Introduction to Metallized Films

Aluminum-coated films, also known as metallized films, are versatile materials created by depositing a thin layer of aluminum onto polymer substrates such as PET, BOPP, or CPP. This process enhances the base film’s properties, combining the flexibility of plastics with the barrier performance and aesthetic appeal of metal.

Widely used in packaging, electronics, and decorative applications, metallized films like metallized PET, metallized BOPP, and metallized CPP offer unique advantages over traditional materials.

In this blog, we’ll explore the types of metallized films, their manufacturing processes, key applications, and how to choose reliable suppliers.

CloudFilm manufactures a complete range of metallized films—including VMPET (aluminized PET), VMBOPP (metallized BOPP), VMCPP (metallized CPP) and VMCPE (metallized CPE)—to support converters and brands that need reliable high-barrier solutions for snacks, coffee, tea, pet food, pharmaceuticals, electronics and industrial products.

Types of Metallized Films

Metallized films can be categorized based on their base material. The most common substrates are PET, BOPP, and CPP, each offering distinct performance advantages.

Metallized PET Films

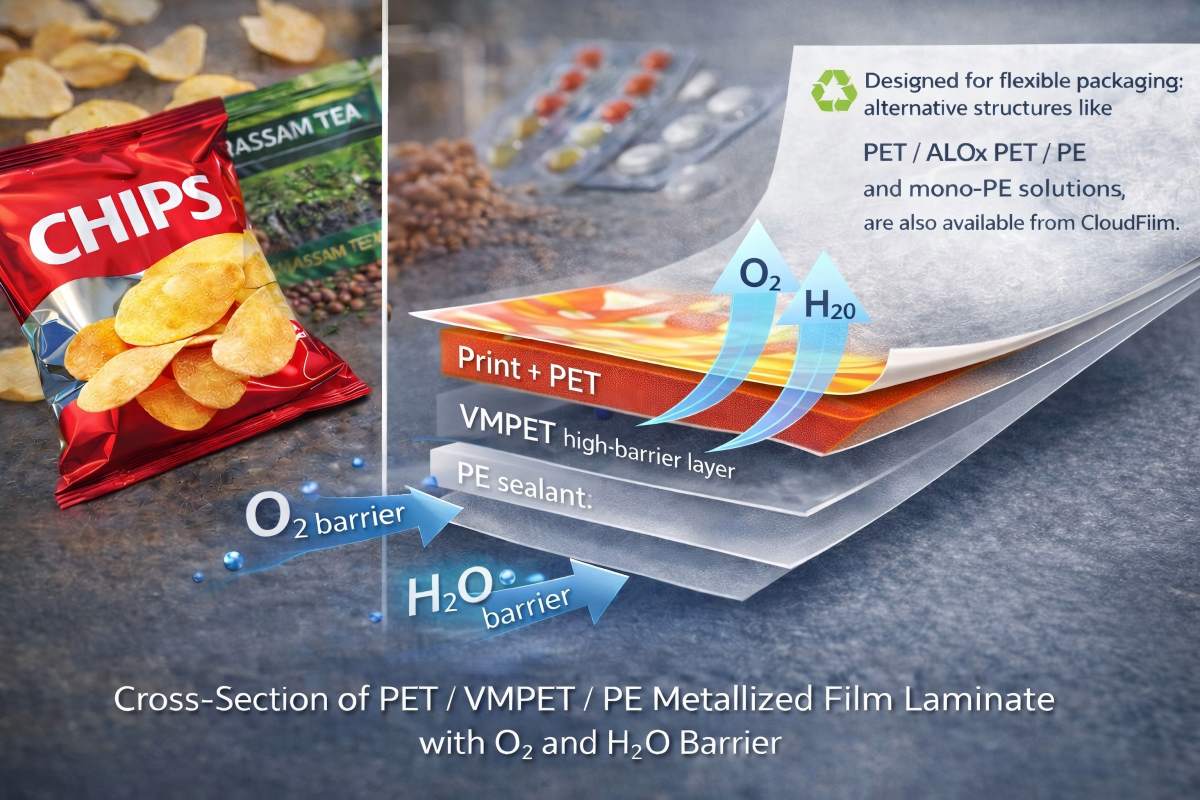

Metallized PET (often referred to as VMPET or aluminized PET) is a polyester film coated with a thin aluminum layer that combines PET’s strength and dimensional stability with high barrier and metallic gloss. It is widely used as a middle barrier layer in laminates like PET/VMPET/PE for dry foods, coffee, tea, pet food and technical packaging.

