Meat products are rich in protein and nutrients, but they are also highly perishable and sensitive to temperature, oxygen, light and mechanical damage. This makes packaging a critical part of your product design – not only for food safety and shelf life, but also for marketing and brand image on the shelf.

In practice, successful meat packaging structures must balance barrier performance, mechanical protection, processability and cost. You need to control oxygen and moisture, resist puncture from bones, survive deep-freeze and sometimes high-temperature retort processes – all without compromising sealing performance or print quality.

As a flexible packaging film manufacturer, CloudFilm supplies high-barrier films such as BOPA Film, ALOx PET Film

and Co-extrusion EVOH Film, as well as inner sealing layers like PE, CPP and Retort CPP Film. Together, these materials help meat processors, brands and converters build reliable, cost-effective meat packaging for fresh, frozen, cooked and retorted products.

Why Meat Packaging Matters For Safety, Shelf Life And Brand Image

Modern meat packaging must do much more than “wrap the product”. It needs to:

- Protect meat from microbial contamination, oxidation and moisture loss

- Maintain color, flavor and texture throughout the cold chain or at ambient conditions

- Meet regulatory and food-contact standards in target markets

- Run efficiently on vacuum, MAP, thermoforming or retort lines

- Support strong branding and clear communication at retail

A well-designed film and laminate structure can reduce complaints, extend shelf life, support longer distribution distances and lower total packaging costs. Poorly selected films, on the other hand, may cause leaks, delamination, fogging, color change, off-flavors and even recalls.

Key Characteristics Of Meat Packaging Films

Meat packaging films need to deliver a combination of barrier, mechanical and converting performance. In real projects, most structures balance oxygen and moisture barrier, puncture and impact resistance, cold and heat resistance, shrinkability, and good printability and sealability.

In CloudFilm’s solutions for meat products, high-barrier layers such as BOPA Film, ALOx PET Film or Co-extrusion EVOH Film are often combined with PE, CPP or Retort CPP Film inner layers, depending on whether you need frozen storage, vacuum, MAP or retort processing.

1. Oxygen And Gas Barrier

Oxygen is one of the main enemies of meat quality. It accelerates fat oxidation, color change and off-flavor development, and also supports microbial growth.

- EVOH, BOPA and ALOx PET offer strong oxygen barrier performance.

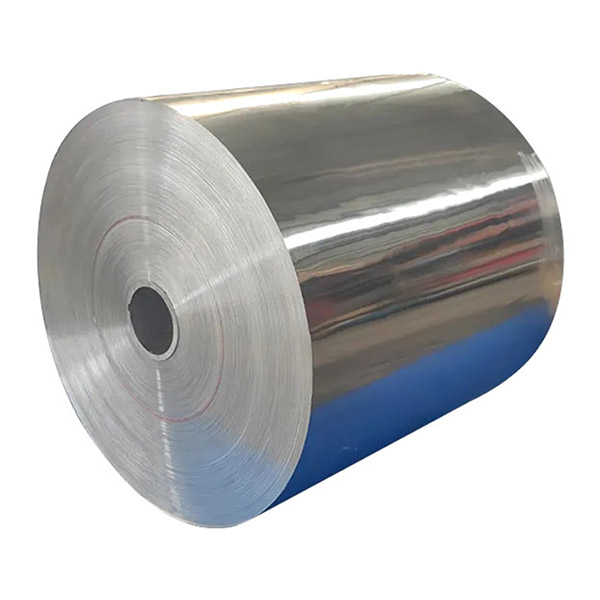

- Aluminum foil provides an almost absolute barrier for oxygen and light.

Buyer Tip: For long-shelf-life sausages, ham and retorted meat products, consider laminates such as BOPA/PE, BOPA/CPP or PET/AL/Retort CPP Film to achieve low oxygen transmission and strong seals.

2. Moisture Barrier

Moisture barrier is essential to avoid weight loss, drying or frost damage (freezer burn).

- PE and CPP provide good moisture barrier and sealability.

- ALOx PET and aluminum foil combine moisture barrier with high oxygen barrier.

Buyer Tip: When you need both moisture barrier and product visibility (for example, dry sausages or jerky), transparent high-barrier films like ALOx PET Film

combined with PE or CPP inner layers work well.

3. Puncture And Impact Resistance

Bone-in meat, frozen blocks and sharp edges can easily puncture weak films.

- BOPA (nylon) and PA/EVOH/PE co-extruded films are known for toughness and puncture resistance.

- Appropriate total thickness and good design of bag corners also help prevent leaks.

Buyer Tip: For bone-in cuts and products with sharp edges, use tough substrates such as BOPA Film or co-extruded PA/EVOH/PE films to prevent puncture and leaks during transportation and distribution.

4. Cold Resistance For Chilled And Frozen Chains

Chilled and frozen meat are typically stored between 0–4 °C or at –18 °C and below. At these temperatures, some films become brittle.

- PE and certain CPP grades maintain flexibility at low temperature.

- BOPA/PE or PA/EVOH/PE laminates are common for deep-freeze vacuum packs.

