focused on flexible packaging films since 2002 and supplies a full PE film portfolio from LDPE film

and LLDPE film to stretch hood film, PE shrink film and high-barrier co-extruded films.

For each 3 layer film project we can:

- Analyse your current film or datasheet and propose an equivalent or upgraded structure.

- Help you balance performance, cost and recyclability, including mono-material PE solutions.

- Offer technical support during trial runs, from extrusion to printing, sealing and packing.

Below are some typical structures CloudFilm can design for your projects:

- General-Purpose PE Film (Bags & Liners)

Simple PE-only structures such as LDPE/LLDPE/LDPE are ideal for T-shirt bags, garbage bags and box liners. You can also refer to our dedicated LDPE film and LLDPE film pages for more details. - Tough Industrial & Logistics Film

Structures like LLDPE/MDPE/LLDPE or LLDPE/HDPE/LLDPE can improve stiffness and puncture resistance for stretch hood, shrink film and protective wraps. For these applications, many customers also check our stretch hood film, PE stretch film and PE protective film. - Simple Barrier 3 Layer Film

For products that need basic oxygen or aroma barrier, a PE/EVOH/PE 3 layer structure can be a cost-effective choice. If you need higher barrier performance or thermoformable sheets, please consider our PP EVOH PP and PE PA PE film , and read our EVOH barrier guide. - Custom-Engineered Structures

CloudFilm can combine different PE grades and functional masterbatches (UV, anti-fog, anti-static, slip, etc.) to design a 3 layer film that matches your sealing window, stiffness, clarity and recycling goals. When you send an inquiry, sharing your current film structure or target spec helps us respond faster with a tailored proposal.

Get Free Sample of 3 Layer Film

Testing is the fastest way to see if a 3 layer structure fits your product. CloudFilm can prepare free samples or trial rolls according to your project.

To receive a quick quote and sample, please share:

- End use (e.g. edible oil pouch, milk film, garbage bag, greenhouse film)

- Target thickness, film width and approximate roll length

- Whether the film will be printed, laminated or used as mono PE

If you want to know more about multilayer technology before testing, you can also read our article on multilayer film packaging.

3 Layer Film Applications

1. Food Packaging

CloudFilm 3 layer films are widely used for food bags, liners and laminated structures. Typical examples include edible oil pouches, pasteurized milk film, frozen food outer bags and box liners.

As an inner sealing layer, 3 layer PE film can be laminated with BOPP printing film or PET film to build high-performance PET/PE or BOPP/PE structures. For simple mono-material PE packaging, you can also combine our 3 layer film with MDO PE film or BOPE film.

2. Agricultural Films

For agriculture, 3 layer film technology is used in mulch films, greenhouse films and silage covers. The multi-layer design allows you to add UV stabilizers, anti-drip or anti-fog additives in specific layers to protect crops and extend film service life.

CloudFilm supplies agricultural films together with dedicated products such as silage film, LDPE film and HDPE film, so you can build a complete PE film portfolio for your farm or distribution business.

3. Medical Packaging

In medical and healthcare packaging, 3 layer films are used for pouches, inner liners and overwraps where clean, chemically stable PE is required. The multi-layer structure helps improve puncture resistance and seal integrity during sterilization, storage and transport.

For applications that need higher oxygen or moisture barrier, 3 layer PE films are often combined with high-barrier structures such as PP EVOH PP or PE PA PE film.

4. Industrial Protective Packaging

Industrial customers use 3 layer films for surface protection, pallet wrapping and heavy-duty bags. The outer layers can be designed for controlled peel strength, while the middle layer provides the required toughness and impact resistance.

CloudFilm offers 3 layer solutions alongside PE protective film, stretch hood film, PE stretch film and POF shrink film, so you can cover both primary and secondary packaging in one place.

FAQ

A 3 layer film is a co-extruded film made from three polymer layers in one step. The outer layers usually provide sealing, printability or slip, while the middle layer adds stiffness, barrier or cost saving. Compared with single-layer PE film, it gives better control of barrier, strength and process stability.

In an ABA structure, the two outer layers use the same material and the middle layer is different. This is useful when you want a consistent surface but a more economical or functional core. In an ABC structure, all three layers can be different, which offers maximum flexibility for combining PE grades or barrier resins like EVOH or PA.

CloudFilm mainly uses PE-family resins such as LDPE, LLDPE, MDPE and HDPE, and can add barrier resins like EVOH when needed. For certain applications we also design PA/PE and PP/EVOH/PP structures – see our PE PA PE film and PP EVOH PP pages for details.

We can customize film structure (ABA or ABC), thickness, width, roll length, core size, corona treatment, slip level, anti-block, anti-fog, UV and other functional additives. When sending an inquiry, please share your target thickness, width, application and any existing datasheet so we can match or improve your current film.

Yes. CloudFilm 3 layer films are designed for flexo and gravure printing and can be laminated with BOPP, PET, PA and other films. If you need ready-to-print material, you can also consider our Roll Stock film and BOPP printing film.

All-PE 3 layer films (for example PE/PE/PE or PE/EVOH/PE with low EVOH content) are easier to recycle in existing PE streams than mixed-material laminates. CloudFilm can help you design mono-material PE solutions together with MDO PE film, BOPE film

and recyclable PE pouches. For more on this topic, see our article on mono material flexible packaging

.

MOQ and lead time depend on the structure, film width and color. As a general reference, standard clear PE structures have lower MOQs and shorter lead times than special colored or barrier films. Share your target order quantity and we will confirm a practical MOQ and production schedule for you.

The best way is to start from your product and packing process: required shelf life, mechanical strength, filling temperature, sealing method and recycling goals. You can send us your current film spec or a simple summary of your needs, and our team will propose a structure using 3 layer PE film or suggest alternatives like LDPE film, LLDPE film or HDPE film when more suitable.

Related News

Introduction: Why EVOH Barrier is the “King of Barrier” in Packaging Materials? In the global packaging industry, […]

Introduction: The Core Technology of Packaging Revolution Multilayer film packaging stands at the forefront of modern packaging innovation, […]

In the world of flexible packaging, where protection, preservation, and presentation are paramount, the technology behind creating the final […]

Introduction – The Recycling Dilemma of Flexible Packaging & the Rise of Mono Material 1.1 The Pain Point: […]

CloudFilm supplies PVDC films, PVDC coated PET (KPET), BOPP (KOPP) and BOPA (KPA) structures to help packaging buyers turn […]