For high-barrier laminates such as PET/VMPET/PE or PET/VMPET/CPP, you can source Aluminized PET Film directly from CloudFilm, with customized thickness, optical density and roll width tailored to your packaging structures.

Metallized BOPP Films

Metallized BOPP film (VMBOPP) combines the stiffness and excellent moisture barrier of BOPP with a reflective aluminum layer. It is often used as the outer or middle layer in snack, biscuit, confectionery and instant noodle packaging due to its high gloss, printability and good machineability.

CloudFilm’s Metallized BOPP Film offers strong moisture barrier, attractive metallic shine and food-grade quality, making it an excellent choice for chips, biscuits, candy and other dry snacks.

Metallized CPP Films

Metallized CPP (VMCPP) is a cast polypropylene film with a vacuum-deposited aluminum layer. It provides good barrier, softness and strong heat-seal properties, which make it suitable as an inner seal layer in many laminate structures. This film is commonly used for snacks, tea, coffee, pet food and certain industrial products that require both barrier and reliable sealing.

When you need a metallized inner seal layer, CloudFilm Metallized CPP Film (VMCPP) brings together barrier, sealing strength and puncture resistance, helping your packs run stably on high-speed lines.

Other Metallized Variants

Beyond these core substrates, metallized structures are also available on CPE, BOPE and other specialty films to meet specific barrier, sealing and recyclability requirements.

CloudFilm also supplies Metallized CPE Film (VMCPE) for mono-PE structures, as well as high-barrier combinations with ALOx PET Film and PET Foil Laminate when ultra-low OTR/WVTR is required.

Manufacturing Process: How Metallized Films Are Made

The metallizing process typically follows these stages:

- Base film preparation – PET, BOPP or CPP film is extruded, stretched (for BOPP/BOPET) or cast (for CPP/CPE), and surface-treated to ensure good adhesion of the aluminum layer.

- Vacuum metallization – The base film enters a vacuum chamber, where aluminum wire or ingots are heated and evaporated. Vaporized aluminum condenses onto the moving film, forming a continuous ultra-thin metal layer.

- Optical density and thickness control – Sensors monitor the metal layer to control optical density (OD), which directly affects barrier level and appearance.

- Slitting and finishing – Metallized jumbo rolls are slit to customer widths, inspected and packed for shipment to converters.

For a deeper technical explanation of vacuum level, web tension, aluminum thickness and optical density control, you can also refer to CloudFilm’s dedicated blog “Metalized Film Manufacturing Process: The Ultimate Guide from Principles to Troubleshooting”.

Key Applications of Metallized Films

Metallized films serve diverse markets thanks to their barrier performance, appearance and cost-effectiveness.

Food and Beverage Packaging

Metallized films are widely used in food packaging to protect products from moisture, oxygen and light while enhancing shelf impact. Typical examples include:

- Snack bags and pillow packs using metallized BOPP for moisture barrier and gloss.

- Coffee and tea bags using aluminized PET as a high-barrier middle layer.

- Pet-food and nutritional powder packs using PET/VMPET/PE or BOPP/VMPET/PE for aroma and flavor retention.

CloudFilm’s Metallized BOPP Film and Aluminized PET Film are frequently chosen for chips, biscuits, coffee, tea and milk powder packaging, balancing shelf life, aesthetics and cost.

Pharmaceuticals and Medical Supplies

In pharmaceuticals and healthcare, metallized films help protect light-sensitive and moisture-sensitive products such as tablets, capsules and certain medical devices. They are used in sachets, overwraps and laminates that require strong barrier and good machinability.

