This guide explains how vacuum metallized films such as VMPET, VMBOPP and VMCPP are produced on industrial lines, so that packaging engineers, buyers and converters can communicate more easily with suppliers like CloudFilm and troubleshoot issues with confidence.

Why This Process Matters

{ Metalized Film Production Line }

Metalized films are the invisible heroes in food packaging, electronics, and renewable energy. At CloudFilm, we’ve engineered over 500M㎡ of precision-coated films that protect delicate products from oxygen, moisture, and light while still looking beautiful on the shelf.

Because CloudFilm designs and manufactures a full portfolio of metallized films – from Metallized BOPP Film to Aluminized PET Film, Metallized CPP Film and Metallized CPE Film – the process insights in this article are based on real production lines, not just theory.

Understanding how metalized film is made is no longer just a “technical curiosity” – it is a real business advantage for:

☑ Buyers who need to compare quotes and specifications from different suppliers

☑ Technical teams who must solve issues like pinholes, low gloss, or delamination

☑ Brand owners who want to balance barrier, cost, and sustainability in their packaging structures

This guide walks you through the complete metalized film manufacturing process – from polymer base film to vacuum metallization, coating, quality control and real-world troubleshooting – so you can speak the same language as your suppliers and make better decisions for your projects.

If you want a broader market-level overview before diving into process details, you can also read CloudFilm’s article on metallized films: types, applications and benefits, and then come back to this page for deeper process know-how.

The 5-Step Manufacturing Workflow

Metalized film manufacturing is no longer a mysterious “black box.” In practice, it is a highly controlled, repeatable process built around five core stages:

- Base Film Production and Selection

- Surface Preparation (Corona, Plasma, Primer)

- Vacuum Metallization (Aluminum Deposition)

- Protective Coating & Post-Treatments

- Winding, Slitting, and Final Quality Grading

For global converters and brand owners, standardizing these five stages with a partner like CloudFilm makes it easier to qualify new metallized films and scale from trial rolls to container-load orders.

Step 1: Base Film Production and Selection – The Foundation of Quality

The performance of any metalized film starts with the base film. Poor base film = unstable metal layer.

- Material Selection: PET film (12–250μm), BOPP film (15–50μm), CPP film (20–100μm) and CPE or other PE-based films for special structures. Different base films offer varying stiffness, heat resistance, and barrier strength.

- Process Type: Most base films used for metalized products are biaxially oriented (BOPET and BOPP) or cast (CPP and CPE), produced by high-speed tenter or cast lines.

- Online Quality Control: Thickness profile, haze, gel count, and surface defects are monitored continuously.

Typical metallized substrates from CloudFilm include Metallized BOPP Film, Aluminized PET Film, Metallized CPP Film and Metallized CPE Film, covering typical outer printing webs, middle barrier layers and inner sealant layers in flexible packaging.

For projects where barrier and yield calculations are critical, many engineers combine this page with CloudFilm’s guide on flexible film density, formulas and yield tables to estimate material consumption more accurately.

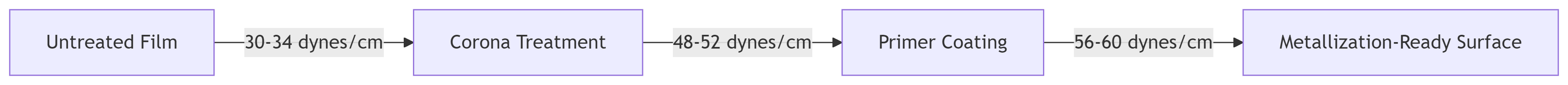

{ Surface Activation Technology }

Step 2: Surface Preparation – Making the Film “Metallizable”

Even the best base film cannot hold metal uniformly without proper surface treatment. The goal here is to increase surface energy and create chemical bonding sites.

- Corona Treatment: High-voltage discharge modifies the surface, increasing wettability (typically to ≥ 40–42 dynes).

- Plasma Treatment: For high-end applications (e.g., capacitors, advanced packaging), plasma treatment can provide deeper and more uniform activation.

- Primer Coating: A thin organic / inorganic primer layer improves metal adhesion, reduces pinholes, and stabilizes optical density (OD).

A well-prepared surface ensures:

- Uniform metal laydown

- Fewer pinholes and dark streaks

- Better lamination and printing adhesion

Step 3: Vacuum Metallization – Building the Barrier Layer

Inside the vacuum chamber, aluminum is evaporated and condenses onto the moving film to form a metal layer only tens of nanometers thick.

Key parameters include:

- Vacuum Level: Typically 10⁻⁴ to 10⁻⁵ mbar

- Aluminum Source: Resistive heated boats or electron-beam sources

- Web Speed: Must be matched to evaporation rate to control thickness

- Optical Density (OD): Target OD depends on application (e.g., 2.0–2.6 for packaging; 3.0+ for capacitors).