Buyer Tip: For frozen meat and seafood vacuum bags stored at –18 °C or below, BOPA/PE laminates or PA/EVOH/PE co-extruded films provide stable low-temperature performance and strong seals.

5. Heat Resistance For Cooking And Retort

Some meat products need pasteurization, cooking, boiling or retort sterilization at 121–135 °C. Films must withstand high temperatures without softening, shrinking or delaminating.

- PET and BOPA are typically used as outer layers in retort laminates.

- Retort CPP Film is a common inner sealing layer for retort pouches and lidding films.

Buyer Tip: Retorted meat and ready meals that go through 121–135 °C sterilization typically use PET or BOPA as the outer layer and Retort CPP Film as the inner sealing layer in structures such as PET/AL/RCPP or PET/BOPA/RCPP.

6. Oil And Fat Resistance

Bacon, sausages and marinated meats contain a high level of fat, which can migrate into weak films and affect print and adhesion.

- BOPA and PET provide good oil resistance.

- Aluminum foil also acts as a strong barrier against oils and aromas.

Buyer Tip: For high-fat products like bacon, sausages and marinated meats, choose films with good oil resistance such as BOPA Film or Flexible Packaging Aluminum Foil in the laminate.

7. Shrinkability And Conformability

Shrinkable films and casings can closely wrap meat products, improving appearance and reducing purge.

- PA/EVOH/PE co-extruded shrink films are used for tight ham and sausage packs.

- Shrink performance must be balanced with barrier and sealability.

Buyer Tip: Shrinkable casings and printed bags for sausages often use co-extruded PA/EVOH/PE films for shrink performance and barrier, with reverse-printed PET or BOPP laminated on top. CloudFilm can support both the shrink film and printed outer film supply.

8. Printability, Sealing And Processability

Meat packaging must also run efficiently on actual equipment: thermoformers, vacuum chambers, tray sealers, flow wrappers or retort lines.

- Films need stable COF, good ink adhesion and a wide sealing window.

- Corona treatment and compatible inks/adhesives are essential.

Buyer Tip: When you share your machine type, typical sealing temperature and running speed with CloudFilm, we can fine-tune film surface treatment, slip and seal layer design to improve uptime and reduce waste.

Main Types Of Meat Product Packaging

Different meat products, distribution conditions and shelf-life targets call for different packaging formats. Here are the main types and where each format works best.

Fresh Meat Overwrap And MAP Trays

Fresh beef, pork and poultry are often sold on trays with overwrap or lidding film.

- Overwrap: PE stretch or shrink film over a foam or plastic tray, mainly for short shelf life.

- MAP trays: Lidding films with good barrier and puncture resistance (PET/PE or BOPA/PE) combined with a barrier tray and modified atmosphere (e.g., high oxygen or CO₂/N₂ mix).

CloudFilm can supply PE Shrink Film for overwrap applications and BOPA Film or PET-based structures for tray lidding films.

Vacuum Packaging For Fresh And Frozen Meat

Vacuum packaging removes air around the meat, slows oxidation and improves distribution stability.

- Vacuum pouches: BOPA/PE, BOPA/CPP or PA/EVOH/PE pouches for fresh or frozen cuts.

- Thermoforming packs: Bottom web (PA/EVOH/PE) plus top web (BOPA/PE or PET/PE).

CloudFilm offers BOPA Film and Co-extrusion EVOH Film specifically engineered for vacuum bags and thermoforming lines. For frozen meat buyers, you can also refer to our article Packaging for Frozen Meat: A Complete, Buyer-Focused Guide.

Shrink Packs For Cured And Smoked Meats

Cured meat, hams and smoked products often use shrink packs to achieve a tight, glossy appearance.

- Shrink bags: PA/EVOH/PE co-extruded shrink films.

- Shrink sleeves or secondary bundles: PE shrink film for multipacks or outer wrapping.

CloudFilm supplies PA/EVOH/PE high-barrier films and PE Shrink Film that combine strong shrink force with good puncture resistance.

Retort Pouches And Shelf-Stable Meat Meals

Shelf-stable meat meals, retorted sausages and meal components undergo high-temperature sterilization. They require excellent barrier and high-temperature resistance.

- Typical structures: PET/AL/RCPP, PET/BOPA/RCPP or PET/AL/PA/RCPP.

- Outer layer provides toughness and printability; aluminum foil or ALOx PET adds barrier; inner Retort CPP Film

ensures strong seals after retort.

For brands that want transparent or partially transparent retort packaging, ALOx PET Film can replace aluminum foil in some designs.

Sausage Casings And Processed Meat Snacks

Sausages, hotdogs and other processed meats use casings, vacuum packs or snack pouches.

- Casings: PA/EVOH/PE co-extruded films with shrink and barrier.

- Snack pouches: PET/AL/PE, PET/AL/CPP or PET/AL/RCPP depending on retort needs.

CloudFilm’s Co-extrusion EVOH Film and Retort CPP Film are frequently used in these structures.