For blister or sachet laminates that require extremely low OTR/WVTR, CloudFilm can combine PET Foil Laminate

with metallized or ALOx PET layers to design the right structure for your filling and sterilization conditions.

Industrial and Electronics

Metallized PET and PET-foil structures provide shielding, moisture protection and mechanical strength for electronic components, cables, insulation materials and technical laminates.

CloudFilm’s aluminized PET and PET Foil Laminate are extensively used for EMI/RFI shielding, cable wrapping and industrial insulation where both barrier and mechanical durability are essential.

Sustainable Packaging

As sustainability requirements grow, the industry is increasingly adopting transparent high-barrier films (such as ALOx PET) and recyclable mono-material structures.

CloudFilm supports recyclable and downgauged designs by combining ALOx PET Film with PE or PP sealant layers, and by providing metallized BOPE, VMCPP and VMCPE options for mono-material PE/PP packaging where local recycling systems permit.

Advantages of Metallized Films Over Traditional Materials

Metallized films offer several advantages compared with uncoated films or full aluminum foil:

- High barrier to oxygen and moisture at relatively low thickness.

- Attractive metallic appearance for premium branding.

- Reduced weight versus aluminum foil laminates, helping to save material and cost.

- Excellent printability and machinability on modern packaging lines.

- Potential to combine with transparent high-barrier films (ALOx PET) or mono-material sealant layers for more sustainable packaging concepts.

By integrating metallized films with clear PET, BOPE, CPP, CPE and ALOx PET, CloudFilm helps customers balance shelf life, recyclability, appearance and total cost in a single structure design.

CloudFilm Metallized Film Portfolio and Typical Structures

CloudFilm is not only a trader but also a manufacturer of key flexible packaging films such as BOPP, BOPET, CPP, CPE and PE. This allows us to build complete metallized structures that match your exact product and process.

Typical metallized and high-barrier structures we support include:

- PET / VMPET / PE – Classic choice for coffee, tea, dry foods and nutritional powders that need strong barrier and good seal strength.

- BOPP / VMPET / PE – Cost-effective solution for snacks and confectionery where metallic look and moisture barrier matter most.

- BOPP / VMBOPP / CPP – For pillow packs requiring improved stiffness and hot-fill or higher seal temperatures.

- PET / VMCPP / PE – Using Metallized CPP Film as the inner layer for snacks, tea, coffee and pet food that need both barrier and strong seals.

- PET / VMCPE / PE – Using Metallized CPE Film for mono-PE-friendly designs.

- PET / AL / PE or PET / AL / CPP – High-barrier PET Foil Laminate structures for demanding coffee, pharma and electronics applications where pinhole-free barrier is critical.

- PET / ALOx PET / PE – Transparent high-barrier structures using ALOx PET Film where product visibility is essential.

With this portfolio, CloudFilm can recommend a realistic structure for almost any metallized or high-barrier requirement—from standard snack packs to premium pet food, from coffee valves to pharma sachets and smart flexible packaging.

How to Choose the Right Metallized Film for Your Project

Choosing the optimal metallized film is not only about material type; it should start from your product and process. CloudFilm usually recommends considering these points:

1. Product type and shelf life

– What are you packing (chips, coffee, pet food, pharma, electronics, insulation, etc.) and how long must it remain stable?

2. Barrier level and appearance

– Do you need very high oxygen/moisture barrier like PET/AL/PE, or is standard PET/VMPET/PE enough? Do you prefer full metallic, windowed or fully transparent packaging (ALOx PET)?

3. Filling, sealing and sterilization conditions

– What are your sealing temperatures, dwell times and any pasteurization/retort steps? These determine whether VMCPP, VMCPE or foil-based laminates are more appropriate.

4. Machine type and line speed

– Horizontal or vertical FFS, pre-made pouches, form-shrink, or flow packs? The film’s stiffness, COF and thickness should fit your equipment.

