Packaging for Frozen Meat: Films, Pouches & Trays

When buyers search for packaging for frozen meat, they’re rarely looking for a material list. They need an end-to-end solution that prevents freezer burn, survives bone puncture, seals consistently in sub-zero conditions, runs cleanly on thermoformers or vacuum lines, prints well for private-label programs, and arrives on time with the right documentation.

This buyer-focused guide turns those needs into practical film structures and pack formats—so procurement, QA, and operations can converge on a robust, scalable specification with a reliable manufacturer & supplier.

Who is this for? Meat processors, private-label brands, co-packers, and sourcing teams running vacuum pouches, thermoforming (bottom web + top web), or vacuum skin packaging (VSP) for beef, pork, lamb, poultry, and seafood.

What Frozen Meat Packaging Must Do (and Why)

1) Control oxygen and moisture to avoid freezer burn

Freezer burn is oxidative damage plus moisture loss (sublimation). Your pack must combine oxygen barrier and moisture management while maintaining seal integrity through the frozen chain.

2) Retain toughness and seal strength at sub-zero temperatures

At −18 °C (or below), films should keep low-temperature impact strength, tear resistance, and peel strength. The sealing system should tolerate light frost/condensate at the seal area, because real plants are not lab-perfect.

3) Resist puncture and abrasion—especially for bone-in cuts

Bones, cartilage, and sharp edges will test your laminate. Choose PA/CPA-rich webs and appropriate thicknesses so the vacuum holds without micro-leaks.

4) Run cleanly on your equipment

Thermoformers and vacuum lines demand stable coefficient of friction (COF), consistent gauge, wide sealing windows, and reliable roll geometry to protect uptime and registration.

5) Support food-contact compliance and branding

Expect food-contact documentation, batch traceability, and printable surfaces with durable inks/adhesives. Matte/gloss combinations can differentiate value tiers on shelf.

The Main Formats for Frozen Meat

Vacuum Pouches (PA/PE or PA/EVOH/PE)

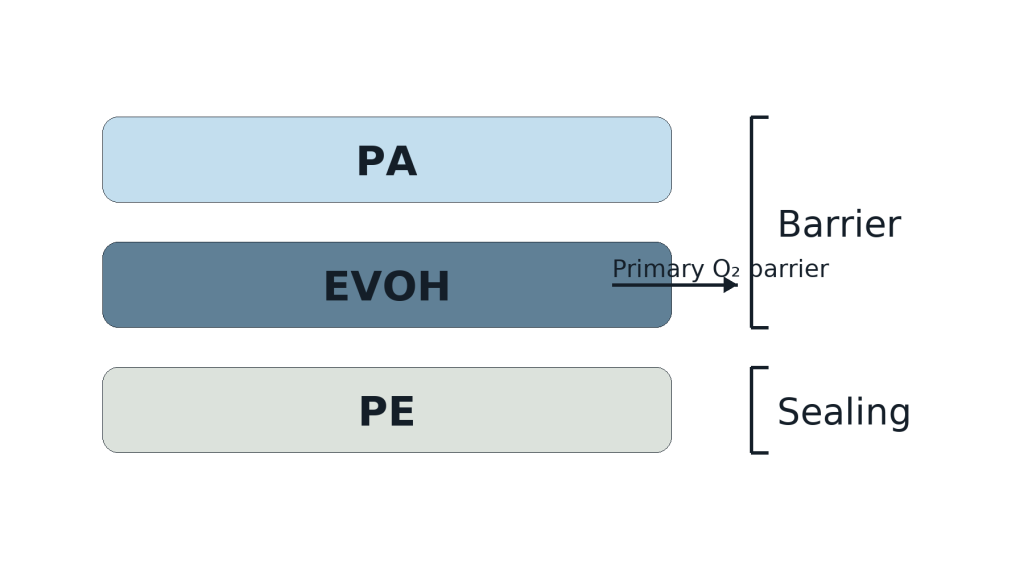

The workhorse for boneless and many bone-in items. Laminated polyamide/polyethylene pouches deliver clarity, toughness, and dependable barrier. For extended frozen storage or export, adding EVOH can further reduce oxygen ingress (EVOH is the primary O₂ barrier; PA contributes strength and secondary barrier).

Best for: portioned cuts, boneless primals, IQF pieces in larger “master bags.”