Recommended Laminates And Films From CloudFilm

Below are some typical packaging structures that CloudFilm supplies for different meat applications. Use them as a starting point when discussing your project with our team.

1. Fresh Meat – Overwrap And MAP Trays

- Typical packs: Fresh beef, pork and poultry on trays

- Recommended structures:

- PE stretch or PE Shrink Film as overwrap

- PET/PE or BOPA/PE laminates for lidding films

- Relevant CloudFilm products:

- PE Shrink Film

- BOPA Film combined with PE sealant

2. Frozen Meat & Seafood – Vacuum Bags

- Typical packs: Frozen bone-in meat, seafood, value-added meat

- Recommended structures:

- BOPA/PE or BOPA/CPP vacuum pouches

- PA/EVOH/PE co-extruded films for deep-draw vacuum packs

- Relevant CloudFilm products:

- BOPA Film

- Co-extrusion EVOH Film

3. Cooked Meats – Vacuum And Shrink Packs

- Typical packs: Ham, cured meats, smoked meats

- Recommended structures:

- PET/PE or BOPA/PE vacuum bags

- PA/EVOH/PE shrink films

- Relevant CloudFilm products:

- Co-extrusion EVOH Film

- MDO PE Film for recyclable PE-based solutions

4. Retorted Meat & Ready Meals

- Typical packs: Shelf-stable meat pouches, retorted sausages, ready meals

- Recommended structures:

- PET/AL/Retort CPP Film

- PET/BOPA/Retort CPP Film

- Relevant CloudFilm products:

- Retort CPP Film

- ALOx PET Film

- Flexible Packaging Aluminum Foil

5. Sausages And Processed Meats

- Typical packs: Cooked sausages, fermented sausages, hotdog-style products

- Recommended structures:

- PA/EVOH/PE co-extruded films for vacuum or MAP sausages

- PET/AL/RCPP pouches for retorted sausage snacks

- Relevant CloudFilm products:

- Co-extrusion EVOH Film

- Retort CPP Film

Why Meat Processors And Converters Choose CloudFilm

Since 2002, Qingdao Cloud Film Packaging Materials Co., Ltd. (CloudFilm) has been manufacturing flexible packaging films for food brands, meat processors and packaging converters in more than 30 countries.

Our portfolio covers:

- High-barrier substrates: BOPA Film, ALOx PET Film, Co-extrusion EVOH Film, Flexible Packaging Aluminum Foil

- Inner seal layers: PE, CPP and Retort CPP Film

- Recyclable options: MDO PE Film for mono-PE structures

By working directly with a film manufacturer, meat packaging buyers can:

- Get clear specifications and tailored film designs

- Receive samples and trial rolls to validate sealing, puncture resistance and shelf life

- Obtain food-contact and migration documentation for local regulations

- Secure stable supply with export experience and support from CloudFilm’s technical team

How To Start Your Meat Packaging Film Project With CloudFilm

To recommend a suitable film or laminate structure, CloudFilm typically needs:

- Meat product type (fresh, frozen, cooked, retorted)

- Target shelf life and storage conditions (chilled, frozen, ambient)

- Filling and sterilization process (vacuum, MAP, pasteurization, retort)

- Current packaging structure (if any) and main issues you want to solve

- Approximate annual volume and roll or pouch format

Share these details via our contact form on CloudFilm’s website, and our team can suggest film structures, thickness ranges and send samples for testing.

Meat Packaging FAQ

Q1: Which films are most commonly used for vacuum packaging of meat products?

For vacuum bags and thermoformed packs, BOPA/PE and BOPA/CPP laminates are widely used because they combine strong puncture resistance with good oxygen and moisture barrier. Co-extruded PA/EVOH/PE films are also popular for deep-draw vacuum packs. CloudFilm supplies both BOPA Film and Co-extrusion EVOH Film for these applications.

Q2: How do I choose between aluminum foil and transparent high-barrier films for meat packaging?

Aluminum foil laminates offer maximum barrier and light blocking, making them ideal for retorted meats and long-shelf-life products. Transparent high-barrier films like ALOx PET Film are better when you want consumers to see the product while still protecting it from oxygen and moisture. CloudFilm can recommend the right option based on your shelf-life targets and branding needs.

Q3: Can meat packaging be designed to be recyclable?

Yes. By switching from mixed materials to PE-based or PP-based mono-material structures, you can improve recyclability. For example, MDOPE/PE laminates for all-PE pouches are one common approach. CloudFilm’s MDO PE Film

is designed for such recyclable flexible packaging solutions.

Q4: What information does CloudFilm need to recommend a meat packaging film?

CloudFilm typically needs to know your meat product type (fresh, frozen, cooked, retorted), target shelf life, filling and sterilization conditions, current structure (if any), and approximate annual volume. Based on this, we can suggest film structures, thickness ranges and send samples for testing.

Q5: Does CloudFilm provide trial rolls or A4 sheets for meat packaging projects?

Yes. For most meat packaging films, CloudFilm can provide free A4 sheets or small trial rolls so that you can test seal strength, sterilization performance and shelf life before placing a larger order.