5. Sustainability and recyclability goals

– Are you targeting mono-PE or mono-PP recyclability, downgauging, or replacement of PVDC/aluminum foil? If yes, ALOx PET, metallized BOPE and VMCPP/VMCPE become key building blocks.

Once you share this information, CloudFilm’s engineers can propose specific grades of metallized PET, BOPP, CPP and CPE, plus detailed laminate structures, so you can move quickly from idea to validated specification and quotation.

Metallized Films FAQ

1. What is the difference between metallized films and aluminum foil?

Metallized films use a very thin aluminum layer on a plastic base, while aluminum foil is a solid metal sheet. Metallized films are lighter, more flexible and less prone to pin-holing or cracking during bending, but aluminum foil still provides the highest possible barrier when absolute protection is required.

CloudFilm can help you compare PET/VMPET/PE, PET/AL/PE and ALOx PET structures so you choose the right balance of barrier, cost and convertability.

2. Which metallized film is best for coffee and tea packaging?

For premium coffee and tea, PET/VMPET/PE or PET/AL/PE are common, using aluminized PET or PET foil as the barrier layer. Metallized BOPP is also used for cost-effective coffee sticks and secondary wraps.

CloudFilm usually recommends Aluminized PET Film or PET Foil Laminate for whole-bean and ground coffee, combined with PE or CPP sealant films depending on your filling temperature and valve requirements.

3. Are metallized films food-safe?

Yes, metallized films used for food packaging are produced under strict quality systems and must comply with relevant food-contact regulations.

CloudFilm’s metallized films can be supplied with ISO, FDA, EU and other compliance documentation upon request, and we can align specifications with your target market (EU, USA, Middle East, Latin America, etc.).

4. Can metallized films be used in recyclable or mono-material packaging?

Traditional metallized PET structures are often classified as mixed flexible packaging in many recycling systems, but mono-PE and mono-PP designs using metallized BOPE, VMCPE or VMCPP are gaining traction where the infrastructure exists.

CloudFilm offers metallized CPE and metallized CPP options that can be combined with PE or PP layers to support mono-material strategies, and we can also propose transparent ALOx PET when you want to replace foil or PVDC while improving recyclability potential.

5. What technical data should I send to CloudFilm to get a quote?

When requesting a quotation, it is helpful to share your packed product, target structure (if known), film thickness, roll width, core size, expected volumes, and any special requirements such as higher barrier level, anti-static properties, special COF or easy-tear performance.

Even if you are not familiar with all parameters, you can simply send CloudFilm photos of existing packaging plus basic filling/storage details; our team will back-calculate a suitable metallized or high-barrier solution and prepare samples and pricing.

6. Do metallized films work for electronics, cables and insulation?

Yes. Metallized PET and PET-foil laminates are widely used for EMI/RFI shielding, cable wrapping and reflective insulation in construction and HVAC.

CloudFilm’s Aluminized PET Film and PET Foil Laminate can be slit to narrow widths and specific winding directions to fit your cable or insulation lines.

7. How does CloudFilm support development projects and trials?

CloudFilm provides technical consultation, structure design, lab testing recommendations and trial rolls or sample pouches so you can test metallized structures on your packing lines before bulk orders. For many standard metallized film grades, we can ship A4 sheets or 200–500 m trial rolls by express, helping you reduce risk and speed up decision-making.

Conclusion: Metallized Films as a Strategic Packaging Tool

Metallized films have become essential in modern packaging and industrial applications thanks to their high barrier, attractive appearance and versatility. By choosing the right combination of substrate (PET, BOPP, CPP, CPE), barrier level and laminate structure, brands can achieve long shelf life, strong shelf presence and improved sustainability.

CloudFilm combines manufacturing expertise in BOPP, BOPET, CPP, CPE, metallized films, ALOx PET and PET-foil laminates with export-oriented service and technical support. Whether you are designing a new snack bag, coffee pouch, pet-food pack, pharma laminate or high-barrier industrial solution, our team can help you translate requirements into a clear, testable specification and deliver consistent film quality from trial to mass production.

Contact CloudFilm today to discuss your metallized film project and request samples or a customized quotation.