Typical pointers

-

70–150 µm total pouch thickness depending on product edges and shipping rigors

-

Consider anti-puncture bag geometry (rounded corners, extra seal widths)

-

Validate seal-through-moisture if your line experiences light condensate

Thermoforming: Bottom Web + Top Web

Thermoforming creates a shaped pocket from a bottom web (PA/PE or PA/EVOH/PE) with a top web lidding that seals over it. It excels at high throughput, consistent footprint control, and retail presentation.

Best for: standardized SKUs, automation-heavy lines, private-label programs where footprints and graphics are unified.

Typical pointers

-

Match draw depth to PA/CPA-rich bottom webs

-

Select a top web that balances clarity, barrier, and sealing (peelable vs. permanent)

-

Tune COF for the infeed, forming, and take-off sections to maintain speed

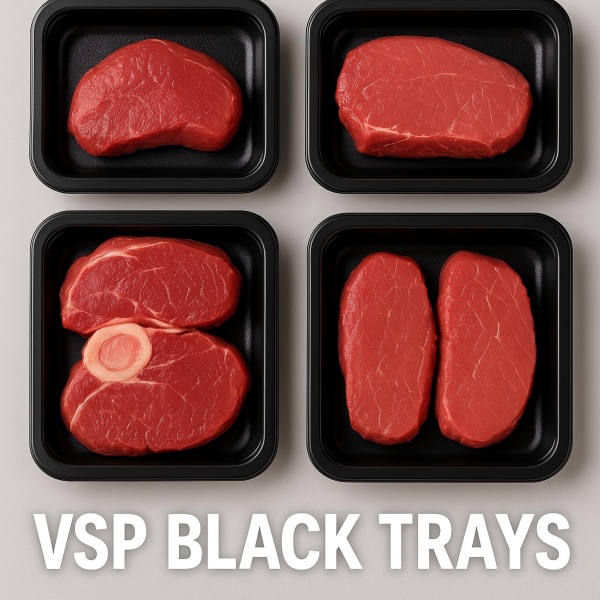

Vacuum Skin Packaging (VSP)

VSP drapes a skin film over the product and backing (tray or board), locking the piece in place and showing natural contours—great for premium cuts and seafood. With barrier-grade skin films, shelf life and distribution robustness improve while presentation looks premium.

Best for: premium steaks, medallions, salmon portions, small roasts.

Typical pointers

-

Verify tray/film compatibility (APET/CPET commonly used)

-

Choose peel strength for the desired customer experience

-

Confirm tight contouring around bones/edges

Choosing Materials & Structures

PA/PE vs. PA/EVOH/PE

-

PA/PE: toughness, clarity, reliable seals; suited to many frozen cycles where turnover is fast and oxygen targets are modest.

-

PA/EVOH/PE: adds EVOH as a primary oxygen barrier for extended storage, complex distribution routes, or stricter oxidation limits.

Why Cast Nylon (CPA) matters

Cast nylon (CPA) is not biaxially oriented and therefore thermoforms deeply while keeping puncture resistance—ideal for deep-draw bottom webs and bone-in packs. Pair with appropriate seal layers to retain vacuum during distribution shocks.

Sealing layer and COF

Prioritize low seal initiation for cold-room environments, seal-through contamination tolerance, and a target COF that matches your form-fill-seal or vacuum lines for smooth infeed and tight registration.

Thickness and draw

Deeper draws require thicker bottom webs or CPA-rich blends; large pouches can step down gauge only after they pass drop and puncture testing at low temperatures.

Printing and branding

Stable surface treatment (e.g., corona level) is essential for consistent ink anchorage. Design graphics for cold lighting environments; matte/gloss or tactile varnishes can signal premium cues without compromising machinability.

PA/EVOH/PE Film—What Each Layer Does

-

EVOH = Primary oxygen barrier (the main reason to choose this structure for long storage/export).

-

PA (Nylon) = Mechanical strength, toughness, and secondary barrier; also provides abrasion resistance.

-

PE = Sealing and low-temperature performance; can be tuned for permanent seals or easy-open peel.

If sustainability targets encourage mono-material pathways, a PE-rich design may be explored—but only after performance testing for puncture, seal integrity, and line speed at −18 °C.

Format-by-Use Recommendations

-

Bone-in cuts (short ribs, T-bones): vacuum pouch or thermoform with PA/CPA-rich bottom webs, reinforced seal geometry, and rigorous puncture testing.

-

Boneless primals & portions: standard PA/PE vacuum pouches; evaluate EVOH for longer hold times or export.