A simplified comparison:

- Lower OD (thinner metal): Better flexibility, easier sealing, lower cost, but lower barrier and opacity.

- Higher OD (thicker metal): Higher barrier, better light-shielding, but more brittle and harder to seal.

Choosing OD also depends on whether the metal layer will be used in single-layer pouches, in laminates such as PET/VMPET/PE, or as a functional electrode in capacitor structures. CloudFilm’s engineers will often propose different OD targets for the same base film depending on your real barrier, appearance and cost requirements.

For readers who want to deepen their understanding of barrier vs appearance trade-offs, CloudFilm’s articles on aluminized PET film and the role of metalized BOPP films in food packaging are good companions to this process guide.

Step 4: Protective Coating & Post-Treatments

For many applications, the raw metal layer is too fragile. Additional steps may be used:

- Protective Lacquer: Enhances scratch resistance and scuff resistance.

- Heat-Seal Coatings: Allow metalized film to be used as a direct sealing layer.

- Anti-static / Slip Additives: Improve handling, winding, and machinability.

Metal layer thickness, roughness, and coating chemistry together determine the final barrier, gloss, and converting performance.

In CloudFilm’s high-barrier portfolio, metallized films can also be combined with high barrier films such as ALOx PET film or PVDC-coated structures, enabling both opaque and transparent barrier solutions for premium foods, medical products and technical packaging.

Step 5: Winding, Slitting, and Final Quality Grading

After metallization and coating, the film is carefully cooled, wound, and slit into customer-friendly widths.

- Winding Tension Control: Prevents wrinkles, telescoping, and blocking.

- Slitting Precision: Ensures clean edges and accurate width tolerances.

- Final Inspection: Surface defects, OD uniformity, and roll build quality are checked before shipping.

CloudFilm can supply metallized film in trial rolls for lab evaluation or in container-load quantities with standard and customized widths, helping international buyers move quickly from R&D to mass production.

If you are planning a new project, sharing your target structure (for example BOPP/VMCPP or PET/VMPET/PE), OD range and converting process with CloudFilm’s technical team allows us to recommend the most suitable metallized substrate from our product portfolio.

Solving Real Production Challenges

| Problem | Likely Root Cause | Practical Solutions |

|---|---|---|

| Pinholes / Poor Barrier | Insufficient surface prep, dust, low OD, base film defects | Increase treatment, improve filtration, raise OD, change base film grade |

| Dark Streaks / OD Variation | Uneven evaporation, web tension fluctuation | Optimize boat layout, stabilize tension, adjust speed and evaporation temperature |

| Poor Lamination Bond Strength | Incompatible adhesives, contaminated surfaces | Change adhesive system, improve corona or primer, review drying conditions |

| Curling / Poor Flatness | Uneven stress, incorrect winding tension | Adjust winding parameters, review base film orientation and conditioning |

| Loss of Gloss after Lamination | Over-curing, rough adhesive layer | Optimize lamination conditions, select smoother adhesives and proper coating weight |

When you face these problems on your own printing or lamination lines, sharing defect photos, OD profiles and laminating conditions with CloudFilm allows our engineers to quickly determine whether to adjust the metallization parameters, change the base film, or modify the laminate structure.

For jobs where yield and film thickness are sensitive, many customers also refer to CloudFilm’s flexible film density, formulas and yield guide when discussing optimization with our team.

Application-Specific Process Tuning

Not all metalized films are created equal. Process parameters should be tuned according to end-use.

Food Packaging Films

Metalized BOPP and PET films must hit the right balance between barrier, sealability, and packaging speed. Typical structures (for the metalized layer) include BOPP/VMCPP, PET/VMPET/PE, etc.

CloudFilm’s Metallized BOPP Film and Aluminized PET Film are widely used as the outer and middle layers in snack, biscuit, coffee and tea packaging, often laminated with Metallized CPP Film or PE-based sealant films to achieve both barrier and machinability.

For a deeper application view, you can also refer to CloudFilm’s article on the role of metalized BOPP films in food packaging, which discusses real structures and shelf-life considerations.

Capacitor Films

For metallized PET or PP capacitor films, the requirements are much stricter:

– Extremely uniform thickness and OD across the width and length.

– Low defect density (no conductive bridges, pinholes, or nodules).

– Precisely tuned metal layer for controlled self-healing behavior.

CloudFilm’s Aluminized PET Film can be adapted for technical and electrical applications where consistent OD, dielectric strength and controlled metallization width are crucial. Project-specific discussions are recommended so that our engineering team can define suitable specifications with you.

Decorative Films

Decorative metalized films used for labels, gift wrap, and holographic effects have their own priorities:

– High reflectivity and color consistency.

– Excellent printability for graphics and brand logos.

– Good scuff resistance for handling and retail display.

Beyond standard metallized films, CloudFilm also supplies BOPP Holographic Film and PET holographic film solutions, which can be combined with metallized layers to build premium gift-wraps, labels and seasonal promotional packaging.

CloudFilm’s Technological Edge

CloudFilm is more than a raw-film supplier – we are a technical partner for metallized film projects.

– 20+ years of experience in flexible packaging films (BOPP, BOPET, BOPA, PE, CPP, specialty films).

– Integrated production of base films and metallized films for better quality control.

– Application-driven R&D for food, pet food, electronics, agricultural and industrial films.

Our dedicated Metallized Films and High Barrier Film categories allow you to combine metallized, ALOx, PVDC and co-extruded structures from a single source, simplifying your supplier base and technical communication.

If you are comparing different film suppliers, CloudFilm’s About Us and Contact Us pages provide a quick overview of our manufacturing base in Qingdao, technical capabilities and global service model.

Future Trends (2025–2030)

Metalized film technology is evolving alongside sustainability, digitalization, and new barrier demands. Key trends include:

– Hybrid Structures: Combining metalized films with transparent high-barrier films (e.g., ALOx PET) for “see-through” yet high-barrier packs.

– Recyclable Mono-Material Designs: Metalized PE and mono-PP structures designed with recycling streams in mind.

– Smarter Quality Control: Inline monitoring of OD, defect mapping, and AI-assisted process optimization.

CloudFilm is actively developing recyclable solutions such as PE-rich and mono-PP structures, as well as transparent high-barrier structures based on ALOx PET Film, to help customers meet both sustainability targets and performance requirements.

For more details on transparent barrier technologies, you can read CloudFilm’s dedicated guide to PET ALOx high-barrier packaging and then discuss with our technical team whether a metallized or ALOx structure is more suitable for your specific project.

FAQs On Metalized Film Manufacturing And Working With CloudFilm

Q1. What is the difference between “metalized film” and “aluminized film”?

In everyday packaging language, the two terms are often used interchangeably. Technically, “metalized film” can refer to any film coated with a metal layer, while “aluminized film” refers specifically to aluminum as the deposited metal. In flexible packaging, however, aluminum is by far the most common choice, so most metalized BOPP and PET films on the market are actually aluminized films.

Q2. How should I choose between metallized BOPP, PET and CPP for food packaging?

As a rule of thumb:

- Metallized BOPP: Good stiffness and moisture barrier; often used as printed outer web for snacks, biscuits and confectionery.

- Aluminized PET: Higher temperature resistance and better oxygen barrier; frequently used as the middle barrier layer in PET/VMPET/PE structures.

- Metallized CPP / CPE: Used as inner, heat-sealable layers when you need both barrier and seal strength.

CloudFilm can propose specific structures such as BOPP/VMCPP or PET/VMPET/PE based on your product type, filling temperature and shelf-life targets.

Q3. What OD (optical density) should I target for my metalized film?

For most snack and dry-food packaging, OD 2.0–2.4 is a good starting range, balancing barrier, flexibility and cost. For very sensitive products or when replacing aluminum foil, higher OD values may be necessary. Capacitor films and technical applications often target OD ≥ 3.0 with much tighter uniformity requirements.

CloudFilm’s lab can measure your current film OD and propose an appropriate OD window when you switch to our metallized BOPP, PET or CPP films.

Q4. Can metalized films be used in recyclable packaging structures?

Yes, but design must be intentional. For example, PE-rich or mono-PP structures where the metallized film is based on PE or PP can be designed to fit into specific recycling streams. The metal layer is extremely thin and, in many cases, acceptable within design-for-recycling guidelines.

CloudFilm offers metallized CPE film and works with customers on recyclable PE or PP-based packaging concepts; in some cases, ALOx PET or co-extruded EVOH films from our high-barrier family may be an even better solution.

Q5. What basic information should I prepare before contacting CloudFilm about a metallized film project?

To speed up technical discussion and quotation, it helps to prepare:

- Product type (snacks, coffee, pet food, capacitor, decorative, etc.)

- Target structure (e.g., BOPP/VMCPP, PET/VMPET/PE, or others)

- Required thickness, width and OD range

- Key performance needs (barrier targets, sealing temperature, machinability, appearance)

- Estimated annual volume and trial roll needs

With this information, CloudFilm’s team can quickly match you to the most suitable metallized BOPP, PET, CPP or CPE film from our portfolio.

Q6. Can CloudFilm provide small trial rolls before I place a large order?

Yes. CloudFilm regularly supplies small trial rolls so that you can test machinability, barrier performance and printability on your own lines before committing to container-load orders. This is especially useful when you are changing from foil to metallized film or optimizing OD and thickness.

Q7. How do I start a metallized film project with CloudFilm?

You can simply send your basic requirements via the quote form on the CloudFilm website or through the contact details on the Contact Us page. Once we receive your inquiry, our sales and technical team will review your structure, suggest suitable metallized BOPP, PET, CPP or CPE options, and then follow up with samples, data sheets and a formal quotation.