-

Premium steaks & fish: VSP (skin film) for presentation + tight vacuum; confirm tray compatibility and peel if required.

-

Private-label multipacks: thermoform + top web; leverage co-extruded EVOH for robust oxygen control and consistent shelf appearance.

Engineering & Validation Checklist (Buyer-Ready)

-

Barrier target: Align O₂ transmission with the desired shelf life and export route risk.

-

Puncture plan: Simulate bones/edges; run cold-room drop tests and vacuum retention checks after shock.

-

Sealing window: Confirm temperature/time/pressure; validate seal-through light frost or moisture.

-

COF & machinability: Set slip/anti-block for your line speeds; avoid telescoping and registration drift.

-

Format constraints: Pouch size, draw depth, tray lip, tooling tolerances, and secondary packaging fit.

-

Regulatory & documentation: Food-contact declarations, migration data as required, lot traceability.

-

Graphics: Verify ink/adhesive systems and corona treatment; design for contrast under chilled lighting.

-

Sustainability: Consider PE-rich or recycle-ready pathways only if performance targets hold.

-

MOQ & lead time: Align forecasts and plan staging for seasonal peaks.

Why Work with a China Manufacturer & Supplier (CloudFilm)

A technical partner should do more than sell film—it should help you land the right spec quickly and keep your lines running. As a specification-driven manufacturer & supplier, CloudFilm supports:

-

Cast Nylon (CPA) films for deep-draw and bone-in toughness, with clear laminations that bond well to PE/PP in vacuum and thermoforming workflows.

-

Co-extruded barrier films (EVOH/PA/PE) tuned for long-haul oxygen control on thermoform lines.

-

Skin Packaging Films (VSP) that combine premium presentation with tight vacuum; tray-compatible solutions for steaks and seafood.

You also get COF tuning, sealing-window optimization, draw-depth consulting, sampling, and clear MOQ/lead-time plans aligned with your production calendar.

Case-Style Examples (What Typically Works)

-

Exported steak portions (6–12 months frozen): thermoformed PA/EVOH/PE bottom/top webs; define O₂ targets and confirm sealing at cold-room conditions.

-

Bone-in ribs for wholesale: CPA-rich draw-capable bottom web + robust pouch or top web; design for puncture resistance and validate in drop tests.

-

Premium retail salmon: VSP skin film on APET/CPET trays; prioritize clarity and tight contouring; set peel force for easy-open.

-

Warehouse master bag of IQF pieces: large PA/PE pouch with heavier gauge; ensure seals survive palletization and long routes.

FAQs: Frozen Meat Packaging

Q1. Vacuum pouch or thermoforming—how should we choose?

Pouches are flexible across SKUs and friendly to lower MOQs. Thermoforming wins at high throughput, standardized footprints, and premium shelf look. If you know the exact footprint you want for years, thermoforming often returns the best total cost of ownership.

Q2. When do I add EVOH?

Add EVOH when you need longer frozen storage, complex distribution, or tight oxidation targets. For fast-moving, local programs with robust cold chains, PA/PE can suffice.

Q3. Is EVOH always necessary for frozen applications?

Not always. EVOH is the primary O₂ barrier when needed; otherwise PA/PE may meet goals. Validate with shelf-life tests.

Q4. Best practice for bone-in protection?

Use PA/CPA-rich webs, reinforce seal geometry (wider seals, anti-pinhole patterns), and run cold-temperature puncture/drop testing.

Q5. Can VSP handle frozen distribution?

Yes. Barrier-grade skin films produce tight vacuum and upscale shelf appeal. Confirm tray/film compatibility and target peel strength.

Q6. Do I need anti-fog for frozen meat?

Usually less critical than for chilled MAP trays. Prioritize barrier, puncture, and seal integrity first.

Q7. Any tips for printing in cold chains?

Confirm surface treatment and use ink/adhesive systems proven for low-temperature logistics. Design artwork for high contrast under cool lighting.

Q8. What thickness should we start with?

For deep draws and bone-in packs, step up thickness or CPA content. For master bags or smoother cuts, lighter gauges may pass tests—only confirm after drop and vacuum retention trials.

Q9. What about recyclability?

PE-rich paths exist, but only after confirming puncture and sealing targets. Many frozen programs still rely on PA/PE or PA/EVOH/PE for risk control.

Q10. Which documents should we expect with shipments?

Food-contact statements, lot traceability, and routine QA data. Export programs may add certificates per customer/market requirements.